(Revised Feb 2007) LOS Budget ManualRev2

advertisement

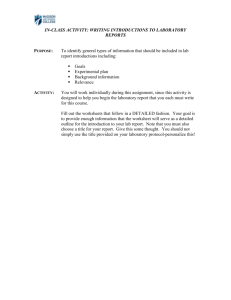

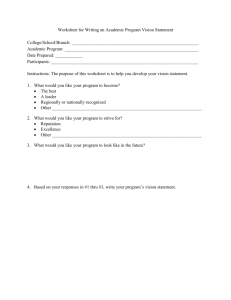

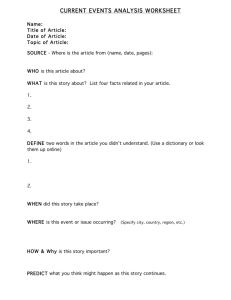

Louisiana Department of Transportation and Development Business Process Improvement Program Maintenance Level of Service Budget Manual February 2007 Contents I. Introduction 1 II. Model Overview 2 III. LOS Budget Model 10 1 I. Introduction As part of the Work Stream 9: Maintenance Planning and Budgeting implementation plan for the Louisiana Department of Transportation and Development (LADOTD), a maintenance management approach was developed. This approach is outcome-based which means that a desired level of service is defined, the annual maintenance programs are designed to provide that level of service, and the resulting conditions are assessed to determine if the desired outcomes were achieved. Budgets were developed at the district level for 23 maintenance elements that included pavement, roadside, drainage, and traffic control features. These budgets allow estimating the required labor, equipment and materials required to maintain these assets at levels of services set by the Department. Results from the district or statewide budgets constitute only a portion of the operations budget. This is mainly due to the fact that not all maintenance activities or assets were included in this approach and overhead and other indirect costs were not accounted for. This document is organized in the following three sections: Overview. Developing a budget using a level-of-service approach required incorporating elements developed in previous tasks (e.g. level of effort factors, condition assessment, etc.) and data from different sources. This section describes these elements, the data used to develop the district-level budgets and the relationship among them. It also describes the methodology and maintenance elements included in developing the budgets. Budget Guidelines. Several Excel workbooks were created to compute a maintenance budget including in-house and contracted maintenance work. This section describes these files, its structure, data and assumptions used to develop the budgets. It also provides instruction to updating the budget files. Next steps. This section lists the actions that will have to be undertaken on a regular basis to repeat the process. It also describes the features of an annual work program and the steps required to develop it. All files used in developing the maintenance management approach implementation are included on a CD ROM. 2 II. Overview Following industry standards for best practices, a maintenance management approach was implemented to improve the budgeting and planning process. This process allows determining the resources required to maintain assets at a specific level of quality that is referred to as level of service (LOS). Exhibit I-I shows the major elements that were developed to implement the maintenance management approach. A description for each element follows. Level of Service Measures Customer Input Approach Current Level of Service Target Level of Service Inventory, historical data Level of Effort Factors Work Standards Annual Work Quantities Unit Costs Annual Budget Level of Service Measures A series of workshops were held with experienced maintenance personnel to determine the maintenance elements to be included in the maintenance management approach, the appropriate units of measurement, and to develop measures for each levels of service (A, B, C, D and F). For example, potholes are measured in number of potholes per lane mile and a level of service “A” means no potholes. Results from these workshops were summarized in a word document named “09702r01 LOS Measures.doc” 3 Current Level of Service Using the level of service measures identified in the previous task, a Data Collection Manual was written and used to train crews from each district. A data collection form was included for crew to record condition for the maintenance elements out in the field and an electronic form was developed to capture the results at the end of each day in an Excel spreadsheet designed for this purpose. Two training sessions were conducted prior to and shortly after each District began collecting data. For practical purposes, data collected out in the field did not match exactly to the level of service measures. For example, crews collected the number of lanes in the sample and the total number of potholes, but the measure was defined as number of potholes per lane mile. The number of potholes per lane mile was computed at a later time using an Excel spreadsheet (This spreadsheet is described in the next section). Each district was provided with a list of random sites. The data collection methodology and random site generation process are described in the word document named “09702r01 LOS Measures.doc” Customer Input Approach Public perception of the Louisiana Department of Transportation and Development’s (DOTD) highway maintenance program was initially obtained using two methods. A statistically valid telephone survey was conducted with 401 Louisiana residents in 64 parishes and two focus groups held with residents in Baton Rouge and Natchitoches, LA to validate telephone survey findings. The results from these surveys are documented in a word document named “09702r03 DOTD Customer Input Report 060428.doc” Public perceptions were captured using eight groups of maintenance elements (e.g., drainage and shoulders), instead of using the thirty-three maintenance elements (e.g. pipes, ditch, shoulder raveling, and high shoulder), to reduce the number of questions to a manageable number and still understand the public’s perception. This means that a group of assets may have included one or more maintenance elements. Target Level of Service Using the level of service measures, target levels of service were set using the results from the field condition assessment and customer input approach. These targets were validated at the District level but had not been reviewed by top management at the time this document was written. Proposed target levels of services were developed using the following assumptions: Each level of service was broken down in three sub-levels, e.g. A+, A, and A- (Note that if the A level was defined as “0” rather than a range of values, then A+ and A- would not apply). The telephone survey results provided data on perceived and desired LOS for groups of assets. The difference between the desired and perceived LOS (i.e., the “delta” value) was computed for each group. 