2003-2004 FSAE Suspension Proposal

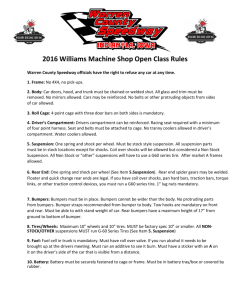

advertisement

2004 Formula SAE Suspension Design The University of Alabama Tuscaloosa, Alabama Department of Mechanical Engineering ME 490 Mechanical Engineering Design II Instructors: Dr. Beth Todd Dr. Joey Parker Client: Dr. Will Sutton Mechanical Engineering Department Head Team Members: Brad Boyer McGhee Caperton Jeremy Hunter Patrick Merry Submittal Date: April 30, 2004 DESIGN PICTURE 2 Figure 1a. 2004 FSAE Front and Rear Suspension Components. Figure 1b. 2004 FSAE Front Suspension Components. 3 EXECUTIVE SUMMARY The purpose of this project is to design, build, and test a suspension system that will be used on the 2004 University of Alabama Formula SAE vehicle. The suspension was designed and built by a team of four students aided by other student SAE members, faculty, and machine shop personnel. The completed suspension includes hubs, spindles, uprights, control arms, push rods, tie rods, rockers, and shocks. The main design issues addressed were the control arm geometry, upright design, and shock selection and placement. The control arm geometry was designed separately for the front and rear, yielding two different solutions tailored to each end of the vehicle. The control arms utilize a short-long arm configuration that gives camber change throughout the suspension travel, allowing for more lateral acceleration to be achieved in cornering. The control arms, tie rods, and push rods were manufactured from 5/8 inch chromoly steel tubing. The upright designs were also tailored to the front and rear of the vehicle. The front upright incorporates a kingpin angle of 6 degrees and a caster angle of 5 degrees. The kingpin angle is part of the 4 bar linkage system (including the control arms) that gives favorable camber change. The caster angle provides auto-centering effects to the front wheels. The front upright also incorporates connections for the steering tie rods, and front brake calipers. The front uprights are manufactured from steel stock and weigh approximately 7 lbs each. The rear uprights have no caster or kingpin angle and have no brake caliper attached but have an adjustment for toe. The rear uprights are machined from aluminum and weigh approximately 2 lbs. each. The shocks for this design are Fox Shox Twin Clickers selected for their reputation, adjustability, and price. The shocks use 500 lbs/inch springs in the front and 600 lbs/inch springs in the rear. The rockers were manufactured from steel stock. 4 The total cost for this project is $2250, and the project took approximately 4 months to complete. 5 TABLE OF CONTENTS Page # I. Glossary II. Introduction III. Design Constraints IV. Final Design A. General B. Control Arms C. Rod Ends D. Shocks E. Front Uprights F. Rear Uprights G. Hubs H. Rockers V. Design Justification A. General B. Control Arms C. Rod Ends D. Shocks/Rockers E. Front Uprights F. Rear Uprights G. Hubs VI. Conclusions VII. Expenses 6 VIII. References IX. Appendices A. AutoCAD Production Drawings B. Hand Calculations C. Excel Spreadsheets D. ADAMS Results E. ANSYS Results F. Purchasing/Vendor Information G. Formula SAE 2004 Rules H. Tire Data I. Bearing Press Fit Data 7 GLOSSARY (v.2) Ackerman’s Principal – While turning, the outer tire follows a larger radius than the inner tire. The geometry used to accomplish this dictates that the tie rod must connect to the front upright along an imaginary line that connects the kingpin axis and the center of the rear drive axis. Figure 2. Ackerman Principle….blah blah. ADAMS - ADAMS/Car is a specialized environment for modeling vehicles. It allows you to create virtual prototypes of vehicle subsystems, and analyze the virtual prototypes much like you would analyze the physical prototypes. ANSYS – ANSYS is a finite-element analysis package used widely in industry to simulate the response of a physical system to structural loading, and thermal and electromagnetic effects. ANSYS uses the finite-element method to solve the underlying governing equations and the associated problem-specific boundary conditions. Anti-dive – A suspension parameter that affects the amount of suspension deflection when the brakes are applied. Anti-squat – A suspension parameter that affects the amount of suspension deflection during acceleration. AutoCAD - AutoCAD is a powerful computer-aided design (CAD) package from AutoDesk, Inc. It was the primary CAD package used for this design. 