Enhancing Responsiveness for Mass

Customization Strategies through the Use

of Rapid Manufacturing Technologies

Hartanto Wong and Daniel Eyers

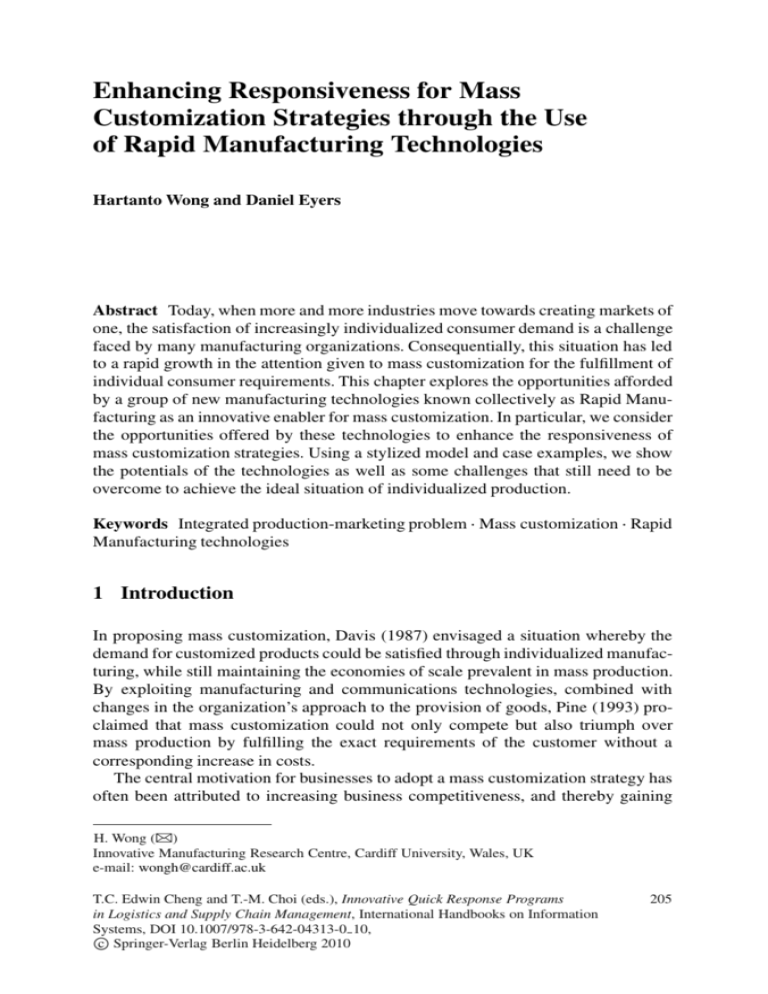

Abstract Today, when more and more industries move towards creating markets of

one, the satisfaction of increasingly individualized consumer demand is a challenge

faced by many manufacturing organizations. Consequentially, this situation has led

to a rapid growth in the attention given to mass customization for the fulfillment of

individual consumer requirements. This chapter explores the opportunities afforded

by a group of new manufacturing technologies known collectively as Rapid Manufacturing as an innovative enabler for mass customization. In particular, we consider

the opportunities offered by these technologies to enhance the responsiveness of

mass customization strategies. Using a stylized model and case examples, we show

the potentials of the technologies as well as some challenges that still need to be

overcome to achieve the ideal situation of individualized production.

Keywords Integrated production-marketing problem Mass customization Rapid

Manufacturing technologies

1 Introduction

In proposing mass customization, Davis (1987) envisaged a situation whereby the

demand for customized products could be satisfied through individualized manufacturing, while still maintaining the economies of scale prevalent in mass production.

By exploiting manufacturing and communications technologies, combined with

changes in the organization’s approach to the provision of goods, Pine (1993) proclaimed that mass customization could not only compete but also triumph over

mass production by fulfilling the exact requirements of the customer without a

corresponding increase in costs.

The central motivation for businesses to adopt a mass customization strategy has

often been attributed to increasing business competitiveness, and thereby gaining

H. Wong (B)

Innovative Manufacturing Research Centre, Cardiff University, Wales, UK

e-mail: wongh@cardiff.ac.uk

T.C. Edwin Cheng and T.-M. Choi (eds.), Innovative Quick Response Programs

in Logistics and Supply Chain Management, International Handbooks on Information

Systems, DOI 10.1007/978-3-642-04313-0 10,

c Springer-Verlag Berlin Heidelberg 2010

205

206

H. Wong and D. Eyers

an advantage over rival companies. By providing customers with products that meet

their requirement, mass customization has been heralded as being “the New Frontier

in Business Competition” (Pine 1993). Porter (1998) identifies two core strategies for the achievement of a competitive advantage – price and differentiation.

Competing on price is often an undesirable consequence of the commoditization

of products, resultant from an absence of differentiation opportunities (e.g., as in

generic pharmaceuticals). Consequentially, negative effects such as margin erosion

are typical of competition based on price. Differentiation can be vertical (typically differentiating on product quality) or horizontal (differentiating on product

attributes). For mass production it may be difficult to increase the horizontal differentiation without incurring greater costs of manufacture. However, for companies

pursuing a mass customization strategy this is the primary focus, and therefore

competitiveness is theoretically increased.

Empirical evidence suggests that the customization is not “free” and needs

to be traded-off against lead time, cost, and other factors (Squire et al. 2006).

In particular, the notion of responsiveness in the context of mass customization

has been exemplified by McCutcheon et al. 1994) in their work considering “the

customization-responsiveness squeeze,” discussing how companies could offer customized products while still ensuring quick delivery times. Following Chopra and

Meindl (2007), who introduced the concept of cost-responsiveness efficient frontier

in explaining the trade-off between supply chain efficiency and supply chain responsiveness, we argue that conceptually there exists a customization-responsiveness

efficient frontier as shown in Fig. 1. The figure indicates the highest possible responsiveness to achieve a given level of customization based on the existing technologies. One of the main challenges pertinent in mass customization is how to shift

the efficient frontier closer towards the ideal state where firms are able to provide

customized products at a comparable speed of equivalent standardized offerings.