4 It was assumed that the relationship between delta and the actual level of service scale is linear and that one unit of delta corresponds to one step above or below in the modified scale. (e.g., from C- to C, B+ to A-, etc.) The corresponding delta was applied to the computed LOS for each asset. For example, LOS for pothole patching is B- and delta is 1.5. Then, the target level of service is B+. Based on the results from focus groups, some assets were given higher priority. For example, litter has a current LOS of F and a delta of 1.6. Instead of setting the target LOS to D- a more acceptable target level of service of C- was proposed. The same target levels of service are used for interstate and non-interstate highways. Table I-1 Proposed Target Levels of Service. Group Asphalt Pavement Concrete Pavement Shoulders Drainage Roadside Traffic Services Maintenance Element Potholes Rutting Raveling Alligator Cracking Longitudinal / Transverse Cracking Area Cracking Sweeping Other (bleeding, humps, sags, etc) Potholes Spalling Longitudinal / Transverse Cracking Longitudinal Faulting Traverse Faulting / Bumps Sweeping High Shoulder Edge Rutting Pipes and Culverts Drop Inlets and Catch Basins Ditches Gutters Erosion Control Noxious Weed Mowing – Rural Mowing – Urban Brush Control Tree Removal Litter Control Rest Areas Raised Pavement Markers Signals Signs – Regulatory and Warning Signs – Other Striping Target B+ A B B+ A BB B B BA B B+ A A B C B B+ A AC C C B C CC D B C C C 5 Level of Effort Factors Each maintenance level of service has been defined by a measurable or observable condition. To change the current level of service to a different level, the difference between the two measures is calculated and converted to a workload, e.g., tons of asphalt. A series of workshops with district maintenance personnel was conducted to develop these factors. This task required determining the relationship between the current LOS, as measured out in the field, and the target level of service and converting that difference into the amount of work required to achieve the target level. This relationship was calculated by first determining the required increase or decrease of work per unit of inventory, then multiplying that unit amount by the inventory quantity. These factors are included and described in the budget files. Work Standards Another series of workshops was conducted with experienced maintenance personnel to revise maintenance activities described in the Maintenance Planning Manual. This Manual was last modified in 1991, with some modifications more recently proposed between 2004 and 2005. These documents were used as a starting point in developing new work standards. Work standards specify the typical crew size, equipment and materials required to accomplish a number of work units per day. One difference between the current manual and the work standards developed during this project, other than the actual values, is the fact that the manual uses ranges of values for crew size, equipment and daily accomplishment, but this project required a single value. Usually, the mid-range value was selected for the budget calculations. During these workshops, it was determined that additional work activities and work standards were required to better track the work performed by the maintenance crews due to the cost or time required to accomplish each treatment. For example, Activity 412 Pothole Patching was split into two activities, 412-01 and 412-02, for Pothole Patching with Patching Machine and Pothole Patching - Hand Method, respectively. In other cases, the need of new work standards was identified (e.g., guardrail inspection). Annual Work Quantities The amount of work required to achieve target levels of service for each maintenance asset was converted into crew-days using the average daily accomplishments defined in the work standards. The number of crew-days required is calculated by dividing the annual work quantity by the average daily accomplishment per crew-day. Annual Budget The annual budget was developed by costing out the number of crew days required for each work activity for each District. Two average hourly rates were established, one for maintenance workers and one for foremen. Hourly rates were obtained for vehicles and equipment. Unit prices were obtained for materials. A budget for each activity was calculated by multiplying the planned annual crew-days by the unit rates for labor, equipment and materials and by the 6 quantities per crew-day. The following example illustrates the process for calculating the budget for a maintenance activity: Labor Budget = [ Σ (Personnel per Crew-day) x (Personnel Cost per Hour) x (8 Hours per Day)] x (Annual Crew-days) Equipment Budget = [ Σ (Equipment per Crew-day) x (Equipment Cost per Hour) x (8 Hours per Day)] x (Annual Crew-days) Material Budget = [ Σ (Material Quantity per Crew-day) x (Material Unit Cost)] x (Annual Crew-days) Contract Budget = (Contract Quantity) x (Contract Unit Cost) Activity Budget = Labor Budget + Equipment Budget + Material Budget + Contract Budget District Budget = Σ (Activity Budgets) Statewide Budget = Σ (District Budgets) It is important to mention that these budgets only include the maintenance elements listed in Table I-2. Other work activities and overhead costs are not included. MOPS tracks approximately 150 work activities and only 63 of them were used in this project. Table I-2: Asset Groups And Maintenance Elements For Assessing Level Of Service (LOS) Asset Group Maintenance Element Included Asphalt Pavement 1. Potholes 2. Rutting 3. Raveling 4. Alligator Cracking 5. Linear Cracking 6. Area Cracking 7. Sweeping 8. Other (bleeding, humps, sags, etc) Yes Concrete Pavement 1. Potholes 2. Spalling 3. Linear Cracking 4. Longitudinal Faulting 5. Traverse Faulting / Bumps 6. Sweeping Yes 7 Shoulders 1. High Shoulder 2. Edge Rutting Yes Drainage 1. Pipes and Culverts 2. Drop Inlets and Catch Basins 3. Ditches 4. Gutters Yes Roadside 1. Erosion Control 2. Noxious Weed 3. Mowing (Rural and Urban) 4. Brush Control 5. Tree Removal 6. Litter Control Yes Traffic Services 1. Raised Pavement Markers 2. Signals (Maintenance) 3. Signals (Section 45) 3. Signs – Regulatory and Warning 4. Signs – Other 5. Striping Yes Rest Areas 1. Condition Rating Yes Bridge and Structural Maintenance 1. Bridge Condition 2. Painting (Steel Bridges) 3. Bridge Approaches 4. Drift 5. Guardrails 6. Impact Attenuators 7. Sweeping No Movable Bridges 1. Condition Rating No Tunnel and Pumping Station 1. Tunnel 2. Pumping Station 3. Backup Power No Ferries 1. Operation Rating 2. Approaches No Some of the maintenance elements in Table I-2 were not included in the budget since no data was ready available. In order to include a maintenance element in the maintenance management approach, it is required to know the amount of work performed in the previous year, the inventory and current LOS condition. In the case of bridge condition, it was originally proposed to use the National Bridge Inspection Program sufficiency rating as the LOS measure. A sufficiency rating is a 100-point scale that 8 describes the structural integrity and functional adequacy of the bridge, but does not necessarily reflect the maintenance work performed on a bridge. Alternative measures were proposed, but the data for each bridge was not available in a database, making it almost impossible to determine the maintenance condition of the thousands of bridges in the state. In other cases, like movable bridge condition, a work activity to specifically track maintenance work did not exist. The modified and new work activities will allow tracking and including these maintenance elements in the future. Element Relationship The relationship between elements is better explained using the example for potholes. The process begins with defining the level of service as shown below: UOM Potholes / Lane-Mile LOS Range: A 0 B 0 0 C 2 2 D 5 5 10 F >10 At each District, crews inspected pre-determined random sample sites, counted and recorded the number of potholes, number of lanes and type of pavement surface at each site. The number of potholes was recorded for each sample site and at the end of the day entered into an Excel spreadsheet. After all sample sites were inspected, the average number of potholes was computed according to the type of surface (asphalt or concrete). The resulting average number of potholes for asphalt pavement for District 02, for example, was 1.06 potholes per lane-mile. Using the results from all Districts, the