Ultrasonic Mixer

advertisement

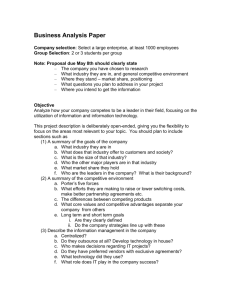

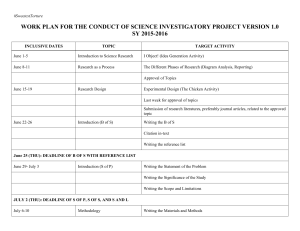

Ultrasonic Mixer Project 99.11 Design Team Members: Katie Kaser katie@udel.edu 731-7638 University Gardens Apartments Newark, DE Lihong Xu arthur@udel.edu 239-4768 Joanna Pirnot 90620@udel.edu 366-7473 Moshe Solomon moshe@udel.edu 455-1246 Sponsor: Don Kupp kupp@frc-de.fraunhofer.com 369-6757 Background Injection molding is an increasingly common manufacturing process, used to produce metal, plastic, and ceramic parts for many applications in medical, biotechnology, automobile, and aerospace industries among others. Plastic injection molding involves melting the thermoplastic material, forcing the molten plastic into a mold cavity, and cooling it to a solid shape. Fine detail and precision are possible, but the quality of the final product is dependent on the quality of the feedstock used to produce it. The PIM (powder injection molding) feedstock that Fraunhofer uses is a metal or ceramic powder in a polymer matrix. It must be a homogeneous mixture, and its homogeneity is determined by the quality of the mixing and compounding steps that disperse the powder into the melted polymer. The next step in processing is to chemically remove all of the polymer from the molded piece, leaving a solid metal part. Currently, the technology used to create the PIM feedstock is a complex mechanical mixer. Problem Statement Traditional mechanical mixers have a number of drawbacks. Because of the complexity of the problem – the necessity of melting the polymer, mixing in the metal powder with mixing screws, carefully controlling temperature and composition of the mixture – mechanical mixers are often large and expensive. The abrasive nature of the metal powder causes wear on the mechanical parts, and as the mixer components wear away, the feedstock can be contaminated. The PIM feedstock is also highly viscous, requiring the mechanical mixer to use a lot of energy. If the mechanical energy source is replaced with an ultrasonic energy source, similar mixing results should be achievable, however certain drawbacks of the mechanical mixer will be eliminated. Ultrasonic mixers are already in use for a variety of applications, including biological research. However, the existing ultrasonic mixers are used for much lower viscosity liquids. Many existing ultrasonic equipment can only handle temperatures up to 150C. Therefore it is necessary to design a new mixing system to deal with the PIM feedstocks. An ultrasonic mixer offers non-mechanical means to create homogenous mixtures of fine powders in a polymer melt, for polymer systems with less than 200C degrees melting temperatures. A non-mechanical mixing device would have several advantages over the existing mixers. Less wear from abrasion should occur, since there would be no mixing components directly in contact with the powder/polymer mix. The difficulty of mixing would be lessened by the use of a high-energy ultrasonic source. Also, the need to elevate the temperature could be assisted by the ultrasonic waves, so reducing the external heat application should be possible. Cleaning of the mixing chamber would also be easy compared to the cleaning of the complex mechanical mixer. A successful nonmechanical mixer would benefit any lab or industry carrying out powder injection molding. Mission Our mission is to design a system incorporating a suitable non-mechanical device for homogenizing powder injection molding feedstocks into relatively high viscosity liquids, by April 1999. We will be using the engineering method, collecting wants and constraints, and selecting the best concept to fulfill our mission. Customers Our primary customer is our sponsor, Fraunhofer, and the company representative we are contacting is Don Kupp. Their wants and constraints are the most important to satisfy, because the satisfaction of the user at Fraunhofer will determine the future use of the design. Also, as they only require lab scale equipment, their wants will be easier to satisfy with an initial prototype than the wants of our industry customers. Many of Fraunhofer’s wants and constraints have already been established. Wants: 1. Produce a measurable quantity of material Metric: Greater than 100 grams/hour 2. Suitable temperature control 3. Easy to clean