Testing Memo

advertisement

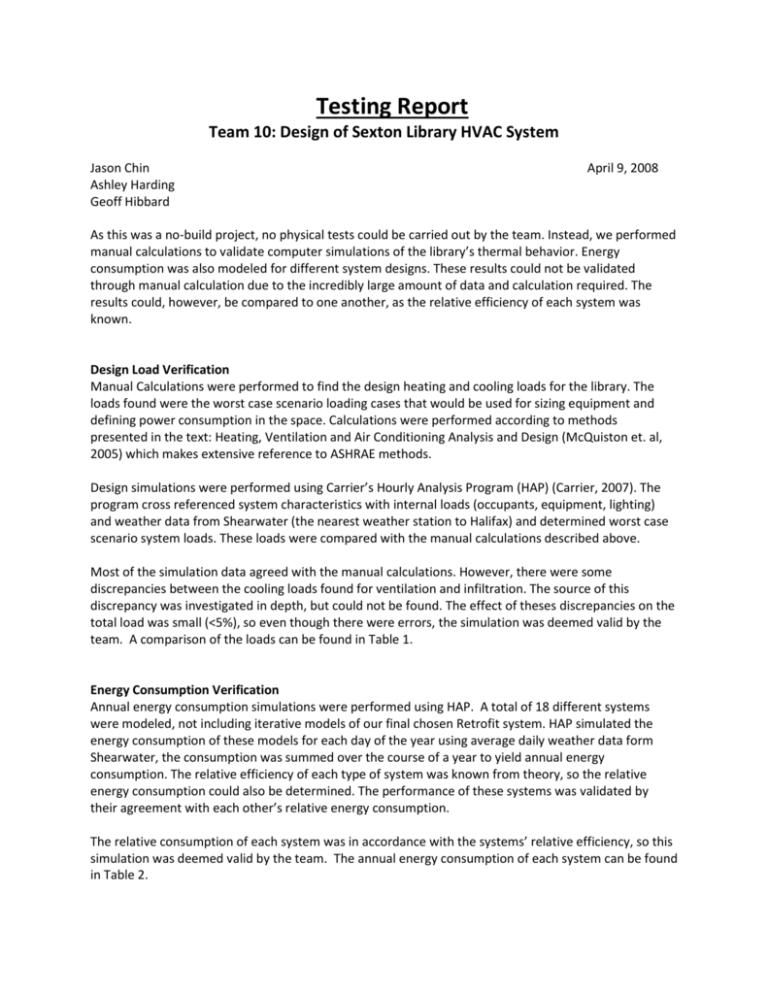

Testing Report Team 10: Design of Sexton Library HVAC System Jason Chin Ashley Harding Geoff Hibbard April 9, 2008 As this was a no-build project, no physical tests could be carried out by the team. Instead, we performed manual calculations to validate computer simulations of the library’s thermal behavior. Energy consumption was also modeled for different system designs. These results could not be validated through manual calculation due to the incredibly large amount of data and calculation required. The results could, however, be compared to one another, as the relative efficiency of each system was known. Design Load Verification Manual Calculations were performed to find the design heating and cooling loads for the library. The loads found were the worst case scenario loading cases that would be used for sizing equipment and defining power consumption in the space. Calculations were performed according to methods presented in the text: Heating, Ventilation and Air Conditioning Analysis and Design (McQuiston et. al, 2005) which makes extensive reference to ASHRAE methods. Design simulations were performed using Carrier’s Hourly Analysis Program (HAP) (Carrier, 2007). The program cross referenced system characteristics with internal loads (occupants, equipment, lighting) and weather data from Shearwater (the nearest weather station to Halifax) and determined worst case scenario system loads. These loads were compared with the manual calculations described above. Most of the simulation data agreed with the manual calculations. However, there were some discrepancies between the cooling loads found for ventilation and infiltration. The source of this discrepancy was investigated in depth, but could not be found. The effect of theses discrepancies on the total load was small (<5%), so even though there were errors, the simulation was deemed valid by the team. A comparison of the loads can be found in Table 1. Energy Consumption Verification Annual energy consumption simulations were performed using HAP. A total of 18 different systems were modeled, not including iterative models of our final chosen Retrofit system. HAP simulated the energy consumption of these models for each day of the year using average daily weather data form Shearwater, the consumption was summed over the course of a year to yield annual energy consumption. The relative efficiency of each type of system was known from theory, so the relative energy consumption could also be determined. The performance of these systems was validated by their agreement with each other’s relative energy consumption. The relative consumption of each system was in accordance with the systems’ relative efficiency, so this simulation was deemed valid by the team. The annual energy consumption of each system can be found in Table 2. Table 1: Heating and Cooling Load Comparison Heating & Cooling Load Calculation Comparison Heating Loads (kW) Transmission Cooling Loads (kW) Manual Calculations Sensible Latent Manual Calculations HAP Calculations HAP Calculations Sensible Latent 40.7 8.5 1.2 2.7 