average number of potholes was calculated and the corresponding level of service determined. This level of services and the results from the customer input approach were used to determine the target level of service (B+). Then, the relationship between the current and target level of service was determined. The historical data from MOPS is used to compute the number of potholes patched during the last fiscal year. It was determined that four work activities were used to patch potholes (412, 414, 416, and 634). Adding up these quantities and converting from number of tons to number of potholes using a conversion factor of 24, the resulting current program was 21,752 potholes. In the case of District 02, the current level of service was 1.062 potholes per lane mile, which is a “B” level of service. To increase the level of service from B to B+, or to go from 1.062 to 0.500 potholes per lane miles will require patching 1,494 additional potholes. This number was computed as the difference between the current and target level of service multiplied by the number of lane miles with asphalt pavement ((1.062-0.5) x 2,658). The resulting total number of potholes is 23,246 (i.e., 21,752 + 1,494), or 967 tons of asphalt. These calculations are done in the various maintenance element worksheets in the individual District Workbooks, for each of the five primary levels of service (i.e., A, B, C, D and F). For example, the calculations for potholes in asphalt pavement will be found in the “A Potholes” worksheet. 9 The WD Worksheet shows how the targeted work quantity will be accomplished and shows the budget for doing so. In this example, the work quantity of 968 tons will be accomplished using the following work activities and corresponding percentages: 412-01 412-02 414 416-01 416-02 634 Pothole Patching (Patcher) Pothole Patching (Hand) Hand Leveling Machine Leveling (Motor Grader) Machine Leveling (Paving Machine) Overlay (Paving Machine) 10% 15% 5% 20% 20% 30% 100% This means, for example, that 96.8 tons of asphalt (968 x 10%) will be used to patch potholes using Work Activity 412-01. The daily accomplishment for each work activity is used to determine the number of days each activity will have to be performed. In this case, the daily accomplishment for wok Activity 41201 is 4 tons, resulting in 24 work days. The daily cost or performing this activity is $862.00. Multiplying these two figures, we obtain the budget for Activity 412-01 for District 02 of $20,828.00. Daily costs for each work activity are also broken down in labor, equipment and materials. These budgets are then added for each maintenance element, group of maintenance elements and District to produce a statewide budget. Maintenance work done by contract is also shown as a separate column in the WD worksheet and included in the district and statewide budget tabulations. Note that the cost of improvements to be done by capital projects are not included in the Maintenance budget, but it is assumed that the projected level of contract work required to reach a level of service objective will be done in the next fiscal year, and credit for that work is taken into account when the projected level of service is calculated. Examples of such improvements are overlays that will correct much of the Alligator Cracking and Area Cracking deficiencies. Note that if the required capital improvements are not done, the target level of service will not be achieved in the next fiscal year. The WD worksheet also shows the projected level-of-service letter grade. In the case of District 02 potholes, if the projected work quantity of 968 tons of patching is done, the resulting level of service should be “B+”, i.e., the same as the targeted value. In some cases, the resulting LOS grade may be greater or less than the targeted LOS grade. For example, the current LOS for some maintenance element may actually be greater than the target level in some districts and, even if no additional work is done, the resulting LOS may be higher than the target level (at least, in the short term). In a few cases, the existing condition was far out in the “F” range and the cost of raising the LOS to the target level in one year would be prohibitive. For example, the statewide target level for “Other” deficiencies on asphalt pavement is “B”. In District 03, the current LOS is “D+”. To get to the target level in one year, a 12-fold increase in work effort would be required. To get to a “C” level, a 5-fold increase would be needed. This was believed to be a more realistic objective, so the budget was calculated to achieve level of service “C” for the next budget year. 10 III. LOS Budget Model A maintenance budget was developed for selected maintenance elements using 14 Excel workbooks. Budgets were developed at the district level and results summarized at the statewide level. This section describes each workbook and worksheet, the relationship between them, data sources, assumptions and instructions to update these files. File Description The DOTD Maintenance Management budgeting model consists of 14 files, including one summary file, three data files, and ten calculation files, one for each district and one for Section 45. Exhibit II-1 shows the schematic relationship between workbooks. A description for each file follows. Exhibit II-1 File Relationship Districts Total District02 District03 ....... .. District62 Section 45 Data Data Files The Excel Data files contain data common to all the district budget calculation files. These files are the repositories for work standards and unit costs. There are nine files, named Data00, Data03, Data04, Data05, Data07, Data08, Data45, Data61, and Data62. The files are basically the same, except that some districts use slightly different complements of equipment for certain activities. The data files are linked to their respective districts, except for Data00 which is linked to Districts 02 and 58, and Data45 which is linked to Section 45 workbooks. Any changes 11 required for work standards or unit costs of labor, equipment, materials and maintenance contracts should be made in these files. The effect of such changes will be reflected automatically in the various district budget worksheets. To the extent possible, such changes should be applied uniformly to all of the Data files. Each of the Data files contains the following worksheets: 1. LaborCost. This sheet contains the statewide average hourly rate for Foremen, Workers, and Bridge Inspectors, based on 2006 labor rates. 2. EquipCost. This worksheet lists the equipment identified in the work standards and the corresponding hourly rates. Rates were converted to daily rates by multiplying hourly rates time eight. Some vehicles like vans and pickups use a per-mile rate. To convert these rates from miles to hours it was assumed that the average daily trip was 60 miles long. 3. MatCost. This sheet contains a list of all major materials and the cost per unit of measure (e.g., ton, cubic yard, gallon, etc.). Items such as fuels and lubricants, minor items such as nuts, bolts and nails, and other miscellaneous, but necessary, items are not included. (The annual cost of these miscellaneous items should be added to the district’s overhead budget and factored up or down in proportion to the increase or decrease in the LOS budget.) 4. ContractCost. The unit prices for maintenance contracts in each district are contained in this worksheet, including mowing, litter and brush control, tree removal, raised pavement markers, striping, signal maintenance agreements and rest areas. 