Generating a Production-Time

advertisement

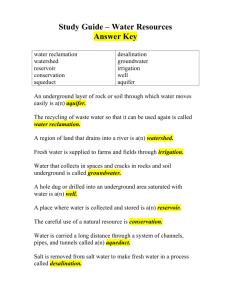

Proposed Module Flow Design Objectives Production time-series analysis has three reservoir-characterization objectives: determine the initial reservoir drive mechanism, understand the effects of previous reservoir production strategies, and, most importantly, understand how the reservoir architecture has influenced fluid flow. The combined influence of these three factors is what has created the reservoir’s production history. Knowledge of their relative effects is critical in reservoir characterization and in determining reserve-growth potential. To achieve the objectives of production time-series analysis, five main tasks must be accomplished, preferably in the order listed below: 1. 2. 3. 4. 5. Analyze initial and spatial time variation of fluid chemistry. Analyze initial conditions for fluid contacts from completion, workover, logs, and pressure. Graph production and annotate along with production-strategy history. Map and analyze time-series history of fluid production. Determine flow direction of injected and encroaching fluids. In this module, we will examine tasks 3, 4, and 5; graphing production and annotating production-strategy history, mapping and analyzing time-series fluid production history, and determining flow direction of injected and encroaching fluids. Module 12 covers the first two tasks to be accomplished when performing production time-series analysis of a reservoir. Knowledge Base Compilation of Completion and Workover Information The compilation of completion and workover information onto maps and logs is critical to understanding effects of previous reservoir-production strategies and what portion of the reservoir the data are associated with. Posting the initial completion date on a base map is the first step in compilation and illustrates both the initial drilling pattern and the relative spatial timing of production. Next, logs should be annotated with initial completion perforations and any subsequent reperforations and workovers, as well as any known production data, such as production rates or cumulative fluid volumes. This information illustrates which genetic units were perforated and produced, along with the timing and production results. Next, completion intervals for each well are posted on the gross sand maps generated when determining the reservoir architecture. This map shows the spatial distribution of completions within each genetic unit and is a first look at possible missed pay zones. Production Time-Series Graphing and Mapping A time-series analysis of fluid flow consists of graphing and mapping of oil, gas, water cut, fluid levels, and pressure-depletion variation over the producing life of a reservoir. Graphing of all produced fluids and pressure is done on both the reservoir and well levels. Reservoir-level graphs illustrate the production of all fluids and should also include the number of wells on line. The wells should be annotated with the timing of any production strategy changes, such as the implementation of secondary or tertiary recovery. Graphs are developed to capture the shortest interval in which data are taken and then are annotated with any workovers that may affect the well performance, such as pumps, well stimulation, tubing changes, and recompletions. Next, fluid-flow trends within the reservoir are established from a set of production-performance maps that illustrate initial potential, cumulative and current production, gas:oil ratio (GOR), fluid levels, water cut, and pressure depletion on a per-well basis. Analysis of these maps captures the historical changes in fluid production throughout the reservoir and highlights important trends in fluid flow. Areas of best production (sweet spots), as well as areas showing impedance to fluid flow, are readily identifiable. Water-cut and pressure maps record the pattern of water migration as reservoir pressures decrease and can highlight preferential pathways of fluid migration. These patterns will most likely indicate fairways of high transmissivity and, thus, reservoir communication. Anomalies in these maps can indicate barriers to fluid flow, which may also indicate reservoir compartmentalization. Four-dimensional seismic is a newly emerging technology in production time-series analysis. It involves the recording of 3-D seismic at two different times in the production life of the reservoir and comparing the differences. Any difference in seismic attributes observed occurs from a change in fluid saturation and thus indicates fluid flow. For example, the encroachment of an aquifer or the expansion of a gas cap could be interpreted from the seismic attributes. Comparison of the initial hydrocarbon-fluid characteristics and the time-series analysis is the primary aid in determining the initial drive mechanism. Monitoring GOR can indicate whether gas-cap expansion or solution-gas drive, or both, are the functioning drive mechanism. Rapidly increasing GOR near the crest of the structure can indicate gas-cap expansion in a reservoir containing initial oil characteristics at or above the bubble-point pressure. A fairly uniform increase