Pressemeldung

advertisement

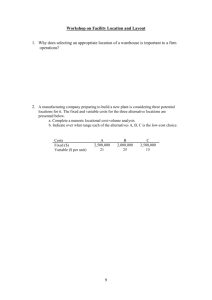

PRESS INFORMATION LANDI Schweiz AG: Ongoing investments in logistics SSI Schaefer is as a reliable partner when it comes to a number of different projects SSI Schaefer has been a business associate of LANDI Schweiz AG since 2002. After the implementation of the WAMAS warehouse management system, the stacker control system as well as an order picking system for the optimisation of the material flow, LANDI Schweiz AG was ready for a new approach in 2006: a new construction of an automated, 7-aisle high bay warehouse. SSI Schaefer has supported this complex logistics project from the very beginning. LANDI Schweiz AG, based in Dotzigen, is a trading and services company that operates throughout Switzerland in the non-food and parts of the food and agricultural sectors. As a subsidiary of the FENACO group of Swiss agricultural companies providing services to the St. Gallen regional association (LV) and the Schaffhausen cooperative association (GVS), LANDI Schweiz AG oversees and supplies the LANDI retail outlets throughout Switzerland. The business employs about 350 permanent staff and provides a selected range of around 8,000 items, ranging from products like garden supplies, small animal care products and soft drinks to plants and even more. Two-thirds of these are managed at the central warehouse in Dotzigen. A distinctive and consistently pursued private brand policy supports the market presence of the LANDI stores. First steps in the central and external drinks warehouse The first order by LANDI Schweiz AG involved the shipment of paperless picking and control systems WAMAS plus the storage location management. The distribution centre consists of the following areas: high bay warehouse, small-parts warehouse, cantilever storage, bulky goods warehouse, goods-in and goods out warehouse, repairs including a spare parts management service. Items, which need to be repaired, are recorded in the WAMAS system. Once they are fixed, the items can be returned to the picking process for retrieval. In order to increase the efficiency of storing small and medium sized goods, the WAMAS system offers the possibilty to add stock via a touch PC. In this way items can be shifted directly to the picking location with special conveying systems, which can reduce the times involved in the stock addition process by a great deal. One special feature of the picking technology is the management of price-tagged items. During the picking process the WAMAS system forwards the relevant price information to the online interface of the internal ERP-system, which on the other hand allows a more detailed settlement of the various orders. A number of different external warehouses of producers and logistics service providers are included in the material flow. The WAMAS system controls, manages and takes care of the replenishment of goods from the external warheouse to the distribution centre. 1 PRESS INFORMATION Pick by voice pilot project Due to the fact that LANDI has always been keen on optimising its logistics, especially when it comes to the increase of quality, performance and security, LANDI - with the help of SSI Schaefer - launched a "Pick by voice" pilot. Within this pilot 5 Vocollect Talkmen T2 have been implemented in the distribution centre in Dotzigen. 40 pickers, who are working in two shifts, are responsible for a picking volume of 85.000 to 100.000 picks a day. This equates to about 25.000 positions. The 8,000 items in the Dotzigen range from small parts to bulky goods, which are divided into different departments within the warehouse. The pick by voicetechnology was implemented in all departments in order to demonstrate where the picking handling could be improved and where an increase in performance could be reached. Integration of customer-specific processes within the voice picking The biggest challenge within the implementation of the voice picking system was the integration of a two-step registration of transport vehicles as well as the handling of price-tagged goods at the picking location. This method allows the picker at the picking location to choose between prices as soon as goods with different prices are available. On request the picker can use the voice operator in order to select between prices and enter the products with the relevant prices online. In order to facilitate the acknowledgement of the picking location, LANDI has introduced a so-called "check digit", consisting of aisle/column/level, which describes the exact storage location. Average increase in performance of 15% The pilot project undertaken by LANDI has demonstrated that the picking process can be easily seen as a verbal dialogue. Depending on the items and the departments, the performance could be increased between 8 and 25 %, which stands for an average increase of 15 %. The highest increase could be recorded in the small parts department. Simon Hochuli, project manager of LANDI Schweiz AG concludes that the outcome of the project was very positive:"The more positions are approached per department and hour, the higher the increase in productivity“. Apart from the increase in performance, also ergonomics at work could be improved and fewer voice-devices had to be repaired. In the meantime a great deal of the picking department in Dotzigen has been transformed and 40 voice devices have been implemented. GC order fully automated high bay warehouse In 2006 LANDI Schweiz AG assigned SSI Schaefer with the implementation of a 7aisle high bay warehouse in Dotzigen. The new and fully automated warehouse has space for more than 16.000 pallet storage locations and 750 picking locations. 7 stacker cranes are equipped with double-depth longitudinal storage systems. Complete logistics systems for all warehouse zones 2 PRESS INFORMATION The WAMAS logistics software by SSI Schaefer organises and optimises all processes involved in logistics - ranging from goods-in, internal transports, stock addition to the high bay warehouse to dispatch. WAMAS controls the automatic supply of picking locations in the picking tunnel as well as the voice-picking. The interplay between the WAMAS software and the integration of stacker cranes, conveyor and subsystems guarantee very flexible and transparent processes within the entire logistics system. With the implementation of the new high bay warehouse in January 2008 also the existing warehouse zones were involved in the complete logistics systems. The services provided by SSI Schaefer covered the solution finding, the elaboration of the most economic alternative, the project management of warehouse technology and conveyor systems, the racking construction plus front, the implementation of WAMAS warehouse management, material flow and controlling systems, the interface to the existing ERP system, the start up of the complete logistics system as well as an ongoing training of LANDI Schweiz AG staff in dealing with new software functions and systems. Expansion of the high bay warehouse The next project stage involves the optimisation of warehouse performance and the distribution of goods as well as the implementation of additional warehouse and picking capacities. The existing high bay warehouse will be expanded by 7 aisles and the picking will be expanded by 6 tunnels. With regard to the stock addition to the high bay warehouse, material flows of the stock addition and the East-West transports will be decoupled. The logistics software WAMAS by SSI Schaefer allows LANDI Schweiz AG to use a system that controls and optimises the material flows in the manual and fully automated warehouse zones. The WAMAS controlling and software integrates the warehouse technology and warehous system components, which has a very positive impact on the consistency and transparency of the goods tracking system. The increase in warehouse performance and the improvement of picking performance are not the only positive effects that support a successful realisation of this project. Simon Hochuli, Logistics and informatics manager at LANDI Schweiz AG: "Due to the success and the satisfaction of the first stage, LANDI Schweiz AG decided to think about an expansion of this project using the same concept." Friesach/Graz, July 2009 3 PRESS INFORMATION Captions to the photographs: - Simon Hochuli, Logistics and informatics manager, LANDI Schweiz AG - Warehouse at LANDI Schweiz AG, Dotzigen - System layout Sources of photographs: LANDI Schweiz AG For further information please contact: Press contact: name, company T: xxx, E-Mail: Contact person LANDI Schweiz AG: Simon Hochuli, Logistics and informatics manager Tel:+41 32 35 20 111, Email: hochuli.simon@landischweiz.ch 4