Illustration of a Conical Spill

advertisement

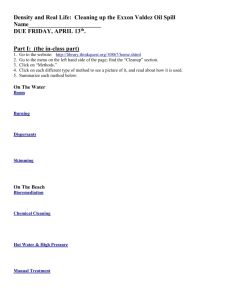

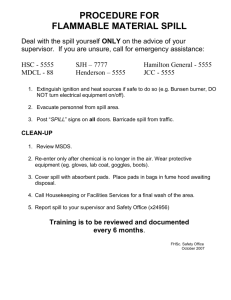

THE GEOMETRY AND REPRESENTATION OF DRY SPILLS OF POWDERS, FINES, AND PARTICULATES James J. Bazley 1.0 SPILL GEOMETRIES This document addresses spills of dry solids, such as powders, fines, and particulates, onto a flat surface with no lateral constraints. Spills of these materials into constrained geometries (e.g., containers, pits, or other equipment) that may provide a more reactive geometry should be covered using different methodologies. A spill of material onto a flat surface will collect in a pile. The spill will, generally, take on the shape of a flat cone although truncated and/or oblong cones are possible. Several factors could affect the resulting shape of the spill of material, including: (1) the size and type of break causing the leak, (2) the distance between the leak and the surface where the leak collects, and (3) the flatness and smoothness of the surface upon which the material collects. These factors affect the initial distribution of the spilled material, the kinetic energy of that material upon impact with the collecting surface, and the ease with which spilled material can move along the collecting surface. Minor grooves, ridges, and hills and valleys on a collecting surface may also affect the spill shape. Reactivity of a given volume of material is maximized when the ratio of the surface area to volume is minimized. Such a configuration achieves the minimum neutron leakage. For a spill to have the smallest surface area to volume ratio, it must exist as a right circular cone. A spill of right circular conical shape would result in a higher height and minimum base surface area of a spill. Deviations from an exact conical shape because of material dispersion (e.g., an oblong base or truncated top) increase the surface area to volume ratio. Minor grooves, ridges, and hills and valleys on the spill collection surface would slightly increase the bottom surface area of the spill without changing the upper surface of the spill. The angle made between the surface and the outside of the cone is referred to as the angle of repose. This is illustrated in Figure 1. The angle of repose achieved in a particular spill will be less than or equal to the maximum angle of repose. The maximum angle of repose is material dependent. Figure 1 Illustration of a Conical Spill Angle of Repose, h R For a right circular cone, the surface area to volume ratio is minimized when the angle of repose is 70.5. Typically, the bottom surface of a cone is much better reflected (e.g., by a concrete floor) than the upper surface. Therefore, the most reactive angle of repose may be closer to that at which the ratio of the upper surface area to volume is minimized. This occurs when the angle of repose is 54.7.1 Therefore, the most reactive angle of repose depends on the reflection conditions, but is bounded by an angle between 54.7 and 70.5. However, for most dry particulates2, the maximum angle of repose is less than 45, which is well below the range where optimum reactivity occurs. Therefore, the higher the angle of repose, the smaller the surface area to volume ratio and the more reactive the spill. It is important to note that, in unconstrained geometry, it is not possible to achieve a geometrical shape more reactive than a cone with the maximum angle of repose. If the material from a spill was scooped up and/or repoured onto the spill or pushed together without completely enclosing the border3, the material would immediately flow out or down the sides of the spill until an angle less than or equal to the maximum angle of repose was obtained. In this manner, it is not physically possible, unless the material is constrained within a container or containing surface, to make a spill taller or more reactive than a perfect conical shape with the maximum angle of repose. The spill, under worse case conditions, could take on the shape of an exact right circular cone exhibiting the maximum angle of repose. The actual angle of repose obtained would likely be much less than this depending on the area over which the leak occurs and the kinetic energy departed to the material as it falls and spreads out. 2.0 CONICAL GEOMETRY The following equations describe the volume, surface area, and angle of repose for a right circular cone as depicted in Figure 1: 1 These optimum angles of repose are derived in Section 5.0 of this memorandum. Reference 1 provides examples of angles of repose for different dry solid particulates. 