5. WS. This sheet contains the work standards, now referred to as performance guidelines, developed during workshops at an earlier stage of the project. For each activity (e.g. 41201 Pothole Patching with Patcher) the corresponding crew size, type and quantity equipment and materials are identified and daily cost calculated. Labor, Equipment and Material unit costs are obtained from their respective worksheets and multiplied by the daily quantities to get the per-day cost of performing each work activity. 6. UnitCost. This is the summary sheet for all the maintenance work activities and the corresponding labor, materials and equipment costs. This worksheet summarizes the daily costs computed in the “WS” worksheet. This sheet also contains the average daily production (ADP) and unit of measure (UOM) for each activity, e.g., the expected ADP for 412-01 Pothole Patching with Patcher (with the specified crew and equipment complements) is 4 tons per day. 7. Labor, Equip and Mat. These three worksheets summarize the daily labor, equipment and material requirements for each activity, from the WS worksheet, for convenience of reference by the District spreadsheets. 12 District Files The ten Excel workbooks, named after each district or section (e.g., “District 02.xls”), contain data, calculations and results specific to that district or section. With the exception of the “Section 45.xls” workbook, which contains five worksheets, each of these workbooks contains 40 worksheets. A description for these worksheets is provided below. There are 33 worksheets, one for each maintenance element, which have the same format and are described in the section entitled Maintenance Elements. 1. Data. Contains the results from the field data collection for the corresponding district and the calculations required to convert the data collected in the field to the measures defined during the LOS workshops. Results from the field data collection are contained in columns A through BC. These columns are in the same order and format used in the electronic data collection form used to capture field results on a computer. Each row corresponds to one 0.1-mile sample. Columns BD through CI are used to convert the raw data to the corresponding level-ofservice measures. For example, total number of potholes was counted and recorded for a 0.1-mile sample, but the actual measure is number of potholes per lane mile. To do this conversion, the total number of potholes was divided by the number of lanes and multiplied by 10. At the bottom of the page, averages are calculated for each maintenance element and linked to the “Summary” worksheet. Columns CK through CN are used to compute the proportion of urban and rural mowable areas by first calculating the number of acres for each sample, classifying them urban or rural and then computing the corresponding percentage for urban and rural areas for the entire population. 2. Summary. This sheet provides an overview of the condition of the maintenance elements for the corresponding district. It lists the maintenance elements, units of measurement, computed LOS, target LOS and LOS five-grade scales. Results from the “Data” worksheet and the LOS measures in columns H though L are used to automatically compute the current LOS for each maintenance element. Columns N through Q contain some constants that are used in equations in Column F to determine whether the LOS letter grade should be “+”, neutral, or “-“. 3. Budget. This sheet lists for each maintenance element the current and target LOS from the Summary sheet (listed again here for convenience), the forecast LOS from the WD worksheet, and the associated costs (labor, equipment, materials and contracts) from the WD worksheet to achieve the target LOS. There is sometimes a difference between the target and forecast LOS because the current LOS may be higher than the target value in some districts and will remain so, at least in the short term, even if no additional work is performed. In some cases, the target level was much higher than the current level and was judged not to be achievable in one budget year due to the extremely high cost of doing so (in some cases, several million dollars would be required to bring just one asset from an F to the 13 target level A or B). In such cases, a multi-year program should be established for those maintenance elements so that the target level can be achieved over a two to five-year period. 4. WD. This worksheet is used to convert the work quantities calculated in the maintenance element worksheets to crew days and corresponding cost (labor, equipment, materials and contracts). Columns A and B list the groups and individual maintenance elements. Columns C and D list the work activity numbers that apply to each maintenance element. Columns E and F contain the work quantity required to achieve the target level of service calculated in the maintenance element worksheets and corresponding units of measurement. Column G shows what percentage of the require work quantity will be accomplished by one or more maintenance activities. Column H and I contains the conversion factor and converted work quantities. These factors are used to convert work units used in the LOS measures to the units defined in the performance guidelines. Columns J and K contains the average daily accomplishment and unit of measure defined in the work standards for the corresponding work activity. Column L contains the number of crew days required to accomplish the amount of work in Column J. Column L is the results of dividing Column I by Column J. This portion of the worksheet is shown in Exhibit II-2. Columns M, N, O and P contain the labor, equipment, material and subtotal cost for each work activity. These columns are calculated by multiplying the number of crew days in Column L by the unit costs per crew-day for labor, equipment and materials from the work standards spreadsheet in the corresponding Data file for the district. Column Q shows the cost of any maintenance work done by contract, followed by the total cost of in-house and contract work in Column R. Columns S and T show the percentage of the total in-house (Subtotal) cost and labor costs associated with each work activity assigned to a maintenance element. These percentages will be used in the scenario modeling, described later in this section. Columns M through T of the worksheet are shown in Exhibit II-3. Columns U, V and W show the total amount of work required and the units of measure, e.g., number of potholes that will be filled, followed by the forecast LOS grade. If Column X contains a footnote reference, indicated by “*”, then part of the total amount of required work will need to be accomplished by an improvement project, funded in the capital budget, not the maintenance budget. Examples would be overlay projects to correct extensive alligator cracking and area cracking deficiencies. A screen capture of this portion of the worksheet is shown in Exhibit II-4. Note that up to this point, the only user input on this sheet is in Column G. Everything else is calculated or obtained from other sheets. 