Basic Strategic Warehouse Management 15 July 09

advertisement

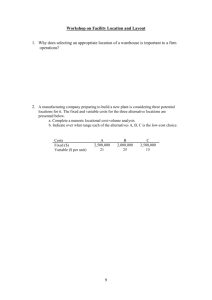

King Mongkut's Institute of Technology North Bangkok Basic Strategic Warehouse Management 1 Speaker’s Profile Academic Backgrounds • Ph.D. in Urban and Transportation Planning, Department of Engineering Systems and Technology, Graduate School of Science and Engineering, Saga University, Saga, JAPAN. • M.Eng. in Transportation Engineering, Transportation and Infrastructure Engineering Program, School of Civil Engineering, Asian Institute of Technology, Pathumthani, THAILAND. • B.Eng. in Civil Engineering, Department of Civil Engineering, King Mongkut’s University of Technology, Thonburi, Bangkok, THAILAND. Working Experiences • Nihon University, Chiba, JAPAN: Senior Researcher and Project Coordinator. • TEAM Consulting Engineering and Management Company, Bangkok, THAILAND: Project Manager and Coordinator / Transportation – Infrastructure – Logistics Engineer. Basic Strategic Warehouse Management 2 Presentation Objectives • Understand Warehousing in term of Definition, Function, and Importance. • Understand Considered Problems in Warehousing. • Know Possible Solutions or Improvement Approaches for Warehousing. • Realize Problems in Warehouse Management, especially for Importance of IT in Warehouse Management. Basic Strategic Warehouse Management 3 Presentation Outline • • • • Part 1: Introduction of Warehousing Part 2: Management and Operation Principles Part 3: Principles to Practices (Case Studies) Conclusion Basic Strategic Warehouse Management 4 Presentation Outline • Part 1: Introduction of Warehousing – What is Warehousing – Importance of Warehousing – Types of Warehouse – Main Functions of Warehouse – Activities and Operations in Warehouse – Warehousing Costs – Considered Issues in Warehousing • Part 2: Management and Operation Principles • Part 3: Principles to Practices (Case Studies) Basic Strategic Warehouse Management 5 Presentation Outline • Part 1: Introduction of Warehouse • Part 2: Management and Operation Principles – Approaches for Warehouse Management Improvements • Better Plan and Design for Warehouse and Facility • Improvement of Warehouse Management • Advanced Technology Application in Warehousing • Part 3: Principles to Practices – Case Studies • • • • Kmart and Wal-mart Warehouse of a transformer factory Tesco-Lotus Warehouse and Distribution Center 7-Eleven Retail Store Basic Strategic Warehouse Management 6 King Mongkut's Institute of Technology North Bangkok Basic Strategic Warehouse Management 7 What is Warehouse • • • Basic Strategic Warehouse Management Most people just imagine warehouse as goods storage. Not many really realize its important role. In particular, very few realize its strategic roles in business developments. Source: http://www.jb-mhg.com/e_logistic 8 What is Warehouse • A part of logistics system storing products, such as raw materials, parts, goods-inprocess, finished goods) at and between point of origin and point of consumption, and providing information to management on the status, condition and disposition of item being stored. Internal Processing Inbound Outbound Internal Processing • • • • Purchases Customer return Transfers Outside Processing • • • • Pick Pack Inspection Count • • • • Assembly Storage Move Replenish • • • • Customer Shipments Vendor Returns Transfers Outside Processing Source: Mark Mandeville, ORACLE Basic Strategic Warehouse Management 9 Importance of Warehousing • • • • Reduce “lead time” for purchasing Encourage for Just-in-Time (JIT) system. Various products for transportation Temporary storage for returned or reproduced items Basic Strategic Warehouse Management • • • • • • Reduce no of times of purchasing or for discounting Stock of raw materials and parts Support for customer service policy Prepare for marketing changes Decrease of transport cost Decrease of production cost 10 Importance of Warehousing • Decrease of production cost Factory Supplier 1 Without Warehouse Supplier 2 Supplier 3 Factory Supplier 1 With Warehouse Supplier 2 Warehouse Supplier 3 Basic Strategic Warehouse