3 Surfaces would not have to completely enclose the material to cause it to be contained. Bridging affects near a split or hole in a containing surface, could be sufficient to contain material. For bridging to occur, the split or hole must generally be smaller than six to ten times the effective diameter of particles contained therein. 2 1 Volume = V = 3 R2 h (Eqn. 1) (Source: Reference 2) Surface Area = R R2 + h2 + R2 (Source: Reference 2) (Eqn. 2)4 h tan = R . (Eqn. 3) For the spills being analyzed, two parameters are known: the volume, V, (or maximum volume) of material that may spill, and the maximum angle of repose, . From these two parameters, the height, h, and radius, R, of the worse case conical geometry can be found. Solving Equation 3 for h yields: h = R tan (Eqn. 4) Substituting Equation 4 into Equation 1 and solving for R yields: 1 V = 3 R2 h 1 V = 3 R3 tan R3 = 3 R= 3V tan 3V tan . (Eqn. 5) Substituting Equation 5 back into Equation 4 allows the height, h, to be determined for a specific volume, V: 3 h= 3V tan tan The surface area given in Reference 2 is for the upper conical surface. A term (R2) was added for the surface area of the bottom circular surface of the cone to provide the total surface area of the cone. 4 h= 3 3V tan (Eqn. 6) Therefore, for a known spill volume, V, and an angle of repose, , the radius, R, and the height of the spill, h, can be determined by using Equations 5 and 6, respectively. 3.0 DETERMINATION OF SAFETY OF SPILLS A simple determination of the criticality safety of spills can be gleaned from a comparison of spill parameters to the maximum subcritical values for infinite slabs and spheres. If the spill height does not exceed the maximum subcritical infinite slab height or the spill volume does not exceed the maximum subcritical volume, then such spills are subcritical. Accounting for a void fraction in the bulk, dry, material, the maximum subcritical limits may be increased by a factor equivalent to the inverse of the packing fraction (i.e., one minus the void fraction).5 To determine if spills greater than these conservative values are safe, calculations must be performed. 4.0 EQUIVALENT BOUNDING GEOMETRIES Because some calculational programs, such as SCALE’s KENO-V.a, do not have the capability to directly model cones, two approximations can be used to bound a conical spill. The first approximation uses a stack of flat cylinders, each of set height but varying radius to envelope a cone. The second approximation uses a hemisphere.6 A comparison of these bounding geometries to a conical spill is provided by Figures 2 and 3. Both figures represent a two-dimensional vertical cut through the diameter of the conical spill (in solid light gray background) and the stacked cylinders or hemisphere (in black outline). Each of the modeling approaches is discussed in further detail below. 5 The maximum reactivity for these systems is achieved at maximum theoretical density. Any decrease in the density, e.g. from void space resulting from a bulk packing density, would, at a minimum, result in the same mass being required to achieve the same keff, assuming that no other parameter, e.g., the degree of moderation, is changed. Therefore, it would be conservative to scale the maximum subcritical values according to the density change. Values greater than the scaled values for the reduced densities would most likely be required to achieve the same keff values as the original values because the interstitial void space would also increase system leakage, resulting in a lower keff. Refer to Reference 3 for core-density exponents if further credit must be taken. 6 The term “hemisphere” is used, herein, to denote spherical segments of one base whose spherical surface exists in the +Z direction. This term is considered synonymous with “truncated sphere” and “truncated hemisphere.” The term “exact hemisphere” is used to denote half a sphere when the slice occurs at the center of the sphere. The term “slice” is used to refer to the base or flat portion of a hemisphere. Figure 2 Comparison of Conical Spill to Stacked Flat Cylinders Spill Model *Note: The height and number of flat cylinders may vary but the overlap approach is consistent. Figure 3 Comparison of Conical Spill to Hemispheric Spill Model *Note: This figure is scaled for an angle of repose of 20 and the shape of the hemisphere and conical spill are consistent for any spill volume. 