14 Exhibit II-2 “WD” Worksheet, Columns A to L. 15 Exhibit II-3. “WD” Worksheet, Columns A to D and M to T. 16 Exhibit II-4. “WD” Worksheet, Columns A to D and U to X. Columns Y to AH provide a workspace to experiment with different overall budget levels (see Exhibit II-5). This section is labeled “’What-If’ No. 1”. In Column Y, highlighted in green, a percent increase (+ value) or decrease (- value) in the overall in-house budget for all listed maintenance elements may be entered in the white box, Cell Y9. That percent change is applied to each maintenance element’s budget and the resulting level of service for each element is shown in Column AH. For example, the target in-house budget level in District 03 is $26,416,502 (see Cell P142). To see what would happen if that target budget level were to be reduced by 10 percent, enter “-10” in cell Y9. The resulting levels of service are shown in Cell AH3, highlighted in green. For asphalt potholes, for example, the target level of service would be reduced from level of service “B+“ to “C-“. The overall budget resulting from the percent change is shown in Cell Y142. Note that the original target budget values in Column T are not changed by any changes made in the “What-If” section. Likewise, no changes occur in the Maintenance Element worksheets, the district Budget worksheet, or the “DistrictTotals” worksheet. To make permanent changes to the budget sheets, changes in level of service must be made on the individual worksheets for the maintenance elements, such as “A Potholes” (see section on Maintenance Elements). 17 Exhibit II-5. “WD” Worksheet, Columns A to D and Y to AH. 18 Columns AU to BD, labeled “’What-if No. 3”, provide an identically formatted experimental workspace, as just described above, except that the percent change entered in Cell AU9 is applied to the target labor budget (in Cell M142). Then, the resulting crew-days, budget and level of service are calculated for each maintenance element. In the previous example, the original targeted labor budget was $1,722,010. If the labor budget value is reduced by 10 percent in Cell AU9, the result for asphalt potholes is level of service “C-“ in Cell BD3. In some cases, it may be desirable to see the impact of changes in targeted budgets for individual maintenance elements. For example, it might be desirable to place more emphasis on safety-related items, such as warning signs, than on aesthetic items such as litter control. To allow this type of “what-if” analysis, the workspaces in Columns AJ to AS (“’What-if No. 2”) and Columns BF to BO (“’What-if No. 4”) were developed. The two workspaces are identical in format to the previous ones described above, except that individual percent changes to targeted maintenance element in-house total budgets may be entered in Column AJ, and individual percent changes to targeted maintenance element labor budgets may be entered in Column BF. Otherwise, the workspaces all perform identical activities to those described previously. Columns BQ to BU contain numerical values that are used in calculating the level-ofservice letter grades in Columns W, AH, AS, BD and BO. These values are obtained from the individual Maintenance Element worksheets. For “What-if No. 1”, the detailed process works as follows. When a targeted in-house budget percent change is entered into Cell Y9, the change is applied to the targeted inhouse budgets for the various maintenance elements and shown in the gray cells in Column Y. Then, using the corresponding percentages in Column S, the new target cost is distributed to the various activities for each maintenance element and shown in Column Z. These costs are divided by the total cost per crew-day to get the number of crew-days that can be performed for that cost and the results are displayed in Column AA. The crew-days are multiplied by the average daily production per crew-day and the resulting amount of work is shown in Column AB. If necessary, the units are converted in Column AD and expressed in level of service measures in Column AF. If some of the work will be done by contract, that amount is added to the in-house work effort, factored up or down by the same percentage as for in-house costs. The resulting LOS letter grades are calculated and displayed in Column AH, by comparing the values in Column AF with the LOS ranges in Columns BQ to BU. The same basic process is used in the other “What-if” scenarios, substituting labor cost for total in-house cost where appropriate. It may be helpful to remember that the oddnumbered what-ifs use in-house total costs and the even-numbered what-ifs use labor costs. 5. CD. This worksheet shows the number of crew-days of work required during the year for each work activity to achieve the target LOS. The crew-days are distributed month by month using seasonal percentages from the work standards worksheet (WS) in the applicable Data file, Columns O to R. The CD worksheet may be viewed as an annual 19 planned work calendar and should be used as a guide for short-term scheduling. The old adage “Plan your work, work your plan” is still valid. If the plan is not followed, the targeted service levels will not be reached. 6. Labor. Using the crew-day distributions in the CD worksheet, the number of people required each month, by job title, are calculated and shown in the Labor worksheet. The initial calculations for each work activity are shown in Columns G through R. The resulting monthly requirements for each job title are obtained by totaling the monthly requirements for each work activity (see Rows 73 and 143). By dividing these totals by the working days per month, the number of people required for each job title is obtained (see Rows 74 and 144). Due to various kinds of leave, training programs, etc., people are not available for work 100 percent of the time. To account for this, an availability factor was calculated in Cell D152 and applied to the numbers shown in Rows 74 and 144. The resulting numbers of people in Rows 75 and 145 are the staffing levels required to ensure that enough people will be available to do the work in any given month. The monthly requirement for maintenance workers is generally not balanced throughout the year…some months may vary by 10 percent or more from the average monthly requirement. The requirement for workers may be balanced by multiplying the monthly requirement for each work activity by the ratio of average total monthly requirement (Cell S145) to total monthly requirement. The same ratio may be applied to Foreman requirements for each work activity to see how the balanced arrangement for Workers will affect the number of Foremen required. The result of this balancing adjustment is shown in Columns V through AH for both Foremen (Row 75) and Workers (Row 145). Since the number of Foremen is not exactly balanced the Mode function was used to get the preferred number (Cell AI75). These same monthly ratios may be applied to equipment and material needs, if desired, to get a more precise assessment of these resource requirements. However, it is usually sufficient to balance the job title that has the largest number of employees, then apply that same ratio to the rest of the job titles. The monthly equipment and material requirements can be used as a planning tool, even if not adjusted to precisely match the balanced crewdays for Workers. 7. Equip. The Equip worksheet applies the daily equipment requirements to the planned number of crew-days each month (from the CD worksheet) for each work activity. By totaling these values, the total monthly requirement for each type of equipment can be determined. Equipment availability factors, contained in Cells D687 to D689, were applied to the calculated equipment needs to obtain the adjusted number of units each month (e.g., for Boom Trucks, see Row 15). The planned number of vehicles or equipment needed is shown as the Mode value in Column T. If the level of service objective is to be reached, the annual work plan must be budgeted and the work plan must be carried out. That means that the number of crew-days called for in the CD worksheet must be carried out each month and, to do that, the equipment 20 requirements shown in the Equip worksheet must be available, either in the in-house fleet, by rental, overtime hours, or by borrowing from another district. 