Management 11 Importance of Warehousing • Decrease of transport cost Factory A Customer 1 Factory B Without Warehouse Factory C Customer 2 Factory A Customer 1 Factory B Warehouse 1 With Warehouse Factory C Customer 2 Basic Strategic Warehouse Management Warehouse 2 12 Types of Warehouse • Three types (in term of business objectives) – Public Warehouse • • • • • • General Merchandise Warehouse Refrigerated or Cold-Storage Warehouse Bonded Warehouse Household Goods and Furniture Warehouse Special Commodity Warehouse Bulk Storage Warehouse – Private Warehouse • Warehouse for Production • Warehouse for Distribution (Economic Order Quantity:EOQ- Makro) • Warehouse for Transportation – Material Warehouse (Hotel, Hospital etc.,) Basic Strategic Warehouse Management 13 Public Warehouse VS Private Warehouse Advantage Disadvantage Public Warehouse Private Warehouse • Conservation of Capital • Can increase space for peak demands • Reduce risk • Economy of scale • Flexibility in resource adjustment • Know specific activity costs • Control • Flexibility in service improvement • Less cost over the long term • Better use of human resource • Tax benefits • Intangible benefits •Communication problem •Lack of specialized services •Shortage of spaces •Lack of flexibility •Financial constraints Basic Strategic Warehouse Management 14 Main Functions of Warehouse • Three main functions – Move goods – Store goods – Transfer information • New Warehouse Management Focuses: – Smooth flow of goods or items rather than goods storage. – By fast and efficiently moving, storing, and transferring in large amount. • Cross-Docking System Basic Strategic Warehouse Management 15 Cross-Docking System •Low level of stocks, especially for popular goods. •Focus on receiving and shipping. •Many value added activities. •Real time data collection. •Maximize profits through product shipping based on customers’ requirements Basic Strategic Warehouse Management 16 Activities and Operations in Warehouse Receiving -Schedule carrier -Unload vehicle -Inspect for damage -Compare to P/O Warehousing Process Put away-Identify product -Identify storage location - Move product -Update records Storage -Equipment -Stock location 1. Popularity 2. Unit size 3. Cube Shipping prep -Packaging -Labeling -Staging Order picking -Information - Walk & pick - Batch picking - AS/RS Shipping -Schedule carrier -Load vehicle -Delivery -Update record Basic Strategic Warehouse Management 17 Warehousing Costs • Warehousing Activity Costs Highest Part Van Den Berg & Zijm (1999) Basic Strategic Warehouse Management • Warehouse affecting the following costs; – Warehousing Cost – Cost of Lost Sales – Inventory Cost – Transport Cost 18 Considered Issues in Warehousing • Three main issues – Inefficient Warehouse Management System – Unproductive Space Utilization in Warehousing – Inappropriate Facility & Equipment Utilizations in Warehousing Basic Strategic Warehouse Management 19 Inefficient Warehouse Management System • Consider warehouse activities – Receiving • incorrect products, uncompleted information etc. – Put-away • Unidentified products, unknown storage location etc. – Storage • Different size of items, appropriate location of storage etc. – Shipping prep • Unsuitable packaging, no labeling etc. – Order picking • Costly picking method, uncompleted picking etc. – Shipping • No scheduling, out of date records, inefficient loading. Basic Strategic Warehouse Management 20 Inefficient Warehouse Management System • Unknown storage location Basic Strategic Warehouse Management 21 Inefficient Warehouse Management System • Order picking Basic Strategic Warehouse Management 22 Inefficient Warehouse Management System • Different sizes of items, Difficult to carry and store. Basic Strategic Warehouse Management 23 Unproductive Space Utilization in Warehousing • Inappropriate position of equipment or goods in warehouse can directly or indirectly affect to the efficiency of warehousing process. – Item Characteristics (Size, Volume, Weight) – Warehouse Characteristics (Height, Width, Length, Structure) Location and Layout of Warehouse