Electrical Ground Support System(EGSE) Design for

advertisement

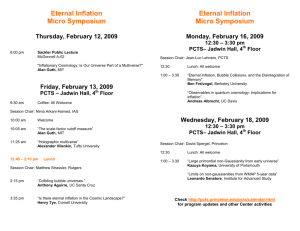

The CBS transponder Testing by the EGSE Jin-Ho Jo, Dong-Han Shin, Jong-Heung Park, Seong-Pal Lee Electronics and Telecommunications Research Institute(ETRI) Yusong P.O box 106, Daejon, KOREA Abstract: Electrical Ground Support Equipment(EGSE) is used to check out satellite payload during the development prior to launch. The main task of EGSE is to check out satellite systems, at system or subsystem level, during integration and validation phases of their life-cycle. This paper represents the EGSE design configurations we implemented for the Communication and Broadcasting Satellite(CBS) transponder performance testing and test results of CBS transponders by the EGSE. Key Words: CBS transponder, EGSE, CTS, PCTS, EQM, FM 1. Introduction Ka-Band Communication Services According to the space development plan of Korean Multimedia service government, CBS payload development project is under Trunk service cooperating between Electronics & Telecommunications VOD service Research Institute(ETRI) and industry in Korea. Broadcasting Services CBS payload is consists of Ku/Ka band transponders and DTH service antennas. In CBS payload development project, ETRI plan to develop EQM(Engineering Qualification Model) Table 2 shows the payload specifications of the CBS. The and FM(Flight Model) payload from May 2000 to Fig. 1 shows the CBS transponder configurations. December 2005. This paper represents EGSE design configurations which Table 2 CBS payload specifications was used for the CBS transponder testing and test results Ku-Band of CBS transponder testing by the EGSE. Ka-Band EIRP 52dBW 55.5dBW G/T 9.4dB/K 9.4dB/K 2. CBS Payload Overview Channel BW 36MHz 100MHz The CBS is a GEO satellite for the communication and Service life Over 15 years broadcasting service over the Korea peninsula area. The No. of Channel 3 channels for EQM Table 1 shows the available services requirements by the Redundancy 3 active, 1 backup Antenna type Offset Gregorian CBS. Table 1 Available service by the CBS Transponder Ku-Band The CBS transponder input coupler and output coupler Services are used for the system verification. All the stimulus Communication Services signals are connected to the input test coupler port and all SCPS-QPSK-FDMA(64kbps) the output response signals are monitored at output test HDR(up to 25Mbps) coupler port in the system testing phase. Trunk service(up to 60Mbps) All equipments are redundancy configurations. The LNA VSAT are 2:1 and channel amplifiers and TWTA are 4:1 Broadcasting Services redundancy configuration. The channel amplifier have Analog FM-NTSC color TV two operation mode, one is Fixed Gain Mode(FGM) and MPEG-2 SDTV the other is Automatic Level Control(ALC) mode. All the MPEG-2 HDTV equipments of the CBS transponders are monitored and 1 controlled by the ground TT&C interface. automatic performance measurement, and simultaneously performs the function for routing the output signal to the measurement instrumentation. Transponder performance measurement can be executed accurately as well as fast by using this RF switch matrix. CTS controller has builtin program required for measurement, and appropriately sets the parameters for various instruments according to each measurement, and provides the function for automatic measurement by controlling the various switch operations of switch matrix. CTS controller stores the measurement results in the DB, and compares the results with the specification, and also printout the results. Ku/Ka CBS Transponder Fig.1 CBS Ka band payload block diagram Stimulus LO Response PCTS CTS 2. EGSE Overview 70VDC CMD TLM RF Switch Matrix Test Point Box The main task of EGSE is to check out satellite systems, at system or subsystem level, during integration and validation phases of their life-cycle. Through a combination of hardware and software elements, EGSE Control Stimulus LO Response DC Power Supply Payload Interface Unit RF Stimulus & monitor Instrumentation GPIB GPIB MIL-1553B supports manual, semi-automatic and fully automated testing. Automation is achieved by offering users simple, yet powerful means to write their own test application programs (test sequences) in high-level, test-oriented language and to run them in a strict real-time CTS Controller (C1) PCTS Controller (C2) Fig.2 EGSE configuration environment. The core of this environment is a userconfigurable real-time database, containing all the PCTS controls the parameters of various transponder information needed to calibrate acquired data, check equipments as well as performs the function for them against predefined thresholds, automatically react monitoring each equipment operation status. PIU to out-of-range conditions, display data using animated receives transponder control command generated from graphics or synoptic windows, and so on. the PCTS controller, and transfers it to the transponder Fig.2 shows the configuration of EGSE being developed after transforming to the suitable command format. PIU for CBS EQM transponder testing. EGSE comprises two also receives the operation status as telemetry, and parts, namely CTS and PCTS. CTS perform