8 Ball Joint – A spherical joint that allows three degrees of rotational freedom in at a joint. In an automotive context, this most often refers to the upper or lower ball joints on the uprights. Body Roll – The leaning of a vehicle's body to one side when cornering due to lateral acceleration. Bump Steer – Toe-in/out of a tire caused by the change in relative position of the tie rod as the suspension travels through its range of motion. Caster Angle – The caster angle is defined by a line from the upper ball joint to the lower ball joint seen from the side view. This parameter affects the wheels ability to automatically recenter itself. By affecting the scrub radius, it can also make the wheels more difficult to turn. Figure 3. Caster and Kingpin Angle. Camber – The tilting of the wheels about an axis parallel to the direction of vehicle motion. The tilting of the wheel affects the shape of the tire patch and the tractive forces the tire can transmit. Reword Figure 4. Negative wheel camber (Milliken & Milliken, 1995). 9 Center of Gravity – Imaginary location indicating where acceleration forces would act if the mass of the vehicle was assumed to be a point mass. Chassis – The chassis (frame) provides protection and a means for connecting various components of the vehicle. This car utilizes a space frame type constructed from round steel tubing Control Arms – The suspension components that connect the front and rear uprights to the chassis and allow it to move up and down. Also known as A-arms. (Figure 1.b) Cornering Force – The lateral frictional force generated by a cornering tire, acting in opposition to the centrifugal force. Front/Rear Roll Center – Point that the front/rear of the vehicle desires to roll about, determined by the front/rear suspension geometry (Figure 5). Hub – The part of the suspension that the wheel mounts to. The hub is connected to the upright through one or two wheel bearings that allow the wheel-hub assembly to spin freely. (Figure 1.b) Instant center – When looking at the vehicle from the front, the instant center for a pair of control arms is the point at which the control arms would meet if they extended infinitely. Instant Center Roll Center Figure 5. Instant center and roll center placement (Milliken & Milliken, 1995). Jacking – When the tires skip as the vehicle turns. Jounce/Rebound – The motion of the suspension corresponding to positive/negative vertical displacement of the wheels. 10 Kingpin – An imaginary line drawn from the center of the upper ball joint to the center of the lower ball joint. (Figure 3) Push rod – The rod linkage that connects the lower control arm to the rockers, transferring vertical loads from the wheels to the rocker. (Figure 1.b) Ride frequency Ride height – The distance between the lowest part of the chassis and the ground. Rocker – The mechanism that transfers force from the pushrod to the shocks. (Figure 1.b) Rocker ratio Rod end – A spherical joint set in a housing which can be screwed onto the ends of control arms, push rods, or tie rods to allow for spherical movement and adjustable length. Roll Axis – The imaginary line that connects the front and the rear roll centers, about which the body will rotate or roll. Figure 6. Vehicle roll axis. Roll Center – Found by projecting a line from the center of the tire contact patch to the instant center of the upper and lower control arm. (Figure 5) Shocks – The shocks for this vehicle consist of a coil over type piston dampener encased in a spring. The shocks absorb energy from the motion of the vehicle and maintain the vehicle’s ride height. (Figure 1) Scrub radius – The distance between the center of the tire patch and the steering axis. 11 Figure 7. Scrub radius. Spindle – A cantilevered bar connected to the front upright on which the hub is mounted. Steering rack – A rack and pinion system that transmits steering wheel motion into horizontal displacement of the steering tie rod. (Figure 1.b) Tie rod – The simple rod linkage that connects the end of the steering rack with the front uprights, transferring the horizontal motion to the wheels. (Figure 1.b) Tire patch – Area of tire in contact with the ground. Toe-in/out – Toe-in is when the front of the tires angle in towards each other and toe-out is when they angle away from each other(Reword). Track width – Distance between the centers of the tire contact areas when viewing the car from the front. Uprights – The centerpiece of the suspension, the uprights connect the tie rod, the upper and lower ball joints, the brake caliper (front only) and the hub. (Figure 1.b) Wheel hop – When the road excites the wheels at the suspension’s natural frequency and the tires lose contact with the ground. Wheelbase – Distance between the front and rear tire centers. 