Statistical Quality Control: IOE 466 Lecture 1

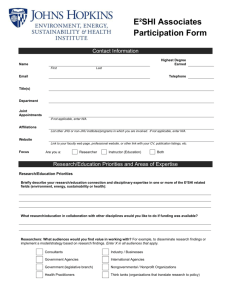

advertisement

List of Topics in Lecture 1

IOE 466

Statistical Quality Control

• What are the course grading rules?

• What do you expect to learn from this course?

• Introduction of SPC

– Why is quality control important?

– Introduce quality engineering terminology

– Evolution of SPC methods

• What are the statistical methods for quality improvement?

• Examples: How to use SPC in real applications?

(MW 12:00 – 1:30pm, Chrysler Center media classroom #165)

Instructor: Prof. Jianjun Shi

1784 IOE

Department of Industrial and Operations Engineering

The University of Michigan

shihang@umich.edu, 734-763-5321(O), 734-764-3451(Fax)

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

1

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

Background Overview

• INSTRUCTORS

- Background

- Availability

• GSIs

- Justin Wayne Kile

- Yu-Li Huang

• CPD Student Support

- Hongbin Jia

• TEXT

- Author

- Prerequisites

- Other References

- Coursepack

2

Introduce Yourself to Others

(2 minutes)

<jwkile@engin.umich.edu

<yuli@engin.umich.edu>

•

•

•

•

<hjia@engin.umich.edu>

Name

Department

Undergraduate or graduate students?

Other Background and more?

• COURSE

- Attendance Policy

- Computers

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

3

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

4

Prerequisites: Review Questions

How many “Yes” do you get?

•

•

•

•

•

•

•

•

•

More Questions

Do you know what is Normal distribution?

Do you know the difference between mean and median?

Do you know how to calculate the variance of a sample?

Do you know the meaning of p-value in hypothesis

testing?

If X follows normal distribution with mean 2 and

standard deviation 3, do you know how to use table to

get the probability of X<0?

Do you know what is type I and type II errors in

hypothesis testing?

Do you know what is partial derivative?

Can you calculate the integral and derivative of x2?

Do you know how to calculate the inverse of a 2-by-2

matrix and the product of any two matrices by hand?

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

• Are you familiar with hypogeometric distribution, Binomial

distribution and Poisson distribution?

• Do you know how to estimate and test the difference in

variances of two normal distribution?

• Are you familiar with OC-curves?

• Do you know when should use S chart and when use R

chart to monitor process variability?

• Do you know what’s the advantage of CUSUM and EWMA

chart to Shewhart control chart?

• Do you know PCR and PCRk?

• Do you know p-chart?

5

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

IOE 466

Statistical Quality Control

Grading Policy

• Homework

• Exam 1

• Exam 2

6

30%

35%

35%

•

•

•

•

- Homework should be handed in during class on the due date;

Fundamentals of Engineering Statistics

Statistical Methods in Quality Improvements

Statistical Process Control

Introduction to Advanced Quality Control

Topics

- No late homework is acceptable;

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

7

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

8

C OURSE O VERVIEW

Objectives

• Introduce statistical tools and concepts

that are useful for product/process quality

improvements

• Demonstrate the procedures of

implementation of the quality engineering

tools in various applications

• This is NOT a course on mathematical

statistics

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

PRODUCTION

PROCESS

• Leave Alone

• Adjust

• Stop

"Feedback"

"Charting"

9

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

Analysis of

Variations

"Feedforward"

"Process Capability Analysis"

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

10

WHY IS QUALITY IMPORTANT?

--- Quality, Productivity and Cost

Contents

• Statistical Methods: Modeling & Inferences

• Statistical Process Control:

– Philosophy

– Control Charts

• Process Capability Analysis

• Advanced Topics

– SPC for Short Run

– Multivariate Quality Control

– SPC with Correlated Data

– Frontier of the Current Research Ideas

• Acceptance Sampling

Measurement

(Samples)

• Accept

• Rework

• Scrap

Ch.2 - Ch3

Ch.4

Ch.5,Ch.6 & Ch8

Ch.7

Ch 9, 10, 11

1. Consumer awareness and quality / performance

sensitive.

2. Product liability laws.

3. Costs of labor, energy, and materials.

4. Competition is doing it.

5. Quality, Productivity and Cost are

complementary !

Ch14

11

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

12

How to describe a product

not meet “Quality” requirements?

Quality Engineering Terminology

— “Quality” Definitions

• Quality means fitness for use

• Quality is evaluated by the variability,

which is inversely proportional to the

variability

• Quality improvement is the reduction of

variability in processes and products

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

13

TWO COMPONENTS OF QUALITY

Manufacturing Industries

•

Nonconforming unit—A unit of product or service containing at

least one nonconformity .

•

Defect—A departure of a quality characteristic from its intended

level or state that occurs with a severity sufficient to cause an

associated product or service not to satisfy intended normal, or

reasonably foreseeable usage requirements.

•

Defective (Defective Unit)—A unit of product or service containing

at least one defect, or having several imperfections that in

combination cause the unit not to satisfy intended normal, or

reasonably foreseeable, usage requirements.

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

14

Quality Engineering and Process Characteristics

• Quality Engineering:

Accuracy

Timeliness

Completeness

Friendliness and courtesy

Anticipating customer needs

Knowledge of server

Esthetics

Reputation

– A set of operational, managerial and engineering activity to ensure the

quality characteristics at a nominal level

• Attributes/Variables depend on the measurements of the

quality characteristics

– attributes: discrete data

• to judge each product as either conforming or non-conforming, or to

count the number of nonconformities appearing on a unit of product

– variables:continuous measurement of quality

characteristics

• Specifications: desired measurements for the quality

characteristics

Freedom from deficiencies

Product free of defects

and errors at delivery,

during use, and during

servicing

Nonconformity—A departure of a quality characteristic from its

intended level or state that occurs with a severity sufficient to

cause an associated product or service not to meet a specification

requirement.

Service Industries

Product features

Performance

Reliability

Durability

Ease of use

Serviceability

Aesthetics

Availability of options

and expandability

Reputation

•

Service free of errors

during original and future

service transactions

Sales, billing, and other

business processes free

of errors

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

– upper/lower specification limits (USL/LSL)

15

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

16

WHO’s Responsible for Quality?

It’s NOT My Job!!!

1. Product planning, marketing, and sales.

2. Development engineering.

3. Manufacturing engineering.

4. Purchasing.

5. Manufacturing management.

6. Manufacturing employees.

7. Inspection and test.

8. Packaging and shipping.

9. Customer service.

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

17

•

This is a story about four people named EVERYBODY,

SOMEBODY, ANYBODY, and NOBODY.

•

There was an important job to be done, and EVERYBODY was

sure that SOMEBODY would do it. ANYBODY could have done it

but NOBODY did it. SOMEBODY got angry because it was

EVERYBODY'S job. EVERYBODY thought ANYBODY could do it,

but NOBODY realized that EVERYBODY wouldn’t do it. It ended

up that EVERYBODY blamed SOMEBODY when NOBODY did what

ANYBODY could have done.

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

18

A Shewhart Control Chart

Dr. Shewhart first proposed usage of control chart in 1924,

which is the start of “statistical process control”

3

What are the statistical methods

for quality improvement?

UCL

2

mm

1

0

Average

-1

-2

LCL

-3

0

10

20

Time

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

19

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

20

Statistical Quality Control Methods

Typing Example

• Three major quality control methods are

– SPC,

– DOE (design of experiments), and

– acceptance sampling.

• This course will cover two of them: SPC and

acceptance sampling. DOE is covered in IOE 465.

• A simple example to illustrate the three methods:

A typing example.

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

•

•

•

•

21

Consider improvement of typing quality, which is measured by typing

accuracy and clearness.