equipment Disassembly possible and easy 4. Have a system which can handle a variety of materials Metric: handle a range of viscosity up to 1000 Pa*s 5. Avoid excessive cost 6. Durable equipment 7. Sensor for viscosity and temperature 8. Method to feed material into device 9. Have reliable performance Repeatable results 10. Easy to use system Constraints: 1. Completion of design project by April 1999 2. Produce a homogenous mixture of powder injection molding feedstock 3. Produce material in a usable form Our other customers include companies which sell or manufacture ultrasonic mixing devices; among these, Advanced Sonic Processing Systems (David Hunicke), Berliner Ultrasonic Processing (Mr. Berliner), Sonic Corporation (Claire Skidd), and Nirvanatron Ultrasonics (D. Ciervo). Other customers would include people who would actually be operating the equipment, such as lab technicians. These people’s wants and constraints will also help determine our focus in the project. (See Appendix 5 for SSD sheet) Wants: 1. Ease of use (controls) On/off switch, feedback mechanisms, automatic temperature/frequency adjustment 2. Easy to clean and maintain Disassembly possible 3. Temperature control 4. Longevity of mixer 5. Ability to handle highly viscous materials Constraint: 1. Sealed and electrically safe product Metric: NEMA (National Electronics Manufacturing Association) rating of 4 or higher Meet NEC (National Electrical Code) standards Benchmarking Given the problem statement, and some wants and constraints, we decided that there were three areas we needed to benchmark. 1. Mechanical mixers, because they successfully produce a homogenous mixture 2. Ultrasonic mixers, because they are non-mechanical and fulfill many of our other wants 3. Metal powders, because their properties are of concern in the mixing process In the first of these three areas, we found a number of companies that are major suppliers of mechanical mixing devices: D-Tex, POMINI, and Leistritz. These mixers operate by extruding the feedstock through co-rotating or counter rotating screws. The mixing time is variable, feeding mechanisms are included, and the material can be extruded into the desired shape. Many mechanical mixers have features that match some of our other customer wants, such as thermal sensors, automatic frequency and amplitude controls, and safeties against overload or overheating. We may be able to incorporate some of their same controls into our design for a non-mechanical mixer, therefore we will continue to look at them. See Appendix 1. Ultrasonic mixers on the market are available in several forms. We obtained a list of 16 companies that specialize in ultrasonics in order to begin our benchmarking. See Appendix 2. One type of mixer involves placing an acoustical tool, known as a probe or horn, into the solution you want to mix. The electrical energy from your power supply is transmitted to the transducer, where it is changed into mechanical vibrations. The probe, creating pressure waves within the solution, intensifies these vibrations. Millions of microscopic bubbles are formed; they expand during the negative pressure excursion and collapse during the positive pressure excursion. This is referred to as cavitation, and the intensity of the cavitation depends on the amplitude of the probe and the properties of the medium. Another type of ultrasonic mixer has a closed chamber that the material is fed into. Opposing diaphragm plates and transducers surrounds the chamber. The liquid in contact with the diaphragm plate or sound source is cavitated as described above, and activating the opposing diaphragm plates intensifies the acoustic pressure wave. Implosive forces are created within the processing chamber, which facilitates the mixing. See Appendix 3. Information about metal powders is in Appendix 4. Budget The sponsor has indicated that the budget is not a concern in the design of this project. A meeting, with our sponsor, has been made for the afternoon of 9/23/98 to establish some financial guidelines. Conclusion Our schedule up until this point has dealt with benchmarking products and gathering wants and constraints, to provide useful information about existing equipment that could relate to our purpose. From this point, we will be looking into specific elements that could meet our established wants