It is evident that the current state of mass customization is achievable through

the adoption of flexible manufacturing systems, introduction of modularization

and postponement, combined with e-commerce. Such continuous developments

Level of customization

high

Fig. 1 The customization vs.

responsiveness efficient

frontier (Adapted from

Chopra and Meindl 2007)

low

low

Responsiveness

high

Enhancing Responsiveness for Mass Customization Strategies

207

of innovative technologies and techniques have been shown to facilitate a more

responsiveness means of introducing customization. In line with the spirit of enhancing the responsiveness of mass customization strategies, this chapter introduces a

group of new manufacturing technologies known collectively as “Rapid Manufacturing” (RM) as an emerging enabler for mass customization. The advent of RM

technologies, which is considered by some authors to be “an industrial revolution

for the digital age” (Hopkinson et al. 2006), may offer a significant leap forward to

reach the ideal state of mass customization.

RM is a collective term for a range of additive layer manufacturing technologies,

whereby layers of material are joined together to form parts, enabling virtually any

product shape to be created from a range of engineering materials (including metals,

resins, composites, and thermoplastics). RM has already achieved extensive usage

in medical applications, where customized products are necessary to best suit the

individual’s physiology, and is emergent in many other sectors of low volume and

custom manufacture. There are several characteristics of RM that make it attractive in a mass customization scenario, particularly in the achievement of responsive

manufacturing. The most relevant attribute is the capability to achieve highly sophisticated geometries in manufacture, but without the need for manufacturing aids such

as moulds and tooling, which are usually requisite in many conventional manufacturing technologies. For conventional standardized production, development of

tooling and moulds is performed prior to the product launch to promote responsiveness. Where customized manufacture results in changes to the geometry, this cannot

be prepared in advance and consequentially manufacturing lead-times are likely to

be extended. Through RM, the elimination of these requirements not only simplifies the overall tasks of the product designer and eliminates cost, but also makes an

important contribution to addressing the responsiveness of the manufacturer.

This chapter aims to examine the potentials of RM, particularly in enhancing the

responsiveness of mass customization strategies (i.e., being able to shift the efficient

frontier much closer to the ideal state). Consequently, our analysis will be focusing

on the economic rather than technical aspects of the technologies. We present a stylized model used to generalize the economic implications of the technologies. More

specifically, we compare two manufacturing configurations. The first configuration

is mass producer (MP) working in a make-to-stock mode to provide a limited number of standard products, which do not meet customer preferences exactly but are

available immediately (or with a relatively short lead time). The second configuration is mass customizer (MC) working in a make-to-order mode to provide custom

products, which meet customer preferences exactly but are available only after a

certain lead time. The model we develop captures the integration of productioninventory as well as marketing related factors. We consider the fact that customer

demand is influenced by product variety and lead time apart from the product’s

price. Increasing the variety for standard products or shortening the lead time for

custom products can enhance the sales and margin. The model can be exploited to

explain the potential of RM to enhance the responsiveness of mass customization.

The rest of the chapter is organized as follows. In the next section we provide a

survey of the relevant literature. In Sect. 3 we present our stylized model, and Sect. 4

208

H. Wong and D. Eyers

presents and discusses numerical examples. In Sect. 5 we close the chapter with a

concluding discussion and some suggestions for future research.

2 Literature Background

In this section we discuss the relevant literature, with emphasis on two streams

of research considered most relevant to this work. The first stream of research

is on different enablers of mass customization that particularly contribute to the

enhancement of quick response strategy. The second stream of research focuses

on examining the business implications of RM as mass customization enabler.

Examples of RM-enabled mass customized products are also presented.

2.1 Responsiveness in Mass Customization

Mass customization was first introduced as being when “the same large number

of customers can be reached as in mass markets of the industrial economy, and

simultaneously be treated individually as in the customized markets of pre-industrial

economies” (Davis 1987). Adopting mass customization combines the best of the

craft era, where products were individualized but costly, with the best of the mass

production era, where everybody could get the standardized, affordable products

(Fralix 2001). Though for many industries customization was largely discarded

in favor of standardization during the twentieth Century as seemingly inefficient

(Lampel and Mintzberg 1996), the implementation of the mass customization concept has been identified as a consequence of changing consumer requirements, with

individualism of demand becoming increasingly apparent and homogenous markets

ceasing to exist (Hart 1995).

This apparent market demand for customized products should promote MC,

where in ideal situations it should be able to achieve individualized manufacturing without incurring tradeoffs when compared to conventional approaches. Three

core attributes of MC are outlined by Tseng and Jiao (1998): quick response,

customization, and the achievement of economies of scale. Responsiveness is discussed throughout the MC literature; however, we note that the intended meaning

of authors with regards to the term responsiveness may differ. There is much scholarly discussion as to what constitutes responsiveness, with the terms of agility and

flexibility often being used interchangeably with responsiveness in operations management literature, despite being distinctly different in their meaning (Bernardes

and Hanna 2009). Several reviews of the concept have been conducted (Bernardes

and Hanna 2009; Holweg 2005; Kritchanchai and MacCarthy 1999; Reichhart and

Holweg 2007), each identifying different interpretations in the literature for responsiveness. Consequentially in this chapter, we are mindful to consider the intention

of authors who discuss responsiveness in the context of MC.

As stated earlier, the notion of responsiveness in the context of mass customization has been exemplified by McCutcheon et al. (1994). In their study, the notion

Enhancing Responsiveness for Mass Customization Strategies

209

of “responsiveness” equates to the total manufacturing and delivery lead-time for

the custom product, and is an interpretation echoed throughout MC literature.

However, while the authors emphasize the potential costs and risks resultant from

needing to address the difficulties of responsiveness, a later survey of MC companies (Åhlström and Westbrook 1999) ranked increased order response times with

other customization negatives, finding (to their surprise), companies reporting this

of lesser importance than other attributes such as material and manufacturing costs.

These findings are from the perspective of the company towards responsiveness and

do not consider the perceptions of the end customer. In a more recent consumer

study, Endo and Kincade (2008) highlight the importance of how quickly a company is able to supply custom products as a determinant of choosing customized

over standardized offerings, which is further supported by the findings of Piller

and Müller (2004) that customers may expect a financial discount to compensate

from extended delivery times. Hence, it is evident that MC companies should focus

their attention not only on achieving mass production level costs, but also on the

achievement of responsiveness to satisfy customer demands.

