Efnisy rlit

advertisement

Aðgerðagreining

Assembly Line Balancing

10.04.2011

Efnisyrlit

1

Title

2

2

executive summary

2

2.1

2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

Findings, conclusion and recommendations

3

4

Methods

4

4.1

Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

4.2

Technology

6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5

references

7

6

Appendix

7

6.1

Mathematical models . . . . . . . . . . . . . . . . . . . . . . . . .

9

6.2

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10

1

Aðgerðagreining(IÐN401G)

Reikniverkefni 2

Assembly Line Balancing

Axel Viðarsson

Ágúst Þorri Tryggvason

Davíð Freyr Hlynsson

10.04.2011

Aðgerðagreining

Assembly Line Balancing

10.04.2011

1 Title

2 executive summary

This paper investigates a Simple assembly line balancing problem (SALBP). The

rst subcategories of SALBP is tybe 1 and its objective function is to minimize

the number of workstations, but in this paper we will concentrate on type 2 and

its objective function is to minimize the desired cycle time.

2.1

An

Introduction

assembly line

is a manufacturing process in which two or more separate tasks

are tted together in a sequential manner to form a new product, and nally

resulting in the nished product. The tasks are generally interchangeable, so

an optimal schedule for in which order they should be processed is needed to

create the nished product as soon as possible, in Operations Management this

is referred to as

assembly line balancing problem

(ALBP)[1].

Henry Ford and Ransom E. Olds are credited with the invention of the assembly

line, although (as is the case with many inventions) the assembly line's development included many inventors. It combined the idea of interchangeable parts

(another gradual technological development that is often mistakenly attributed

to one individual or another). After 5 years of empirical development, Ford's

rst moving assembly line (employing conveyor belts) began mass production

on or around April 1, 1913. The concept was rst applied to subassemblies, and

shortly after to the entire chassis. Although it is inaccurate to say that Ford personally invented the assembly line, his sponsorship of its development and use

was central to its explosive success in the 20th century. In large factories, which

are based on many dierent workstations with dierent production time, Such

as the Ford factory is, there are often optimization problems to be resolved.

One of the most common Things That factories want is to nish its product

in Shorter amount of time or rear They range workstations.

Those kind of

problems are called assembly line Balancing Problem (ALBP).

In an Assembly Line Balancing Problem (ALBP) a set of tasks have to be

assigned to an ordered sequence of workstations in such a way that precedence

constraints are maintained and a given eciency measure is optimized, such

as, for example, the number of workstations or the workstation time (i.e. the

cycle time). In the simplest case, referred to in the literature as SALBP: Simple

Assembly Line Balancing Problem, a serial line processes a single model of one

product. Basically, the problem is restricted by technological precedence relations and the cycle time constrains.[2]

A classication proposed by Baybars (1986) divides all balancing problems into

two classes: a rst class of problems known as simple, SALBP , whose members

are clearly stated in the aforementioned work, and a second class of problems

known as generals, GALBP, which is constituted of all other problems not

belonging to the SALBP class.

The SALBP class is constituted of assembly

problems where only two kinds of task assignment constraints are taken into

2

Aðgerðagreining

Assembly Line Balancing

10.04.2011

account in relation to the stations

(1) Cumulative constraints associated to the available time of work in the

stations.

(2) Precedence constraints created by the requirement of some tasks to be

performed after other tasks have been nished.

Any other problem taking into account any additional considerations like

incompatibilities between tasks, dierent line shapes, space constraints or parallel

stations, between many others, are included in the GALBP class.[3]

To nd an optimal solution for this kind of problems you will need to use either

exact methods or heuristics methods.

Generally heuristics are more ecient

and in this letter we will use that method.

3 Findings, conclusion and recommendations

We did take closer look on four data les and found their cycle time with two

seprate programs, Matlab and Gusek. Whith their help we could nd LE(e.Line

eciency), SI(e.Smoothness index) and LT(e.Total time on the assembly lines),

those numbers are kept in the Appendix. It was not simulare to drive the data

in Matlab or Gusek, Matlab did nd solution fast but the SI was greater, which

tell us that Gusek showed lot better solution (more balanced). Gusek did end up

whit eighter very good solution or infesible solution, it had to run for a couple

of hours sometimes to get some values. When we had few tasks it did take few

seconds for Gusek but only part of a second for Matlab. Both programs came up

whith simular solution when the problems weren´t to hard. Heuristic method,

Longest time task and GNS showed not much dierence but if they did then

GNS had little better solution.