4.1 STACKED FLAT CYLINDERS MODEL The conical spill is modeled by stacking a particular number of cylinders of a set height to enclose the volume of the spill. Figure 4 shows this model for a spill with a 20 angle of repose. This can be compared to the two-dimensional vertical cut through the diameter of the model and the spill as shown in Figure 2. Figure 4 Stacked Flat Cylinders Model The exact number of stacked cylinders and height of the individual cylinders is selected to conservatively bound the conical spill at the desired angle of repose. The same cylinder height is used for all cylinders in the model. Although the last, smallest cylinder may use a shorter height to minimize excess material at the top of the stacked cylinders. The radius of each flat cylinder is set equal to the radius of the cone at the particular elevation of the bottom of the cylinder. In that way, the geometry of the conical spill is contained inside the stacked cylinders with a conservative quantity of material added to the outside edge of the cone. The extra material added to the system by this modeling approach is a function of the height of the individual cylinders. Smaller individual cylinder heights add less extra material to the system and afford a better approximation of the conical geometry. As the height of these individual cylinders approaches zero, the model approaches a prefect representation of a cone. However, practical limitations in the time required to generate such models lead to a compromise between the acceptable level of extra material added to the model and the number of cylinders modeled. Note, though, that regardless of how many cylinders are modeled, the model conservatively bounds the spill because the entire conical geometry is always contained inside the stacked flat cylinders. The radius, R1, of the initial base flat cylinder is determined using Equation 5. Subsequent radii, Rn, of the stacked flat cylinders are determined given Equation 7: n-1 h - h 1 Rn = , tan (Eqn. 7) where h is the height of the conical spill as calculated from Equation 6, h is the height of the individual flat cylinders, and is the angle of repose. If the height of the final cylinder, hN, is shortened so it matches the height of the conical spill, the height of that cylinder is determined given Equation 8: N-1 hN = h - h , (Eqn. 8) 1 where h is the height of the conical spill as calculated from Equation 6 and h is the height of the individual flat cylinders. The resulting stack of flat cylinders, as shown in Figure 5, conservatively bounds the conical spill. Figure 5 Conical Spill Within Stacked Flat Cylinders Angle of Repose, h R 4.2 HEMISPHERE MODELS The spill is modeled by equating the conical spill to a hemisphere. A hemisphere is modeled because the spherical shape would minimize the surface area to volume ratio (and, hence, neutron leakage) while bounding particular parameters of the conical shape. Several types of bounding hemispheric models could have been developed. Figure 6 presents four conservative modeling approaches to bounding a conical spill. Figure 6 Comparison of Different Hemispherical Modeling Approaches Exact Hemisphere of Equivalent Volume Enclosing Hemisphere Hemisphere of Equivalent Height and Volume Hemisphere of Equivalent Average Angle of Repose and Volume Order of Decreasing Conservatism *Note: This figure is scaled for an angle of repose of 20 and the shape of the hemisphere and conical spill are consistent for any spill volume. The most simple modeling approach would be to model an exact hemisphere (exactly one half of a sphere) containing the volume of the spill. This representation of a spill is the simplest, most conservative, and is frequently used; but, for large quantities of material that have spilled, this approach could be too conservative (in the height of the material and minimized leakage modeled). The next set of modeling approaches use the hemisphere chord function in KENO-V.a. Using the chord function allows shorter and squatter