Acceptance sampling—several sample pages are inspected from

every “lot” (for example, every 100 typed pages). If the selected

sample pages have satisfactory quality, the whole “lot” is accepted.

Otherwise, the whole lot is rejected and rework should be done.

Statistical process control (SPC)—Every hour one page is selected

and its quality is measured. Plot the measurements from each hour

on a control chart. If a shift of quality is detected, the root cause of

this shift (such as typist tiredness, lack of ink) is identified and fixed.

Design of experiment (DOE)—Conduct experiments with

combinations of different typists, typewriters, papers, working

schedules. The best combination of these factors are selected to

achieve optimal typing quality.

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

22

Variation Reduction

Approaches

Phases in Quality

Engineering Methods

100

Percent of Application

Acceptance

Sampling

Process

Control

Designed

Experiments

0

Time

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

23

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

24

SPC Example

Statistical Process Control Procedures

Quality Improvement Example

Process

Problem: Cowl side reinforcement panel I/O variation

Implementation

Take action

Observation

Data collection

Diagnosis

Faulty discovery

Decision

Formulate action

Evaluation

Data analysis

5L (y=3.16)

2L (y=2.91)

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

25

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

SPC Example (Cont’d)

26

SPC Example (Cont’d)

Quality Improvement Example

Quality Improvement Example

Root causes and action:

Data Analysis: spikes with a cycle of 26

Welding robot #3 after tip dressing, after 26 panels, skip two welding spots

4.0

04/10/92

Welding spots

3.5

Sample of 160

3.0

Y

[mm]

2.5

2.0

Missed welding spots

Cowlside Reinforcement panel

1.5

1.0

Evaluations

0.5

Time

BEFORE

CORRECTION

BEFORE

200

180

160

140

120

100

80

60

40

20

0

0.0

6 SIGMA

2 L_Y

2 L_Z

5 L_Y

5 L_Z

Process knowledge: welding robot changing tip dressing after 26 welding

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

AFTER

Sensors

AFTER

CORRECTION

27

2.91

2.02

3.16

1.44

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

6 SIGMA

1.0

1.4

2.0

0.9

28

Total Quality Person

Total Quality Management (TQM)

•

•

•

•

Statistical techniques must be implemented within a management system

that is quality driven.

One of the managerial frameworks used is total quality management.

TQM is a strategy for implementing and managing quality improvement

activities on an organization-wide basis.

TQM emphasizes on continuous improvements.

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

Companies today are turning to total quality management to

improve their capabilities. To adapt to TQM, management

styles have had to change to new form of employee-employer

relationships. But what about the individuals involved in this

transformation? Are they TQM people?

29

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

30

Planning

Personal Leadership

3. Every day I take time to plan my daily activities around

that which is important to me.

1. I take on responsibility for my actions and don’t rely on

others to plan my future.

Rarely

1

2

Sometimes

3

4

5

6

Always

7

8

9

Rarely

10

1

2. I enjoy the people and things in my environment.

Rarely

1

2

Sometimes

3

4

5

6

8

9

4

Rarely

10

1

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

3

5

6

Always

7

8

9

10

4. I have a good sense of how personal values, strengths,

and weaknesses align with what I am doing.

Always

7

2

Sometimes

31

2

Sometimes

3

4

5

6

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

Always

7

8

9

10

32

Improvement

Interpret Your Score

5. I constantly strive to measure whether I am meeting my

personal goals.

Rarely

1

2

Sometimes

3

4

5

6

12-17: Grade F. You might want to adopt some of these individual total

quality strategies to get your life back on track.

18-25: Grade D. You might want to analyze your daily living patterns

and goals in life. You do not demonstrate and individual total quality

philosophy.

Always

7

8

9

10

26-31: Grade C. You demonstrate some patterns of a total quality person

but need to more consistent on daily basis.

32-45: Grade B. You have a good individual foundation in total quality

principles and could serve as a role model for others.

6. I celebrate my successes and improvements.

Rarely

1

2

Sometimes

3

4

5

6

46-60: Grade A. You are a great total quality role model, with a solid set

of principles in leadership, planning, and continuous improvement.

Always

7

8

9

10

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

33

Six-Sigma Program

34

Chapter 2: Probability Review

- Fundamentals of Engineering Statistics

• First developed by Motorola in the late 1980s.

• To reduce the process variability so that the

specification limits are six standard deviations

from the mean. Then there will only be about 2

parts per billion defective.

• Four phases of six sigma project:

Measure Analyze Improve Control

• SPC is a major tool of Six-Sigma

• An introduction to six-sigma is posted on course

web site.

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

• Describing Variation

– Frequency Distribution &

Histogram

– Numerical Summary of Data

– Probability Distribution

• Important Distributions

• Some Useful Approximations

35

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

36

Need for Statistics

•

•

•

Some variation is inevitable in manufacturing

processes.

Variation reduction is one of the major

objectives in quality control

Variation needs to be described, modeled,

and analyzed

Describing Variation

Method 1: Frequency Distribution & Histogram

How to do it?

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

37

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

38

An Example:

Forged Piston Rings for Engines (Text Book P43-46)

•

Frequency Table & Frequency Histogram

Variable Data (Table 2-2, P44):

– the inside diameter of forged piston rings(mm)

– 125 observations, 25 samples of 5 observations each.

• To construct a frequency table

1. Find the range of the data

– start the lower limit for the first bin just slightly below the

smallest data value

– b0<min(x), bm=max(x), (m: # of bins)

2. Divide this range into a suitable number of equal intervals

– m=4 ~ 20, or N (N is the total number of observations)

3. Count the frequency of each interval

– if bi-1< x ≤ bi,

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

39

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

40

Frequency Distribution for Piston-Ring Diameter Table 2-3 (P45)

•

•

Data range b0=73.965, bN=74.030

– Min[x(i,j)]=73.967(i=14, j=2); max[x(i,j)]=74.030 i=1, j=1

# of Bin m=13, Interval=(74.030-73.965)/13=0.005

•

count for each bin: bi-1< x ≤ bi,

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

Fig. 2-4 (P44)

Histogram for Piston-ring Diameter Data

- A graphical display of the frequency table

41

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

42

Describing Variation

Method 2: Numerical Summary of Data

Interpretation based on the Frequency Histogram

• Center Tendency:

sample average

n

x=

Visual Display of Three Properties of Sample Data

•

•

•

Shape:

– roughly symmetric and unimodal

The center tendency or location

– the points tend to cluster near 74mm.

Scatter or spread range

– variability is relatively high (min=73.967; max=74.030)

∑x

i

i =1

n

• Scatter: sample variancen or sample standard deviation

σˆ 2 = S 2 =

∑(x − x)

i =1

2

i

n −1

;

• Shape: skewness and kurtosis

– skewness: measure the lack of symmetry of the distribution

βˆ 1 = 0 symmetry;

βˆ 1 < 0 mean<median

βˆ 1 > 0 mean>median;

– kurtosis: indicates the heaviness of the tails of the data distribution

larger β̂ 2 has a heavier tail

n

βˆ 1 =

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

43

M3

M

; βˆ 2 = 42 ; M j =

(M 2 )3 / 2

M2

∑ (x

i =1

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

i

− x) j

n

44

Theoretical & Sampling Distribution

Describing Variation

Method 3: Probability Distribution

Smoother

•

•

A Probability distribution is a mathematical model that relates the

value of the variable with the probability of occurrence of that

value in the population.

Two types of distributions:

– Continuous: if the variable being measured is expressed on a

continuous scale

– discrete :if the parameter being measured can only take on

certain values, e.g.. 1,2,3,4,..

f(x)

∞

∑ p( x

+∞

∫ f ( x )dx = 1

p(xi)

−∞

i

Increase samples

•

If we consider each interval as one unit, then each rectangle in the

histogram will have an area equal to its relative frequency. The

total area of the rectangles will be unity ∫ f ( x )dx = 1

+∞

−∞

•

If we could increase samples and make the intervals much smaller

and still maintain enough data for each interval. When the

intervals become narrower, the histogram will appear smoother.

