L03 - Coefficient of Static Friction

L03 The Coefficient of Static Friction 1

Pre-Lab Exercises

Full Name:

Lab Section:

Hand this in at the beginning of the lab period. The grade for these exercises will be included in your lab grade this week.

1.

Draw a free body diagram showing all forces acting on a box of mass m resting on a flat table if the coefficient of static friction between the box and the table is µ s and there is a force, F applied

, directed on the box from left to right.

2.

Using your free body diagram above, write an equation for the magnitude of the force of static friction on the box in terms of its mass and the acceleration of gravity.

3.

What is the formula for calculating percent difference (difference between two measured quantities: x1 and x2)?

4.

What is the formula for calculating the standard deviation of an entire population of quantities?

L03 The Coefficient of Static Friction

The Coefficient of Static Friction

Full Name:

Lab Partners’ Names:

Lab Section:

Introduction:

The purpose of this laboratory experiment is to investigate the property of friction as it applies to two objects in contact and at rest with respect to each other. Friction is a highly complex phenomenon but can be simply approximated by assuming the quantity called the coefficient of static friction remains constant regardless of the mass of the object. As always, be sure to complete all bold-faced items, as they will be graded. The fact that there are fewer items to grade in this exercise means that each one will, of course, be worth more points.

Equipment:

Science Workshop interface

Dynamics Track

Dynamics Cart

Force Sensor

Bubble Levels

Friction Boxes

Masses

Balance (500 grams +)

Procedure:

1.

Setting up the equipment:

1.1 Connect the Science Workshop interface to

The computer, turn on the interface and

then turn on the computer. (This may have been done for you already.)

1.2 Open DataStudio. In the Experiment

Setup box, add the Force Sensor and

connect it as indicated.

1.3 Double click on the Force Sensor icon to

the right. Under the General tab, make

sure that the force sensor is set to

measure “Slow Force Changes” and that the sampling frequency is 50 Hz.

2

L03 The Coefficient of Static Friction

1.4 Under the Measurement tab, make sure the force sensor is set to “Force,

Channel A”.

1.5 Close the experiment setup window. In the display frame on the lower left,

open a graph for your data. Level the track using the bubble level and the

leveling screw.

3

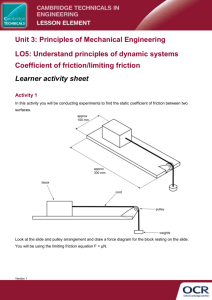

Step 2.4 Step 2.9

2.

Taking Data:

2.1 You can connect a rubber stopper to the force sensor to measure pushes or

connect a hook to measure pulls. The sensor will record data from –50N to

+50N with a pull on the hook measuring as a negative force and a push on the

stopper measuring as a positive force. Connect the rubber stopper if it is not

already connected.

2.2 Connect the force sensor to the dynamics cart using the small Phillips head

screwdriver. Measure the mass of the friction box and masses provided.

2.3 Reset the force sensor to zero by pressing

the button on the side labeled “tare” while

making sure the force sensor is not touching

anything. Do this between every trial.

2.4 Place the dynamics cart onto the dynamics

track and place the plastic-bottomed friction

box with the “flat” side (as opposed to the

one with the small hook) facing the force

sensor. You will have to offset the friction box slightly so that the rubber

stopper will press against the box.

2.5 Place a black mass into the friction box.

2.6 Push on the plastic-bottomed friction box ten times with the force

sensor/dynamics cart as follows:

Apply constantly increasing pressure to the friction box. You will notice

that although the box does not move the force sensor is detecting an

increase in the push on the button. At a certain point the box will “break”

free and begin to move. At this point you have exceeded the maximum

static friction force. Stop pushing at this point. You will see a severe drop

L03 The Coefficient of Static Friction 4

in the graph. (See above graph for an example.)

2.7 Click on the the smart/xy-tool icon and drag the icon that appears over

ten of the peaks on this graph. You will see an (x,y) pair for the data point

you have selected. Record the force values for these ten peaks in a chart in

Excel. See the table below for an example.

2.8 Add another mass to the friction box and repeat steps 2.6 and 2.7, recording

the values in your chart.

2.9 Now push on the friction box ten times from the other side with the two

masses in it. You will see a plastic hook that you will need to push on with

the force sensor. Do not simply rotate the friction box! Take the cart and

place it on the other side of the friction box. Record this force data as well.

2.10 Repeat steps 2.3 through 2.9 for the felt and cork bottomed boxes.

Standard

Deviation

Material: Plastic

# of

Direction Black Mass Max Max Max Max

Force Force Force Force

Masses (kg) (N) (N) (N) (N)

Flat

Flat

1

2

Hook 2

Material: Felt

Direction

# of

Black Mass Max Max Max Max

Force Force Force Force

Masses (kg) (N) (N) (N) (N)

Flat

Flat

1

2

Hook 2

Material: Cork

Direction

# of

Black Mass Max Max Max Max

Force Force Force Force

Masses (kg) (N) (N) (N) (N)

Flat

Flat

1

2

Average

Max

Force

(N)

Average

Max

Force

(N)

Average

Max

Force

(N)

Force (N)

Standard

Deviation

Force (N)

Standard

Deviation

Force (N)

Hook

3. Analyze the data:

2

3.1 Print one graph that you collected, along with titles and axis labels.

3.2 In Excel calculate the average max force of friction and the standard deviation for each series of 10 pushes.

Create an additional columns in your chart for your calculation. Click

on the box that you want to contain Fmax avg for your first data run. Now

enter the equation =AVERAGE(1 st

Fmax:10 th

Fmax) in the equation line up

top, just like you did in the last lab. NOTE: Actually put in the correct box

location for 1 st

and 10 th

Fmax. For example: (B2:K2). Create an additional

column in your chart for calculating the standard deviation of the max forces

using the equation =STDEV(1 st

Fmax:10 th

Fmax).

L03 The Coefficient of Static Friction 5

3.3 Calculate the coefficient of static friction and its standard deviation using

Excel. Make sure your values for µ and standard deviation are recorded in

your chart.

3.4 Print out a copy of your chart, complete with all data runs and average

values of force and static coefficient of friction.

Questions:

1. What is the percent difference between the coefficient of static friction for

the flat side of the box with one mass and for the flat side of the box with

two masses? Calculate the percentage difference for the other two

surfaces.

2. How did you expect an increase in mass to affect the coefficient of static

friction? Is the effect of increased mass large compared with the standard

deviation? If so, what would be a physical justification for a difference in µ

when the mass is increased?

3. How does the type of material on the bottom of the box affect the

coefficient of static friction?

4. Does the coefficient of static friction seem to depend on the direction with

which you push on the box? Why or why not? In answering this question

you should consider whether the effect is large compared with the standard

deviation.