hemispheres to be modeled. These shorter and squatter hemispheres may more appropriately represent the worse case conical spill with the angle of repose of interest. Refer to Figure 7 for the following discussions. Figure 7 Hemispherical Segment/Slice Dimensions Angle of Repose, h a R Three potential models are considered. In the first, a hemisphere could be modeled that encloses the conical spill within it such that the hemisphere slice height, h, and radius, a, are defined by the height, h, and radius, R, of the conical spill. This is also equivalent to maintaining the height of the hemisphere slice to that of the conical spill and maintaining the angle of repose. This is an overly conservative approach, though, which models significantly more volume of material than is actually in the spill. For large angles of repose, this excess volume increases rapidly beyond a point reasonable for use. In the case of a 20 angle of repose, the approach models 56.6% more material than is actually present in the spill. In the second potential model, a hemisphere could be modeled such that the height of the conical spill, h, along with the volume of the spill, V, is maintained. This modeling approach effectively reduces the surface area of the spill while moving material in the lower outer ring of the conical spill into a more reactive position near the top center of the hemisphere. Since the hemisphere chord height and volume are constrained, the approach is only valid for angles of repose with resulting heights less than the spherical diameter for the particular volume (which corresponds to a maximum angle of repose of 54.7). It conservatively bounds the conical spill but contains too much conservatism for the larger spills of interest. The third modeling approach, which is used to determine the safety of spills, maintains the angle of repose and volume. The average angle of repose of the hemisphere is set to that of the maximum angle of repose of the spill. In that way, the “geometry” of the spill is maintained. Note that this configuration is not physically possible because material toward the edges of the hemisphere (which is modeled at tangential angles of repose greater than the maximum angle of repose) would fall off at an angle of repose less than or equal to the maximum angle of repose. The model, as represented in Figure 8, effectively moves material from the outer edge of the conical spill to more reactive positions near the center of the cone. A small amount of material is removed from the very top of the conical spill and redistributed also. This material, although slightly more reactive than material removed at the edge of the conical spill, is also at the upper edge of the cone only contributing minorly to the reactivity of the spill. The overall affect is to move material to more reactive locations on the surface of a lower neutron leakage hemispherical surface. Figure 8 Comparison of a Conical Spill to a Hemisphere of Equivalent Average Angle of Repose and Volume Angle of Repose, h a R For a 45-liter spill assuming a maximum angle of repose of 20, the minimum conical surface area would be 15,600 cm2 (8,050 cm2 on the upper surface). The surface areas for an “exact” hemisphere, “enclosing” hemisphere, and an “equivalent height and volume” hemisphere are 7,280 cm2 (4,860 cm2 on the upper surface), 16,100 cm2 (8,560 cm2 on the upper surface - but this is for a volume of 70.5 liters as compared to the 45 liters used in all the other cases, so the surface area to volume ratio is actually reduced), and 10,400 cm2 (5,700 cm2 on the upper surface), respectively. With the spill modeled using the “equivalent average angle of repose and volume” hemisphere modeling approach, the surface area (and hence neutron leakage) is reduced to 12,000 cm2 (6,350 cm2 on the upper surface). The hemisphere models minimize the neutron leakage as compared to that of the conical spill. These models conservatively bound the conical spill condition. Equations used to generate the models are derived below. 4.3 HEMISPHERICAL GEOMETRY The following equations describe the volume, surface area, and angle of repose for a hemisphere as depicted in Figure 7: 1 Volume = V = 3 h2 (3R - h) (Source: Reference 2) 1 Volume = V = 6 h (3a2 + h2) (Eqn. 9) (Eqn. 10) (Source: Reference 2) Surface Area = 2Rh + a2 (Eqn. 11)7 (Source: Reference 2) h tan = a . (Eqn. 12) The subsequent sections derive equations for spherical radius and hemispherical height from these equations for the different types of hemispheres. 