E. Translation of Program Expenses to FERC Accounts

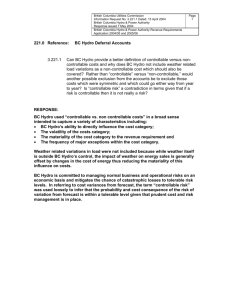

advertisement