Module 7

advertisement

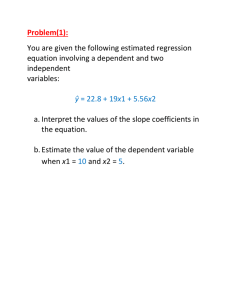

Concept of Cost Estimation 1. Identify . . . 3. This results in reduced . . . Relationship between activities and costs Costs We estimate costs to: manage costs make decisions plan & set standards. 2. Manage . . . Activities 1 One Cost Driver and Fixed/Variable Cost Behavior TC = F + VX Where: TC = Total Costs F = Fixed Costs V = Var. Cost Driver Rate X = # of Cost Driver Units This model ignores other cost behaviors and other cost drivers. 2 One Cost Driver and Fixed/Variable Cost Behavior TC = $190 + (.16 x Miles Driven) 600 510 500 Cost 400 350 300 200 $.16 190 Slope = Cost Driver Rate = ΔY/ΔX 100 Intercept = Fixed 3000 Cost 0 0 1000 2000 Miles driven per month 3 Cost Estimation Methods Regression Analysis A statistical method used to create an equation relating independent (or X) variables to dependent (or Y) variables. Past data is used to estimate relationships between costs and activities. Independent variables are the cost drivers that are correlated with the dependent variables. Dependent variables are caused by the independent variables. 4 Cost Estimation Methods Regression Analysis The simple cost model is actually a regression model: TC = F + VX Caution: Before doing the analysis, take time to determine if a logical relationship between the variables exists. Click This model will only be useful within a relevant range of activity. ? Here 5 Cost Estimation Methods Regression Analysis A set of data can be regressed using several techniques: •Manual computations •SPSS or SAS Statistical Software •Excel or other spreadsheet The result of the regression process is a regression model: TC = F + VX Each regression model has an R-square (R2) measure of how good the model is. Range of R2 = 0 to 1.0 6 Cost Estimation Methods Multiple Regression Analysis Multiple Regression is a regression that has more than one independent (X) variable. For example, demand Want an for a product may be example? affected by things such as inflation, interest rates, and competitors’ prices. Can be very useful in situations where the dependent variable is impacted by several different independent variables. 7 Cost Estimation Methods Account Analysis A method that looks at past costs to estimate current cost-driver rates. Break costs into categories corresponding to each cost driver. Sum total costs for each cost driver category. Divide total cost for a given cost driver category by cost driver volume. 8 More expensive than regression, and requires more detailed breakdown of costs. Cost Estimation Methods Engineering Method Cost estimates based on measurement and pricing of the work involved in the activities that go into a product. Not based on past costs. 9 WHY DO WE NEED TO ESTIMATE COSTS? CONTROL PURPOSES – STANDARD COSTS COST ALLOCATION-IDENTIFY SUITABLE COST DRIVERS DECISION MAKING-PRICING OF FUTURE PRODUCTION BREAK-EVEN ANALYSIS (NEXT CHAPTER) 10 REGRESSION ANALYSIS: TC = F + VX TC = F + V1X1 + V2X2 + V3X3 + V4X4 (1) where TC = total cost; F = fixed costs; V = variable cost per unit; X number of units produced; V1 = variable cost (#1) per unit of cost driver (for example, machine hours); X1 = number of units of costs driver consumed in the total production (machine hours). Regression Estimation of Equation (1) TC = α0 + α1X1 + α2X2 + α3X3 + α4X4 + (estimation error) (2) where TC = dependent variable; α0 = intercept (measures fixed costs); α1, etc. = regression coefficients (estimates of V1, etc.); X1, etc. = independent variables (as in equation 1) Standard Regression Output: Coefficients Estimates Standard Errors α0 α1 α2 α3 α4 $5.9 mill. $2.1/mach hr. $1.3/labr hr. $9.1/cubic ft. $5.5/units produced 6.1 1.0 1.1 4.2 3.9 t-statistics* Conclusion 0.97 2.1 1.18 2.17 1.41 Not significant Significantly > 0 Not significant Significantly > 0 Not significant * t-statistics = (Estimate / Standard error) = 5.9 / 6.1 = 0.97 Rule: If -2 < t < 2 then coefficient is not significant (not different from zero) If t < -2 or t > 2 then coefficient is significant (different from zero) R2 (R square) is a measure of "goodness of fit". It tells us how well the regression equation describes the actual cost generating process. R2 lies between 0 and 1. A 0 implies a "poor" fit; a 1 implies a "perfect fit"; a 0.5 implies a "good fit." If there are two regressions equations to choose from, the one with the higher R2 should be selected. 