•

Extending this concept to the extreme case where the histogram

becomes a smooth curve. This smooth curve is called a

“theoretical probability distribution” or “theoretical distribution”.

)=1

i=1

p(x4)

p(x3)

p(x5)

p(x2)

p(x6)

p(x1)

x

a b

p(x7)

x1 x2

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

x3 x4

x5

x6

x7

x

45

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

46

Review of Probability Distribution Calculation

Continuous Distribution

Probability

b

P { a ≤ x ≤ b ) = ∫ f ( x )dx

Important Distributions

Discrete Distribution

P ( x i ) = p( x i )

1. Discrete Probability Distribution

a

Distribution mean

µ=

• Hypergeometric distribution

• Binomial distribution

• Poisson Distribution

∞

+∞

µ = ∑ xi p( xi )

∫ xf ( x)dx

i =1

−∞

Distribution variance

+∞

V ( x ) = σ2 = ∫ ( x − µ)2 f ( x )dx

−∞

i =1

2. Continuous Probability Distribution

n

Sample mean

x=

Sample variance

∞

V ( x ) = σ2 = ∑ ( xi − µ)2 p( xi )

∑x

i =1

n

σˆ 2 = S 2 =

i

n

∑( x

i=1

i

• Normal distribution

• Chi-Square distribution

• Student t distribution

− x )2

n−1

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

47

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

48

Example 1: Special-purpose circuit boards are produced in

lots of size N = 20. The boards are accepted in a sample of n =

3 if all are conforming. The entire sample is drawn from the lot

at one time and tested. If the lot contains D=3 nonconforming

boards, what is the probability of acceptance?

Hypergeometric Distribution

•

Suppose that there is a FINITE population consisting of N items. Some

number , say D (D≤N), of these items fall into a class of interest. A random

sample of n items is selected from the population without replacement, and

the number of items in the sample that fall into the class of interest, say x,

is observed. Then x is a Hypergeometric random variable with the

probability distribution:

⎛ D ⎞⎛ N − D ⎞

⎜⎜ ⎟⎟⎜⎜

⎟

x n − x ⎟⎠

p( x ) = ⎝ ⎠⎝

x=0, 1,…,min(n,D)

⎛ N⎞

⎜⎜ ⎟⎟

n

⎝ ⎠

nD

nD ⎛ D ⎞⎛ N − n ⎞

µ=

σ2 =

⎟

⎜1 − ⎟⎜

N

N ⎝ N ⎠⎝ N − 1 ⎠

•

•

⎛a⎞

a!

⎜⎜ ⎟⎟ =

⎝ b ⎠ b! ( a − b)!

Used as a model when selecting a random sample of n items without

replacement from a lot of N items of which D are noncomforming or

defective

Excel function: HYPGEOMDIST(x,n,D,N)

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

49

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

50

Binomial Distribution

Example 2: (Textbook Problem 2-28) A lot of size N = 30

contains five nonconforming units. What is the probability that

a sample of five units selected at random contains exactly one

nonconforming units? What is the probability that it contains

one or more nonconformances?

Bernoulli trials: A sequence of n independent trials, where the outcome of each trial

is either a “success” or a “failure”

Binomial Distribution: If the probability of a success on any trial is a constant, p, the

number of "success" x in n Bernoulli trials has the Binomial distribution

⎛n ⎞ x

n–x

p(x) = ⎜x⎟ p (1 – p)

⎝ ⎠

E(x) = np

x = 0,1,2,...,n

V(x) = np(1 – p)

0 ≤p≤ 1

[Note: V(x) < E(x)]

Assumption:

(1) Constant probability of success p; (2) Two mutually exclusive outcomes; (3) All trials

statistically independent; (4) Number of trials n is known and constant

Application: used as a model when sampling from an infinitely large population. The

constant p represents the fraction of defective or nonconforming items in the population

Excel Function: BINOMDIST(x,n,p,false) (True:accumulative probability)

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

51

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

52

Example 1: Sixty percent of pulleys are produced using Lathe

#1, 40% are produced using Lathe #2. What is the probability

that exactly three out of a random sample of four production

parts will come from Lathe #1 ?

Estimation of Binomial Distribution Parameter

•

p̂ is the ratio of the observed number of defective or

nonconforming items in a sample x to the sample size n

Ans:

x

p̂ =

n

•

the probability distribution of p̂ is obtained from the binomial

[ na ]

⎛n⎞

x

P{p̂ ≤ a} = P{ ≤ a} = P{x ≤ na} = ∑ ⎜⎜ ⎟⎟p x (1 − p) n − x

n

x =0 ⎝ x ⎠

−

p

(

1

p

)

µ p̂ = p

σ 2p̂ =

n

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

53

54

Example 3: A firm claims that 99% of their products meet

specifications. To support this claim, an inspector draws a

random sample of 20 items and ships the lot if the entire

sample is in conformance. Find the probability of committing

both of the following errors:

(1) Refusing to ship a lot even though 99% of the items are in

conformance.(False alarm)

(2) Shipping a lot even though only 95% of the items are

conforming.

(Miss detection)

Example 2: (Textbook problem 2-23)

A production process operates with 2% nonconforming

output. Every hour a sample of 50 units of product is taken,

and the number of nonconforming units counted. If one or

more nonconforming units are found, the process is stopped

and the quality control technician must search for the cause of

nonconforming production. Evaluate this decision rule.

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

55

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

56

Example 4: (Textbook problem 2-25) A random sample of 100 units is

drawn from a production process every half hour. The fraction of

nonconforming product manufactured is 0.03. What is the probability

that p̂ ≤= 0.04 if the fraction nonconforming really is 0.03?

Poisson Distribution

The number of random events occurring during a specified time period:

p(x) =

E(x) = λ

.9

–λ x

e λ

x!

V(x) = λ

x = 0, 1, 2,...

β 1β 1= =

11

λλ

1

β =3+

2

λ

Uses:

a. number of "defects" per unit

b. number of "defects" per unit of area

c. number of random occurrences per unit of time

d. approximate

binomial

with

→∞

if

n the

; p → 0distribution

, np = cons

tanλ=

t np when np Š 5 and p Š .1 or

then

Binomial → Poisson

Assumptions: 1. The average occurrence rate (λ) is known and constant.

2. Occurences are equally likely to occur during any time interval.

3. Occurences are statistically independent.

Excel Function: POISSON(x,λ, false) (True:accumulative probability)

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

57

Example 1: Arrivals of parts at a repair station are Poisson

distributed, with a mean rate of 1.2 per day. What is the probability

of no repairs in the next day?

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

58

Example 2: What is the probability that today the number of parts

requiring repair will exceed the average by more than one standard

deviation?

59

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

60

Example 3: Glass bottles are formed by pouring molten glass into a

mold. The molten glass is prepared in a furnace lined with firebrick.

As the firebrick wears, small pieces of brick are mixed into the molten

glass and finally appear as defects (called "stones") in the bottle. If

we can assume that stones occur randomly at the rate of 0.00001 per

bottle, what is the probability that a bottle selected at random will

contain at least one such defect?

Example 4: The billing department of a major credit card company

attempts to control errors (clerical, keypunch, etc.) on customers'

bills. Suppose that errors occur according to a Poisson distribution

with parameter λ = 0.01. What is the probability that a customer's bill

selected at random will contain one error?