is important Need Good Plan and Design !!! Basic Strategic Warehouse Management 24 Inappropriate Facility & Equipment Utilizations • How to use appropriately and productive equipments. Basic Strategic Warehouse Management 25 King Mongkut's Institute of Technology North Bangkok Basic Strategic Warehouse Management 26 Warehousing Costs • Warehousing Cost (Source: Somphong, 2550) Warehousing Cost is small portion, but significant impacts It can affect to Inventory Cost and Transport Cost Basic Strategic Warehouse Management 27 Approaches for Warehouse Management Improvements • Three possible approaches – Better Plan and Design for Warehouse and Facility – Improvement of Warehouse Management – Advanced Technology Application in Warehousing Basic Strategic Warehouse Management 28 Better Plan and Design for Warehouse and Facility • Factors of Warehouse Investment – Market’s Demands • Existing Warehouses • Characteristics of Goods • Economic Situation – Resources • • • • • Area Equipments Staffs Capital Know-how or Specialists – Regulations – Others Basic Strategic Warehouse Management 29 Better Plan and Design for Warehouse and Facility Source: Kamnai, 2007 Basic Strategic Warehouse Management 30 Better Plan and Design for Warehouse and Facility • Factors of Warehouse Location Selection – Qualitative Factors • • • • • • • Source of raw material or items Transportation Networks Source of Labors Community’s Attitudes Public Facility Environments Future Opportunities – Quantitative Factors • • • • • • • • • Land Costs Construction Costs Labor Costs Raw Material and Finished Goods Shipment Modes Distances between the Factory and Suppliers Facilities around the Site Proximity to Customers and Markets Public Infrastructures • Best Location Based Tax and Insurance on the Lowest Unit Cost (Baht/m3 or Ton etc.) Basic Strategic Warehouse Management #$%& ' 31 ( ) $)* *+% ,./ 012/ 34564/ 60"+7 8 987 ! ! ! 0 ! " !$ ' # ! %&%3 ! & .! * "# ,-. & % % #!"# 1! / & !. * ! ! ! ) , #$%&$ ' )( * ( + " "! ,.-0/ 102 ) !! ! ' '( * 1 ! %& ' * ,2 ) "#% / #$%3( + " #$% 5 #$%$& & 78)/ 5 9:"8 ;=<> #$%@A& #$%&$ ' 8 D + 5 E + @A7 ( % ', / 402 60/ 402 ?0/ -02 ,'/ B02 C0/ -02 1'B0/ F02 % %# '% +% ! * Basic Strategic Warehouse Management 32 :; <=> @ 8(=> ? ? A :; <=> @ 8(=> ? ? :; <=> @ 8(=> ? ? Basic Strategic Warehouse Management 33 Better Plan and Design for Warehouse and Facility • Factors of Warehouse Design – – – – Goods Similarity Goods Popularity Size, Weight, and Quantity Characteristics of Material (Hazardous/Sensitive/Perishable Material, Needed Storage Capacity) – Space Requirements (To know Gross Space for Storage Operations and Net Storage Space) • Structural Loss • Space for Storage Support Function • Aisles – – – – – – Main Aisles Cross Aisles Aisles in Retail Bin Area Personal Aisles Service Aisles Fire Aisles Basic Strategic Warehouse Management 34 Better Plan and Design for Warehouse and Facility • Turn over rate of goods VS Warehouse Layout Design BC 3DE3F60. E6G2HE3F60. IJ./E3F60. Basic Strategic Warehouse Management 35 Better Plan and Design for Warehouse and Facility • Design of Direction of Storage • PART A: easy but not flexible • PART B: the depth of row decreased and no. of rows increased. Good for forklift and pallet • PART C: good for middle size and easy for access • PART D: Full Area Utilization and a lot of items kept. Source: Kamnai, 2007 Basic Strategic Warehouse Management 36 Better Plan and Design for Warehouse and Facility • Warehouse Layout for General Goods Basic Strategic Warehouse Management 37 Better Plan and Design for Warehouse and Facility • Layout for Flammable Storage Warehouse Basic Strategic Warehouse Management 38 Better Plan and Design for Warehouse and Facility • Layout for Transit Shed • KN P168 -2 Picts. Basic Strategic Warehouse Management 39 Better Plan and Design for Warehouse and Facility • Warehouse Floor Plan – An efficient tool for managing spaces – General Scale: 1:400 (Source: Kamnai, 2007) Basic Strategic Warehouse Management 40 Better Plan and Design for Warehouse and Facility • Layout Design for Cold Storage: Case 1 Poor Design