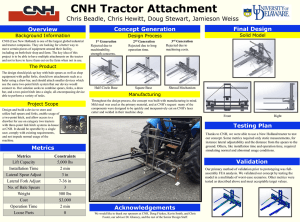

6 Mb - CNH Industrial

advertisement