Claas Variant 350 baler - Polagra

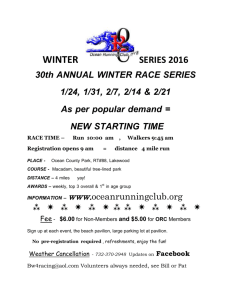

advertisement