Basic Strategic Warehouse Management 41 Better Plan and Design for Warehouse and Facility • Layout Design for Cold Storage: Case 2 Good Design Basic Strategic Warehouse Management 42 Improvement of Warehouse Management • Receiving Process – Record Input Data from P/O • Separate purchasing and warehouse systems • Combine both • Transfer P/O Data into Text File – Process • Carrier Scheduling • Record Product Details: – ID – Unit – Weight & volume for specific storage location • Put-away Task Generation – Storage Type – Storage Location – Code of Storage (Pallet) • Report & Pallet Code – Equipment – Routing Basic Strategic Warehouse Management 43 Improvement of Warehouse Management • Put-away / Storage – Separate types of goods and storages. – Record Input Data (Ex. Locator Card) • • • • • Product Details Product Conditions Receiving Date Quantity for in and out flows No. of Stocks – Physical Counting – Location System Basic Strategic Warehouse Management 44 Improvement of Warehouse Management • Put-away / Storage – Stock Keeping Unit (SKU) – Collect number of unit load for benefits of storage, movement. – Generally, SKU can divided into 3 characteristics; • Single Item (Ex. Clothes, Can) – Carrier: Ex. Container, Box (Consider weight & storage space mainly) • Carton (Ex. Parcel Pack) – Consider no. of item per SKU, storage space in term of WxLxH • Pallet (Standard Size: 100 cm. x 120 cm.) – Consider no. of item, weight, Allowable Height. (for moving) Basic Strategic Warehouse Management 45 Improvement of Warehouse Management • Put-away / Storage – Seibu Reizo – Yamamoto Foods Basic Strategic Warehouse Management 46 Improvement of Warehouse Management • Put-away / Storage – Warehouse Layout of Location System Basic Strategic Warehouse Management 47 Improvement of Warehouse Management • Put-away / Storage – Location System • Bulk Storage Location • Retail Storage Location Basic Strategic Warehouse Management 48 Improvement of Warehouse Management • Put-away / Storage – EAN13 (European Artificial Numbering) or TAN: Only Numeric, 13 Columns 885: Thailand K( 7 L@9 7 GTIN )7 *=#M=% Basic Strategic Warehouse Management 49 Improvement of Warehouse Management • Put-away / Storage – GTIN – GLN : Global Location Number: 13 Digits • • • • 3 Digits: Country 6 Digits: Company or Org. 3 GLN Digits 1 Check Digit – Ex. 885 123400 999 2 • • • Basic Strategic Warehouse Management 50 Improvement of Warehouse Management • Put-away / Storage – Paul M. Swamidous, 1998 100 % of respondents 90 80 70 Benefits of Using Bar Code Production Cost Decrease 81 68 83 Inventory Turnover Rate Increase 81 82 83 84 88 89 70 60 50 40 30 20 10 0 Never use Beginner Intermediate User Type Regular User Experts Basic Strategic Warehouse Management 51 Improvement of Warehouse Management • Order Processing – Consists of the following activities; • Selection (Pick List) • Withdrawal (Picking Orders) – Customer Order Handling Methods – Basic Order-Pick Methods – Order-Picker Routing Patterns • Marshalling • Sorting (based on customer orders) Basic Strategic Warehouse Management 52 Improvement of Warehouse Management • Order Processing – Customer Order Handling Methods • • • • Discrete Picking Batch Picking Zone Picking Wave Picking – Basic Order-Pick Methods • Picker walks to pick items. • Picker uses the equipment or vehicle to pick items. • Items are transported to pickers. Basic Strategic Warehouse Management 53 Improvement of Warehouse Management • Order Processing – Order-Picker Routing Patterns: various methods such as • • • • • S-shape Method Return Method Mid-point Method Largest Gap Method Etc. B320N6O,6P3./ 606/JCA Basic Strategic Warehouse Management 54 Improvement of Warehouse Management • Order Processing – Order-Picker Routing Patterns: Basic Strategic Warehouse Management 55 Improvement of Warehouse Management • Dispatching – Goods grouping – Re-packaging – Re-labeling – Documentation – Scheduling – Vehicle Preparation Basic Strategic Warehouse Management 56 Improvement of Warehouse Management • Effectiveness Evaluation in Warehouse Management – Consider “Inventory Turnover Rate” 1 2 3 Sold