To achieve both production economics and responsive manufacturing, one widely

implemented method of mass customization enablement is modularity, originally

envisaged by Pine to promote economies of both “scale and scope” (Pine 1993). For

mass customization to minimize costs while maximizing individualization, modularity is often applied (Feitzinger and Lee 1997; Pine 1993). An exact definition of

modularity is uncertain in the literature; however, a consensus exists that modularity entails the combination of a series of modular components in the creation of a

modular product (Gershenson et al. 2003). In mass customized manufacture, this

equates to the manufacture of a variety of standardized components, which are then

integrated as part of the overall customized product. Through this approach, not only

should costs be maintained at mass production levels, but also issues of responsiveness addressed. McCutcheon et al. (1994) discussed how an organization adopting

modularity of its components could make some effort to address the “customizationresponsiveness squeeze,” resulting in greater substitution to satisfy customer orders.

It was observed that, although this is beneficial to the organization’s responsiveness,

unless all core components can be modularized, it will not be possible to completely

address the squeeze through modularity. Furthermore, in order to accommodate

the large variety of demand but still satisfy customer delivery time expectations,

the evidence is that the firms increase inventories of potential components. Customized mainframe manufacturer Amdahl is widely cited as attempting to provide

customized built computer in a week by stocking every potential component, but

at the cost to the business of holding millions of dollars in excess inventory (Pine

et al. 1993; Radder and Louw 1999).

Another concept recognized as mass customization enabler is postponement or

delayed product differentiation. The concept is appealing particularly in dealing

with uncertainty due to proliferation in product varieties and uncertain demands

from customers. This is achieved by properly designing the product structure and

the manufacturing and supply chain processes so that one can delay or postpone the

final customization of the product to the maximum extent possible, pending more

210

H. Wong and D. Eyers

accurate product demand information. One of the classic examples of successful

postponement application is Hewlett–Packard (HP) for their DeskJet printers (Lee

et al. 1993; Feitzinger and Lee 1997). The company opted to customize the printers

at its local distribution centers rather than at its factories. For example, instead of

customizing the DeskJet at its factory in Singapore before shipping them to Europe,

HP has its European distribution center near Stuttgart, Germany, perform this job.

HP restructured its printer production process by manufacturing a generic DeskJet

printer and later localizing the generic product by integrating in the localized modules (power supplies, packaging, and manuals) at its local distribution centers. This

way, HP was able to maintain the same service levels with an 18% reduction in

inventory, saving millions of dollars. Another celebrated example is Benetton who

used postponement to cope with volatile fashion trends and long production leadtimes (Signorelli and Hesket 1984; Dapiran 1992). By using un-dyed yarn to knit

about half of its clothing and delaying the dying process to a later stage, Benetton

has a better idea of the popular colors for the season. Other examples include IBM

(Swaminathan and Tayur 1998), Whirpool (Waller et al. 2000), and Xilinx (Brown

et al. 2000). We refer the reader to Van Hoek (2001); Swaminathan and Lee (2003);

Yang et al. 2004) for a comprehensive review of research on postponement.

2.2 Rapid Manufacturing as an enabler for mass customization

Through the application of RM technologies, it is possible to manufacture parts of

highly sophisticated and complicated geometries, but without the need for costly

tooling. It is this absence of tooling that promotes the feasible production of parts in

quantities as needed, rather than in large batches that Hopkinson et al. (2006) claim

may make “volume of one” manufacturing economically viable. However, despite

the recognized potential for RM to enable the mass customization concept, there

has been limited research conducted in this field, and almost no consideration of the

implications for manufacturing responsiveness.

RM has evolved from the technology origins of rapid prototyping (RP), where the

research literature is predominantly based on the engineering capabilities of emergent technologies, used to create one-off products for the prototyping industries.

However, some of these technologies appeared promising for actual production

environments, and the term rapid manufacturing has started to become a familiar

vocabulary. One of the defining texts during this transition was that of Pham and

Dimov (2001), who provided an extensive review of the process technologies and

the applications, particularly from an engineering viewpoint. Although RP and RM

both utilize the same principal technologies, the distinction between the two is usually classified on the final application of the created part, with RM featuring only

parts that will be used in end-use finished goods.

While a large body of literature exists for RP (and, to a lesser extent, RM), the

limited research into enablement of mass customization using these has predominantly employed case studies to showcase both opportunities and constraints of the

Enhancing Responsiveness for Mass Customization Strategies

211

technologies. In a medical context, Hieu et al. (2005) identified medical applications

to include biomodels, surgical aids, implants, training models, and scaffolds for tissue engineering, using reverse engineering (RE) scanners and computer tomography

(CT) scans as a basis for generating 3D models needed to create RP/RM components. Further work related to customization for individual human geometries can

also be found in the work of Tuck et al. (2008), who explored the opportunities to

reduce pilot fatigue using RM to produce custom seating and Barrass et al. (2008)

who considered customization in tennis racket grips.

Within the field of mass customization, the involvement of customers is an

important concept, with early involvement in the production cycle leading to higher

degrees of customization in the finished product (Duray et al. 2000). Hague et al.

(2003) discussed how customers could be involved in the design stages of the production cycle for customized products, suggesting limitations in their abilities for

this task and proposed options to overcome this issue. Hague noted the use of the

internet for codesign of customized products, a theme also explored by Bateman

and Cheng (2006) through several case scenarios. Their work outlined both the techniques for eliciting customization preferences for products via the internet and also

the realization of these through RM processes.

One case example of RM for mass customization is that of customized hearing aid shells. In traditional manufacture, shells would be manually created by a

skilled technician as described by Cortex et al. (2004). Having achieved a cast from

the supplied mould, nine further steps involving recasting, trimming, and drilling

are necessary to create the final product. This manual process takes an experienced

technician approximately three hours to achieve and suffers from high variability in

product quality. The technician’s continual cutting and trimming of the shell down to

size is highly error prone, and often it is necessary to reattach erroneously removed

material using adhesives. In severe cases, the shell must be discarded, significantly

affecting the responsiveness of the manufacturer. Resultantly, manufacturing leadtimes were often quoted at approximately 1 week, and typically about 35% of the

dispatched products are returned to the manufacturer for adjustment (a “first-fit” rate

of 65%).