the function transfers this message to the PCTS controller by for accurate automatic testing of transponder RF transforming to MIL-1553B format. PCTS controller also performance. provides operator GUI environment, and interfaces with RF stimulus & monitor instrumentation module of CTS PIU for command generation and monitoring of consists of signal generator and signal measurement transponder. PCTS also supplies DC power required for device, which generates various signals required for the operation of transponder equipments. transponder performance measurement, and analyzes the CTS controller and PCTS controller have connected by transponder output signals. TCP/IP, and share various information required for test, RF switch matrix routes and transfers the signal to the control and monitor of transponder. transponder generated from RF stimulus & monitor 3. EGSE H/W Design instrumentation suitable to each measurement item for 3.1 CTS H/W Design CTS H/W comprises three parts: RF stimulus & monitor supply function, and command & telemetry function for instrumentation, CTS controller, and RF switch matrix. the equipments of Ka/Ku-band transponders. RF stimulus & monitor instrumentation consists of CW overall PCTS configuration is shown in Fig.4. generator, Sweep generator, Spectrum analyzer, Vector The PCTS has a DC power supply for providing +70 V network analyzer, Power meter, Attenuator & switch system power to Ka/Ku transponders during the ground driver and Data acquisition unit. These equipments GPIB test. interfaced with CTS controller, and operation parameters power to D/C, TWTA, and also for generating the of the equipments are controlled as well as monitored by secondary the CTS controller. transponder. CTS controller configured with PC of windows98 The PIU of PCTS will provide command(CMD) and environment. CTS controller has a built-in test sequence telemetry(TLM) function for configuring the components program for transponder performance testing, and of transponder during the ground test. In general, these provides functions for collecting and storing transponder CMD & TLM I/O interfaces are used to distribute measurement results, and printing out the results of commands to the payload and to gather telemetry from comparisons controller the payload. For this function, PCTS has the PCTS interfaces with PCTS controller through the hub, and controller and the PIU which are connected with MIL- shares the data each other. STD-1553B data bus. The RF switch matrix module located in the EGSE, will command data which will be sent to the PIU and serve as a central interface between the measurement and monitors the telemetry data which will be sent from the stimulus equipment and the Unit Under Testing(UUT). PIU, and the PIU is used to distribute commands to the All signal connections to the UUT will be made through payload and to gather telemetry from the payload. this switch matrix at all the test modes. The RF switch data between the PCTS controller and PIU is transferred matrix will contain the necessary circuitry for switching via the MIL-STD-1553B data bus, with the PCTS and routing the UUT stimulus and response signal to and controller acting as the bus controller and the PIU acting from the appropriate measurement instrumentations. It as remote terminal. with specifications. CTS The The +70 V will be used for providing primary voltages will also provide external auxiliary ports, where in DC/DC converter of the The PCTS controller generates All Fig.4 PCTS Configuration appropriate, for injection or monitoring of special signals. Fig.3 shows the CTS configuration. Ku/Ka band CBS Transponder Fig.3 CTS Configuration TLM Ku/Ka CBS Transponder CW Gen. Test Point Box Switched 70VDC Payload Interface Unit (PIU) Input Test Coupler Sweeper Spectrum Analyzer CMD MIL-1553B RF Switch Matrix LO Test CPL To CTS Controller ethernet GPIB 70VDC 70VDC PSU PCTS Controller 4. EGSE S/W Design VNA Ouput Test Coupler Power Meter The EGSE software was designed in a hierarchical structure. This was implemented by building standard functions that perform discrete tasks. These functions are CTS Module Atten/SW Control Data Acquision then called at many points in the software, the reuse of GPIB these functions minimizes the size and complexity of the CTS Controller 3.2 PCTS H/W Design The PCTS is used to provide the +70 V Main power total system. Code that is modified is automatically updated in all modules that use the specified routines, additionally this allows for easier maintenance of the accessible from program control, which includes, but is system software. The EGSE software is divided into 3 not limited to manual configuration and storage of the RF primary systems as CTS system, PCTS system and switch setup, graphical representation of the active RF PODS. The overall EGSE S/W configuration is shown in path, access to the system calibration files for graphical Fig.5. viewing and printing, and the ability to upload correction CTS system performs all RF data collection. It has the factors to the RF instruments. responsibility of controlling all RF data collection, EGSE The test scheduler is responsible for launching the RF switch matrix, and calibration. It