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

61

Normal Distribution

f(x) =

1

2πσ2

–(x–µ)2/2σ2

e

E(x) = µ

β1 = 0

x ~ N(µ, σ 2 ) ;

Pr{x ≤ a} = Pr{z ≤

f(x)

σ2

V(x) = σ

β2 = 3

µ

z ~ N(0,1)

a −µ

a −µ

} = Φ(

)

σ

σ

62

Example 1: The tensile strength of a metal part is normally

distributed with mean 40 LB. and standard deviation 8 LB. If 50,000

parts are produced, approximately how many would fail to meet a

minimum specification limit of 34-LB tensile strength? Approximately

how many would have a tensile strength in excess of 48 LB?

–∞ ≤ x ≤ ∞

2

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

x

Pr(µ−σ≤x≤µ+σ)=68.26%

Pr(µ−2σ≤x≤µ+2σ)=95.46%

Pr(µ−3σ≤x≤µ+3σ)=99.73%

If x1, x2 are independently normally distributed variables, then y=x1+x2

also follows the normal distribution, i.e. y~N(µ1+µ2,σ12+ σ22)

The Center Limit Theorem: if x1, x2, …, xn are independent random variables, with

mean µi and variance σi2, and if y=x1+x2+…+xn, then the distribution

approaches the N(0,1) distribution as n approaches infinite.

(y −

Excel Function: NORMDIST(x,µ,σ,true)

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

n

n

∑µ ) / ∑σ

i =1

i

i =1

2

i

63

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

64

Example 3: A quality characteristic of a product is normally

distributed with mean µ and standard deviation one. Specifications

on the characteristic are 6 < x < 8. A unit that falls within

specifications on this quality characteristic results in a profit of C0.

However, if x < 6, the profit is –C1, while if x > 8, the profit is –C2.

Find the value of µ that maximizes the expected profit.

Example 2: Three shafts are made and assembled in a linkage. The length

of each shaft, in centimeters, is distributed as follows:

Shaft 1: N ~ (75, 0.09)

Shaft 2: N ~ (60, 0.16)

Shaft 3: N ~ (25, 0.25)

(a) What is the distribution of the linkage?

(b) What is the probability that the linkage will be longer than 160.5 cm?

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

65

y>0

E(x) = ν

•

V(x) = 2ν

ν

ν

ν

Γ(2 ) = (2 – 1) (2 – 2)... 3 • 2 • 1

5 3

ν

ν

π

= ( – 1) ( – 2)... • •

2

2

2 2

2

66

Student t Distribution (with degrees of freedom ν)

Chi–Squared Distribution (with degrees of freedom ν)

2

1

f ( y) = n / 2

y ( n / 2 ) −1e − y / 2

2 Γ ( n / 2)

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

for ν even

for ν odd

f(x ) =

E (x ) = 0

1

πν

– (ν + 1 )

⎡ν + 1 ⎤

Γ⎢ 2 ⎥ ⎛

2

x 2 ⎞⎟

⎣

⎦ ⎜

1 +

ν ⎠

⎡ν ⎤ ⎝

Γ ⎢2 ⎥

⎣ ⎦

ν

β1 = 0

V (x ) =

ν – 2

6

β2 = 3 + n – 4

β 1=8/ν, β 2=3+12//ν,

fo r n > 4

N o te : A s n → ∞ th e d is trib u tio n o f x (d is trib u te d a s a S tu d e n t t

ra n d o m v a ria b le ) a p p ro a c h e s th a t o f a s ta n d a rd n o rm a l ra n d o m

v a ria b le .

The Chi-squared Distribution is associated with squared normal

random variables.

ν

ν

ν

Γ ( 2 ) = ( 2 – 1 ) ( 2 – 2 )... 3 • 2 • 1

y = x12 + x 22 + + x 2n

Y follows χ 2n−1 If x1, x2, …, xn are normally

5

3

ν

ν

π

= ( – 1 ) ( – 2 )...

•

•

2

2

2

2

2

fo r ν e v e n

fo r ν o d d

and independently distributed random variables

•

Application: If x and y are independent standard normal and chi-square

random variable respectively, then t = x

is distributed as t with k

degrees of freedom.

y/k

The most popular use of this distribution is for testing hypotheses

about variances of samples from normal distributions.

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

67

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

68

Example 1: (Textbook Problem 2-27) An electronic component for a laser rangefinder is produced in lots of size N = 25. An acceptance testing procedure is used

by the purchaser to protect against lots that contain too many nonconforming

components. The procedure consists of selecting five components at random from

the lot (without replacement) and testing them. If none of the components is

nonconforming, the lot is accepted.

INTERRELATIONSHIPS BETWEEN DISTRIBUTIONS

Hypergeometric, Binomial, Poisson, Normal

Sampling without

replacement

in finite population

Hypergeometric

finite population

if n/N≤0.1

N: population size

n:sample size

a. If the lot contains three nonconforming components, what is the probability of

lot acceptance?

p=D/N, n

The sum of a sequence of

n Bernoulli trials in

infinite population with

probability of success p

Number of defects

per unit

Binomial

if larger n, smaller p <0.1

λ=np constant

Poisson

if λ ≥15

µ= λ, σ2= λ

Normal

b. Calculate the desired probability in (a) using the binomial approximation. Is this

approximation satisfactory'? Why or why not?

If np>10 and p ≥0.5

µ=np, σ2=np(1-p)

c. Suppose the lot size was N=150. Would the binomial approximation be

satisfactory in this case?

⎛ a + 0.5 − np ⎞

⎛

⎞

⎟ − Φ ⎜ a − 0.5 − np ⎟

Pr( x = a ) ≈ Φ ⎜

⎜ np (1 − p ) ⎟

⎜ np (1 − p ) ⎟

⎝

⎠

⎝

⎠

⎞

⎛

⎛ b + 0.5 − np ⎞

⎟ − Φ ⎜ a − 0.5 − np ⎟

Pr( a ≤ x ≤ b ) ≈ Φ ⎜

⎜ np (1 − p ) ⎟

⎜ np (1 − p ) ⎟

⎠

⎝

⎠

⎝

⎛

Pr( µ ≤ pˆ ≤ ν ) ≈ Φ ⎜

⎜

⎝

⎛

⎞

ν− p

⎟ − Φ⎜

⎜

p (1 − p ) / n ⎟⎠

⎝

⎞

µ− p

⎟

p (1 − p ) / n ⎟⎠

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

69

Example 2: A textbook has 500 pages on which typographical errors

could occur. Suppose that there are exactly 10 such errors randomly

located on those pages. Find the probability that a random selection

of 50 pages will contain no errors. Find the probability that 50

randomly selected pages will contain at least two errors.

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

d. Suppose that the purchaser will reject the lot with the decision rule of finding

one or more nonconforming components in a sample of size n, and wants the lot to

be rejected with probability at least O.95 if the lot contains five or more

nonconforming components. How large should the sample size n be?

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

70

Example 3: A sample of 100 units is selected from a production

process that is 2% nonconforming. What is the probability that p̂

will exceed the true fraction nonconforming by k standard deviations,

where k = 1, 2, and 3?

71

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

72

Chapter 3 Inference About Process Quality

- Statistics Review

Interrelations Normal, Chi-Squared, Student t, F

1.

N(0,1)

= t(ν)

χ 2(ν)/ν

• Motivation

• Estimation

– point estimation

– interval estimation

• Hypothesis Testing

– Definition

– Testing on means

2

2. χ (ν) / ν = F(ν,∞)

1

3. F(α,ν1,ν2) =

F(1-α,ν2,ν1)

4.

χ 2(α,ν) = ν F(α,ν,∞)

5. t(α/2, ν) = F(α,1,ν) 1/2

• known and Unknown variance

– Testing on Variance

6. t(∞) = N(0,1)

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

73

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

74

Random Samples

The need of “Statistical Inference”

• Random Sample:

– Sampling from an infinite population or finite

population with replacement: A sample is selected

so that the observations are independently and

identically distributed.