12 INTRODUCTION The purpose of this project is to design, build, and test a suspension system that will be used on the 2004 UA Formula SAE vehicle. The design process of the vehicle requires that the frame be designed to fit the suspension, which puts priority on completing the suspension design first. A complete and well functioning design will form the foundation for the vehicle and a solid performance by UA at the 2004 Formula SAE Competition in Pontiac, Michigan May 1923, 2004. The design of this suspension includes determining the suspension geometry, mounting points, shock selection, steering behavior, and complete engineering drawings of all parts. All parts of the completed design will be purchased or manufactured and assembled. All engineering and cost analysis will be presented following the format of the Formula SAE Rules. The goal for a suspension system on an SAE Formula vehicle is to maximize the performance and handling characteristics while providing several functions. Some of these functions include: Maintaining wheel steer & camber angles Resisting roll of chassis Keeping wheels in contact with road Providing vertical compliance to isolate the chassis from motions caused by irregularities in road profile The goal of the Formula SAE racecar is to maneuver around a racetrack as quickly as possible, therefore the suspension will be designed to offer maximum tractive force and optimize the vehicle’s road handling. This is accomplished by making a desirable camber angle, creating a low roll center height by the placement of the upper and lower control arms, avoiding wheel hop, and having short-long arm suspension. Control and handling are key factors in determining the performance of a race vehicle. The tie rods must comply with the suspension geometry to prevent bump. The suspension and steering geometries must coincide to provide stable and consistent handling of the vehicle. 13 Designing a suspension is an iterative process. The best performance is a compromise between all performance parameters. The final design should take into consideration the conditions under which the vehicle will be traveling. Because the Formula SAE suspension must steer, travel over bumps, and provide other functions, maximum performance will be a combination of compromises in order to maximize several functions. 14 DESIGN CONSTRAINTS (v.2) Economic – Crimson Racing minimized spending where possible to provide a cost effective design to The University of Alabama Formula Car Team(We manufactured some parts). Environmental –The suspension links, wheels, springs, and other components are largely recyclable materials. Sustainability – The suspension is designed to win at competition with no fractures or bends to any component designed and released by Crimson Racing. Manufacturability – The design is fully manufacturable by any full service machine shop. Ethical – Crimson Racing is in compliance with the ASME Code of Ethics. Health and Safety – The suspension is sized to accommodate the weight of the driver and all components without failure under anticipated race conditions. The location of the suspension components was determined such that they would not present a danger to the driver under normal operating conditions. Social – The car was built in conjunction with other University of Alabama Formula SAE groups, such as engine, frame, and testing groups. A smooth integration was accomplished through team meetings (mention memos, meetings, etc.?). Political – A strong finish at competition will potentially create interest in the University of Alabama’s Mechanical Engineering school to prospective students and professors. 15 FINAL DESIGN The final design for the 2004 University of Alabama Formula SAE suspension meets all of the goals set forth by the design team. The design is a well working suspension consisting of control arms, rod ends, shocks, uprights, hubs, tie rods, push rods, and rockers. This section describes the details of this design, but does not describe the analysis or calculations involved. The next section will discuss these issues. This section includes all the major characteristics of the suspension, both assumed and derived, as well as describes the purchased parts used in the suspension design. General In order to begin the design process, some assumptions had to be made regarding the basic characteristics of the suspension. Chief among these is the center of gravity of the vehicle, which was assumed to be 15 inches above the ground based on research done on typical Formula SAE car characteristics. The wheelbase of the car was chosen to be 60 inches. A track width of 50 