makes all of the specific battery of tests required for the selected required RF test measurements. operational mode. It will provide the core ABORT PCTS system is responsible for DC stimulus, command control for the individual test routine, or the entire and telemetry functions for the EGSE test system. battery of tests to be terminated. The test scheduler also PODS(Paper On Demand System) is responsible for allows the operator to programmatically retile, and bring supplying all hardcopy data as well as a means of data the current test windows to the foreground at any time archival and storage. Data is able to be viewed, analyzed during the testing process. immediately after the data collection has been performed The calibration routine is invoked from the Test without interfering with the RF data collection process. Executive program. It allows the user to independently Fig.5 EGSE Software Configuration calibrate the EGSE RF paths. This routine contain built in self checks to reduce calibration errors by insuring that the selected paths are physically connected. The system PCTS System Data Acquisition Data Transmitter/ Receiver stores the calibration files in standard ASCII format. CMD & TLM Subroutine System calibration values can be viewed in the utilities CTS System menu. In addition the center frequency calibration values PODS System Test Executive User Interface Abort TCP/IP RF Test Data Files Print Manager User Interface Data control all of the EGSE switching for the selected paths. Summary File Update Test Scheduler Data EGSE configuration program supply the user with a Print? Automated Test Martix EGSE Configuration will be printed on the data hardcopy. This routine can EGSE Utilities Calibration Routine RF Test Routines means of interactively updating the operation of the Yse No Print Data Store Data EGSE through a GUI. It Data Reprint allow the user to change the active test level, EGSE operational mode, and load the Printer ASCII.INI files to the binary encoded system files for 4.1 CTS System program use. The user also able to define EGSE RF The CTS system software is running on the Microsoft switch paths, calibration files, define payload switch Window 98 operating system. It was written in the configuration graphical programming language and developed with information. and review configuration control National Instrument LabView. Test executive is a small low overhead routine that 4.2 PCTS System launches at system that is responsible for enabling user PCTS System is the PC-based system with MIL-STD- access to automated EGSE functions. When testing is 1553B I/F card for the telemetry data transfer, which are selected to run, the test executive will prompt the all COTS (Commercial off-the-shelf) products. The operator for the required information to begin testing. application software on Windows-NT is coded in C++ Based on the operator’s input, only the test modules that language, and consists of two tasks as shown in Fig.6. have been selected will be loaded into system memory. For the GPIB interface, GPIB command is formatted in At the conclusion of testing, utilities, or calibration, the GPIB interface function, and sent to Power Supply for system will return to the test executive main screen, and +70V power on, and the GPIB telemetry is collected and remain there until another function has been selected. displayed on the telemetry window of GUI. The Utility software bundle provide the operator with the ability to access EGSE functions that are normally Fig.6 Task Diagram of PCTS System DC Power Supply PIU hardcopy results when desired. The system can be CMD TLM configured as that the user can view the data, on the 1553B I/F GPIB I/F WrapArround RD CMD DISC CMD Heater CMD Bi. Serial CMD TLM (PA/AA/DG/Heater/Serial /CMD Status) PODS monitor, in its final form prior to printout. In this way the user can decide which data is generated into hardcopy. CMD TLM CMD DB TLM Display GUI TLM DB Each data file contains a data page revision that is allow archived data to be viewed in it’s original form if the data CMD GUI page format is incompatible with the current version. HDD Event Log CMD/TLM Data Batch printing can be accomplished by creating a .LST Event/Error Display GUI Error/Event Data file in a standard ASCII editor with the filenames of the data to be printed out. This file can then be copied into The 1553B command function is quite simple. Each the print directory of the PODS minimizes the amount of command to be transferred is selected on the command ‘non-essential’ hardcopy test results due to system aborts, window of GUI, and frame formatted in 1553B interface incorrect setup, special testing, etc. function for 1553B command. And then, this formatted The test computer will create all archive data files in command is sent to the transponder through the PIU for standard ASCII delimited format. This feature of the the command execution. For the 1553B telemetry system is allowed viewing on multiple platforms for monitoring future retrieval/off line post processing in database function, PCTS system operation is performed as follows: programs such as Excel, Dbase, Lotus etc. This process At first, the PCTS controller sends