4.3.1 Exact Hemisphere For an exact hemisphere that maintains the volume, V, (or maximum volume) of material that may spill, the hemisphere radius, R, is determined by substituting R for h, the hemispherical height, into Equation 9 and solving for R: 1 V = 3 h2 (3R - h) 1 V = 3 R2 (3R - R) 1 V = 3 R2 (2R) 2 V = 3 R3 R= 3 3V . 2 (Eqn. 13) 4.3.2 Enclosing Hemisphere To generate an enclosing hemisphere in KENO-V.a, the sphere radius, R, and the chord, C, must be determined. Equations 9 and 10 are equated to obtain an equation with terms The surface area given in Reference 2 is for the upper spherical surface of the hemisphere. A term ( a2) was added for the surface area of the bottom circular surface of the hemisphere to provide the total surface area of the hemisphere. 7 for the spherical radius, R, the hemispherical slice height, h, and the hemispherical slice radius, a. The resulting equation is solved for R: V=V 1 2 1 2 2 h (3R h) = 3 6 h (3a + h ) 1 h (3R - h) = 2 (3a2 + h2) 1 3Rh - h2 = 2 (3a2 + h2) 1 3Rh = 2 (3a2 + 3h2) 1 a2 R = 2 ( h + h) . (Eqn. 14) Equation 12 is solved for h: h tan = a h = a tan (Eqn. 15) and the variables a and h in Equation 14 are isolated by substituting Equation 15 for h in the term containing a: 1 R=2( a2 + h) a tan 1 a R= ( + h) . 2 tan (Eqn. 16) Equation 16 now expresses the spherical radius, R, of the hemisphere as a function of the hemispherical slice radius, a, and the hemispherical slice height, h. For an enclosing hemisphere, the hemisphere slice height, h, and radius, a, are defined by the height, h, and radius, R, of the conical spill. Therefore, Equations 5 and 6 are substituted into Equation 16 to obtain the spherical radius, R: 1 R= 2 3 3V tan tan + 3 3V tan2/3 3 3V R= R= 2 1 ( 4/3 + tan2/3 ) tan 3 3V 1 (tan2/3 + ) . 8 tan4/3 (Eqn. 17) To generate the hemisphere in KENO-V.a, a sphere radius, R, and chord, C, need to be determined. The spherical radius is determined using Equation 17. The chord is determined according to: Chord = C = h - R , (Eqn. 18) where the height of the hemispherical slice, h, is the conical spill height, h, determined using Equation 6. 4.3.3 Hemisphere Of Equivalent Height And Volume For a hemisphere that maintains the volume, V, (or maximum volume) of material that may spill, and of the maximum height a conical spill, the previous equations must be used to derive the hemispherical slice height, h, and sphere radius, R. The spherical radius of the hemisphere, R, can be determined by solving Equation 9: 1 V = 3 h2 (3R - h) 3V = 3R - h h2 3V + h = 3R h2 3V +h h2 R= 3 R= V h 2 +3 . h (Eqn. 19) The conical spill height, h, from Equation 6 is substituted into Equations 19 to derive the final value for R. To generate the hemisphere in KENO-V.a, the hemisphere chord, C, needs to be determined. The chord is determined according to Equation 18, where the height of the hemispherical slice, h, is determined using Equation 6 and the sphere radius, R, is determined according to the previous paragraph. 4.3.4 Hemisphere Of Equivalent Volume And Angle Of Repose For a hemisphere that maintains the volume, V, (or maximum volume) of material that may spill, and the maximum angle of repose, , the previous equations must be used to derive the hemispherical slice height, h, and sphere radius, R. Equation 20 is derived by solving Equation 12 for a: h tan = a a= h . tan (Eqn. 20) Equation 21 is derived by substituting Equation 20 into Equation 10 and solving for h: 1 V = 6 h (3a2 + h2) 1 h2 V = h (3 2 + h2) 6 tan 6V 6V h2 + h2) tan2 = h (3 3 = h3 ( 2 + 1) tan h3 = h= 3 6V 3 ( 2 + 1) tan 6V 3 ( 2 + 1) tan . (Eqn. 21) With the hemispherical slice height, h, derived, the spherical radius of the hemisphere, R, can be determined using Equation 19, as previously derived. To generate the hemisphere in KENO-V.a, the chord, C, needs to be determined. The chord is determined according to Equation 18, where the height of the hemispherical slice, h, is determined using Equation 21 and the sphere radius, R, is determined according to the previous paragraph. 