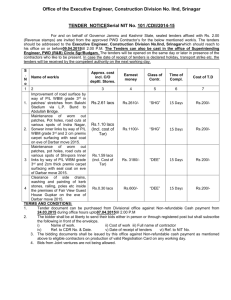

engineering (civil) department

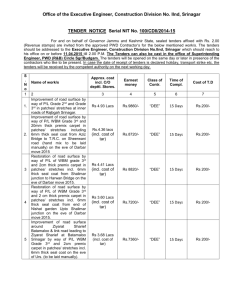

advertisement