11 Case Study: United Packaging Evaluating alternative regression functions, accrual accounting adjustments Trevor Kennedy, the cost analyst at a can manufacturing plant of United Packaging, used a regression model to examine the relationship between total engineering support costs reported in the plant records and machine hours. After further discussion with the operating manager, Kennedy discovers that the materials and parts numbers reported in the monthly records are on an “as purchased” basis and not on an “as used” or accrual accounting basis. By examining materials and parts usage records, Kennedy is able to restate the materials and parts costs to an “as used” basis. (No restatement of the labor costs was necessary.) The reported and restated costs follow:(1) (2) (3) (4) (5) = (2) + (3) (6) = (2) (4) (7) Total Materials Materials Engineering Labor: and Parts: and Parts: Support: Reported Reported Restated Reported Month Costs Costs Costs Costs March $347 $847 $182 $1,194 April 521 0 411 521 May 398 0 268 398 June 355 961 228 1,316 July 473 0 348 473 August 617 0 349 617 September 245 821 125 1,066 October 487 0 364 487 November 431 0 290 431 Total Engineering Support: Restated Costs $529 932 666 583 321 966 370 351 721 Machine Hours 30 63 49 38 57 73 19 53 42 The regression results, when total engineering support reported costs (Column 5) are used as the dependent variable, are : Regression 1: Engineering Support Reported Costs =f(Machine Hours) Variable Coefficient Constant 1,393.20 Independent variable 1: Machine hours -14.23 r² = 0.43 : Durbin-Watson statistic = 2.26 Standard Error 305.68 t-Value 4.56 6.15 -2.31 The regression results, when total engineering support restated costs (Column 6) are used as the dependent variable, are: 12 Regression 2: Engineering Support Restated Costs = f (Machine Hours) Variable Coefficient Constant 176.38 Independent variable 1: Machine hours 11.44 r² = 0.94 : Durbin-Watson statistic = 1.31 Standard Error 53.99 t-Value 3.27 1.08 10.59 UNITED PACKAGING: DISCUSSION Required 1. Present a plot of the date for the cost function relating the reported costs for total engineering support to machine hours. Present a plot of the date for the cost function relating the restated costs for totak engineering support to machine hours. Comment on the plots. 2. Contrast and evaluate the cost function estimated with regression using restated date for materials and parts with the cost function estimated with regression using the date reported in the plant records. 3. Kennedy expects 50 machine hours to be worked in December. What engineering support costs should Kennedy budget for December ? 4. What problems might Kennedy encounter when restating the materials and parts costs recorded to an “as used” or accrual accounting basis ? Evaluating alternative regression functions, accrual accounting adjustments. 1. Solution Exhibit 10-C1 presents the two date plots. The plot of engineering support reported costs and machine hours shows two separate groups of date, each of which may be approximated by a separate cost function. The problem arises because the plant records materials and parts costs on an “as purchased” rather than an “as used” basis. The plot of engineering support restated costs and machine hours shows a high positive correlation between the two variables (the coefficient of determination is 0.94) ; a single linear cost function provides a good fit to the data. Better estimates of the cost relation result because Kennedy adjusts the materials and parts costs to an accrual accounting basis. 2. The cost function estimated with engineering support restated costs better approximates the regression analysis assumptions. See Solution Exhibit 10-C2 13 for a comparison of the two regressions. 3. Using the cost function estimated with restated costs, Kennedy should budget $748.38 as engineering support costs for December calculated as follows: Engineering support costs = $176.38 + ($11.44 per hour x 50 hours) = $748.38 4. Problem Kennedy might encounter include: (a) A perpetual inventory system may not be used in this case; the amounts requisitioned likely will not permit an accurate matching of costs with the independent variable on a month-by-month basis. (b) Quality of the source records for usage by engineers may be relatively low; e.g., engineers may requisition materials and parts in batches, but not use them immediately. (c) Records may not distinguish materials and parts for maintenance from materials and parts used for repairs and breakdowns; separate cost functions may be appropriate for the two categories of materials and parts. CRITERION 1. Economic Plausibility 2. Goodness of Fit 3. Significance of Independent Variables Solution Exhibit 10-C2 REGRESSION 1 Dependent Variable: Engineering Support Reported Costs Negative slope relationship is economically implausible over the long run R2 = 0.43 Moderate goodness of fit. t-statistic on machine hours is statistically significant (t = -2.31), albeit economically implausible. 14 REGRESSION 2 Dependent Variable: Engineering Support Restated Costs Positive slope relationship is economically plausible. R2 = 0.94. Excellent Goodness of fit. t-statistic on machine hours is highly statistically significant (t = 10.59).