3

Aðgerðagreining

Assembly Line Balancing

10.04.2011

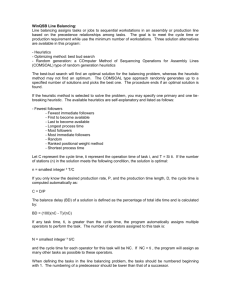

350

300

Right value

GUSEK

MATLAB (long)

MATLAB (followers)

Cycle time

250

200

150

100

50

0

B(m=7)

B(m=14)

K(m=7)

K(m=6)

T(m=12) T(m=17)

Mynd 1: Matlab plot from selected data les, b is for buxey, k is for kilbridge,

t is for tonge, m for number of workstations.

Matlab does nd an solution a lot quicker than Gusek but its value is often

not good enough, while Gusek takes its time to nd solution that is good enough.

When the problems become bigger and harder you will often have to give some

time limit for how long the programs can operate. On the bar graph above are

taken couple of our data set (see data). For example, rst you see Buxey whit

7 workstations optimized whit dierent programs compared to the real value.

After closer look you can see that Gusek is approaching better than Matlab.

That is maybe reverse to some bars here above but that is because of the time

limit we gave the programs and how they operate.

4 Methods

4.1

Theory

We want to design an assembly line consisting of

consisting of

n

m

work stations for a product

tasks. Each workstation preforms a number of tasks,

wj

, on an

item before passing it on to the next workstation in the assembly line.

Each

task has an indivisible operation time , ti , wich is assumed to be integral. Each

product spends the same amount of time at each workstation, called

C. The workload of workstation

j

is

wj =

∑

ti , (1)

i∈Wj

and its idle time or slack time is

sj = C − wj , (2)

4

cycle time

,

Aðgerðagreining

Assembly Line Balancing

10.04.2011

and the sum of all idle times is called balance delay time,

Due to technical restrictions there are

S=

precedence constraints

∑m

j=1 sj .

on the tasks,

partially specify the sequence for the assembly line production e.g. one can't

screw a bolt before drilling a hole. An immediate precedence matrix, P, is a binary matrix of dimension nxn, where P(i,j)=1 if task j is an immediate successor

to task i, 0 otherwise. An immediate followers matrix ,F, is simply the transpose

of P. An example of ALBP is given in Fig.1 with n = 9. The task index is given

within the circle; its operation time is given on the upper right hand side of the

circle; the arrows show the direction of the precedence constraints for the tasks.

For example it shows that task 1 and 4 can start immediately; task 2 can start

after task 1 has been completed; task 6 can start when both tasks 1 and 5 have

been completed, etc. Its immediate precedence and followers matrices are

P =

0

1

0

0

0

1

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

F =

and

Simple assembly line balancing problem(SALBP)

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

1

0

0

0

1

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

1

0

0

0

1

0

0

0

0

0

0

0

0

0

1

0

(1)

describes a mass-production

of a homogeneous product with a known production process; paced line, i.e.,it is

assumed that the time to move items between stations is negligible; xed cycle

time; deterministic operation times; only assignment restrictions are precedence

constraints; serial line layout with

m

stations; all workstations are uniform, i.e.,

equally equipped regarding workers and machinery; and lastly line eciency is

to be maximized,[8].SALBP has several subcategories. The rst

is of type 1 (SALBP-1) and its objective function is to minimixe the number

of workstations,

m

. This may have to do with the cycle time being related to

the workers shifts duration. Other subcategory is of type 2(SALBP-2) and its

objective function is to minimize the cycle time, C , in other words minimize

the amount of work on the busiest workstation, i.e. the assembly line's bott1

leneck, thereby maximizing the production rate,

C , og the assembly line. In a

job shop scheduling context this is equivalent to minimizing the makespan on

identical parallel machines. Another subcategory SALBP-E combines these two

objective functions, i.e., minimize cycle time and number of stations in order to

maximize the line's eciency.

