final examination - Mymancosa .com mymancosa.com

advertisement

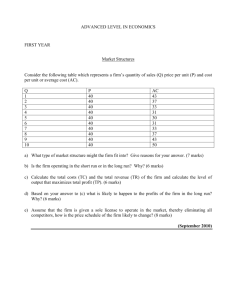

FINAL EXAMINATION PROGRAMME: MASTER OF BUSINESS ADMINISTRATION (MBA): GENERAL AND TOURISM- YEAR ONE MODULE: OPERATIONS MANAGEMENT INTAKE: JANUARY 2011 DATE: 17 NOVEMBER 2011 TIME: 09h00 – 12h00 DURATION: 3 Hours TOTAL MARKS: 100 EXAMINER: Mr T Naidoo MODERATORS: Dr G Chapman Mr S Naicker INSTRUCTIONS TO THE CANDIDATE: 1. Questions must be attempted in the answer book provided. 2. All queries should be directed to the invigilator; do not communicate or attempt to communicate with any other candidate. 3. You have THREE HOURS to complete this paper. You are not allowed to leave the examination room within the first hour and in the last 15 minutes of this examination. 4. This is a CLOSED BOOK examination. 5. Answer ALL questions from Section A and ANY TWO (2) from Section B. 1 SECTION A QUESTION 1 Read the extract below and answer ALL questions that follow NUMMI – NEW UNITED MOTOR MANUFACTURING In practically all parts of the world, Japanese motor manufacturers are producing their cars to rigorously high standards of quality and cost by using production methods similar to those developed in Japan. One of the most remarkable of these Japanese ‘implants’ is the Toyota plant in Freemont, California. The plant is in fact a joint venture between General Motors (GM) and Toyota using a plant which GM had previously closed in 1982. The reasons for GM closing this particular plant were not difficult to understand. Through the ‘70s and early ‘80s the quality of products produced in the Freemont plant was extremely poor, even by the relatively low standards of the time. Productivity was among the lowest of any GM plant in the United States, absenteeism was running at around 20 per cent of the workforce, labour relations in the plant were such that it had earned a national reputation for militancy and wild-cat strikes, and alcohol and drug abuse was a problem both inside the plant and out. Soon after GM had closed the plant, it began discussions with Toyota about the possibility of a joint venture. Agreement was reached in 1983 to produce a Japanese-designed car, sold under the GM name but manufactured using Toyota’s methods of production. The NUMMI plant, as it was now called, was formally opened in 1984. Over the next two years the plant built up production levels, progressively hiring more workers, about 85 per cent of whom had worked in the plant before GM had closed it; several came from the old union hierarchy. The first to be recruited were the team leaders, 450 of whom, together with the entire NUMMI management team, took part in a three-week training programme in Japan. Those trained then played a part in organizing and training the new workers. The performance of the NUMMI plant could hardly have contrasted more with that of the old GM-run factory. Even though the workforce was largely the same, by the end of 1986 the plant’s productivity was more than twice as high as when it was run by GM, and higher than any other GM factory. Indeed productivity was almost as high as Toyota’s Takoaka plant in Japan, in spite of the fact that NUMMI’s workforce was new to Toyota’s production methods and, on average, ten years older. Quality also improved dramatically. Audits showed that quality levels were almost as high as Takoaka’s and certainly higher than any other GM plant. Absenteeism had dropped from over 20 per cent in the old GM-run plant to between 3 and 4 per cent. Industrial relations had also improved very significantly. Such improved levels of performance attracted increased investment, both in new manufacturing technology and new products. Many reasons for the success of the NUMMI plant have been put forward. These include clearer organizational goals, a selective approach to recruiting those employees who had been employed previously in the plant, the move towards single status and dress codes for every-one in the factory, even the pride of working on an intrinsically better [60 marks] 2 designed product. However, what is notable is that the new plant and its management did not abandon the techniques of scientific management which the previous plant’s regime had supposedly used. The philosophy of job standardization was still rigorously applied, if anything more rigorously than in the past. Every job in the plant is carefully analysed using method study principles to achieve maximum efficiency and quality. Jobs are timed, using stop watches, and the detail of jobs questioned critically. Yet there is a major difference between the way the old GM-run plant approached scientific management job design and the way it happens under the NUMMI philosophy. Whereas before, the company’s industrial engineers were in charge of