in GOR around the field can indicate a solution-gas-drive mechanism and uniform pressure depletion. A time series of the water:oil ratio that displays increases up structure over time can indicate a water-drive mechanism. Another key is whether the oil in the reservoir is undersaturated or saturated with solution gas. An undersaturated oil reservoir can produce substantial volumes of oil with a significant pressure drop before gas will come out of solution in the reservoir. This situation will be seen in a steadily producing GOR at a value near the initial-solution gas:oil ratio. In contrast, saturated oil begins to produce at elevated GOR's soon after production with only a minor pressure drop. Analysis of Pressure History (Step 1) Pressure data can be valuable information in characterizing a reservoir for determining fluid flow compartments. Pressure data are normally obtained from downhole measurement and/or measurement at the wellhead. The pressure measurement desired is the reservoir pressure surrounding the well bore. There are several difficulties to obtaining an actual reservoir pressure. The well must be shut-in a sufficient length of time for the pressure to stabilize so that the measurement does not reflect a transient state. Wells nearby, if not also shut-in, may cause interference from their drawdown, resulting in a measured pressure lower than the actual reservoir pressure. If the well bore is open to more than one production zone the measured pressure may reflect only the most permeable zone. Additionally, if the reservoir pressure has been determined from shut-in wellhead measurements, unknown liquid loading in the well bore may cause the calculated reservoir pressure to be less than the actual pressure. One method of analyzing pressure history is through the concept of material balance. This concept states that in a closed system the moles of hydrocarbons produced must equal the initial moles of hydrocarbons minus the remaining moles (Beggs, 1984). This concept is readily used in the analysis of gas reservoirs where pressure data are periodically measured. When the gas law is applied to this concept it results in the linear equation below, where the x value is Gp and the y value is P/Z. Note that when P/Z (y value) equals zero then Gp/G is equal to one. Therefore, a linear extrapolation of a P/Z vs Gp plot (materialbalance plot) to a value of P/Z equal to zero results in obtaining the original gas in place (G). P/Z = -[Pi/(ZiG)]Gp + Pi/ZI , where P = pressure Z = gas-compressibility factor I = initial oil in place G= original gas in place Gp = cumulative gas produced Gas-material-balance plots, if correctly interpreted, can give valuable information about reservoir character and fluid flow. Characteristics are interpreted from the shape of the material balance plot. (Fig. 1). Changes in the gas-material-balance plots can occur from two sources. The first source is the effect that reservoir-production practices can have on the material-balance plot. For example, a new well drilled in a gas field can change the drainage pattern of the existing well causing "interference," which can reduce the effective drainage area of the existing wells. This interference will cause the slope of the line on the material-balance plot to decrease, reflecting the reduced effective-drainage volume. Perforating a new zone can result in an abrupt increase in the material-balance plot as the pressure from the newly perforated zone increases the overall pressure. Reservoir characteristics are the second control on change in the gas-material-balance plots. The volumetric depletion of a single reservoir compartment results in a straight line that can be extrapolated down to 0 P/z to determine the original gas in place. If, however, a well is perforated in multiple zones that contain highly variable permeability, the resulting material-balance plot will likely not be straight. The more-permeable zones will deplete first, followed by the less-permeable zones, resulting in kinks on the line. The initial drive mechanism also affects the material-balance plot. An aquifer drive will give pressure support to the reservoir, causing the material-balance plot to curve and flatten out at the pressure-support value. Abnormally high pressure (geopressure) can cause the material-balance plot to not decline as the expansion of the sediments occurs, followed by a rapid decline reflecting the depletion of the compartment. See the examples below. (Add links to text and figures) Figure 1 Pressure History Exercise (Step 2) The Lisa # 1 well was completed at 7,800 ft with an initial pressure of 3,435 psi. The production and pressure depletion over the next several years is shown in the table below. Using this information, input the pressure values shown in the table below into spreadsheet5-2.xls (gas gravity), to generate the gas-compressibility coefficient for each pressure and to complete the table below. Well name: Lisa # 1 Cumulative production (MMscf) Pressure Gas(p) compressibility coefficient (z) 0 3435 100 3000 400 2700 700 2500 1100 2300 1600 2200 Once you have completed these steps, a material-balance plot will be automatically generated on the basis of your answers. Study this plot to answer the following questions. For additional help, select Ask the Expert. Well name: Lisa # 1 Cumulative Pressure Gasp/z production (p) compressibility (MMscf) coefficient (z) 0 3435 0.8798 3,904 100 3000 0.8666 3,462 400 2700 0.8624 3,131 700 2500 0.8620 2,900 1100 2300 0.8636 2,663 1600 2200 0.8652 2,543 Graph filled in with results: This plot is automatically generated on the basis of your answers in the table. 