– Sampling n samples from a finite population of N

⎛N ⎞

items without replacement if each of the ⎜⎜⎝ n ⎟⎟⎠

possible samples has an equal probability of being

chosen

• The parameters of a probability distribution are

unknown.

– Estimation of Process Parameters

• The parameters of a process can be time

varying, how do we identify a process change?

– Hypothesis Testing

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

75

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

76

METHODS FOR ESTIMATION

1. METHOD OF MOMENTS (MOM):

Terminology Definition

• Estimate: a particular numerical value of an estimator, computed

Principle:

from sample data.

if E{|x|r}<∝, then sample rth moment converges with

probability 1 to the population rth moment when sample size

is larger enough.

– Point estimator: a statistic that produces a single numerical

value as the estimate of the unknown parameter

– Interval estimator: a random interval (or called confidence

Analysis procedures:

interval) in which the true value of the parameter falls with some

level of probability.

• If p.d.f has k unknown parameters, equating the first k

population moments to the first k sample moments.

• Solve k parameters from these simultaneous equations

• Statistic:

– any function of the sample data that does not contain unknown

parameters.

Property:

• Simple to generate but may not have desired

properties

• Sampling distribution:

– The probability distribution of a statistic.

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

77

Example:

Exponential: f(x) = λ

a.) Given x 1 , x 2 , ..., x n from f(x) define

n

f(x i)

or L* = ln(L)

L=

,x≥0, λ>0

∏

i=1

1

Population Mean (First Moment): E(x) =

λ

Sample Mean: −

x

Estimate:

Poisson:

b.) Maximize L or L* usually by setting

dL*

d(parameter of interest) = 0

and

c.) Solve system of simultaneous equations.

1

λ̂ =

−

x

E(x)=λ, thus,

78

METHODS FOR ESTIMATION

2. Method of Maximum Likelihood Estimation(MLE)

METHOD OF MOMENTS (MOM): Example

e –λx

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

Usually preferred to MOM since the MLE's are

1.

2.

3.

4.

λ̂ = x

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

79

Consistent

Asymptotically Normal

Asymptotically Efficient

May not be unbiased.

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

80

Assessment of Estimation

METHOD OF MLE: Example

A. PROPERTIES

∧

1. U N BIAS ED: An estimate θ of parameter θ is unbiased if

∧

E( θ ) = θ

∧

2. CON S IS TEN T: An estimate θ of parameter θ is consistent if

∧

2

E( θ – θ ) → 0 as n → ∞

∧

∧

3. EFFICIEN T: θ is more efficient than θ if it has a minimum variance

1

2

∧

∧

2

2

E( θ – θ ) < E( θ – θ )

1

1

2

2

–λx

Exponential: Suppose f(x) = λ e

,x≥0, λ>0

n

–λxi = n e –λΣxi

L=

λe

λ

i

L* = ln(L) = n ln λ – λ Σxi

∏

dL *

n

=

dλ

λ

– Σx = 0

i

1

Thus the estimate λ̂ =

−

x

(same as MOM) .

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

81

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

METHODS FOR ESTIMATION

3. Interval Estimation

•

•

Interval Estimation

If x is a random variable with unknown mean µ and known

variance σ2, what is estimation interval for mean µ?

Estimate the interval between two statistics that include the true

value of the parameter with some probability

– Example: Pr{ L≤ µ ≤ U}=1-α

– The interval L≤ µ ≤ U is called a 100(1- α)% confidence interval (C.I.)

for the unknown mean µ

– two side C.I. (L is lower confidence limit, U is upper confidence limit)

– single side C.I.:

• lower side L≤ µ , Pr{ L≤ µ }=1-α

• upper side µ ≤ U, Pr{ µ ≤ U}=1-α

n

xi ) / n

– Select a statistic x = (∑

i =1

– The approximate distribution of x is N (µ, σ 2 / n) regardless of the

distribution of x per the central limit theorem.

– Given confidence level α, then

• 100(1-α)% two-side confidence interval on µ is:

α/2

α/2

x − Zα / 2

Analysis procedures:

x

L

U

µ

– get the samples

– compute the statistic

– determine the statistic reference distribution

– select confidence level

– find the lower and/or upper confidence limits based on the reference

distribution

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

82

σ

σ

≤ µ ≤ x + Zα/2

n

n

where

Pr{z ≥ Z α / 2 } = α / 2

• 100(1-α)% upper confidence interval on µ is:

µ ≤ x + Zα

σ

n

• 100(1-α)% lower confidence interval on µ is:

x − Zα

83

σ

≤µ

n

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

84

Example 2: A chemical process converts lead to gold.

However, the production varies due to the powers of

the alchemist. It is known that the process is normally

distributed, with a standard deviation of 2.5 g. How

many samples must be taken to be 90% certain that an

estimate of the mean process is within 1.5 g of the true

but unknown mean yield?

Example 1: The strength of a disposable plastic

beverage container is being investigated. The

strengths are normally distributed, with a known

standard deviation of 15 psi. A sample of 20

plastic containers has a mean strength of 246 psi.

Compute a 95% confidence interval for the

process mean.

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

85

Interval Estimation of the Binomial

Distribution Parameter with A Larger Sample

Size

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

86

Hypothesis Testing

^

• From the central limit theorem: p =x/n~ Normal (p, p(1-p) /n )

• Statistical hypothesis:

– a statement about the values of the parameters of a

probability distribution

• Hypothesis testing:

Example 1: (Textbook Problem 3-18) A random sample of 200

printed circuit boards contains 18 defective or nonconforming units.

Estimate the process fraction nonconforming. Construct a 90% twosided confidence interval on the true fraction nonconforming in the

production process.

– Making a hypothesis concerning what we believe to be true

and then use sampled data to test it.

• Two Hypotheses (Two Competing Propositions)

– Null Hypothesis H0: will be rejected if the sample data do not

support it.

– Alternative Hypothesis H1: a hypothesis different from the null

hypothesis

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

87

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

88

TESTS FOR COMPARING

ONE POPULATION MEAN WITH A

STANDARD

Hypothesis Testing Procedures

A ssu m in g K n o w n P o p u latio n V arian ce

1) State the null and alternative hypothesis,

and define the test statistic.

2) Specify the significance level α.

3) Find the distribution of the test statistic

and the rejection region of H0.

4) Collect data and calculate the test

statistic.

5) Compare the test statistic with the

rejection region.

6) Assess the risk.

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

−

x – µ

σ/ n

H0 : µ = µ0

R ejec t H 0 : µ < µ 0

R ejec t H 0 : µ > µ 0

89

Assuming Unknown Population Variance

x − tα / 2

σ

σ

≤ µ ≤ x + Zα/2

n

n

⎪

⎪−

⎪x – µ0⎪

if ⎪

⎪ > Z (α /2 )

⎪ σ/ n ⎪

−

x – µ0

if

< -Z (α )

σ/ n

−

x – µ0

if

> Z (α )

σ/ n

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

90

Example 3: The mean time it takes a crew to restart an aluminum

rolling mill after a failure is of interest. The crew was observed

over 25 occasions, and the results were x = 26.42 minutes and

variance S2 =12.28 minutes. If repair time is normally distributed,

find a 95% confidence interval on the true but unknown mean

repair time.

TESTS FOR COMPARING

ONE POPULATION MEAN WITH A STANDARD

−

x–µ

~ t(n-1)

s/ n

H1

R ejec t H 0 : µ ≠ µ 0

~ N (0 ,1 ) x − Z α / 2

s

s

≤ µ ≤ x + tα / 2

n

n

H1

⎪

⎪−

⎪x – µ0⎪

Reject H0: µ ≠ µ0 if ⎪

⎪ > t(α/2, n-1)

⎪ s/ n ⎪

−

x – µ0

Reject H0: µ < µ0 if

<- t(α, n-1)

s/ n

−

x – µ0

Reject H0: µ > µ0 if

> t(α, n-1)

s/ n

H0 : µ = µ0

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

91

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

92

Example 4: The life of a battery used in a cardiac pacemaker is

assumed to be normally distributed. A random sample of 10

batteries is subjected to an accelerated life test by running them

continuously at an elevated temperature until failure, and the

following lives are obtained.