Goods Quantity Averaged Inventory • Suitable when the same SKU applied for all goods Total Income from Sold Goods Averaged Value of Inventory • Suitable for retailed goods (trading), because of easy calculation Total Cost from Sold Goods Averaged Value of Inventory • Need Cost Data, but evidently show the flow of goods Basic Strategic Warehouse Management 57 Advanced Technology Application in Warehousing • Equipment Utilization – Pallet Rack – Push-Back Pallet Rack – Forklift & Pick-to Vehicles Basic Strategic Warehouse Management 58 Advanced Technology Application in Warehousing • Equipment Utilization – Barcode Printer & Scanner – Automated Guided Vehicle – Unit Load Automated Buffer – Mini Load Automated Buffer – Sorting Transfer Vehicle Basic Strategic Warehouse Management 59 Advanced Technology Application in Warehousing • Automated Warehouse – Automated Storage and Retrieval System - AS/RS – AS/RS Effectiveness • Increase the efficiency of order process 3 times. • Decrease the damage of goods for 50 % • Increase the accuracy of inventory and services for 65 % – Rack Support Building: RSB • Drive-in rack or Selective rack (cheap structure and easy and fast for construction) – In Thailand, Sanyo: H 30 m. and construction cost reduced by 15 % – Generally, 2 Systems: Unit and Mini Load Automated Buffer Basic Strategic Warehouse Management 60 Advanced Technology Application in Warehousing • Equipment Utilization – Unit Load Automated Buffer http://www.mhinfo.com Basic Strategic Warehouse Management 61 Advanced Technology Application in Warehousing • Equipment Utilization – Mini Load Automated Buffer http://www.mhinfo.com/ Basic Strategic Warehouse Management 62 Advanced Technology Application in Warehousing • Equipment Utilization – Sorting Transfer Vehicle http://www.mhinfo.com Basic Strategic Warehouse Management 63 Advanced Technology Application in Warehousing • Information Technology Utilization – Warehouse Management System (WMS) • It is the system combining material handling and information systems. • It requires the study of goods or material flows for better warehouse management By David E. Mulcahy (1988) Basic Strategic Warehouse Management 64 Advanced Technology Application in Warehousing • Information Technology Utilization – Should we use WMS for our warehouse? • Needs of organization • Available Budget • Compatible with the existing warehouse structure (Ex. Physical conditions) • Directly Answer to Decision Maker’s Strategy or Policy. (Source: Arun, 2004) Basic Strategic Warehouse Management 65 Advanced Technology Application in Warehousing • Information Technology Utilization – Generally, WMS consists of the following functions; • • • • • • • • Real time labor management Labor planning, tracking, and management Integrated host system communication Real time transaction-based operating systems Modular software development Material handling device control Automated storage equipment control In/Outbound traffic management Source: Sirang, 1997 Basic Strategic Warehouse Management 66 Advanced Technology Application in Warehousing • Information Technology Utilization – Benefits of using WMS • Reduce the losses of materials and goods • Significantly Improve the accuracy of warehouse and inventory system. • Real time recognition of any change of material or goods information. • Increase the productivity of warehouse workers • On time goods delivery • Improve the customer services. Source: Sirang, 1997 Basic Strategic Warehouse Management 67 Advanced Technology Application in Warehousing • Information Technology Utilization – Warehouse Management System • Isolated software or module – Power House – IntelliTrack Warehouse Software – Etc. • Combined software or module (Concept of ERP) – ORACLE – SAP – Etc. “Senior level executives now realize that the automated warehouse is as much a part of e-commerce and e-fulfillment as the Internet.” - Supply Chain Yearbook Source: Mark Mandeville, ORACLE Basic Strategic Warehouse Management 68 Advanced Technology Application in Warehousing • Cost Saving of WMS Source: Trunk, 1998 Basic Strategic Warehouse Management 