8. Mat. The Mat worksheet is similar to the Equip worksheet in that it applies the daily material requirements to the planned number of crew-days each month for each work activity. By totaling these values, the total monthly requirement for each type of material can be determined. These values may be used as a planning guide for procurement of materials, to ensure that the required materials and quantities will be available when the work is performed. 9. Maintenance Elements. There are 33 worksheets, one for each maintenance element, that contain the Level of Effort calculations. These worksheets are used to determine the amount of work required to increase or decrease the level of service for the corresponding maintenance element. The level of service measure and range of values defined for the corresponding maintenance element are included in Row 4. Midpoints for each level of service range are calculated in row 5. In some cases, it was necessary to convert the units of measurement of the level of service ranges. Cell P4 contains the conversion factor, if applicable, and Rows 6 and 7 contain the converted level of service ranges and midpoints. For example, Raveling was measured in percentage of the area deficient. The conversion factor was used to express the area in square feet deficient. If no conversion is required, then Cell P4 contains a factor equal to “1”. Rows 10 through 16 list the work activities and corresponding historical work quantity values from MOPS that apply to that maintenance element. In some cases, these work activities only partially apply to maintaining the specific element. For example, in the case of Potholes, only 10 percent of Work Activity “414 – Hand Leveling” applies to fixing potholes. These percentages were estimated during the level of effort workshops and validated by all Districts. Then, work quantities are converted to the same units of measurement used in the LOS ranges. In the case of Potholes, historical work quantities are expressed in number of tons and converted to number of potholes. The total number of converted potholes is shown in Cell M17. Cells E19 and M19 contain the inventory for the applicable maintenance asset and corresponding District. Cell K19 allows converting inventory units to the applicable maintenance element. For example, in the case of Shoulders, the inventory is not known, but the number of roadway miles and the shoulder density (obtained from the field data collection process) are known. In District 02, it was found that there are on average 1.8 shoulder miles per roadway mile. Cell G23 contains the calculated number of deficiencies. This cell is linked to the “Data” worksheet. In the case of Potholes for District 02, it was found that there were 1.062 potholes per lane mile. (Note that Cells C22, E22, G22 and E23 are not used.) The bottom portion of the worksheet contains the calculation for the level of effort. For each level of service, the difference between the current condition and midpoint level of service is multiplied by the inventory and is calculated in Row 27. Then the current work quantity from Cell M17 is added to determine the total amount of work required to achieve that specific level of service. Following the example of District 02 for Potholes, 21 the current program is 21,752 potholes and the additional work to achieve a level of service “B+” is 1,494 potholes ((1.062-0.5) x 2,658) resulting in a total of 23,246 potholes or 967 tons of asphalt (Cell P31). Note that the value in Cell Q25 is the target level of service value (derived from the converted LOS scale on Rows 6 and 7). Exhibit II-6 shows a screen capture of the asphalt potholes worksheet, “A Potholes”, for District 02. Exhibit II-4 “A Pothole” Screen Capture 10. MOPS. The MOPS worksheet contains data from the Maintenance Operations System for the corresponding district or section. Data was imported to each worksheet from a HTML format provided by the MOPS Administrator. This worksheet contains five columns in the following order: Activity Number, Description, Direct Cost, Redistributed Cost, Total Cost, Regular Man Hours and Total Accomplishment. These worksheets are used as the data source for the Maintenance Element worksheets in Cells E11 through E16. The Section45.xls file is similar to the district files, but only has five worksheets, Summary, Budget, WD, one maintenance element (i.e., SignalsI), and MOPS. The formats for these five are identical to those in the district files. 22 District Totals File The Excel file “DistrictTotals.xls” summarizes the budget results from all districts. This file contains four worksheets. The first worksheet shows the total dollar amount by maintenance element and district or section. The other four worksheets break down the costs for labor, equipment, materials and maintenance contracts, all using the same format. Exhibit II-7 shows a screen capture for a portion of this file. Exhibit II-7. “DistrictTotals.xls” Screen Capture 23 Assumptions This section list a number of assumptions used in developing the budgets. The same target levels of service were applied to all Districts. MOPS data was assumed to be correct and not modified although some inaccuracies are known to exist due to entering work accomplishments under the wrong work activity numbers, entering incorrect amounts or the wrong units of measure. The same average costs for materials, equipment and labor were used for all Districts. In general, the same performance guidelines were used for all Districts. However, a few activities were different, mainly due to types of equipment used, so separate Data workbooks were compiled for Districts 03, 04, 05, 07, 08, 61 and 62, and Section 45. Districts 02 and 58 use the Data00 workbook. The same proportion of contract and in-house work was applied to additional work required to achieve the target LOS. For example, if a 10 percent increase was required to reach a certain level of service, the same increase was applied to contract work as well as in-house work, including work done by capital improvement projects. Inventory for many maintenance assets was collected as part of the field data collection and extrapolated from the sample to estimate the district total. The percentage of each work activity that applies to each maintenance element was estimated with the help of experienced maintenance personnel. For example, it was determine that Activity 414-Hand Leveling applies to the following maintenance elements: Percentage applicable 414 Hand leveling Potholes Rutting Raveling Alligator Cracking 10% 5% 42.5% 42.5% The work activities and corresponding proportions of additional work that will be accomplished using each one of them was estimated with the help of experience maintenance personnel. These proportions are a policy decision that should be validated by management. For example, it was assumed that the proportion of potholes that will be patched using hand method (Activity 412-02) was 15% and the proportion of potholes that will be patched with a patcher (Activity 412-01) was 10%. 