21.7 74.8 41.9 7.4 1.2 2.3 20.3 73.1 30.7 0.6 0.7 0.2 26.4 9.8 23.6 91.9 6.3 6.3 37.1 1.1 1.0 0.6 21.6 2.5 25.0 89.0 3.8 3.8 4.8 0.4 3.7 8.9 5.0 0.4 3.6 9.0 3.4 0.1 3.5 1.3 8.5 16.7 1.1 1.1 2.4 0.0 3.8 0.3 8.9 15.5 0.5 0.5 5.2 0.4 3.9 9.5 5.4 0.4 3.9 9.7 3.7 0.1 3.8 0.5 7.4 15.3 0.8 0.8 2.4 0.3 4.1 0.7 6.6 14.1 0.8 0.3 1.1 61.8 5.2 63.0 0.6 0.5 0.0 13.7 1.2 5.1 0.1 13.0 0.2 Stacks Windows North and West Wall East Wall South Wall Roof Occupants Auxiliary TOTAL Foyer Windows North Wall Roof Occupants Auxiliary TOTAL Offices Windows North Wall Roof Occupants Auxiliary TOTAL Total Ventialtion Total Infiltration Table 2: System Energy Consumption System Type Econom izer Reclaim er Total (MBTU) Total (MWh) CAV Termial Reheat N N 1990 584 0 0 1914 75 CAV Termial Reheat DB N 1325 389 665 195 1250 75 CAV Termial Reheat Enthalpy N 1289 378 701 206 1213 75 CAV Termial Reheat Non-int N 1512 443 478 140 1436 75 CAV Termial Reheat N Y 1984 582 6 2 1908 75 CAV Termial Reheat DB Y 1319 387 670 197 1244 75 CAV Termial Reheat Enthalpy Y 1282 376 707 207 1207 75 CAV Termial Reheat Non-int Y 1506 442 484 142 1430 75 CAV 4 Pipe N N 1165 342 825 242 1151 15 CAV 4 Pipe N Y 1129 331 861 253 1114 15 VAV N N 1012 297 977 287 998 15 VAV DB N 698 205 1292 379 683 15 VAV Enthalpy N 676 198 1314 385 661 15 VAV Non-int N 844 247 1146 336 829 15 VAV N Y 980 287 1010 296 965 15 VAV DB Y 664 195 1326 389 649 15 VAV Enthalpy Y 642 188 1347 395 628 15 VAV Non-int Y 810 238 1180 346 795 15 N Y 985 278 1005 295 942 43 RETROFIT Energy Energy Saved Saved (MBTU) (MWh) Total Therm al (MBTU) Total Fan (MBTU) The team set out to achieve several goals based on comfort conditions inside the library. The conditions in the library with the Retrofit system were simulated using HAP and maximum and minimum temperatures were found. Equipment was also specified to meet our design goals. These goals and results are summarized in Table 3. Table 3: Design Goals Requirement Result Goal Acheived? 20.4°C Yes 25°C (decrea s es requi red cool i ng, ASHRAE 55 s ti l l met) 25.1°C for 11 hours tota l Yes 30% mi ni mum (energy s a vi ngs , expert reccomenda ti on) 30% mi ni mum No - Energy Savings 0.13m/s ma x 0.03m/s a t occupa nt l evel Yes Bel ow NC 35-40 Di ffus ers : NC 26 Fa n Coi l Boxes : NC 40 60-65% Effi ci ency fi l ters i ncl uded wi th Fa n Coi l s Yes Minimum Temperature 20°C Maximum Temperature 22°C 40-45% Humidity Air Flow in Space Noise Level Filtering Efficiency 35-60% Design Changes Yes The Maximum temperature requirement was changed to decrease the energy consumption of the system, and still fell within comfort ranges defined by ASHRAE. The humidity requirement was changed to lower system energy consumption after a discussion with Don Baker, an HVAC expert (Discussion of March 13, 2008). References Carrier Corporation. (2006). Hourly Analysis Program (HAP), 8760 Hour Load & Energy Analysis. Retrieved from: http://www.commercial.carrier.com/commercial/hvac/general/0,,CLI1_DIV12_ETI496_MID4355,00.html McQuiston, F.C., Parker, J.D., Spitler, J.D. (2005). Heating, Ventilating, and Air Conditioning: Analysis and Design, 6th Edition. John Wiley and Sons: USA.