2 5 .5 h

2 6 .1 h

2 6 .8

2 3 .2

2 4 .2

2 8 .4

2 5 .0

2 7 .8

2 7 .3

2 5 .7

TESTS FOR COMPARING TWO POPULATION MEANS

Assume Known Population Variances

_

_

x

σ1

n

1

2

-

x

+

1

2

σ2

n

2

~ N ( 0 ,1 )

_

1

H1

_

x -x

Reject H 0 : µ1 < µ 2 if

x -x

Reject H 0 : µ1 > µ 2 if

x -x

1

2

σ

σ2

+ 2

n1 n2

2

1

_

93

− Zα/2

σ1

n

2

+

σ2

1

n

2

≤ µ1 − µ 2 ≤

_

_

x -x

1

2

+ Zα/2

2

σ1

n

2

+

1

σ2

n

2

2

_

Reject H 0 : µ1 ≠ µ 2 if

> Zα / 2

_

1

2

σ

σ2

+ 2

n1 n2

2

1

_

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

2

2

H 0 : µ1 = µ 2

Construct a 90% two-sided confidence interval on mean life in the

accelerated test.

_

x -x

< −Zα

_

1

2

σ12 σ 22

+

n1 n2

> Zα

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

94

TESTS FOR COMPARING TWO POPULATION MEANS

Example 5: A bakery has a line making Binkies, a big-selling junk

food. Another line has just been installed, and the plant manager

wants to know if the output of the new line is greater than that of

the old line, as promised by the bakery equipment firm. 12 days of

data are selected at random from line 1 and 10 days of data are

–

selected at random from line 2, with x = 1124.3 cases and

1

–

2

x = 1138.7. It is known that σ = 52 and σ 2 = 60. Test the

2

1

2

appropriate hypotheses at α = 0.05, given that the outputs are

normally distributed.

1. Assume Unknown Population Variances

a) Assume Homogeneity ( σ

_

x -x

1

Sp

2

= σ 12 = σ 22 )

_

where S p =

2

H 0 : µ1 = µ 2

~ t (n1 + n2 − 2) ; x 1 - x 2 − t α / 2 , n + n − 2 S p

_

2

1 1

+

n1 n2

_

1

2

1

n

+

1

1

n

≤ µ1 − µ 2 ≤

2

_

_

x -x

1

2

+ t α / 2 , n1 + n 2 − 2 S p

1

n

+

1

1

n

(n − 1) s 2 + (n − 1) s 2

1

2

1

2

n1 + n2 − 2

H1

Reject H 0 : µ1 ≠ µ 2 if

_

_

x -x

1

_

Reject H 0 : µ1 < µ 2 if

2

1 1

+

n1 n2

Sp

_

x -x

1

2

1 1

+

n1 n2

Sp

> t (α / 2, n1 + n2 − 2)

_

< −t (α, n1 + n2 − 2)

_

x -x

2

> t (α, n1 + n2 − 2)

1 1

Sp

+

n1shihang@umich.edu,

n2

J. Shi, the University of Michigan,

734-763-5321(O)

1

Reject H 0 : µ1 > µ 2 if

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

95

96

2

TESTS FOR COMPARING TWO POPULATION MEANS

Textbook problem: 3-11. Two quality-control technicians measured the

surface finish of a metal part, obtaining the data shown below. Assume that

the measurements are normally distributed.

Technician 1

Technician 2

1.45

1.54

1.37

1.41

1.21

1.56

1.54

1.37

1.48

1.20

1.29

1.31

1.34

1.27

1.35

Assuming that the variances are equal, construct a 95% confidence interval

on the mean difference in surface-finish measurements.

2. Assume Unknown Population Variances

b) Assume Heterogeneity ( σ

_

2

1

≠σ

_

x1 - x 2

2

1

2

2

s

s

+

n1 n2

H 0 : µ1 = µ 2

2

2)

2

(s / n + s / n )

(s / n ) (s / n )

~ t (v) where v =

2

1

1

2

1

1

n1 + 1

H1

_

2

2

2

2

2

+

2

−2

2

2

n2 + 1

_

Reject H 0 : µ1 ≠ µ 2 if

x -x

Reject H 0 : µ1 < µ 2 if

x -x

Reject H 0 : µ1 > µ 2 if

x -x

1

2

2

1

s

s2

+ 2

n1 n2

_

> t (α / 2, v)

_

1

2

2

1

s

s2

+ 2

n1 n2

_

< −t (α, v)

_

1

2

s12 s22

+

n1 n2

> t (α, v )

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

97

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

98

TESTS FOR COMPARING ONE "NORMAL"

POPULATION VARIANCE WITH A STANDARD

(n −1)s2

2

~ χ (n – 1)

σ2

t α,ν

χ 12− α / 2 , n −1 ≤

( n − 1)S 2

≤ χ α2 / 2 , n −1

σ2

2

2

H 0 : σ = σ 0 H1

(n - 1) s

(n - 1) s

2

2

Reject H : σ ≠ σ if

2 > χ (α/2,n - 1) or

2 < χ (1 - α/2,n - 1)

0

o

σo

σo

2

(n - 1) s

2

2 < χ (1-α,n - 1)

σo

2

(n - 1) s

2

Reject H : σ > σ if

> χ (α,n - 1)

2

o

0

σo

Reject H : σ < σ if

0

o

( n − 1) S 2

( n − 1) S 2

≤ σ2 ≤ 2

,

2

χ α / 2 , n −1

χ 1 − α / 2 , n −1

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

99

Pr{ χ 2n −1 ≥ χ α2 / 2 , n −1 } = α / 2

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

100

TESTS FOR COMPARING TWO NORMAL

POPULATION VARIANCES

Consider the data in Exercise 3-3. Construct a 90% two-sided

confidence interval on the variance of battery life. Convert this into

a corresponding confidence interval on the standard deviation of

battery life.

2 5 .5 h

2 6 .1 h

2 6 .8

2 3 .2

2 4 .2

2 8 .4

2 5 .0

2 7 .8

2 7 .3

2 5 .7

S 12 / σ 12

2

2

~ Fn1 −1, n 2 −1 W ith H 0 : σ 1 = σ 2

S 22 / σ 22

2

2

for H 1 : σ 1 ≠ σ 2

Reject H 0

if

s 2

1

s 2

2

s 2

1

s 2

2

> F (α/2,n –1,n –1) or

1

2

< F (1–α/2,n –1,n –1)

1

2

2

2

for H 1 : σ 1 < σ 2

Reject H

0

if

s2

s1

2

2

> F

(α,n 2 –1,n 1 –1)

2

2

for H : σ > σ

1

1

2

s

Reject H

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

101

0

if

s

2

1

2

> F

2

(α,n 1 –1,n 2 –1)

S 12

σ2 S 2

F1− α / 2 , n 2 −1, n1 −1 ≤ 12 ≤ 12 Fα / 2 , n 2 −1, n1 −1 ,

S 22

σ2 S2

F1− α / 2 , µ , ν = 1 / Fα / 2 , ν ,µ

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

102

The Use of P-Values in Hypothesis Testing

(Textbook Problem 3-11 - AGAIN) Two quality-control

technicians measured the surface finish of a metal part, obtaining

the data shown below. Assume that the measurements are normally

distributed.

1. Traditional hypothesis testing:

– Given α to determine whether the null hypothesis was rejected

– Disadvantage:

b. Construct a 95% confidence interval estimate of the ratio of the variances of

technician measurement error.