Using RM technologies, manufacturing responsiveness and quality can be

improved. Moulds are 3D scanned and this data file is used by the RM equipment for manufacture. Although each hearing aid will be of different shape, in

actual manufacturing environments the simultaneous production of multiple customized products is commonplace (as shown in Fig. 2). Through this technique,

setup and fixed costs can be amortized across a larger production run, improving the

commercial viability of the process. Therefore, while demand from an individual

customer in MC manufacturing requirement will typically be low (i.e. one-off), as

the actual processes of manufacturing do not need to differentiate between products, many items can be produced in a single build, resulting in the achievement of

“mass” volume in mass customization.

In terms of responsiveness, the application of RM technologies together with

efficient operations management results in an improved situation. Under normal

circumstances, devices can be designed, manufactured, configured, tested, and

212

H. Wong and D. Eyers

Fig. 2 Left: 3D Model of configured ITE device; Right: multiple batched devices for manufacture

(Courtesy of Materialise)

dispatched within a single working day, with first-fit rates in excess of 95%. Resultantly, the use of RM technologies for the commercial manufacture of hearing aid

devices is commonplace, displacing the conventional craft approach to customized

manufacture.

A second case example is that of customized lamps, which are often formed from

modular components, allowing the selection of base and shades in terms of shape

and color from a predetermined catalogue of options. While this encompasses the

efficiencies of mass production in the production of shades and bases, the limitations

of this assemble-to-order approach can be observed in the restricted number of permutations possible in the final product. However, since the component parts are mass

produced, these costs should remain unchanged. For more extensive customization

of lamps, the convention is to engage the services of a designer. While this approach

will enable a higher level of product customization, this tends towards the craft

approach and often results in higher unit costs and significantly extended response

times, moving away from the ideal state of MC. A hybrid strategy is also evident

from some companies, whereby modularity of components is maintained, but with

each component hand-crafted. Resultantly, product options are constrained in a similar manner to mass production, but individually crafted by hand on a make-to-order

basis with a manufacturing lead-time of 4–6 weeks.

Through RM, highly sophisticated lamp designs can be made without affecting the delivery lead time of the product (Fig. 3 shows a range of MGX designer

lamps). Customers may affect attributes such as size, color, and embedded text, or

for some designs perform customizations by supplying parameters for mathematical

expressions but control the placement of product features.

MGX lamps combine component modularity with RM technologies to facilitate product customization. For these products, both the base and the shade can be

customized, with bases selected from a modular range of possibilities and shades

individually manufactured. Despite the extent of customizations which can be made

to the shade, achieving these with RM does not significantly affect the manufacturing costs. For MGX lamps, the customizations require relatively trivial intervention

by the manufacturer, requiring only parameter changes in the CAD model prior to

submission for building. This compares favorably to the expenses that would be

incurred in injection molding, whereby a mold would require design and fabrication

Enhancing Responsiveness for Mass Customization Strategies

213

Fig. 3 Left: Tulip.MGX by Peter Jansen; Right: Lily.MGX by Janne Kytannen (both images are

courtesy of Materialise)

to enable manufacture, or in craft manufacture, where the time of the designer/maker

will also increase the product costs. In RM, greater costs will be incurred only if

more material is used, or the geometry increases the overall size of the build. Where

customization does not affect these attributes, there will be no increase in costs

compared to standardized items, achieving one of the main prescribed principles of

mass customization.

The absence of molds not only eliminates a cost of production, but also results in

improved responsiveness. Compared to standardized manufacturing, the principal

delays resultant from customization in RM are the reconfiguration of the electronic

model of the product to accommodate customization; however, these do not extend

the normal 2–3 week manufacturing lead-time. Resultantly, customers will receive

either custom or standardized RM lamps within the same timescale.

We would like to close this section by emphasizing the importance of this chapter

in enhancing the awareness of academics as well as practitioners, particularly those

working in the area of mass customization, of the emerging RM technologies that

seem to offer opportunities in advancing the current state of mass customization.

3 Model

We now present a stylized model used to generalize the economic implication of

the technologies. Our model is similar to those considering the coordination of marketing and operations decisions in the context of mass customization as studied

214

H. Wong and D. Eyers

by some authors, including, for example, Jiang et al. (2006); Alptekinoglu and

Corbett (2008); Mandelson and Parlaktürk (2008). In comparison to Jiang et al.

(2006), our model is different mainly in the following aspects. First, we specifically

consider a pure customization based on a make-to-order configuration while they do

not. Second, their model ignores the effect of congestion at the production facility,

while we explicitly model the queuing effect as a result of considering a capacitated

production facility. The other two studies, Alptekinoglu and Corbett (2008); Mandelson and Parlaktürk (2008), model competition between two multiproduct firms,

where one firm is a mass customizer while the other is a mass producer. Our analysis

is different from theirs as we do not model competition, and furthermore, they focus

on firms’ product and pricing decisions without considering lead time as a factor

affecting customer purchase decisions.

We consider a market with customers who have heterogeneous preferences

for product attributes. Similar to De Groote (1994), we model the product space

‚ D Œ0; 1 using the spatial location model of Hotelling (1929) and its extensions

by Lancaster (1990). To make the model more tractable and focus on product

line decisions associated with a horizontal differentiation, customer ideal tastes are

assumed to be uniformly distributed on ‚. This assumption is commonly used in

the Hotelling-style models. Each product is characterized by x 2 ‚, a single point

on the unit product line segment. This can represent, for example, the size or color

attribute of the product. As stated earlier, we intend to compare two types of manufacturing configurations: MP that produces standard products and MC that produces

individually customized products. The two configurations will be assessed on the

basis of their respective expected profit. Our notation and parametric assumptions

are summarized in Table 1.

3.1 Customer Choice

Our model captures the situation in which customer demand is sensitive to price,

product characteristics, and also delivery lead time. Specifically, the utility of a

type- customer derives from buying a product with characteristic x, price p, and

lead time T is equal to

U.; x; p; T / D r p vj xj wT;

(1)

where the reservation price r>0 is the customer’s willingness to pay for her ideal

product (all customers are assumed to have a common reservation price). We assume

that r is large enough so that the net utility is always greater than zero and so all

customers will buy a product. Products are offered with price p, assumed to be identical for all products. The uniform pricing scheme is reasonable when the products

are horizontally differentiated (in which qualities of products are at the same level).