1. Does the gas-compressibility factor change linearly as pressure decreases? 2. What is the estimated original gas in place (OGIP) from this material-balance plot? Add Expert Warning here if values do not match exact graph. 3. From analyzing the pressure and production history, what reservoir characteristics can be inferred? Ask the Expert (1) At a constant temperature the gas-compressibility factor is not a linear factor but instead varies in a parabolic manner. An OGIP (original gas in place) could be estimated for these data, but because the plot is somewhat concave, it is likely that these data reflect pressure maintenance because of an active aquifer drive. (Add the answers to the 3 questions here) Water-Production Analysis (Step 3) Water production is one of the most critical fluid-flow trends to understand when identifying reservegrowth potential. The production of water can indicate encroachment of an aquifer, rendering portions of a reservoir void of reserve-growth potential. However, water can often finger or channel into the productive interval, leaving substantial reserve-growth opportunities behind. The risk of additional reservoir development can be substantially reduced when detailed water-production analysis is incorporated into a reservoir-characterization model. Characteristics of Aquifer Encroachment Aquifer encroachment decreases ultimate recovery in gas reservoirs. Encroaching water traps residual gas behind the invading water front and maintains reservoir pressure. These effects reduce the volume of gas that will be produced, as compared with conventional pressure depletion. Also, as water volume flowing into the well bore increases, loading can eventually occur, which will effectively kill the free flow of gas, resulting in down time, sporadic well production, costly well maintenance, and, ultimately, abandonment of the well. Additionally, high volumes of produced water can increase disposal costs, rendering a well uneconomic. Careful planning, design, reservoir characterization, and well handling are needed to maximize gas recovery when aquifer encroachment occurs. Oil reservoirs, in contrast to gas reservoirs, can benefit from aquifer encroachment. Water encroachment from a connected aquifer can act as a water drive, maintaining pressure and displacing oil. The maintenance of pressure sustains flow rates, and the displacement of oil by water increases sweep efficiency. Again, if water encroachment is irregular, however, substantial oil can be bypassed, resulting in poor recovery. Aquifer and hydrocarbon-reservoir characteristics and production history govern water encroachment, and understanding these factors is critical to optimizing oil and gas recovery. The main aquifer attributes that influence a hydrocarbon reservoir are aquifer size, pressure, and geologic character. Size and pressure characteristics affect the pressure support transmitted to the hydrocarbon reservoir. The larger the aquifer relative to the hydrocarbon reservoir (dimensionless radii), the greater and longer the pressure support and the higher the recovery efficiency in oil reservoirs. A greater pressure differential between the aquifer and a depleting gas reservoir can reduce ultimate recovery. Recovery efficiencies for gas reservoirs and aquifers at lower initial pressures will be less affected by aquifer encroachment, whereas higher pressure systems may result in faster water encroachment (Agarwal and others, 1965). Permeable and homogeneous aquifer/gas reservoir systems undergo faster water encroachment at higher reservoir pressures and thus have lower gas recovery efficiency. Also, higher residual gas saturation resulting from poor geometry and higher relative permeability to water will lead to lower recovery efficiency. High residual-oil saturation occurs when pressure depletion is not uniform in the oil leg and when the oil has high viscosity relative to the encroaching water. Overall, characteristics that promote water influx and decrease oil or gas reservoir incremental pressure drop cause lower recovery efficiency. See Figure 2. Production history also influences aquifer encroachment. An increased gas production rate can result in an increased recovery of gas (Agarwal and others, 1965; Matthes and others, 1973; Lutes and others, 1977). An increased production rate often leads to greater pressure depletion before wells water out, thus resulting in greater gas recovery. The performance parameters proposed by Hower and Jones (1991) illustrate the interrelationship between gas flow rate and reservoir characteristics. High production rates, however, must be designed so that no coning or fingering occurs. Relative permeability and residual gas saturation