Lince balance

refers to nding a feasible solution to ALBP in such a manner

that each task is assigned to exactly one workstation and fullling its precedence

constraints and each station's workload does not exceed the cycle time. A simple

station- oriented algorithm is given in Fig.3. Of course there are many slightly

dierent heuristic rules that can be applied, or assign the algorithm in a taskoriented manner, but as described in [8] station-oriented algorithms are more

ecient than had it been task-oriented.

There are several performance measures associated with ALBP [7,9,6], their

5

.

Aðgerðagreining

n

m

M

P

Assembly Line Balancing

number of tasks on the assembly line

number of workstations in the assembly line

maximum number of workstations

immediate precedence matrix of dimension

P (i, j) = 1

F

if task

j

if task

j

n × n,

is an immediate successor of task

immediate followers matrix of dimension

F (i, j) = 1

C

ti

Wj

wj

sj

S

10.04.2011

i,

0 otherwise.

n × n,

is an immediate follower of task

i,

0 otherwise.

cycle time of the assembly line

i

operation time of task

j -th workstation

∑

j -th workstation, wj = i∈Wj ti

the slacktime for the j -th workstation, sj = C − wj

∑m

balance delay time, S =

∑ j=1 sj

the set of tasks assigned to the

the workload of the

m

j=1

LE

line eciency,

LE =

SI

smoothness index,

LT

total time on the line,

wj

C·m

√

SI =

∑m

j=1 (C

− wj )2

LT = C · (m − 1) + wm

Mynd 2: Notation used in this paper

main measures being:

Line eciency

,LE, that shows the utilization of the line

as a ration between the total workload and by the cycle time multiplied by of

number of utilized machines,

∑m

LE =

Smoothness index

j=1

wj

C ∗m

.(4)

,SI, describes the relative smoothness for a given assembly, it

is derived from the slack times,

v

u∑

um 2

SI = t

sj .(5)

j=1

the smaller the SI the smoother the line is, and SI=0 indicating a perfect balance. Finally the

total time on the assembly line

, LT , tells how long time it

takes the product to be completed,

LT = C ∗ (m − 1) + wm .

4.2

Technology

Heuristic evaluation is a discount usability engineering method for quick, cheap,

and easy evaluation of a user interface design. Heuristic evaluation is the most

popular of the usability inspection methods.

Heuristic evaluation is done as

a systematic inspection of a user interface design for usability.

6

The goal of

Aðgerðagreining

Assembly Line Balancing

10.04.2011

1 for j := 1 to M do (assign tasks on workstation)

2

Identify available tasks, A, whose predecessors have been assigned

a workstation ≤ j .

3

Determine from available tasks, At = {i | ∀i ∈ A : ti ≤ sj }

4

Choose a task i ∈ At by some heuristic.

5

if At = ∅ then break 6

if all tasks are assigned then return ALBP sequence using m := j

workstations 9 od

Mynd 3: Simple station-oriented algorithm for nding a solution to ALBP.

heuristic evaluation is to nd the usability problems in the design so that they

can be attended to as part of an iterative design process. Heuristic evaluation

involves having a small set of evaluators examine the interface and judge its

compliance with recognized usability principles (the "heuristics").[4]

5 references

1. Baybars, I.:A survey of exact algorithms for the simple assembly line balancing problem. Management Science(1986)

2.Betancourt, L.: ASALBP: the Alternative Subgraphs Assembly Line Balancing Problem. Formalization and Resolution Procedures(2007)

3.Bautista, J; Pereira, J.: A dynamic programming based heuristic for the

assembly line balancing problem (2009)

http://www.useit.com/papers/heuristic/ [4]

6 Appendix

Reiknirit/stærðfræðilíkan fyrir glpk.