• No information on how close to/far away from the rejection region

• predefined α may not reflect different decision maker’s risk assessments

c. Construct a 95% confidence interval on the variance of measurement error for

Technician 2.

2. P-Value approach

– P-Value: the smallest level of significance would lead to rejection of the

null hypothesis

– if the predefined α>P= αmin, reject the null hypothesis

x1 = 1.3829, S1 = .11485 , n1 = 7

Ans:

x2 = 1.3763, S2 = .1249, n2 = 8

S

2

p

f(x)

6 (.11485 ) 2 + 7 (.1249) 2

=

= .0145

13

Φ(Z0)

1-Φ(Z0)

Z0<0

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

103

µ=0

x

Z0>0

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

104

Φ(z) = 1 − α / 2

Φ(z) = 1 − α

two size C.I.

one side

C.I.

(90%)

(95%)

Use of P Value for the Normal Distribution

H0: µ=µ0 , standard statistic Z0~N(0,1)

– P=2[1-Φ|Z0|] for two- tailed test with H1: µ≠µ0

– P=1-Φ(Z0) for an upper-tailed test with H1: µ>µ0

– P=Φ(Z0) for an lower-tailed test with H1: µ<µ0

– e.g. Textbook Page 100, P=1-Φ(Z0)=0.00023,

If α>P then rejected.

If α=0.01 rejected; however, If α=0.00001, not rejected.

f(x)

Φ(Z0)

1-Φ(Z0)

Z0<0

x

µ=0

Z0>0

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

105

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

106

Testing on Binomial Parameters

Test on Poisson Distribution

•

•

To test whether the parameter p of a binomial distribution equals a

standard value p0

The test is based on the normal approximation to the binomial distribution

H 0 : p = p0

H 1 : p ≠ p0

⎧ ( x + 0.5) − np0

⎪ np (1 − p )

⎪

0

0

Z0 = ⎨

( x − 0.5) − np0

⎪

⎪⎩ np0 (1 − p0 )

if

x < np0

if

x > np0

Or using the central limit theorem

H 0 : p1 = p2

H1 : p1 ≠ p2

•

Z0 =

pˆ 1 − pˆ 2

;

1 1

pˆ (1 − pˆ )( + )

n1 n2

pˆ =

•

A random sample of n observation is taken, say x1, x2, ..,xn. Each

{xi} is Poisson distributed with parameter λ. Then the sum x= x1+ x2

+...+xn is Poisson distributed with parameter nλ.

Example 3-9 show how to use Poisson distribution to do hypothesis

test directly

•

If n is large, x =x/n is approximately normal with mean λ and

variance λ/n

x − λ0

Z0 =

Test hypothesis

λ0 / n

H0: λ =λ0

H1: λ ≠λ0

The null hypothesis would be rejected if |Z0|>Zα/2.

H0 is rejected if | Z 0 |> Z α / 2

Z0 =

x − p0

p0 (1 − p0 ) / n

n1 pˆ 1 + n2 pˆ 2

if

n1 + n2

•

p1 = p2

•

The null hypothesis is rejected if |z0|>Zα/2

J. Shi, the

University of 3-7,

Michigan,

shihang@umich.edu, 734-763-5321(O)

Example

p108

107

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

108

The Probability of Type II Error

— Detection of a mean shift

Two Types of Hypothesis Test Errors

•

Type I error ( producer’s risk):

– α = P{type I error} = P{reject H0 |H0 is true}

=P{product is rejected| but product is good}

•

Type II error (consumer’s risk):

– β = P{type II error} = P{fail to reject H0 |H0 is false}

=P{product is not rejected|although product is bad}

•

•

β = Pr{H 0 | H1}

= Pr{µ 0 − Zα / 2 σ / n ≤ x ≤ µ 0 + Z α / 2 σ / n | H1}

= Φ ( Zα / 2 −

Power of the test:

– Power = 1- β = P{reject H0 |H0 is false}

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

Type II error= β=Pr{H0 |H1 |}=Pr{within the control limits|has a mean shift}

H0: µ = µ0

µ1 = µ 0 + δ, if

δ>0

H1: µ = µ1≠ µ0 with known σ2

δ n

δ n

) − Φ(− Zα / 2 −

)

σ

σ

OC curve see Fig. 3-7 P109

• The larger the mean shift, the smaller the type II error

• The larger the sample size, the smaller the type II error

109

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

110

Motivation

How to do?

Ch 4. Methods and Philosophy of SPC

• Distinguish two process variations:

– Chance causes and assignable causes

• Decide the status of a process

– in control

– out of control

• Continuously improve quality

• Chance Causes and Assignable Causes

of Variations

• Statistical Basis of Control Charts

• Implementation of SPC and Examples

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

111

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

112

Chance and assignable causes of variation

Chance Cause & Assignable Cause

Textbook Fig. 4-1 P155

•

•

Chance causes/common causes/system faults/chronic problems

– system problems/inherent problems (natural

variation/background noise)

– “in statistical control”

Assignable causes/special causes/local causes/sporadic

problems

– problems arise in somewhat unpredictable fashion (operator

error, material defects, machine failure)

– “out of statistical control”

Textbook Fig. 4-1 P155

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

113

Purpose of Using Control charts

- Improve Process and Reduce Process Variation

1. Most processes do not operate in a state of

statistical control.

2. Consequently, the routine and attentive use of

control charts will identify assignable causes. If

these causes can be eliminated from the process,

variability will be reduced and the process will be

improved.

3. The control chart will only detect assignable

causes. Management, operator, and engineering

action will usually be necessary to eliminate the

assignable cause.

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

114

Objectives of SPC

• To quickly detect the occurrence of

assignable causes or process shifts so that

investigations of the process and corrective

actions may be undertaken before many

nonconforming units are manufactured.

• Process Variation Reduction

115

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

116

Continuous Improvement

Procedures of implementing SPC

–

–

–

–

–

Monitoring the process and detecting process changes

Diagnosing the assignable causes

Providing corrective actions plans

Dealing with resistance to changes/actions

Instituting controls to hold the gains

Take

Action

Process

•

Problem/

Variation

Formulate

Action

Measurement/

Observation

Find Root

Causes

Data

Analysis

Assignable Causes

"Continuous improvement" (called Kaizen by the Japanese) –

enduring efforts to act upon both chronic and sporadic problems

and to make refinements to processes.

– For sporadic problems, it means taking corrective action on

periodic problems;

– For chronic problems, it means achieving better and better

levels of performance each year (move mean to target);

– For process refinements, it means taking such action as

reducing variation around a target value.

Take

Action

Evaluation

Problem/

Variation

Process

Chances Causes

Formulate

Action

Find Root

Causes

Measurement/

Observation

Data

Analysis

Evaluation

Control mean close to the target

Reduce variation

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

117

Assignable Causes

Chances Causes

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

Example: Implementation of Continuous Quality

Improvement

118

Concept of Control Charts

•

•Special cause: tool broken, operator injury

•easy to fix

•manufacturer problem

•

•

•Chronic problem: design problem, degradation

•continuous improvement

Control Chart: is a graphical display of a quality characteristic that has

been measured or computed from a sample versus the sample number or

time.

Center Line – represents the average value of the quality characteristic

corresponding to the in-control state (only chance causes are present.)

Upper Control Limit (UCL), Lower Control Limit (LCL) – are chosen so that

if the process is in control, nearly all of the sample points will fall between

them.