69 Advanced Technology Application in Warehousing • Cost Saving of WMS Source: Trunk, 1998 Basic Strategic Warehouse Management 70 King Mongkut's Institute of Technology North Bangkok Basic Strategic Warehouse Management 71 Case Study 1: Kmart VS Walmart Inventory Turnover Rate Cost of Goods Storage (Cent per 1 $) 3.6 5 7.3 2 Kmart loosed the profits about $ 1.9 Billion, when compare with the inventory cost of Wal-Mart Kmart bankrupted in 2002 Basic Strategic Warehouse Management 72 Case Study 2: Warehouse of a transformer factory • Identify the problems and rood causes – Problem Analysis Tools: (Panika, 2000) • Tree Diagram • Relations Diagram Basic Strategic Warehouse Management 73 Basic Strategic Warehouse Management 74 Basic Strategic Warehouse Management 75 Improvement Warehouse Layout Before After - Zoning - Racking Basic Strategic Warehouse Management •Picking error 2.47 % •Counting error 2.11 % (485,309 B) •Ave. moving time 3.95 min/box. •Picking error 0.03 % •Counting error 0.07 % (1,623 B) •Ave. moving time 1.71 min/box. 76 Case Study 3: TESCO-LOTUS Warehouse and Distribution Center • TESCO-LOTUS Warehouse and Distribution Center was established in 1994. – In 2004, they occupied; • • • • • 43 Hypermarkets (Planned to increase by 6) 1 Super Market 2 Lotus Value 9 Lotus Express (Planned to increase by 21) About 2,500 Suppliers with trading 45,500 MB. – Construction Cost of the center 2,000 MB. – Distribute more than 800,000 units a day. Basic Strategic Warehouse Management 77 Case Study 3: TESCO-LOTUS Warehouse and Distribution Center • In the beginning; LOTUS had about 2,000 goods items per store. • Big Problem: – Each store has their own orders more than 2,000 items or about 22 million orders a year. – In the principle of LOTUS, they have to order 365,000 times a year, generate 22 million bills a year. – Cost during the order processing 100 MB. Basic Strategic Warehouse Management 78 Case Study 3: TESCO-LOTUS Warehouse and Distribution Center • Lotus utilizes the computer network consisting of 3 systems; – SCS (Stock Control System) for managing stores – RAMS (Richter Automated Merchandising System) in Head Office • Control goods and information • Contact to Vendor for replenishment (use EDI) and DC – PCS (Product Controlling System) for managing Warehouse and Distribution Center. • Vendor Managed Inventory (VMI) Basic Strategic Warehouse Management 79 Case Study 3: TESCO-LOTUS Warehouse and Distribution Center • Vendor Managed Inventory (VMI) Replenishment Vendor 1 Inventory Consumers Sale & Forecast Retailer Consumers Inventory Vendor 2 Sale & Forecast Consumers Replenishment Basic Strategic Warehouse Management 80 (Sourcing) Basic Strategic Warehouse Management (Stock Chamber) (Cross Docking Chamber) & !"#$ % Basic Strategic Warehouse Management ' !'(() !"#$ % B320N6O A Q Case Study 3: TESCO-LOTUS Warehouse and Distribution Center • Use “Visualize Scanner” (6,000 boxes per hour); – Throughput Level: 1,000,000 cases a day. • AUTO Shoe Sorter: 80 Outlets with 5,200 boxes/hr. Basic Strategic Warehouse Management 83 Case Study 3: TESCO-LOTUS Warehouse and Distribution Center • They separated suppliers into 2 groups; – High performance suppliers: On time delivery and stocks not required. – Low performance suppliers: not on time delivery and need to stock. – 90% for cross docking – 10% for warehouse The modern and biggest warehouse / DC in SEA. Basic Strategic Warehouse Management 84 Case Study 4: 7-Eleven Retail Store • 7-Eleven Convenience Stores • Expect to expand for 3,000 shops over the country. • 4 DCs (Sukhumvit, Sukhumvit 101, Chokechairaummit, Bangbuathong) • Combine Distribution Center (CDC) focuses on fresh and daily Products (Small Size about 650 sq.m.) • For the overall scale, about 1.4 million customers a day. • 2,000-3,000 goods types per shop • 5600 shops and franchisees Basic Strategic Warehouse Management 85 Problems in Retailing Store * +((,"-./ -0-1 (.2(() * 3(( 3()45 1) 6 7* 3(( ,"-"7 # -1"-)8 "1 6 (- * 9: ".2(() 9 : 6 0. * ; / -< (#"1 6 (-+ 5 !-(: (7.