1

2

3

4

5

6

7

8

9

10

11

12

#

#Reikniverkefni 2

#

/*set af akvardanabreytum*/

set workstations;

set tasks;

/*pharameters*/

param P{i in tasks,w in tasks};

param t{i in tasks};

7

Aðgerðagreining

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

Assembly Line Balancing

10.04.2011

/*Akvordunarbreyta */

var x{i in tasks,j in workstations}, binary;

var Ct ≥0, integer;

/*Minimize cicle time*/

minimize z:Ct;

/* Skorur */

s.t. pre{i in tasks,w in tasks : P[i,w] = 1}:

sum{j in workstations} j*x[w,j] ≤ sum{j in workstations} j*x[i,j];

s.t. workst{i in tasks} : sum{j in workstations} x[i,j] =1;

s.t. bla{j in workstations}: sum{i in tasks} t[i]*x[i,j]≤Ct;

solve;

display z;

data;

set tasks:= 1 2 3 4 5 6 7 8 9;

set workstations:= 1 2 3 4 5 6;

param t :=

1

6

2

6

3

4

4

4

5

5

6

4

7

5

8

2

9

9;

param

1 0

2 1

3 0

4 0

5 0

6 1

7 0

8 0

9 0

P : 1

0 0

0 0

1 0

0 0

0 0

0 0

0 0

0 0

0 0

2 3 4

0 0

0 0

0 0

0 0

1 0

0 1

0 0

0 0

0 0

5 6 7

0 0

0 0

0 0

0 0

0 0

0 0

1 0

0 1

0 0

8 9 :=

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

1 0;

end;

8

Aðgerðagreining

Assembly Line Balancing

10.04.2011

We used GLPK to calculate the minimum cycle time for example 1.

example included six workstations and 9 Tasks.

The

In the program reikn2.mod

which can be seen in the appendix, we begin to dene workstations and tasks,

then set the matrix P as parameter, it contains information for tasks.

Decisions variables were only x [i, j] and Ct (cycle time).

The

X [i, j] is actually

a variable that describes what tasks are carried out in worsktations.Then were

the constraints set up as they were in the mathematical model.

data le, containing the information that were given.

We created

The program sequence

each task down to a workstation and nds the cycle time. For this sample the

z (cycle time) = 9

6.1

Mathematical models

According to the optimization objective considered, four versions of SALBP are

distinguished (Scholl (1999)):

SALBP-1: minimizes the number of workstations m given a cycle time ct.

SALBP-2: aims at minimizing the cycle time ct given the number of workstations m.

SALBP-E: seeks to maximize the line eciency E, where E=tsum/(mct) and

tsum is the summation of all task processing times.

SALBP-F: is a feasibility problem that tries to establish whether a feasible task

assignment exists for a given cycle time ct and a number of workstations m. [2]

The cycle time is the variable to be optimized, i.e., objective function(i) furthermore, as the number of workstations is a given parameter, since all workstations existence variables

yj

are equal to 1. This is for SALBP-2.

minimizez = tc(i)

m

∑

xi j = 1(ii)

j=1

n

∑

m

∑

j=1

i = 1ti xi j ≤ ct∀j(iii)

jxp j ≤

m

∑

jxi j, ∈ P Dt (iv)

j=1

9

Aðgerðagreining

6.2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

1

2

3

4

5

Assembly Line Balancing

10.04.2011

Applications

function [C_longest,C_maxf] = salbp2(n,t,P,F,m,Cmin)

mstar_v_longtt = [];

mstar_v_maxf = [];

seq_v_longtt = {};

seq_v_maxf = {};

C_v_longtt = [];

C_vigur_maxf = [];

tilv_longtt = 0;

tilv_maxf = 0;

tilv_alls = 0;

for i = Cmin:sum(t);

[seq1,mstar1] = salbp_Longesttt(n,t,P,i);

[seq2,mstar2] = salbp_maxf(n,t,P,F,i);

seq_v_longtt = {seq_v_longtt seq1};

seq_v_maxf = {seq_v_maxf seq2};

if (mstar1 == m) && (tilv_longtt == 0)

C_longest = i;

C_v_longtt = [C_v_longtt i];

tilv_longtt = 1;

end

if (mstar2 == m) && (tilv_maxf == 0)