The customer’s disutility of misfit relative to her ideal preference is expressed as

vj xj, where v > 0 is the linear transportation cost, which also represents the

intensity of customer preference, and j xj is the distance from her ideal product

Enhancing Responsiveness for Mass Customization Strategies

215

Table 1 List of Notation

Demand parameters

Total potential demand rate

0

i

First choice probability of product i

i

Demand rate for product i

r

Customers’ reservation price

Production input parameters

Production rate for the MP configuration

Production rate for the MC configuration

0

Cost parameters

h

Unit inventory holding cost for MP

c

Unit production cost for the MP configuration

Unit production cost for the MC configuration

c0

F

Product proliferation cost for the MP configuration

v

Linear transportation cost (customers’ preference intensity)

w

Linear waiting cost (customers’ sensitivity to delay)

Decision variables

Si

S

n

xi

x

p

T

Base stock level for MP’s finished goods

Vector of base stock levels

Number of product lines

Product i 0 s characteristic

Vector of product characteristics

Product price

Average delivery lead time (determined by inventory policy)

Performance measures

Ii

Expected on-hand inventory level

Z

Expected total profit

attribute. Further, the disutility of waiting is represented by wT, where w > 0 is the

customer’s sensitivity to delay and T is the expected delay.

We assume that demands arrive according to a Poisson process with rate, or

demand intensity 0 , and they differ only in their ideal products 2 ‚. Upon arrival,

the customer observes the product offerings and selects the product that maximizes

her utility, provided that it is nonnegative, otherwise she does not make a choice.

Product i is said to be the first choice of a given customer if it gives a non-negative

utility to that customer and its utility is the maximum among all products offered

by the manufacturer. Denote i as the first choice probability of product i , and the

demand rate for product i can be defined as i D i 0 , i D 1; 2; : : : ; n. Consistent

with the assumption of non-negative net utility, we also assume that complete market

coverage is optimal. This assumption is common in the marketing and economics

literature (Alptekinoglu and Corbett 2008).

3.2 The MP Configuration

In this configuration the manufacturer offers n standard products, indexed by i D

1; 2; : : : ; n. This configuration is modeled as a single stage production-inventory

216

H. Wong and D. Eyers

system. We assume that the processing times are i.i.d. random variables and exponentially distributed with rate 1=. These assumptions make the problem tractable,

without a significant loss in accuracy, especially as our emphasis is deriving qualitative patterns and managerial insights. For stability, we require that the utilization

rate 0 = D < 1. Demand is satisfied from stock unless the corresponding inventory is empty. All shortages are backlogged. We assume that a base-stock policy is

used for the inventory control. Let Si denote the base stock level for finished product

i . Furthermore, changeover times between products are assumed to be negligible.

Let c denote the unit production cost incurred for this configuration. Also, we

assume that the cost is the same for all standard products. For each unit in stock,

the manufacturer also incurs inventory holding cost h per unit time. Further, there

is a product proliferation cost F , incurred every time the manufacturer offers a

new product variant. This cost could include redesign, tooling, and setup costs.

We assume that the cost of variety is linear in the number of products offered,

which is in line with common observation in the operations literature (Dobson and

Waterson 1996; Benjaafar et al. 2004). The manufacturer makes simultaneous decisions regarding how many products to offer and their characteristics, base stock level

of finished products, and price, maximizing the expected profit. Note that the decision on the base stock level will also influence the average lead time experienced by

customers.

3.2.1 Evaluation model

Following Buzacott and Shanthikumar (1993), for a given base stock level Si , the

expected inventory for finished product i is given by

Ii .Si / D Si where Oi D i = . i / and i D

i

0

P

S

1 Oi i ;

(2)

j .

j ¤i

The expected lead time for a given Si is given by

S

T D

Oi i

:

0

(3)

3.2.2 Optimization

Define x D Œx1 x2 : : : xn as a vector of product characteristics and S D ŒS1 S2 : : :

Sn as a vector of base stock levels. We formalize the manufacturer’s optimization

problem as follows.

Max Z.n; x; S; p/ D

Xn

i D1

.p c/ i .n; xi ; Si ; p/h Ii .Si / Fn:

(4)

Enhancing Responsiveness for Mass Customization Strategies

217

Following de Groote (1994), an optimal design of the product line can be determined as follows. For a given n, the optimal product line has a simple structure:

the market should be partitioned in segments of equal lengths, the characteristics of

the products should correspond to the taste of the customers located in the middle

of the segments, and the manufacturer should set prices as to make the customers

located at the extreme of the segments indifferent between buying and not buying.

To put it more formally, given that n, T , v, and w are fixed, we obtain full market

coverage with the maximum revenue by setting

xi D

2i 1

;

2n

p D r wT i D 1; 2; : : : ; n and

(5)

v

:

2n

(6)

Following (5), the optimal product line has a structure in which the market should

be partitioned in segments of equal lengths. This means for a given n, 1 D

2 D D n and so 1 D 2 D D n , and as a consequence, we have

identical optimal base stock levels for all products, that is, S1 D S2 D D Sn .

The problem in (4) can now be solved in two stages. In the first stage, we fix n

and find the optimal S. And in the second stage we optimize n. From (3) it can be

shown that the promised lead time T is decreasing with Si before reaching a zero

level. It can also be proven that Ii .Si / is increasing and is a convex function of

Si . The optimal n can be determined by gradually increasing n starting from n D 1.

For each value of n we optimize x, p, and S. The search can be terminated when the

condition .r c/0 Fn is met. The first term .r c/0 is a constant and represents

the maximum profit, which can be gained by setting the price equal to the reservation

price. The second term Fn represents the product proliferation cost, which is linearly

increasing with n. This condition ensures that no better improvement is possible by

increasing n.