= : 6 5 "1 6 (- * 3(( 41 (# >: "1 6 (-!6 ,"-"7 # -1 >,% Basic Strategic Warehouse Management B320N6O A Q Warehouse and DC in Sourcing Warehouse and Distribution Center can influence with CPFR Basic Strategic Warehouse Management Collaborative Planning, Forecasting & Replenishment • The ability between trading partners to contribute their own insights and competencies to develop and share demand plan and forecast. • CPFR Goal is to enhance the relationship and create significantly more accurate information that can drive the value chain to greater sales and profits. Basic Strategic Warehouse Management Customer Relationship Management !" #$% & +, -! ."% )* '( * ? @ ABCD ? DEF * F G * * * * D @L FH &@ FK IJ FH &@ CM CL CM FN OP H QFR? :5 1(-6 53(6 -1(<S": T38S ": U :5 1(-6 53". # -1 Basic Strategic Warehouse Management B320N6O A Q King Mongkut's Institute of Technology North Bangkok Basic Strategic Warehouse Management 90 Warehousing Functionality Spectrum Product / Order Complexity High Low ly on m m to n co due atio s ie RF egr n t pa p at x in exity m pl e o Co st pl Com m existing o c Highly Automated Facilities Automate physical inventory handling Warehouse Management Implement true ““execution execution system” system” using system directed tasks and task management RF / Barcode Only Improve accuracy and reduce latency of existing transactions Manual Inventory Record transactions and track balances Small Transaction Velocity / Volume Large Source: Mark Mandeville, ORACLE Basic Strategic Warehouse Management 91 Business Pressures Just-in-Time Delivery Guaranteed Availability • How do I integrate operations to reduce order processing time? • How do I create a global view of inventory? • How can I improve the speed of warehouse operations? Inbound One Size Fits One • How can I manage SKU proliferation? • How do I ensure labeling compliance? • How can I improve order promise accuracy? Internal Processing Outbound Lowest Total Cost • Where can I reduce inventory while maintaining high fill rates? • How do I improve labor efficiency? Source: Mark Mandeville, ORACLE Basic Strategic Warehouse Management Operational Challenges Procurement Manufacturing Order Management Warehouse System 1 Warehouse System 2 Warehouse System N RF Middleware RF Middleware RF Middleware Integration and Operation Complexity, Localized Solutions Source: Mark Mandeville, ORACLE Basic Strategic Warehouse Management A Need for Change Leading Business Trends • Fulfillment Processes Integrated with Partners • Support All Company Processes (e.g. Service, Mfg) • Automated Material Handling for Improved Productivity • Mobile and Automatic Data Capture (e.g. RF, RFID) • Streamlined Material Flow (e.g. Cross-Docking) Telecommunication Technology (XML / EDI) Modofied from : Mark Mandeville, ORACLE Basic Strategic Warehouse Management Import and Export in One Stop Service (OSS) Concept DC at Mukdahan !"# U,V #$ %& *+ % TBB 8 #9 $ $ % & 8 #9 M=% % '( $& ) < RS $ % '( $& $ % & 8 #9 Basic Strategic Warehouse Management 95 Future Development in Warehouse and DC • Virtual Warehousing (VW) (By Stuart et al., 1995) – A worldwide system carrying out dynamic and continuous material logistics functions – By utilizing hybrid algorithm performing at the efficiency and accuracy levels achieved only world-class single-location distribution Centers. Basic Strategic Warehouse Management 96 Improvement of Warehouse Management • Information Flow. Supply Chain Process Management Information System “Important” Information Flows During Production Process Raw material - Purchasing Moving Finished Goods Selling Goods Flows Logistics Process Basic Strategic Warehouse Management 97 Information Technology for Supply Chain Supply Chain Deliver Decision Decision Decision Information Information Information Data Data Data Raw Material Stock Points Raw Material Stock Points Basic Strategic Warehouse Management Analytical IT Ex. APS Execution Execution Make Execution Source Transactional IT Ex. ERP Raw Material Stock Points Physical Movement Ex. Material Handling Storage 98 King Mongkut's Institute of Technology North Bangkok Thank You Very Much & Discussion Basic Strategic Warehouse Management 99