March/April - Cornell Fruit

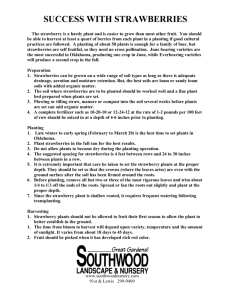

advertisement