are important considerations in judging the effectiveness of higher production rates. Permeability, relative permeability, and residual gas saturation characteristics affect the broadness of the pressure gradient between gas reservoir and aquifer. A broad pressure gradient will increase the waterinvaded zone and result in a larger volume of trapped gas. Oil recovery is increased when reservoirpressure depletion is uniform. This uniformity reduces water fingering and, thus, bypassed oil as the aquifer waterfront encroaches. Interpreting Field Data (Step 4) Determining the movement of water into an oil or gas reservoir characterizes the aquifer/hydrocarbon reservoir interaction and aids in reservoir development. Modeling the direction of encroachment is best accomplished by analyzing water/gas ratios (WGR), reservoir pressure, oil—water cut (percent water), downhole production logging-tool response (spinner tests), and produced-water characteristics in a time series of maps. This analysis is dependent on monitoring data at short time intervals so that significant trends can be observed. Map time-series observation facilitates determination of fluid movement in three dimensions and integration of geology and engineering, and it aids in reservoir simulation. Increases in WGR can occur as a result of four different scenarios: (1) water coning or fingering, (2) reservoir communication with a small passive aquifer, (3) reservoir communication with a strong aquifer, and (4) communication with a water zone behind casing. Figure 3 demonstrates these concepts. (Qac784c) An increasing water:hydrocarbon ratio (WHR) is the first phenomenon signifying a water-production problem and possible aquifer encroachment. At the onset of increasing WHR, the possibility that water coning or fingering is occurring in a single well must be suspected. Either of these occurs when a well bore pressure drawdown is high enough to cause a local change in the hydrocarbon—water contact (HWC) such that it comes in contact with the well bore. Reservoirs that have good permeability and/or high permeability heterogeneity are most susceptible to coning and fingering. Diagnostic features of coning or fingering include rapidly increasing WHR or WHR increasing in only one well while others at structurally equivalent positions show no WHR increase (water crosscutting structure). This crosscutting of structure can occur in multiple wells. Coning or fingering may occur when WHR increases rapidly immediately after drawdown on a well has been increased. In some cases, production logging tools can identify whether water is coming from the lowest perforations. A time series of WGR or WOR maps will show a rapid increase in WGR or WOR in localized spots (like bull’s-eyes). Over time, WHR will increase in those wells that have coning or fingering problems. WHR can also increase when a passive or small aquifer is connected to a reservoir (no water drive or only a weak one). In this scenario, a steady WHR increase will occur with a large drop in overall reservoir pressure over an extended period. Aquifer encroachment will gradually follow up structure, with the hydrocarbon—water contact rising on a reservoir scale. Local variation in permeability may cause faster localized WHR changes; however, it is unlikely that water encroachment will crosscut structure significantly. A strong water-drive aquifer can cause the WHR to increase early in the production life of a reservoir. Encroachment of water will follow up structure, increasing the WHR over time, corresponding to overall reservoir pressure drop and cumulative hydrocarbon production. The final scenario that can increase WHR is communication with a water zone behind casing. Water problems occur when poor casing cementation permits water to move between casing and formation. If a water-behind-casing problem results from a poor cement job, the initial WHR may be high and the well may appear to have been completed in the hydrocarbon/water transition zone. When the cement job deteriorates over time, WHR may increase slowly. Water-behind-casing problems can be diagnosed when increasing WHR does not correspond to reservoir cumulative production or pressure changes or when the problem is localized and as a result does not occur in other nearby wells. Monitoring and analyzing reservoir pressure can determine whether water problems are related to one of the four scenarios described earlier and can indicate direction of water influx. Aquifer encroachment causes the rate of pressure depletion to decrease over time with increasing cumulative production. Neither coning and/or fingering nor increased WHR from water behind casing will provide pressure support. A passive aquifer will provide little pressure support. By mapping and interpreting material-balance plots in gas reservoirs, the area for which pressure support is occurring can be determined. Figure 1 illustrates the effect different reservoir characteristics have on material-balance plots. Strong evidence of pressure support is provided when the pressure support corresponds to rapid increases in WHR up structure. The direction of increasing WHR and pressure support illustrates the