The Development and Testing of Liquid Injection Thrust Vector

advertisement

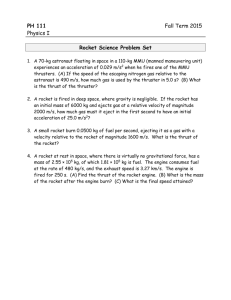

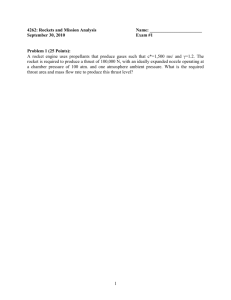

The Development and Testing of Liquid Injection Thrust Vector Control For a Rocket Motor AE6024 CEng Individual Project Student: Mathew Bestelink Supervisors: Dr Adam Baker, Dr Martin Heywood 1 1 Introduction Launch Vehicles require thrust vector control (TVC) for guidance and flight stability. TVC systems: • Jet vanes • Gimbal or hinged • Small control thrusters (Vernier thrusters) • Flexible nozzle joint • Flexible laminated bearing • Jetavator • Jet tabs • Fluid side injection RBSP Night Launch (Killian, 2012) 2 2 LITVC Theory Exhaust flow without fluid injection. Deflection induced through fluid injection normal to the exhaust flow. Inert: -momentum transfer. Reactive: - momentum transfer - shock wave formation CFD images of exhaust flow deflection (Rajendran, et al., 2013) (Rocket Propulsion Elements, cited in Sutton, 2001, p609, p610) 3 3 LITVC Theory Liquid Injection Thrust Vector Control (LITVC) system is advantageous in the following ways: ! Proven technology. ! Rapid production of side forces – 20msec (NASA, 1974). ! Long term storage (inert fluids). ! Isp nearly offsets weight penalty. ! Easy to perform preflight check. ! Components are reusable. ! ± 6° rocket exhaust deflection angle. ! Increase in thrust during injection (reactive fluids). (Rocket Propulsion Elements, cited in Sutton, 2001, p619) 4 4 Aims & Deliverables Aim 1: Verify, build, and test a LITVC model for the KU 50N Bi-propellant rocket motor based on a BEng individual project by Jaipal Dhiman. Deliverables: Aim 2: Design and build an inert fluid LITVC model (for the KU 50N Bi-propellant rocket motor) and experiment capable of testing multiple injection points, angles, and distances from the nozzle throat. The experiment will also explore the impact of fluid injection on motor thrust performance. 2. Design drawings and Bill of Materials. 1. Working experimental LITVC model/s, feed system/s, and test stand. 3. Detailed report including data acquired from cold flow and hot firings. Secondary objectives: Aim 3: Develop a design capable of utilising a reactive fluid for LITVC and the required experiments to explore the use of such a fluid. This design is to be based upon the data obtained from the inert fluid LITVC experiments. The assumption is that the reactive fluid will be liquid or gaseous oxygen. Ensure the KU Rocket Lab is fit for purpose i.e. reinforcement, door lock, lighting, CCTV, etc. 5 5 Progress to Date Inert fluid and reactive fluid feed systems have been designed and proposed. Inert fluid feed system requires unique components: – Cylinder neck connector (completed). – Step-down connector (designed and to be manufactured). The manufacture of the cylinder connector. Inert Fluid Feed System 6 6 Progress to Date Components for the inert fluid TVC (KU 50N bi-prop use): – Nozzle endplate (completed). – Nozzle (to be manufactured). – Injector nozzle (awaiting assembly). Aim 1 nozzle endplate Cut away view of the inert fluid TVC assembly for Aim 1. 7 7 Progress to Date ! The KURL test stand has been redesigned and in the process of manufacture and assembly. It has been modified to be compatible with Airborne Engineering’s stand. Isometric view of the KU Rocket Lab Test Stand. KURL test stand in the process of manufacture and assembly. 8 8 Progress to Date ! Monitoring and recording system for Aim 1 has been selected and ordered (to be assembled), and the backboard (for exhaust deflection) to be manufactured. ! A Bill of Materials is under development. Several items have been purchased. ! Secondary objectives: – – – – – Test cell door lock has been installed. Shielding for windows has been manufactured and installed. Test cell lighting has been installed. CCTV has been installed in both the Rocket Lab and test cell. Data Acquisition from Airborne Engineering to be collected and installed. 9 9 Progress Plan for TB1 TW3 TW4 TW5 EAW TW7 TW8 TW9 TW10 TW11 TW12 Step-down connector Nozzle Cold flow test Hot firing 10 10 References Killian, M., 2012. RBSP Night Launch.[image online]. Available at:< http://apod.nasa.gov/apod/ap120902.html >[Accessed 11th October 2014] NASA, 1974. Solid Rocket Thrust Vector Control.[PDF]. Available at:< http://ntrs.nasa.gov/search.jsp?R=19760010106 >[Accessed 11th October 2014] Rajendran, S.S., Kumar, A.T.R., Naveshkumar, K.S., Ragothaman, S., Raveendran, R., Kumar, S.V.R., 2013. Studies on Thrust Vector Control using Secondary Injection Sonic and Supersonic Jets.[PDF]. Available at:< http://psrcentre.org/images/extraimages/513675.pdf >[Accessed 22nd May 2014] Sutton, G.P., 2001. Rocket Propulsion Elements. 7th Ed. United States of America: Wiley-Interscience Publications. 11 11 Bibliography Case, E., n.d., Preliminary Design of a Hybrid Rocket Liquid Injection Thrust Vector Control System. Purdue University. Sutton, G.P., 2006. History of Liquid Propellant Rocket Engines, Reston: American Institute of Aeronautics and Astronautics. Collier, W., 2001. A Study into the Steering of Hybrid Rocket Engines. The Open University. Sutton, G.P., 2010. Rocket Propulsion Elements. 8th ed. New Jersey: John Wiley & Sons. Dhiman, J., 2014. Design and CFD Analysis of a Liquid Injection Thrust Vector Control System. BEng (Hons). Kingston University. Edgley, B., 2014. Further Development of a Large Hybrid Rocket Motor. MEng. Kingston University. Humble, R.W, Henry, G.N, and Larson, W.J., 1995, Space Propulsion Analysis and Design, 1st ed. United State of America: Mcgraw-Hill Companies. Marlow, J.J, 2013. Research, Design and Construction of a Small Bi-propellant Liquid Rocket Engine. BEng (Hons). Kingston University. National Aeronautics and Space Administration,1974. Solid Rocket Thrust Vector Control.[PDF]. Available at:<http://ntrs.nasa.gov/search.jsp?R=19760010106 >[Accessed 11th Oct 2014] Sellers, J.J, 2005. Understanding Space: An Introduction into Astronautics. 3rd ed. United States of America: McGraw-Hill Higher Education. 12 12