3.3 The MC Configuration

In this configuration the manufacturer offers individualized customized products,

which means no decision to be made on the number of products. As for MP, this

configuration is also modeled as a single stage production-inventory system, with

the only difference being that this configuration does not hold any finished goods

inventory. Hence, we have a special case of the MP configuration with zero base

stock levels. The processing times are i.i.d. random variables and exponentially distributed with rate 1=0 . 1=/. This reflects our attempt to capture the potential

of RM technologies in reducing the total manufacturing lead time. Let c 0 denote

the unit production cost incurred for this configuration. To reflect a premium cost

associated with the adoption of new technology, we assume that the direct cost of

manufacturing is nondecreasing when switching from MP to MC (i.e., c 0 c/. The

new cost c 0 already includes the amortized value of such premium cost. To reflect the

highly flexible feature of RM technologies, we assume that there is no proliferation

218

H. Wong and D. Eyers

cost incurred for this configuration. However, this is not for free as the development

of such a flexible technology will certainly incur a high investment and production

cost, which in our model has been reflected by a higher unit cost c 0 .

3.3.1 Evaluation

For this special case, the expected inventory level is zero and the average lead time

is given by

1

:

(7)

T D

0

3.3.2 Optimization

For this configuration, price is the only relevant decision variable. The profit

maximization problem can be formulated as

Max ZŒp D .p c 0 /0 :

(8)

Solving the above problem is very straightforward as we just need to find the maximum price value that does not give a negative utility for customers. From (6) and

(7), the optimal price can be determined as follows:

pMC

D r wT D r w

1

:

0

(9)

4 Numerical Examples

In this section we present several numerical examples to enhance the understanding of how different factors may affect the preference of one configuration to the

other. In particular, we intend to generalize how the advent of advanced manufacturing technologies such as RM enhances the responsiveness of mass customization

strategies as indicated by increased profitability of the MC configuration relatively

compared to the MP configuration.

4.1 Base example

In this example we present a situation in which all the parameters are identical for

both the MP and MC configurations. Both configurations are different only with

respect to finished goods inventory. Consider the following system parameters:

Aggregate demand rate 0 D 5=time unit

Reservation price r D 500

Enhancing Responsiveness for Mass Customization Strategies

219

Production rate D 0 D 6=time unit

Product proliferation cost F D 10 (only for MP)

Unit production cost c D c 0 D 100=unit

As the expected profits for both configurations are influenced by the customer’s

sensitivity to delay and preference intensity, a range of w and v values were experimented. It is also notable to mention that as the sensitivity of the profit function to

each of the two parameters can be different, some preliminary experiments were

conducted to find a sensible range of values from which we are able to derive

insights. The following values are used: w D [2, 4, 6, 8, 10, 12, and 14] and vD [20,

40, 60, 80, and 100].

For the MP configuration, the main results from this example are summarized in

Table 2. In the table we show the expected profit as well as the optimal number of

product variety for each combination of v and w.

It is indicated in the table that the average profit first decreases as a function of

the waiting cost, but there is a threshold value of waiting cost after which the profit

becomes constant. This occurs because by increasing the waiting cost, the MP configuration will react by holding a higher inventory level. From a certain w value,

however, the inventory level is high enough to cause a zero lead time, thereby making the profit function constant. The table also shows how the customers’ preference

intensity influence the number of product variety, that is, increasing v values tends

to increase n .

For the MC configuration, the results are presented in Table 3. As MC is able to

offer individual customized products, the profit is affected only by the customers’

sensitivity to delay, that is, there is no effect of the customers’ preference intensity.

It is obvious that the expected profit is linearly decreasing as a function of w.

Given all other parameters are fixed, the profit for MC depends only on the optimum

Table 2 Optimal profit and number of products for different v and w(MP)

wD2

wD4

wD6

wD8

w D 10

w D 12

w D 14

v D 20

1,916

n D 2

1,883

n D 2

1,863

n D 2

1,861

n D 2

1,859

n D 2

1,859

n D 2

1,859

n D 2

v D 40

1,898

n D 3

1,863

n D 3

1,838

n D 2

1,836

n D 2

1,834

n D 2

1,834

n D 2

1,834

n D 2

v D 60

1,883

n D 4

1,847

n D 4

1,821

n D 3

1,818

n D 3

1,816

n D 3

1,815

n D 3

1,814

n D 3

v D 80

1,871

n D 4

1,834

n D 4

1,806

n D 3

1,802

n D 3

1,800

n D 3

1,798

n D 3

1,797

n D 3

v D 100

1,861

n D 5

1,823

n D 5

1,794

n D 4

1,786

n D 4

1,784

n D 4

1,782

n D 4

1,782

n D 4

Table 3 Optimal profit for different w (MC)

wD2

wD4

wD6

wD8

1,990

1,980

1,970

1,960

w D 10

1,950

w D 12

1,940

w D 14

1,930

220

H. Wong and D. Eyers

2000

MC

1950

Profit

1900

v

v

v

v

v

1850

1800

1750

=

=

=

=

=

20

40

60

80

100

1700

1650

0

10

20

30

w

40

50

60

Fig. 4 Maximum waiting cost w0 for different values of v

low

Customers’ sensitivity to delay - w

MC

high

w0

as

af

un

ctio

no

fv

MP

low

Customers’ preference intensity - v

high

Fig. 5 Maximum waiting cost w0 separating MC and MP areas

price, which is a linear function of w. For the selected range of w, the MC configuration seems to be superior compared to the MP configuration, giving indication

that the selected parameters do not really represent situations in which customers

are concerned about the lead time. As expected, increasing w further may lead to

observations where MC is less profitable than MP. In relation to this, we suggest

to use w0 , defined as the value of w at which the profits for both MP and MC are

equal. A small w0 can be seen as an indicator of nonsupportive environment for

mass customization strategies, and vice versa. Determining w0 is straightforward as

we know that MP’s profit is a constant and the MC’s profit is a linear function of w.

We summarized the results in Fig. 4.

Conceptually, the preference of offering individual customized products to standardized products as influenced by customer’s sensitivity to delay and preference

intensity, that is, the lead time vs. product variety trade-off can be represented in

a diagram depicted in Fig. 5. In this diagram we show that offering customized

Enhancing Responsiveness for Mass Customization Strategies

221

products is preferable when customers are willing to wait longer for a product that

matches very well with their ideal preference. In contrast, offering standard products is more likely to be more profitable when lead time is more an issue compared

to product variety. The maximum waiting cost function, w0 , as defined above serves

as the separation line of the two extreme markets.

