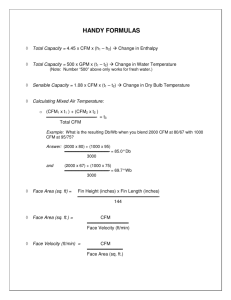

Equipment selection

advertisement

PART C: INSPECTION OF AIR CONDITIONING SYSTEMS State Senior Mechanical Engineers/Mechanical Engineers are invariably called upon to supervise air conditioning System on behalf of JKR Headquarters as well as for their state projects. I wish to stress and emphasize that progressive inspection and supervision of the project is a must and inspection is obvious as the ducts, chilled water pipes, some of the valve and water pumps etc are insulated, and covered up and if this are only inspected when the installation is completed, it is not possible to check the gauges, class and type of material and equipment used. 2. Therefore the following major items are to be checked against the specification as and when they are delivered to site and in the process of being installed: a) Air-conditioning, plant and its associated equipment These are relatively simplier to check as the type model and size are stamped on the machine and are factory built. b) All Motors and Starters The H.P as well as the RPM of the motors are to be checked. Contractors may supply and install higher RPM than specified. For the same capacity, higher RPM motor much cheaper, not so lasting and very noisy in operation. Starters shall be of the following types to comply with TNB regulation: i) Up to 3 H.P motors – direct – on direct line ii) Above 3 H.P and up to 10 H.P motors star-delta or auto transformer iii) Above 10 H.P motors – auto – transformer or secondary resistance starters. c) Air Handling Units: If these are factory built, then it is relatively simplier to check but you will have to ensure that they are not locally fabricated as the materials and insulation used are usually of poor quality and the workmanship leaves much to be desired. d) Ducting e) Chilled water and condenser piping Obviously the gauge of GI sheets and the gauge and class of pipes used have to be checked before these are insulated and covered up. f) Supports and hangers These should be of rugged construction so that each length of ductwork shall be rigidly supported. Direct fastening of duct of support with screw are not permitted. g) Insulation The type, thickness, thermal conductivity and density of the insulation are to be checked against the specification. Generally for ductwork, 2” fiberglass insulation a thermal conductivity not greater than 0.26 BTU/hr/sq.ft./°F and density not less than 2 lb/cu.ft. are used. All ductwork within the plant room shall have 2” cork insulation, and within the ceiling space below the roof or in any vertical shaft, 2” fiberglass insulation is required. For the air handling unit, the ductwork is insulated with 1” coporight or approved equivalent with vapour seal. Obviously thinner thickness and lower density insulation is not acceptable. h) Vapour Barrier With the recent imposition of the Fire Regulations, double sided, fiberglass reinforced, fire resistant aluminum foil are specified as against the single sided aluminum foil previously used. Special attention should be paid as the price difference can be as much as RM 0.20/sq.ft. Hence single sided aluminum foil should not be permitted if double sided is specified. i) Valve These are applicable more for chilled water systems and generally our specification calls for cast steel body type of valve below 3” with a working pressure of 250 psi type & lower working pressure valves are not only below specification but also the price difference will come to a few thousand dollars for the large size of valves. j) Chilled water and condenser water pumps. Centrifugal water pumps with horizontally split casing, bronze impeller and stainless steel shaft are specified and it must be ensured that cheaper types of pumps e.g. vertically split casing, cast iron impeller and mild steel shaft are not supplied and installed. k) Cooling Tower. In most cases Marley USA type of Cooling Towers or approved equivalent are specified and accepted and the inspection present no serious problem. However if locally fabricated Cooling Towers are accepted then a very stringent and detail examination has to be made to check the quality of materials & workmanship. l) Automatic Controls. You will have to ensure that the correct make and type of controls and their associated equipment are supplied as offered in the specifications. 