doc

advertisement

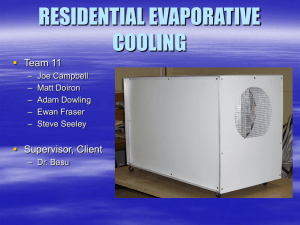

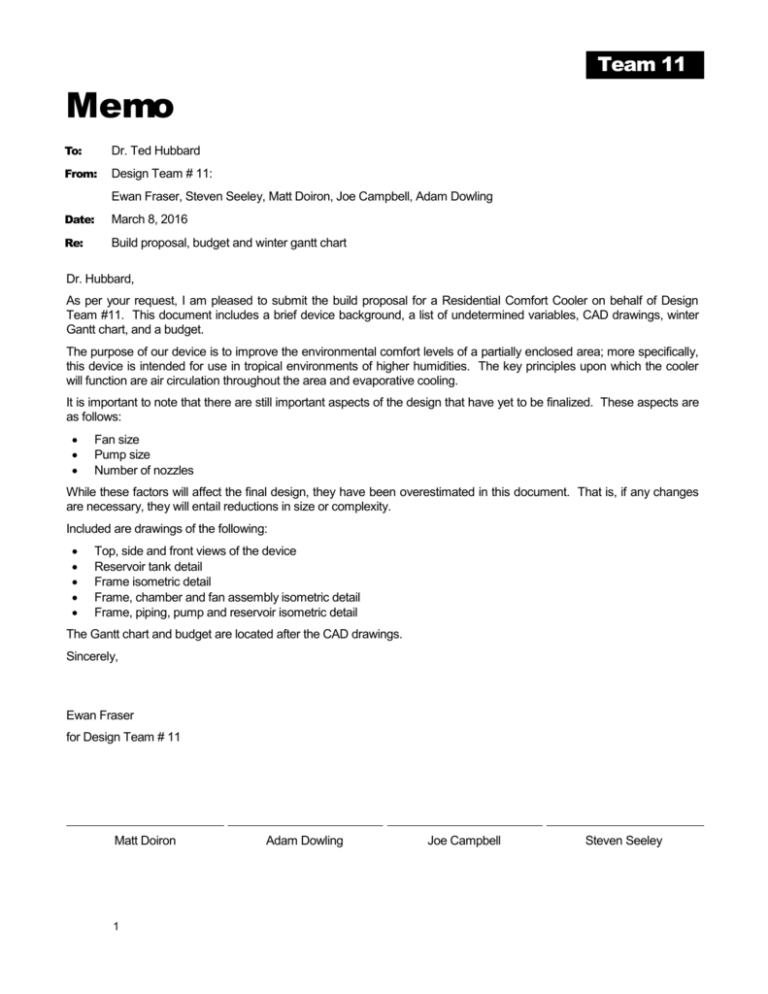

Team 11 Memo To: Dr. Ted Hubbard From: Design Team # 11: Ewan Fraser, Steven Seeley, Matt Doiron, Joe Campbell, Adam Dowling Date: March 8, 2016 Re: Build proposal, budget and winter gantt chart Dr. Hubbard, As per your request, I am pleased to submit the build proposal for a Residential Comfort Cooler on behalf of Design Team #11. This document includes a brief device background, a list of undetermined variables, CAD drawings, winter Gantt chart, and a budget. The purpose of our device is to improve the environmental comfort levels of a partially enclosed area; more specifically, this device is intended for use in tropical environments of higher humidities. The key principles upon which the cooler will function are air circulation throughout the area and evaporative cooling. It is important to note that there are still important aspects of the design that have yet to be finalized. These aspects are as follows: Fan size Pump size Number of nozzles While these factors will affect the final design, they have been overestimated in this document. That is, if any changes are necessary, they will entail reductions in size or complexity. Included are drawings of the following: Top, side and front views of the device Reservoir tank detail Frame isometric detail Frame, chamber and fan assembly isometric detail Frame, piping, pump and reservoir isometric detail The Gantt chart and budget are located after the CAD drawings. Sincerely, Ewan Fraser for Design Team # 11 Matt Doiron 1 Adam Dowling Joe Campbell Steven Seeley Frame: Dimensions may change slightly based on sizing of fan. Shown are the MAXIMUM dimensions. All angles are at 90 degrees. Material: Angle Iron or Square Tubing (Aluminum or Iron). Assistance required: Welding and Shaping. Frame, Chamber, Fan and Baffle Assembly: Page 2 Fan and Baffle will be purchased. Materials: Light steel or plastic for Evaporation Chamber (blue in above Diagram). Assistance Required: o Holes to install brackets to stabilize Chamber, Fan and Baffle against Frame. o Holes in Evaporation Chamber sized for our Nozzles (45 degree intervals). o Possible mounting of Fan to Frame. Frame, Piping, Pump and Reservoir Assembly: Page 3 Pump, Nozzles and Elbows/T’s will be purchased. Materials: o Flexible Plastic Hose (Navy Blue in Figure) o Rigid Pipe (Copper or PVC) or Flexible Plastic Hose (Magenta in Figure) o Plastic or Sheet Metal for Reservoir under Evaporation Chamber Assistance Required: o Holes in Evaporation Chamber for Nozzles o Brackets welded to frame to support Piping o Possible Welding of Reservoir Page 4