direction of water encroachment. Production logging tools (spinners) can also assist in determining the characteristics of water production. These tools demonstrate what water volume, different perforations, and/or sandstone zones contribute to total water production. When water is coming almost exclusively from upper perforations, communication with a water zone behind the casing should be suspected; when only the lowest perforations are contributing to water production, however, coning or fingering should be suspected. A specific reservoir sandstone connected to an aquifer may be isolated in the case of multiple sandstone zones. Information gained from production logging tools can guide the use of dual completions, permeability profile modification, and/or selective perforation plugging. Monitoring produced-water chemistry can indicate the origin of water and thus aid in determining water fluid-flow trends. Changing water chemistry should be analyzed over time and between wells. Freshening of produced water may indicate communication with a water zone behind the casing above the reservoir (water dumping), whereas increasing salinity may indicate production from an aquifer that is more saline than the connate water. Proper interpretation can be accomplished only when the specific reservoir water chemistry (as well as that of the overlying and underlying aquifers) is known. Aquifer Encroachment Exercise (Step 5) The reservoir-characterization team has delineated a correlatable fault-bounded genetic unit. Now the aquifer encroachment needs to be interpreted and the team wants to test whether this genetic unit is acting as a flow unit. The production data are to be analyzed in order to answer these questions. First, a time-series analysis of water production is to be performed. The production rate vs. time graphs (5 FlowUnit History Graphs) for oil rate and water cut are provided. Also provided on a map (b3400 structure map) are subsea structure and depth of lowest water production. Use the map and graphs to complete the table (Solution to Aquifer Encroachment Exercise), and determine the timing of initial water breakthrough and the changes of water cut over time. Well name Date of 1st production Depth of lowest perforation (feet ss) 308 310 309 313 329 Look at the map to fill in Depth of lowest perforation and the five graphs in order to put in the Date of 1st production. Now that you have completed the table, answer the following questions. To review the correct results, or for additional help, select Ask the Expert. 1. 2. 3. 4. What is the order in time of water breakthrough for these wells? Does structure affect the encroachment of water? Should the reservoir characterization team consider this genetic unit a flow unit? When well 329 was drilled and completed in June 1991 did it initially produce water-free? Ask the Expert (2) 1. By creating a table of well name, date of first water production and subsea depth of lowest perforation, the order of water break-through can be determined. By mapping the date of first break-through along with the depth of lowest perforation onto a structure map, the movement of water can be assessed. Well name Date of 1st production Depth of lowest Notes perforation (feet ss) 308 January 1970 -3871 Produced water after 1 month of production 310 October 1970 -3869 Produced water after 1 month of production 309 October 1983 -3797 13 years w/o water producing 3.4 MMSTB 313 July 1990 -3734 Produced water after 2 months of production 329 October 1991 -3784 44% water cut for IP 2. Within this area the structure sand-body geometry and production are controlling aquifer encroachment. Water is encroaching up structure from the northeast to the southwest; however, it reached its structural high in the southwest corner before the northwest corner (well 309). This fact indicates that structure alone is not influencing aquifer encroachment. 3. The water encroachment trend indicates that it is likely that this genetic unit is in fluid-flow communication and can therefore be interpreted as a fluid-flow compartment. Figure 4 demonstrates this point. 4. No. From the subsea depths of water encroachment, it is as if the aquifer had encroached up to the depth at which well 329 was perforated. References Agarwal, R. G., Al-Hussainy, R., and Ramey, H. J., Jr., 1965, The importance of water influx in gas reservoirs: AIME, Journal of Petroleum Technology, November, p. 1336–1342. Beggs, D. H., 1984, Gas production operations: Tulsa, Oklahoma, Oil and Gas Consultants International, Inc., 304 p. Hower, T. L., and Jones, R. E., 1991, Predicting recovery of gas reservoirs under waterdrive conditions, in Society of Petroleum Engineers 1991 Annual Technical Conference and Exhibition, Reservoir Engineering Proceedings, SPE No. 22937, p. 525–540. Lutes, J. L., Chiang, C. P., Rossen, R. H., and Brady, M. M., 1977, Accelerated blowdown of a strong water-drive gas reservoir: Journal of Petroleum Technology, December, p. 1533–1538. Matthes, G., Jackson, R. F., Schuler, S., and Marudiak, O. P., 1973, Reservoir evaluation and deliverability study, Bierwang field, West Germany: Journal of Petroleum Technology, January, p. 23–30.