3. The above are considered as the major items that should be progressively checked and inspected. The salient feature and points are enumerated against the major items and of course there are numerous other items and points to be considered and checked against the specification and technical data as offered by the contractor. Not only the quality of materials and equipment and their compliance to specification should be looked into but also the standard of workmanship should be to the best engineering practices. The use of sub-standard materials and equipment will lower the performance of the air conditioning system and the design conditioning may not be achieved. Also the life of the plant and equipment would be expected to be shorter than normal and maintenance cost in terms of repairs and rectification will be comparatively higher. Therefore it is most essential to have a proper progressive inspection of Air Conditioning systems for reasons stated above and to safeguard government funds. Air changes / HR – National Catalog Home Hotel Restaurant Theater Kitchen Bathroom & toilet Living room Ball room Dining room Kitchen Corridor Toilet Dining room Kitchen Banquet hall 15 10 6 8 8 15 5 10 6 20 10 Auditorium Corridor Smoking room Projection room 6 6 12 20 Industrial plant Ordinary building School General working area Printing area Generator room Office Waiting room Conference room Exhibition hall 6 20 20 6 10 12 10 Chemical lab Auditorium Gymnasium Library & classroom 6 6 8 6 Equipment selection Water Cooled Packaged Unit Compressor: Total capacity = ______ BTU/HR (CHECK SHC) Evaporator Air = ______ CFM Entry wet bulb temp. = ______ °F Condition temp. ______ 105°F = Refer catalogue 50BA page 4 & 5 HP required Cooling Tower: Total Heat Rejection = ______ TR x 15000 BTU/HR Quality of water required = ______ TR x 15000 US GPM 500 x ∆ t = ______ x 0.83 IGPM = ______ temp. difference = ______ 7.5°F or 10°F (for chilled water) ∆t Cooling Tower Fan Motor (refer catalogue) Evaporator Fan Static Head of system: Duct = 0.1 100 x ______ length Coils (4 rows) Bends and fittings Supply Air Grille Return Air Grille Filters = = = = = = TOTAL: 10% Safety factor = Grand Total: Refer Catalogue: Unit No. CFM External Static Pressure (above) RPM} Required BHP} HP = BHP 0.06 0.15 0.15 0.15 0.15 ____ ________ Water Pump Water quantity (USG PM) – Above Pipe diameter Frictional Losses 5’ H20/100 ft. Floor length of pipe Height length of pipe (No. of) Elbow Equivalent length (No. of) Gate Valve = = = = Total Length: ________________ Frictional Losses = total length x 5/100 Static head of pipe (cooling tower) Condenser Pressure Drop (refer catalog) Safety Factor 10% Total: (Take to nearest 5 or 10) IGPM = Ft. Head (Above) BHP = IGPM x Ft. Head 33000 x 2 HP = BHP x 1.25 Velocity = 550 fpm = = = = _________________ (ft. head) x 10lb Gallon x 100 70 x Coils CFM = __________ supply air Area cfm 550 = Cooling Tower: i) Recirculated water quantity = ii) Evaporation Losses iii) Windage Losses GPM GPM = w = bw TR x HRF x 24 = TR x 1.25 x 24 temp. rise of water temp. rise of water TR x HRF x 24 = TR x 1.25 x 24 HFG 1050 0.2% H2O Quantity 100 80 iv) Bleed of = windage GPM = bw USGPM (windage losses) 4.25-1 vi) Bleed of GPM = USGPM – USGPM bw w b vii) Make Up ( USGPM *) = USGPM + USGPM + USGPM e w b viii) Storage Tank = IGPM x HRS s Electrical Energy Consumption Cost = [ total HP x 0.746 x HRS x DAYS x 0.12 ] = [ 0.8 x ( Compressor HP + Evap. Fan HP + Cooling Tower Fan HP + Water Pump HP )] x 0.746 x HRS x DAYS x 0.12 Load (tons) Quantity (USGPM) x (Temp. Rise °F) x Specific Head x Specific Gravity 0.15” 0.15” 0.15” Bends and Fittings Supply Air Grille Return Air Grille = = = Ducts x Length of Duct 100 ft. 0.1 in Filters (2”) = Coils (4 Rows) = Add 10% for safety factor 0.12” 0.37” Return Air Grille Area x velocity Velocity of air = = cfm 500;600;700 ft/min Table of Grille CFM Neck Size Base Size ≤ 300 10” x 10” 301 - 400 12” x 12” 401 - 500 14” x 14” 501 - 600 16” x 16” 601 - 700 18” x 18” CHILLED WATER COOLING COIL 14” x 14” 16” x 16” 18” x 18” 20” x 20” 22” x 22” Determine Job Requirements: Given, Grand Total Heat = Air Quantity = Max. Coil Face Velocity = Entering Air Temp = Leaving Air Temp = Entering Water Temp = Water Flow Rate = Max. Water Pressure Loss = Approx. Coil Size = Min Coil Face Area: Required Min. coil face area = cfm Coil face velocity Coil Face Velocity: Actual Face Velocity = cfm Tabulate coil face velocity Water temp. Rise (WTR) = ∆ t WTR = GTH 500 x GPM Actual Water Velocity (WV) Assume a 6 – pass, full (28) circuit coil Actual WV = GPM x 1.18 Coil circuit Actual Leaving Air temp. (t1) - °F and GTH Removal GTH = Rated MBtuh/ft² x tabulated coil face area Static Head for Fan AHU fan Duct length (ft) x 0.1 = x” Static Head = x” + 1.2 x 10% = y” Exhausts Fan Duct length (ft) x 0.1 = y” 100 Static Head = y”+ 0.3 + 10% = z” ~ Cooling Tower Lower than package must put a butterfly valve so that when switch off the unit no water will flow suck to the cooling tower as to make the pipe empty. Exhaust Fan = (volume) 60 = - (Air Change) CFM = total CFM x 144 550 = x = TAO x 144 550 = x Sq.ft. S.A friction = 0.1 R.A friction = 0.05 1 l/m = 0.035 CFM R.A.G F.A.G