4.2 The effect of increased production rate

We now extend the base example by capturing the fact that the total manufacturing

lead time is reduced due to the exploitation of new technologies. We use the following values for the production rate for the MC configuration: 0 D[6, 7, 8, 9, and 10],

while the production rate for MP is kept at D 6. All the other parameter values

are not changed. Figure 6 is presented to show the benefit of increasing production

rate for MC as indicated by larger w0 values.

By using the concept introduced in Fig. 5, we can explain that technologies such

as RM that are able to enhance responsiveness by reducing the total manufacturing

lead time (without sacrificing quality) will increase the maximum waiting cost w0

for a fixed v value, that is, shift the w0 function down, thereby expanding the total

market potential for customized product offerings (see Fig. 7).

4.3 The effect of increased production rate and production cost

Maximum waiting cost w0

We now present the final example to represent the most realistic situation for RM

in which the increased production rate needs to be balanced against the higher

unit production cost. Five values are chosen for the MC’s unit production cost:

c 0 D [100, 105, 110, 115, and 120]. Similar to the previous analysis, we determine

250.0

v

v

v

v

v

200.0

150.0

100.0

50.0

0.0

6

7

8

Production rate - m

Fig. 6 Maximum waiting cost w0 affected by production rate

9

10

=

=

=

=

=

100

80

60

40

20

222

H. Wong and D. Eyers

low

Customers’ sensitivity to delay - w

MC

high

MP

Ne

w

res w 0fu

po

nsi nctio

n

ve

ma due

t

nu

fac o mo

r

tur

ing e

low

high

Customers’ preference intensity - v

Fig. 7 Expansion of MC’s market potential

Maximum waiting cost w0

150

100

50

0

120

10

9

115

110

MC

’s u

n

it pr

8

odu

105

ctio

n co

st c

’

7

100

6

’s P

MC

on

ucti

rod

rate

m’

Fig. 8 Maximum waiting cost w0 as a function of c 0 and 0

the maximum waiting cost w0 for each combination of production rate and unit

production cost. The results (only for v D 20) are depicted in Fig. 8.

In Fig. 8, the lighter area of the surface represents the situations that are more

favorable for mass customization strategies. Despite the fact that it remains challenging for RM-enabled mass customization to reach this light area, especially due

to the cost issue, the successful application of RM in the hearing aids industry gives

indication that this area is not unachievable. Significant year-on-year growth in the

Enhancing Responsiveness for Mass Customization Strategies

223

3500

3000

Count

2500

2000

1500

1000

500

0

88

89

90

91

92

93

94

95

96

97

98

99

00

01

02

03

04

Year

Fig. 9 Additive systems worldwide sales 1988–2004 (Wohlers 2007)

RM industry (as shown in Fig. 9), together with the launches of new machines and

products, suggests a wide scale confidence in the opportunities for the RM technologies. Furthermore, as the industry develops, competition between vendors is likely

to reduce both maintenance and material costs (Hopkinson et al. 2006).

5 Conclusion

This chapter explores the opportunities afforded by the emerging RM technologies

as a promising enabler for enhancing the responsiveness in the provision of mass

customized products. The topic is of great relevance, because today, where more

and more industries move towards creating markets of one, the use of innovative

technologies and methods that are capable of enhancing responsiveness can be seen

as a competitive advantage.

Through our case examples, we present two applications of mass customization,

and consider the implications for responsiveness and cost using both conventional

and RM approaches. Though the products are from very different markets, we find

some commonalities consistent with the prescribed methods of mass customization envisaged by Pine (1993). The elimination of molds in production increases

the geometric customizations possible without incurring additional manufacturing

costs, supported by the use of modularity for some components of the products. By

adopting these approaches, responsiveness between customized and standardized

has been improved in both examples when compared to conventional manufacturing

involving higher degrees of customization.

The stylized model developed in this chapter helps us gain more insights into the

potentials as well as the limitations of the RM technologies. The model captures

the interaction of production-inventory and marketing factors that are prevalent in

the context of mass customization, and in particular, is helpful to explain how the

224

H. Wong and D. Eyers

RM technologies may affect the existing trade-off between responsiveness vs. customization. Through numerical examples we show how some advantages offered

by RM technologies such as reduced lead times and improved flexibility are beneficial for mass customization strategies. More specifically, as market segments can be

represented by the customer’s preference intensity and sensitivity to lead time, we

show how those advantages may result in an expansion of the total market potential for mass customized products. Further, the examples also demonstrate how the

high cost attribute associated to RM technologies may inhibit successful applications RM-enabled mass customization. This is in accordance with some emergent

applications discussed earlier, where highly customized products serve only a niche

market that can afford a high premium. However, it is encouraging to see a very

active research in this new area that may eventually rule out the cost as a major

constraint.

Many opportunities for future research arise from this work. Empirical research

to assess different parameters in real settings is a challenge. In particular, research

to estimate customer preference intensity and sensitivity to lead time would be very

valuable. This research will reveal which sectors are favorable (or indeed unfavorable) for the implementation of RM-enabled mass customization strategies. We

believe such information is very useful to further assess the viability of the technologies in the long term. Another opportunity is to extend the model by incorporating

the fact that products manufactured by the two configurations may co-exist in the

market. Such a study will complement the existing models analyzing competition

between mass producers and mass customizers. Another possible extension is to

extend the market demand model by, for example, allowing customers to have

uncommon reservation price for their ideal products as well as by allowing customer

preferences to follow any distribution rather than the more usual and restricted uniform distribution. Such extensions would certainly make the model more realistic

and may lead to some interesting managerial insights.

