RAC - pnhgrp.com

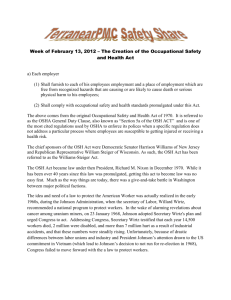

advertisement