applying method study techniques, now it is the operators (or team members as they are called) themselves who perform the analysis of their own jobs. Team members time each other, using stop watches, and analyse the sequence of tasks in each job. They look for alternative ways of doing the job which improve safety and efficiency and can be sustained at a reasonable pace throughout the day. Each team will then take its improved job proposals and compare them with those developed by the comparable team doing the same job on a different shift. The resulting new job specification is then recorded and becomes the standard work definition for all staff performing that job. NUMMI’s claim is that the standardization of tasks results in less variability in task performance, which has in turn led to several further benefits: Safety and work-related stress injuries improve because potentially dangerous or harmful elements have been removed from the job. Productivity improves because wasted elements of the job have been eliminated Quality standards improve because potential ‘fail points’ in the job have been analysed out. Flexibility improves and job rotation is easier because standards are clearer and all staff understands the intrinsic structure of their jobs. One team leader compared the way in which the industrial engineers in the old plant had designed jobs with the way it was done under the NUMMI regime: ‘I don’t think the industrial engineers were dumb. They were just ignorant. Anyone can watch someone else doing a job and come up with improvement suggestions … and it’s even easier to come up with the ideal procedure if you don’t even bother to watch the worker at work, but just do it from your office … almost anything can look good that way. Even when we do our own analysis in our teams some of the silliest ideas can slip through before we actually try them out … there’s a lot of things than enter into a good job design … the person actually doing the job is the only one who can see all factors.’ 1.1 Briefly discuss the concept of Organizational Effectiveness (Work study) and how it was applied to the NUMMI plant, to improve performance. (20 marks) 3 1.2 Critically discuss how the company was transformed from an under-performing GM Plant to an efficient leading manufacturer under NUMMI management. Your discussion should focus on the turn-around strategy, and encompass the theory you have studies 1.3 (20 marks) As the new General Manager for operations, what supply chain strategies would you utilise to improve efficiency and gain a competitive advantage. (20 marks) SECTION B [40 marks] Answer ANY TWO (2) questions QUESTION 2 (20 marks) Mkhondo Manufacturing produces a range of plastic products, situated 5 kms outside the Durban area, is considering entering the SADC market (Botswana, Namibia, Lesotho, Swaziland and Zimbabwe). Prepare a report that will assist them in: Forecasting their capacity requirements (7 marks) Developing their capacity alternatives (7 marks) Identifying the factors that will determine their effective capacity. (6 marks) QUESTION 3 (20 marks) Delaware Appliances, a subsidiary of Defy Corporation, manufactures stoves, fridges and chest freezers for the local market. Over the last three months, late deliveries have increased by 35%, resulting in a major customer (MassMart) threatening to cancel all new orders and move to a new supplier who has a better ‘on-time’ delivery schedule. John Barnes, the CEO, of Delaware has requested you, the Operations Director, to provide a proposal to improve delivery schedules. Having benchmarked your organization, you have decided to use a Just in Time (JIT) approach to rectify this problem. Explain: Key elements of a JIT system and how you could implement at Delaware (7 marks) Benefits of a JIT system (7 marks) How you would convert Delaware’s existing system to a JIT one. (6 marks) 4 QUESTION 4 4.1 (20 marks) Solaris, an international distributor of solar powered generators, expects to sell 12 500 units annually. Carrying costs are R50.00 per unit and the order cost is R65.50. Solaris works 302 days per annum. Determine: 4.1.1 The Economic Order Quantity (EOQ) (4 marks) 4.1.2 The number of orders per year (3 marks) 4.1.3 The length of the order cycle (3 marks) 4.2 Company X has the following stock items on hand: Stock Number Quantity Value (Rands) Counting Policy MD234 10 000 55 000 Every 10 days LZ456 25 750 500 Every 50 days SS785 120 420 750 Every 50 days PQ210 3000 45 000 Every 10 days TL220 500 125 000 Every 5 days ZH750 12 000 35 000 Every 10 days QT422 35 150 500 Every 5 days REQUIRED: 4.2.1 Using the ABC Stock Analysis Technique, classify the stock listed in the table above. (5 marks) 4.2.2 Determine how many stock items must be counted daily. END OF PAPER (5 marks)