and requirements, as well as starting our calculations to determine what our power needs are. Our continued research on mechanical and ultrasonic mixers will help us better define our wants and constraints. Our schedule up until the progress review, Oct. 28, 1998, is attached at the end of this report. We will be talking to our sponsor, and considering recommendations of people in industry, to determine if certain existing components can be incorporated into our project. GROUP 11 CODE OF COOPERATION 1. Everyone should participate equally 2. Everyone should agree on meeting times 3. Be flexible about meeting times 4. Everyone attend all meetings 5. Attend all meetings on time 6. Be prepared for meetings 7. Be respectful of each other and each other’s ideas 8. Ask questions if you don’t understand something 9. Help each other when needed 10. Distribute tasks according to people’s strengths 11. Keep other people informed of your work 12. Share responsibility Schedule ID 1 Task Name Duration First meeting with customer 0.06 days Thu 9/17/98 Start Thu 9/17/98 Finish T 2 define project 0.06 days Thu 9/17/98 Thu 9/17/98 1 3 collected list of wants and constraints 0.06 days Thu 9/17/98 Thu 9/17/98 1 4 saw existing equipment 0.03 days Thu 9/17/98 Thu 9/17/98 1 5 introduced to the process of making PIM feedstock and the materials used in the feedstock 0.03 days Thu 9/17/98 Thu 9/17/98 1 3.19 days Mon 9/14/98 Thu 9/17/98 3.19 days Mon 9/14/98 Thu 9/17/98 0.5 days Mon 9/14/98 Mon 9/14/98 0.19 days Thu 9/17/98 Thu 9/17/98 6 7 benchmarking contact manufacturers 8 ultrasonic 9 mechanical mixers 10 contact consultants of ultrasonic processing 0.25 days Mon 9/14/98 Mon 9/14/98 11 contact people in industry or research that would use an ultrasonic mixer 0.13 days Mon 9/14/98 Mon 9/14/98 0.88 days Tue 9/22/98 Tue 9/22/98 12 written proposal 13 oral proposal 1 day Thu 9/24/98 Thu 9/24/98 14 meet with customer 1 day Thu 10/8/98 Thu 10/8/98 15 clarify wants and constraints 1 day Thu 10/8/98 Thu 10/8/98 16 view present ultrasonic mixer 1 day Thu 10/8/98 Thu 10/8/98 1 day Thu 10/8/98 Thu 10/8/98 1 day Tue 9/22/98 Tue 9/22/98 21 days Thu 9/24/98 Thu 10/22/98 17 18 obtain access to laboratory equipment and computers Establish metrics for wants and constraints 19 Brainstorm 20 address whether the process is batch or continuous 21 days Thu 9/24/98 Thu 10/22/98 21 address energy requirements 21 days Thu 9/24/98 Thu 10/22/98 22 21 days Thu 9/24/98 Thu 10/22/98 21 days Thu 9/24/98 Thu 10/22/98 24 research ultrasonic equipment: probes, transducers, etc… determine whether the equipment is mobale or stationary address contamination issues 21 days Thu 9/24/98 Thu 10/22/98 25 address maintenance issues 21 days Thu 9/24/98 Thu 10/22/98 26 determine required sensors: temperature, frequency and amplitude of sound waves, watt meter, viscosity determine production volume 21 days Thu 9/24/98 Thu 10/22/98 21 days Thu 9/24/98 Thu 10/22/98 23 27 28 Progress Review 1 day Wed 10/28/98 Wed 10/28/98 1 Customer Data and Wants Formulation Project Title: Ultrasonic Mixer Mission Statement: Design a system incorporating a suitable non-mechanical device for homogenizing powder injection molding feedstocks into relatively high viscosity liquids. Customer Information Name Organization Want Information 10 Rank 0.45 1st Want 0.25 2nd Want Priority 0.15 3rd Want Don Kupp Fraunhofer 1 Produces a Will be suitable for a Temperature control homogenous mixture variety of materials and viscosities David Hunicke Advanced Sonic Processing Systems 2 Long Life Sealed and Electrically Safe Tim Weaver Penn State University 3 Ability to handle highly viscous materials Temperature control Consistent Performance Dr. Karl Frank Hens Thermat: President and CEO 4 Mr. Berliner Berliner Ultrasonic Processing 5 Claire C. Skidd Sonic Corporation D. Ciervo Nirvanatron Ultrasonics Miriam Blednick The Virtis Company Dennis Atallian General Motors Dr. Majidi UD Material Science Department Produces a Durability: must homogenous mixture account for the fact that the radiating face erodes fairly rapidly Controls: on/off, wattmeter, feedback mechanism/sensor Ability to use a wide variety of materials 0.1 4th Want Repeatability 0.05 5th Want Quantity of product: small Easy to clean and maintain Continuous Processing From an external Ultrasonic source Temperature control