a kind of telemetry will update a test summary data file that can be used to request to the PIU such that the PIU can send the easily identify completed/remaining tests. This is done telemetry raw data in response to it. And then, when the when the PODS write the data file to the archive data raw telemetry data frame comes, it is parsed into each storage directory. mnemonic in accordance with the telemetry database. The parsed telemetry mnemonic is converted with 5. Testing engineering unit data to represent a physical value of the EGSE have two different kinds of modes for the telemetry. For the analog telemetry, this engineering unit operation, the component level testing mode and system data is calculated from a fifth-order polynomial equation level testing mode. of its calibration equation curve with coefficients in In component level testing mode, EGSE operation is telemetry database for every mnemonic. And, for the manual for the RF performance testing of the transponder digital telemetry and heater status, this engineering unit components. In this mode operation, special utility value that is character type is decided in accordance with software tools are allows EGSE user to configure discrete state of “0” and “1” in telemetry database for switches in the test system and also to plot display each mnemonic. contents to the system printer. Finally, these EU values of telemetry are displayed on the Most of EGSE testing are performed automatically by telemetry GUI, and stored into hard disk of BC Station RF testing sequence program S/W in system level test simultaneously. For event log function, the system mode. Before test, EGSE performs calibration procedure gathers all control and status information including for getting accurate testing results. RF testing sequence command sent, errors, etc.. And the gathered Event log program is consist of test sequences for the transponder will be displayed on the GUI, and stored into the hard RF performance testing. It performs RF stimulus disk. generation, switch control and data gathering and analysis through equipment control. 4.3 PODS System The PODS allows the EGSE to be configured to deliver 5.1 RF Performance Test Before satellite transponder testing, EGSE performed function to the operator and data analysis functions. transponder functional The implemented EGSE was used for the CBS EQM verification it self. The satellite transponder simulator has level transponder testing in the laboratory. EGSE will same structure and functions with satellite transponder plan to be used for the FM model transponder testing. simulator testing for the except it have only one RF channel. After EGSE verification with simulator testing, EGSE performed satellite transponder RF performance testing. The parameters of the satellite transponder RF performance testing by EGSE were as following, Input, output VSWR Noise figure Saturation output power Phase shift AM/PM conversion coefficient Channel amplifier gain control functions LO frequency stability In band frequency response & group delay Out of band frequency response Inter-modulation characteristics Fig.7 Transfer function of Ku band transponder Spurious output Over drive conditions References: [1] Nicklaussen, D., “The `Abrixas' EGSE Architecture Except VSWR measurement, all the testing on above are performed automatically by EGSE. The VSWR measurements are manual. 5.2 Test Results The RF performance testing for the Ku/Ka band CBS transponder was performed over 3 month in Korea facilities. The testing environmental were nominal, thermal cycling and vibration conditions. In total 143 testing items, some of testing results were not comply requirement specifications slightly. But these no comply items do not affect overall system performance. The Fig.7 shows a test result sheet of the transfer function of the Ku band CBS transponder. 6. Conclusion The EGSE described on above, is a self contained semimobile test station for the CBS transponder testing. It has capability of performing several different tasks. The EGSE can measure many RF performances of the CBS transponder automatically. It has capability of monitor status and control commands for transponder. It also provides in both real time and port test mode data review and EGSE Software Development Approach,” ESA report to the ... COSPAR meeting, Vol. 409, 1997, pp. 37-42. [2] Kaufeler, J.-F., “ESA Committee for Operation & EGSE Standardization: Its Contribution to ECSS,” ESA report to the ... COSPAR meeting, Vol.394, No.3, 1996, pp. 1153-1160. [3] Jones, M. Melton, B. Bandecchi, M., “TEAMSAT's Low-Cost EGSE and Mission Control Systems,” ESA bulletin. Bulletin ASE, No 95, 1998, pp. 152-157. [4] Chiroli, P. Martinelli, E., “ECHO: A "Core EGSE SW" Running on Windows-NT,” ESA report to the ... COSPAR meeting, Vol. 457, 2000, pp. 439-446. [5] La Rosa, G. Gianotti, F. Fazio, G. Segreto, A. Stephen, J. Trifoglio, M., “The EGSE Science Software of the IBIS Instrument On-Board INTEGRAL Satellite,” AIP conference proceedings, No. 510, 2000, pp. 693-697. [6] Tri T. Ha, Digital Communication System, 2nd ed., New York: McGraw-Hill, 1990. [7] T. Pratt and C. W. Bostian, Communications. New York: Wiley, 1986. Satellite