24 Some errors were found in the results of the field data collection process. For example, in some cases, the results showed the number of deficiencies to be greater than the inventory. In such cases, it was assumed that the number of deficiencies was equal to the inventory resulting in a 100% failure. In the case of raised pavement markers there was some confusion among the crews collecting data. Some crews counted the number of RPMs deficient and others the number of feet with deficient RPMs. It was assumed that RPMs were spaced every 40 ft or 13 RPMs in a 0.1-mile segment. In some cases, when converting linear feet of deficient RPMs to number of RPMs the resulting number was greater than 13. In such cases it was assumed that all RPMs in the sample were deficient. According to MOPS documentation, accomplishment for raised pavement markers is recorded as number of RPMs installed. In some cases, MOPS data showed zero accomplishment, but reported expenditures greater than zero. Where that occurred, it was assumed that RPMs were installed using a contractor. Data on RPM contracts was obtained from the traffic division. The “Other” maintenance element includes a combination of deficiencies not identified in any other maintenance elements. The combination of possible deficiencies and corresponding treatments has not been fully determined. Therefore, the target level of service was set equal to the current program. The number of samples that contained Gutters was not sufficient to be statistically valid. Therefore, the target level of service was set equal to the current program. The target level of service for Alligator Cracking was originally set to “A”. Fixing all areas with Alligator Cracking resulted in a very high cost. Because a level-of-service “B+” was acceptable to everyone, the target level of service was changed to “B+”. Two assumptions were made for mowing. The field data collection process was performed in January 2005 when grass is not growing as fast as in spring. It was assumed that the average grass height during spring and summer was 16 inches, or level of service “D”. The relationship between the number of mowing cycles and the grass height was assumed as there is no data to derive these numbers. These assumptions can be found in the mowing worksheets. Rest area maintenance is currently performed under contract. The amount of work performed in the past at each rest area is not known as private firms are not required to report work accomplishments, so expenditures were used as the measure of accomplishment. The average LOS for most rest areas was “C” and the target level of service was “C”. As no data is available to calculate the level of effort required to go from a LOS C to B, expert judgment was used. It was estimated that a change in rest area maintenance expenditures of 15% would be required to move up or down by one letter grade and therefore the amount of work performed to achieve the target LOS. 25 Currently only two districts seal cracks as part of their preventive maintenance program. The proposed budget assumes that all districts will undertake this activity in the future as more funds become available, either in-house or by contract. A managerial decision should be made regarding whether to undertake a crack sealing program or allow pavements to deteriorate to the point that a more costly treatment is required. Update Instructions The process for updating the budget files includes the following steps: 1. Random Sites. Every year new random sites should be generated to determine the locations where maintenance elements will be assessed. The number of sample sites will depend on the number of road miles maintained by the Department. It is recommended to include for each site the district, route, mile point, control section, direction of travel (if divided roadway), and parish. As a general rule, the number of samples should be sufficient to provide results with a precision of +/- 5 percent at the 95 percent level of confidence. 2. Current Level of Service. Every year LOS condition on maintenance elements should be assessed at the random sites by a combination of field observations or using an Automated Road Analyzer (ARAN), as determined by management. These values should be replaced in the district files in the “Data” worksheets. In general, field condition assessment should be performed once at any time of the year. Exceptions are mowing and litter which should be performed at least twice during summer months. 3. Inventory. It is recommended to collect inventory data as part of the yearly field condition assessment to improve accuracy of current estimated inventory. This specifically applies to shoulders, drainage, roadside and traffic control elements. Resulting values should be replaced in the Data worksheet for each district. Pavement inventory values (asphalt and concrete pavement lengths) should be updated in the corresponding Maintenance Element worksheets for each district. As physical changes are made to the road system, e.g., additional lanes constructed, the District Maintenance Engineer should update the inventory for the district. 4. Maintenance Operation System Data. The MOPS data should be updated in each of the nine districts and section files in the last worksheet named “MOPS”. New data should consist of the last fiscal year’s data. It is important that one full year worth of data is included to account for seasonal variation. 5. Cost Data. Every year, labor rates, equipment rates, and cost of materials should be updated in each of the Data workbooks. 6. Contract Work. Every year, contract work accomplishment data should be collected for the previous fiscal year and updated in the Mowing, Litter, Brush, Trees, Rest Areas, 26 Raised Pavement Marker, and Striping worksheets for each of the districts. Contract cost data should be updated in the Data workbooks. 7. New Target LOS. Based on the customer input approach, legal mandates, or management considerations, target levels of service should be reviewed every year and changed, as appropriate. These values will have to be updated in every maintenance element worksheet for every district in Cells P25 and Q25. 8. Capital Improvements. Note that road improvements that are funded out of the capital budget are not shown in the maintenance budget figures, but the level of effort to achieve the target level of service includes these improvements and assumes that they will be made within the next year. The maintenance elements that depend on capital improvements to achieve the desired level of service are mainly Alligator Cracking, Longitudinal/Transverse Cracking, and Area Cracking. It is important to note that if the improvement projects are not undertaken, the desired levels of service for those maintenance elements will not be achieved. 