C_maxf = i;

C_cigur_maxf = [C_vigur_maxf i];

tilv_maxf = 1;

end

if (tilv_maxf == 1) && (tilv_longtt == 1) && (tilv_alls == 0)

break

end

if tilv_longtt == 0

C_v_longtt = [C_v_longtt i];

end

if tilv_maxf == 0

mstar_v_longtt = [mstar_v_longtt mstar1];

end

end

function [seq,mstar] = salbp_Longesttt(n,t,P,C)

M=n; % upper bound on number of workstations needed

nr_unassigned=n; % Intially all tasks are unassigned

10

Aðgerðagreining

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

1

2

3

4

5

6

Assembly Line Balancing

10.04.2011

unassigned=1:n;

s=C*ones(M,1); % Initially the slack on all workstations is C

seq = [];

for j=1:M % Assign tasks on workstation

while 1

% Identify available tasks, A, whose predecessors have been assigned

A=[];

for i=unassigned

if P(i,unassigned)==zeros(1,nr_unassigned), A=[A i]; end

end

% Determine from available tasks, Afit = {i | for all i in A : t(i)≤s(j)

Afit=[];

for i=A

if t(i)≤s(j), Afit=[Afit i]; end

end

% if Afit is empty then break

if isempty(Afit),

break % from the while-loop and procede to next machine j+1

end

% Choose a task i in Afit by some heuristic; at least two distinctly

% different heuristics (hint: read the introduction)

%i = heuristic(Afit,...); % YOUR TASK

i = Longesttt(Afit, t)

seq = [seq i j];

s(j)=s(j)-t(i); % update the slack

unassigned=setdiff(unassigned,i);

nr_unassigned=nr_unassigned-1;

end

% if all tasks are assigned then return ALBP sequence using m:= j

% workstations

if isempty(unassigned)

mstar = j;

break; % from the for-loop

end

end

end

function [seq,mstar] = salbp_maxf(n,t,P,F,C)

M=n; % upper bound on number of workstations needed

nr_unassigned=n; % Intially all tasks are unassigned

unassigned=1:n;

11

Aðgerðagreining

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

1

2

3

4

5

6

7

8

Assembly Line Balancing

10.04.2011

s=C*ones(M,1); % Initially the slack on all workstations is C

seq = [];

for j=1:M % Assign tasks on workstation

while 1

% Identify available tasks, A, whose predecessors have been assigned

A=[];

for i=unassigned

if P(i,unassigned)==zeros(1,nr_unassigned), A=[A i]; end

end

% Determine from available tasks, Afit = {i | for all i in A : t(i)≤s(j)

Afit=[];

for i=A

if t(i)≤s(j), Afit=[Afit i]; end

end

% if Afit is empty then break

if isempty(Afit),

break % from the while-loop and procede to next machine j+1

end

% Choose a task i in Afit by some heuristic; at least two distinctly

% different heuristics (hint: read the introduction)

%i = heuristic(Afit,...); % YOUR TASK

i = maxfollowers(Afit, nr_unassigned, F)

seq = [seq i j];

s(j)=s(j)-t(i); % update the slack

unassigned=setdiff(unassigned,i);

nr_unassigned=nr_unassigned-1;

end

% if all tasks are assigned then return ALBP sequence using m:= j

% workstations

if isempty(unassigned)

mstar = j;

break; % from the for-loop

end

end

end

function i = maxf(Afit, nr_unassigned, F)

fjoldi_e = [];

h = 1;

for k = Afit

fjoldi_e(h) = length(find(F(k,1:nr_unassigned)));

h = h+1;

end

12

Aðgerðagreining

9

10

11

12

13

14

15

16

17

18

19

1

2

3

4

5

6

7

8

Assembly Line Balancing

[margir,nr_margir] = max(fjoldi_e);

if margir == 0

lokastakid = Afit(1);

else

lokastakid = Afit(nr_margir);

end

i = lokastakid;

end

function i = Longesttt(Afit,t)

T = [];

for k = Afit

T = [T t(k)];

end

Stort = find(max(T));

i = Afit(Stort);

end

13

10.04.2011