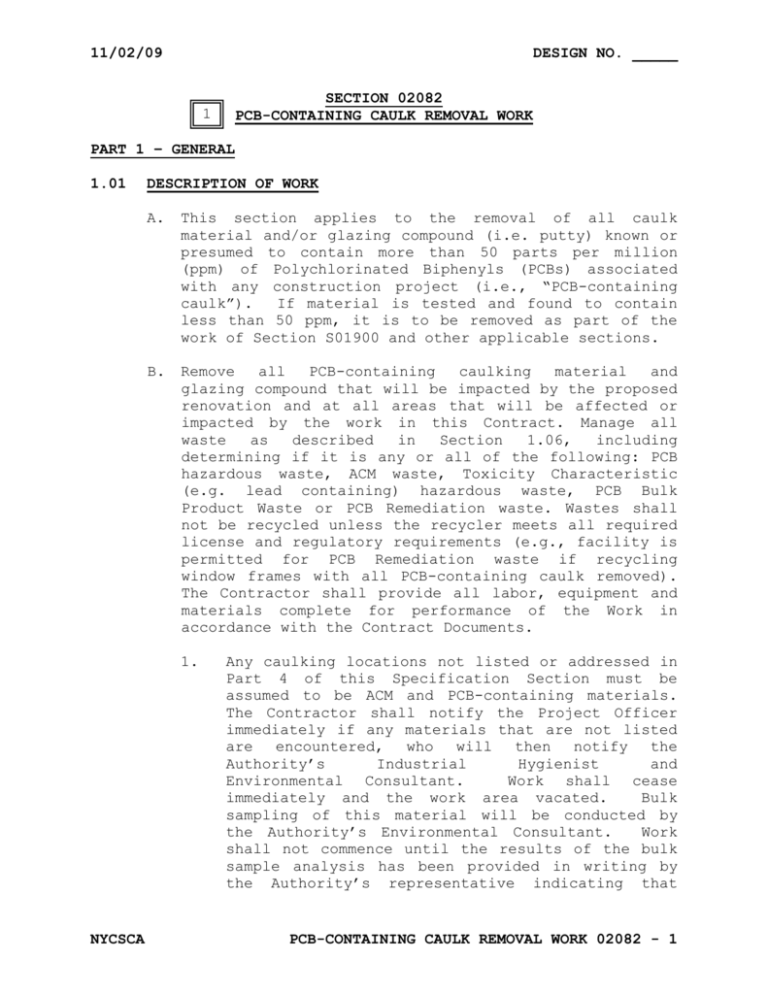

02082 - nycsca

advertisement