References

Åhlström P, Westbrook R (1999) Implications of mass customization for operations management:

An exploratory survey. Int J Oper Prod Manag 19(3):262–273

Alptekinoglu A, Corbett C (2008) Mass customization vs. mass production: Variety and price

competition. Manuf Serv Oper Manag 10:204–217

Barrass DF, Roberts J, Jones R, Hague R, Dickens P (2008) The use of structured relationship

modelling techniques as a tool to elicit customizable product features. Proc IME C J Mech Eng

Sci 222(2):247–255

Bateman RJ, Cheng K (2006) Extending the product portfolio with ‘devolved manufacturing’:

methodology and case studies: Int J Prod Res 44(16):3325–3343

Benjaafar S, Kim JS, Vishwanadham N (2004) On the effect of product variety in productioninventory systems. Ann Oper Res 126:71–101

Bernardes ES, Hanna MD (2009) A theoretical review of flexibility, agility and responsiveness in

the operations management literature. Int J Oper Prod Manag 29(1):30–53

Enhancing Responsiveness for Mass Customization Strategies

225

Brown AO, Lee HL, Petrakian R (2000) Xilinx improve its semiconductor supply chain using

product and process postponement. Interfaces 30:65–80

Buzacott J, Shanthikumar JG (1993) Stochastic Models of Manufacturing Systems. Prentice-Hall,

Upper Saddle River

Chopra S, Meindl P (2007) Supply Chain Management: Strategy, Planning and Operation. Pearson

Prentice Hall, Upper Saddle River

Cortex R, Dinulescu N, Skafte K, Olson B, Keenan D, Kuk F (2004) Changing with the Times:

Applying Digital Technology to Hearing Aid Shell Manufacturing: Hear Rev 11:30–38

Dapiran P (1992) Benetton – Global logistics in action. Int J Phys Distrib Logist Manag 22:7–11

Davis SM (1987) Future Perfect. Addison-Wesley, Boston, MA

De Groote X (1994) Flexibility and marketing/manufacturing coordination. Int J Prod Econcs

36:153–167

Dobson P, Waterson M (1996) Product range and inter-firm competition. J Econ Manag Strat

35:317–341

Duray R Ward PT, Milligan GW, Berry WL (2000) Approaches to mass customization: configurations and empirical validation: J Oper Manag 18(5):605–625

Endo S, Kincade DH (2008) Mass customization for long-term relationship development: Why

consumers purchase mass customized products again. Qual Market Res 11(3):275–294

Feitzinger E, Lee HL (1997) Mass customization at Hewlett Packard: the power of postponement.

Harv Bus Rev 75:116–121

Fralix (2001) From mass production to mass customization: J Textil Apparel Tech Manag 1(2):1–7

Gershenson JK, Prasad GJ, Zhang Y (2003) Product modularity: definitions and benefits: J Eng

Des 14(3):295–313

Hague RJM, Campbell I, Dickens P (2003) Implications on design of rapid manufacturing. Proc

IME C J Mech Eng Sci 217:25–30

Hart C (1995) Mass customization: conceptual underpinnings, opportunities and limits. Int J Serv

Ind Manag 6(1):36–45

Hieu LC, Zlatov N, Vander-Sloten J, Bohez E, Khanh L, Binh PH, Oris P, Toshev Y (2005) Medical

rapid prototyping applications and methods. Assemb Autom 25(4):284–292

Holweg M (2005) The three dimensions of responsiveness. Int J Oper Prod Manag 25(6):603–622

Hopkinson N, Hague RJM, Dickens PM (2006) Rapid Manufacturing: An Industrial Revolution

for the Digital Age, Wiley, Chichester

Hotelling H (1929) Stability in competition. Econ J 39:41–57

Jiang K, Lee HL, Seifert RW (2006) Satisfying customer preferences via mass customization and

mass production. IIE Trans 38:25–38

Kritchanchai D, MacCarthy B (1999) Responsiveness of the order fulfillment process. Int J Oper

Prod Manag 19(7):812–833

Lampel J, Mintzberg H (1996) Customizing Customization: Sloan Manag Rev Fall 21–30

Lancaster K (1990) The economics of product variety: A survey. Market Sci 9:189–206

Lee HL, Billington C, Carter B (1993) Hewlett Packard gains control of inventory and service

through design for localisation. Interfaces 23:1–11

Mandelson H, Parlaktürk AK (2008) Product-Line Competition: Customization vs. Proliferation.

Manag Sci 54(12):2039–2053

McCutcheon DM, Raturi AS, Meredith JR (1994) The Customization-Responsiveness Squeeze.

Sloan Manag Rev 35(2):89–99

Pham DT, Dimov S (2001) Rapid Manufacturing: The Technologies and Applications of Rapid

Prototyping and Rapid Tooling, Springer, London

Piller FT, Müller M (2004) A new marketing approach to mass customization. J Comput Integrated

Manuf 17(6):583–593

Pine BJ (1993) Mass Customization: The New Frontier in Business Competition, Harvard Business

School Press, Boston, MA

Pine BJ, Victor B, Boynton AC (1993) Making mass customization work. Harv Bus Rev 108–119

Porter ME (1998) Competitive advantage: creating and sustaining superior performance, Free

Press, NY

226

H. Wong and D. Eyers

Radder L, Louw L (1999) Mass customization and mass production: The TQM Magazine

11(1):35–40

Reichhart A, Holweg M (2007) Creating the customer-responsve supply chain: a reconciliation of

concepts. Int J Oper Prod Manag 27(11):1144–1172

Signorelli S, Hesket JL (1984) Benetton A, Harvard Business School Case, 9–685–014

Squire B, Brown S, Readman J, Bessant J (2006) The impact of mass customization on

manufacturing trade-offs. Prod Oper Manag 15:10–21

Swaminathan JM, Tayur S (1998) Managing broader product lines through form postponement

using vanilla boxes. Manag Sci 44:S161-S172

Swaminathan JM, Lee H (2003) Design for postponement, In: Graves S, de Kok (Eds) Handbooks in Operations Research and Management Science: Supply Chain Management: Design,

Coordination and Operation. Elsevier Publishers, pp 199–228

Tseng MM, Jiao J (1998) Concurrent design for mass customization. Bus Process Manag J 4(1):

10–24

Tuck CJ, Hague RJM, Ruffo M, Ransley M, Adams P (2008) Rapid manufacturing facilitated

customization. Int J Comput Integrated Manuf 21(3):245–258

Van Hoek RI (2001) The rediscovery of postponement: a literature review and directions for

research. J Oper Manag 19:161–184

Waller MA, Dabholkar PA, Gentry JJ (2000) Postponement, product customization, and marketoriented supply chain management. J Bus Logist 21:133–159

Wohlers TT (2007) Wohlers report 2007: State of the Industry Annual Worldwide Progress Report.

Wohlers Associates Inc

Yang B, Burns ND, Backhouse CJ (2004) Postponement: a review and an integrated framework.

Int J Oper Prod Manag 24:468–487