4.3.5 Summary Of Equations To Use For Hemispheres An exact hemisphere is calculated using Equation 13 to determine the spherical radius of the hemisphere, R. An enclosing hemisphere is calculated using Equation 17 to determine the spherical radius of the hemisphere, R, and Equation 6 to determine the hemispherical slice height, h. A hemisphere of equivalent height and volume is calculated using Equation 6 to determine the hemispherical slice height, h, and then using Equation 19 and the resolved value for h, the spherical radius of the hemisphere, R, is determined. A hemisphere of equivalent volume and angle of repose is calculated using Equation 21 to determine the hemispherical slice height, h, and then using Equation 19 and the resolved value for h, the spherical radius of the hemisphere, R, is determined. Finally, if the KENO chord function is being used, the chord value is calculated using Equation 18 while using the values derived for R and h. 5.0 ADDITIONAL DERIVATIONS The following derivations are provided to substantiate statements in Section 1.0. 5.1 DETERMINATION OF THE ANGLE OF REPOSE THAT RESULTS IN THE MINIMUM SURFACE AREA TO VOLUME RATIO To determine the angle of repose that results in the minimum surface area to volume ratio, Equation 1 is divided into Equation 2. The following equation results: Surface Area R R2 + h2 + R2 = Volume 1 2 3R h R R2 + h2 1 2 3R h R2 +1 2 3R h 3 R2 + h2 3 +h . Rh (Eqn. 22) Substitute Equation 4 into Equation 22: 3 R2 + R2 tan2 3 + R2 tan R tan 3 1 + tan2 3 + . R tan R tan (Eqn. 23) Substituting Equation 4 into Equation 1 and solving for tan yields: 1 V = 3 R2 h 1 V = 3 R3 tan tan = 3V . R3 Substituting Equation 24 into Equation 23 yields: 3 3V 2 1 + 3 3 R + 3V 3V R 3 3 tan R R (Eqn. 24) 9V 1 + 2 6 R R2 + V V 2 R 2 R2 V 2 2 9V R 1 + 2 6 + V R R22 + V R2 2 9V2 R2 2 6 + V V R 2R4 V2 9 R2 + R2 + V . (Eqn. 25) To determine the minimum surface area to volume ratio, take the first derivative of Equation 25 with respect to R, set it equal to zero, and solve for R: (Eqn. 25) = R 2R4 V2 9 R2 9 1/2 R2 2R4 + R2 + V 2 + 2 + R V V = =0 R R 1 2R4 9 -1/2 42R3 (-2)9 2R 2 + 2 2 + 2 V R V R3 + V = 0 1 2R4 9 -1/2 42R3 18 -2R 2 + 2 2 + 3 = 2 V R V R V 1 2R4 9 -1/2 42R3 18 2 -2R 2 + 2 2 + 3 = 2 V R V R V 1 4 9 -1 2R4 2 + 2 R V 4R2 42R3 182 2 + 3 = R V2 V 16R2 2R4 9 42R3 182 2 + 3 = 2 + 2 2 R V R V V 164R6 1442 324 164R6 1442 + = V4 V2 R6 V4 + V2 2 -1442 324 1442 + 2 6 = V R V2 324 2882 6 = R V2 2882R6 = 324V2 R6 = 324V2 9V2 = 2882 82 2 9V 1/6 R = 2 . 8 (Eqn. 26) To determine the angle of repose that satisfies this value of R, substitute Equation 26 into Equation 24 and solve for : tan = tan = 3V R3 3V 3V 3V 2 3/6 = 2 1/2 = 9V 9V 3V 2 2 8 8 8 tan = 8 = 2 2 = arctan (2 2 ) = 70.5 . 5.2 DETERMINATION OF THE ANGLE OF REPOSE THAT RESULTS IN THE MINIMUM UPPER SURFACE AREA TO VOLUME RATIO To determine the angle of repose that results in the minimum upper surface area to volume ratio, Equation 1 is divided into the first term of Equation 2. The first term of Equation 2 represents the upper surface area of the cone. The following equation results: Surface Area R R2 + h2 = 1 Volume 2 3R h 3 R2 + h2 . Rh (Eqn. 27) Substitute Equation 4 into Equation 27: 3 R2 + R2 tan2 R2 tan 3 1 + tan2 . R tan (Eqn. 28) Substituting Equation 24 into Equation 28 yields: 3 3V 1 + 3 R 3V R 3 R 2 9V 1 + 2 6 R V 2 R 2 R2 V 9V 1 + 2 6 R 2 R22 R2 2 9V2 + 2 6 V V R 2R4 9 V2 + R2 . (Eqn. 29) To determine the minimum upper surface area to volume ratio, take the first derivative of Equation 29 with respect to R, set it equal to zero, and solve for R: (Eqn. 29) = R 2R4 V2 R 9 + R2 = 9 1/2 2R4 V2 + R2 R 1 2R4 9 -1/2 42R3 (-2)9 2 + 2 2 + 2 V R V R3 = 0 =0 42R3 18 2 - 3 = 0 R V 42R3 18 V2 = R3 42R6 = 18V2 R6 = 18V2 9V2 = 42 22 2 9V 1/6 R = 2 . 2 (Eqn. 30) To determine the angle of repose that satisfies this value of R, substitute Equation 30 into Equation 24 and solve for : tan = tan = 3V R3 3V 3V 3V 2 3/6 = 2 1/2 = 9V 9V 3V 2 2 2 2 2 tan = 2 = arctan ( 2 ) = 54.7 . REFERENCES: 1. F. A. Zenz and D. F. Othmer, “Fluidization and Fluid-Particle Systems” in Reinhold Chemical Engineering Series, Reinhold Publishing Corporation, 1960 (p. 140). 2. W. H. Beyer, ed., CRC Standard Mathematical Tables and Formula, 29th Edition, CRC Press, Inc., 1991, Mensuration Formulae (pp. 110 & 111). 3. H. C. Paxton and N. L. Pruvost, “Critical Dimensions of Systems Containing 235U, 239 Pu, and 233U,” LA-10860-MS, July 1987 (p. 19).