3

UCL

2

mm

1

0

Average

-1

-2

LCL

-3

0

10

20

Time

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

119

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

120

General Model for a Control Chart

The Basis of Control Charts

Distribution of

sample subgroup

mean x-bar

Let w be a sample statistic that measures some quality characteristics of

interest, and suppose that the mean of w is µw and the standard deviation

of w is σw. Then the center line, the upper control limit, and the lower

control limit become

Distribution of

individual

measurements x:

3

3σ / n

2

1

mm

UCL

UCL = µw + k σw

Center line = µw

LCL = µw - k σw

2σ / n

1σ / n

0

Average

3 sigma control limits:

•

Action limits: K=3 (p=0.0027)

•

Warning limits: K=2 (p=0.0455)

-1

where k is the "distance" of the control limits from the center line,

expressed in standard deviation units

-2

LCL

-3

0

10

20

Time

Probability limits (Western Europe):

•

Action limits: 0.001 limits (p=0.002)

•

Warning limits: 0.025 limits (p=0.050)

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

Control Charts vs. Hypothesis Test

H 0 : µ = µ0

H 1: µ≠ µ0

⎪−

⎪

⎪x – µ0⎪

if ⎪

⎪ > Z(α/2)

n

σ/

⎪

⎪

• Control Charts

• Control chart has UCL & LCL

• The process is out of control if the data beyond the control limits

•

Type I error ( producer’s risk):

– α = P{type I error} = P{reject H0 |H0 is true}

=P{conclude out of control|although the process is truly in control}

•

Type II error (consumer’s risk):

– β = P{type II error} = P{fail to reject H0 |H0 is false}

=P{conclude in control|although the process is truly out of control}

•

Power of the test:

– Power = 1- β = P{reject H0 |H0 is false}

f(x)

µ1

f(x)

α/2

α/2

α/2

LCL

µ

122

Review of Two Types of Hypothesis Test Errors

• Hypothesis Testing

• Hypothesis testing has a rejection region

• H0 is rejected if the data follow in the rejection region

Reject H0

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

121

LCL

x

UCL

0

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

α/2

123

x

µ0

UCL

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

β

124

OC curve with α=0.05 (P119, Fig. 3-9)

The Probability of Type II Error

— Detection of a mean shift with a known σ

•

•

Type II error= β=Pr{H0 |H1 |}=Pr{within the control limits|has a mean shift}

H0: µ = µ0

µ1 = µ 0 + δ, if

δ>0

H1: µ = µ1≠ µ0 with known σ2

•

The larger the mean shift, the smaller the type II error

The larger the sample size, the smaller the type II error

β = Pr{H 0 | H1}

= Pr{µ 0 − Zα / 2 σ / n ≤ x ≤ µ 0 + Z α / 2 σ / n | H1}

= Φ ( Zα / 2 −

δ n

δ n

) − Φ(− Zα / 2 −

)

σ

σ

increased

δ

σ

/

d =| δ | / σ

n

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

125

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

126

Summary of Type I and Type II Errors

Two Types of Errors

Nature :

– Type I error:

– Concluding the process out of control when the process is

really in control

– Type II error:

– Concluding the process in control when it is really out of

control.

"In Control"

"Out of

Control"

You Conclude :

"In Control"

Confidence Consumer

Error, β

1–α

f(x)

µ1

α/2

"Out of

Control"

Producer

Error, α

Pow er

1–β

α/2

LCL

x

µ0

UCL

β

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

127

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

128

Average Run Length (ARL)—Out of Control

Average Run Length (ARL)— In Control

•

• If the process is actually “out-of-control”, and the probability

ARL: The average number of points that must be plotted before a

point indicates an out-of-control condition.

that the shift will be detected on

• the first sample is 1-β

• the second sample is β(1-β)

• the rth sample is βr-1(1-β)

The following table illustrates the possible sequences leading to

an "out of control" signal:

Run length

Probability

1

α

2

1

α (1– α)

ARLin −control =

α

3

α (1– α)2

:

:

:

k

α (1– α)k–1

•

•The expected number of samples taken before the shift is

detected is

∞

1

ARL out −of −control = ∑ rβ r −1 (1 − β) =

1− β

r =1

Remark: we want 1–β to be large. Thus, the "out of control"

condition can be quickly detected.

Example: ARLin-control = 1/α= 1/0.0027 = 370. Even the process is in control, an

out-of-control signal will be generated every 370 samples on the average.

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

129

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

Example: Suppose that a control chart with 2-sigma limits is used to

control a process. If the process remains in control, find the average

run length until a false out-of-control signal is observed. Compare

this with the in-control ARL for 3-sigma limits and discuss.

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

130

Sample Size and Sample Frequency

- Operating-Characteristic (OC) Curve

131

•

Strategies:

– Small samples at short intervals (favorite in High volume or

more problem processes)

– larger samples at longer intervals

– Adaptive or variable sampling interval

•

An OC curve shows the relationship between a process parameter

(the mean for an X bar chart) and the probability of a type II error

•

Average run length (average time to signal=ARL*sampling

interval) is considered in design and then check the detection

power.

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

132

Control Chart Patterns and Causes

Process Out of Control

JU MPS IN PROCES S LEVEL

1.

2.

3.

4.

5.

6.

Out of control process:

• When one or more points fall beyond the control limit

• Plotted points exhibit some nonrandom pattern of behavior

Description of nonrandom pattern

• a nonrandom pattern with a longer run up or run down, or a run of

length 8 or more

–

–

–

–

•

NEW SUPPLIER

NEW WORKER

NEW MACHINE

NEW TECHNOLOGY

CHANGE IN METHOD OR PROCESS

CHANGE IN INSPECTION DEVICE OR METHOD

HIGH PROPORTION OF POIN TS N EAR OU TER LIMITS

1.

2.

3.

4.

5.

6.

Run up: a sequence of increasing observations

Run Down: a sequence of decreasing observations

Run: a sequence of observations of the same type

Run of length: the number of samples in a run

OVER CONTROL

LARGE DIFF IN MATERIAL QUALITY, TEST METHOD

CONTROL OF 2 OR MORE PROC. ON ONE CHART

MIXTURES OF MATERIALS OF DIFFERENT QUALITY

MULTIPLE CHARTERS

IMPROPER SUBGROUPING

S TRATIFICATION (LACK OF VARIABILITY)

a periodic pattern

1. INCORRECT CALCULATION OF CONTROL LIMITS

2. SYSTEMATIC SAMPLING

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

133

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

SUMMARY OF OUT-OF-CONTROL CRITERIA

— Western Electric Rules (Zone Rules for Control

Control Chart Patterns and Causes

Charts)

RECURRING CYCLES

1.

2.

3.

4.

5.

6.

134

TEMPERATURE AND OTHER CYCLIC ENVIRONMENTAL EFFECTS

WORKER FATIGUE

DIFFERENCES IN MEASURING DEVICES USED IN ORDER

REGULAR ROTATION OF MACHINES OR OPERATORS

SCHEDULED PREVENTIVE MAINTENANCE (R CHART)

TOOL WEAR (R CHART)

Enhance the sensitivity of control charts for detecting a small shift

or other nonrandom patterns

1. One point plot outside 3σ limits.

2. Two successive points plot outside 2σ limits

3. Four consecutive points plot at a distance of 1σ or beyond

from the center line (one side)

4 A run of length eight points

TRENDS

1.

2.

3.

4.

GRADUAL EQUIPMENT DETERIORATION

WORKER FATIGUE

ACCUMULATION OF WASTE PRODUCTS

IMPROVEMENT OR DETERIORATION OF WORKER SKILL/EFFORT

(ESPECIALLY IN R CHART)

5. DRIFT IN INCOMING MATERIALS QUALITY

More other sensitizing rules for Shewhart control chart; Table 4-1, P176

The final type I error: the process is concluded out of control if any

one of the rules is applied

k

α = 1 − ∏ (1 − α i )

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

135

αi is the type I error of using one rule i alone

i =1

J. Shi, the University of Michigan, shihang@umich.edu, 734-763-5321(O)

136

Rational Subgroups

•

•

•

•