27 IV. Next Steps The maintenance management approach is a self-improving process. Every year, as more data becomes available, future outcomes will be predicted with a higher level of reliability. The overall process consists of defining a desired level of service, developing an annual maintenance programs to provide that level of service, obtaining the budget for the program, executing the program, and assessing the resulting road conditions to determine if the desired outcomes were achieved. This assessment of desired-versus-actual outcome is used as the basis for refining the maintenance program for the following year. This section describes the steps that will be required to repeat and improve this process, other than the ones already described in the previous section. Level of Service Measures The level of service for the current maintenance elements are expressed in ranges that should be reviewed to determine if they properly reflect the current condition of the assets. For example, the level of service “A” range for some pavement elements is zero, meaning that there is no allowance for A+ or A- ratings, i.e., conditions must be perfect to achieve an A rating. If some tolerance is desired for an A grade, a range of values could be provided, such as 0.0 to 0.5. However, it is recommended that the LOS scales not be changed until a couple of years of experience with the existing LOS scales have been reviewed. It also should be determined if more maintenance elements should be included. For example, work standards were developed for bridge elements and movable bridges, but have not been included since no previous accomplishment data was ready available. Current Level of Service Every year, new data on the condition of the maintenance element should be collected using the approach described in the word document named “09702r01 LOS Measures.doc”. With the exception of mowing and litter, which should be rated two or three times per year, the rest of the maintenance elements should be rated on a yearly basis. The Planning and Programming Section currently contracts the collection of data for road features using an Automated Road Analyzer (ARAN) truck. A meeting was conducted with personnel from the Planning and Programming Section to determine if this data could be used as input for determining current level of service. Some of the advantages of using an ARAN truck include avoiding duplication of data collected, obtaining data for the entire system opposed to a random sample and increased safety as crews do not have to measured pavement distresses out in the field. Some of the disadvantages include data collected only every two years, required postprocessing of data to extract items related to roadway and roadside maintenance elements, video is captured in only one direction, and possible timing conflicts. It is recommended to use a combination of both methods to leverage the ARAN contract to collect pavement data related to maintenance and use field data inspections for the rest of the assets. 28 Evaluate performance Every year, results from the latest field condition assessment should be compared against the target levels of service. This yearly evaluation will help in determining the right amount of work required to achieve target levels of service. In some cases, these differences can be explained by external factors such as weather, price changes and labor or equipment shortages. In other cases, these differences can be explained by incorrect underlying assumptions in the work standards, such as average daily accomplishments or crew sizes and, if so, appropriate corrections should be made. Target Level of Service Setting target levels of service is a policy decision that should be taken by top management. At the time the target levels of service are defined, the corresponding budget should be looked at to determine if the amount of work and corresponding costs are viable or if a deferred program should be implemented to gradually improve the condition of the maintenance elements. During the first iteration, the same target levels of service were applied to Interstate, US and State roads. The management team should decide if different target levels of service should be used for the different types of road. The current sampling methodology supports setting target levels of service for each type of road. Another option is to set different target levels of service for different functional classes of roads, e.g., arterial vs. collector, to account for differences in traffic volumes, operating speeds, or other road attributes. Customer Input Approach It is recommended that citizen input and/or focus group surveys be conducted at least every five years. This will allow enough time for implementing a proposed maintenance program and accomplishing the target levels of service. It is also highly probable that public’s opinion will not change from one year to the next. Results from each year can be assumed to be valid until the next customer survey is conducted. Annual Work Program An annual work program provides two important pieces of information: 1) a work calendar and 2) the resources required to accomplish the work quantities. Results from the budget calculations are converted into an annual work calendar for each District. The work calendar will show the annual amount of work to be done, the labor, equipment, and materials that are needed to accomplish the work, and the monthly time frames in which the resources will be needed. Typically, seasonal work is scheduled first. Then, other work without seasonal constraints is scheduled to level out the annual workload. With this information in hand, managers can determine if there are sufficient resources available, and in the right place at the right time, to accomplish the work program. If not, arrangements will 29 need to be made to transfer resources to another location, hire additional permanent or temporary personnel, use overtime, engage contract forces, or buy or lease more equipment to get the work done. The following steps are required to develop an annual work program: 1. For each District, determine the number of crew days required to accomplish the targeted amount of work calculated in the “WD” worksheet. The number of crew days of each type of work is shown on the CD worksheet. 2. Using a tool such as Microsoft Project or Excel, schedule each activity following the monthly distribution of work as defined in the district CD worksheets until all activities have been scheduled. 3. Balance the resources by running an optimization routine to minimize the resources needed to accomplish the work program. This might result in rescheduling, splitting or delaying tasks. Balancing resources will move tasks from months where unconstrained tasks are over-scheduled to months where tasks are under-scheduled. 4. Compute the quantity and type of resources needed to accomplish the balanced work program. 5. Determine if the available resources (labor and equipment) at the corresponding District are sufficient. If the number or type of resources is not sufficient, determine if the additional work should be contracted, accomplished by hiring additional personnel or use of overtime, acquiring or renting additional equipment, or changing the target level of service. 6. Repeat the process for each District. 7. Total the district results to obtain the statewide summary. Conclusion It is important to stress that the target levels of service cannot be achieved unless the budget and resources for the performance-based work program are available in the required amounts in each district and the maintenance managers in each district ensure that the performance-based work program is substantially implemented. The following conditions must be met, otherwise the entire process is an interesting, but purely academic, exercise: 1. The performance-based budget for the desired level of service must be approved and provided by DOTD management. 2. District maintenance managers must arrange for the required resources to carry out the approved work plan. 30 3. Work must be scheduled and executed in substantial compliance with the work program. 4. Annual accomplishments must be assessed to determine if the target levels of service were achieved. Appropriate adjustments to planning assumptions and annual levels of effort must be made to the next year’s work program and budget.