inches was chosen, but had to be modified to 52 inches for the front suspension due to space limitations for the driver. Based on the required suspension travel of one inch in jounce and one inch in rebound, the ride height of the car was chosen to be 2 inches. The total weight of the car including the driver was predicted to be 700 lbs, with a weight distribution of 40% in the front and 60% in the rear. Control Arms The suspension will utilize unequal length unparallel control arms with pushrod-activated shock absorbers manufactured from 5/8 inch chromoly tubing. This design was selected using four bar linkage analysis for the front view geometry of each suspension, front and rear. The final lengths and angles from horizontal for each control arm are given in Table 1. The unequal length control arms provide a change in camber of 3.6 degrees front and 6 degrees rear throughout the suspensions travel. The reasons and benefits of the arrangement will be 16 discussed in more detail in the next section of the report. The chosen side view angles were chosen to optimize anti-dive and anti-squat, which are calculated to be 41% and 0% respectively. Picture of front and side view w/dimensions? Table 1. Front and Side View Front Suspension Geometry Front View Geometry Dimensions length angle (inches) (degrees) Upper Control Arm 11.5 8 Lower control arm 13 -7 Kingpin Axis 10 5 Frame Connection 6.8 84.6 orientation from horizontal from horizontal from vertical from vertical Side View Geomtry Dimensions angle orientation (degrees) Upper Control Arm -5 from horizontal Lower Control Arm 5 from horizontal Rear Suspension Geometry Front View Front Geometry Dimensions length angle orientation (inches) (degrees) Upper Control Arm 10.5 10 from horizontal Lower control arm 13 -15 from horizontal Kingpin Axis 10 0 from vertical Frame Connection 5.3 65.3 from vertical Side View Geomtry Dimensions angle orientation (degrees) Upper Control Arm 0 from horizontal Lower Control Arm 0 from horizontal 17 Rod Ends The control arms are fastened to the chassis and uprights by means of adjustable rod ends. Rod ends were chosen based on their versatility, adjustability, and ease of installation. The lower ball joint which connects the uprights to the lower control arm uses a 5/8 inch rod end. This joint requires a larger rod end because the vertical forces on the tires are translated through this joint to the push rods. The rest of the joints sustain very little vertical loading and were sized at 5/16 inch. Shocks The Fox Shox Twin Clicker was chosen as the shock for our design based on their availability and price, adjustability, and reputation. Spring rates for the shocks are chosen based on the geometry of the pushrods and rockers and the desired deflection characteristics at the wheel. The track width determines the weight shift in cornering and is also used to size the springs. The spring rates were chosen to be 500 lbs/inch for the front and 600 lbs/inch for the rear based on these parameters. The details of this process are described in the next section of the report. Front Uprights The front uprights were design to connect all the necessary parts of the suspension as shown in Figure 8. The design incorporates a kingpin angle of 6 degrees and a caster angle of 5 degrees. The design provides a mounting point for the brake caliper as well as a 0.16 inch clearance from the brake rotor. The front uprights are manufactured from steel stock and weigh approximately 7 lbs each. 18 Brake Rotor Tie Rod Brake Caliper Control Arms Front Upright Figure 8. Front upright with attached components. Rear Uprights The design of the rear upright includes no caster or kingpin angle. These features are not necessary for the rear wheels because the toe does not change. The rear uprights are each one piece. Two 6061 aluminum blocks were CNC milled into the 2 lbm shape shown in Figure 9. The upright houses a press fit double roller bearing that allows power to transfer through the center of the upright from the stub axle to the hub. The bearing’s position is maintained with a shoulder and snap-ring enclosure. 19 Figure 9. Rear Upright Design Hubs The wheel hub is the component of the suspension that connects the wheel to the upright via a single or pair of roller bearings. The hubs for the front wheels are (designed for a Ford Pinto class of racing called Mini Stock) from a Ford Pinto and were chosen because they matched the bolt pattern of the wheels that had already been purchased for the vehicle. Using this hub requires the use of the matching spindle which was incorporated into the front upright design. The hub mounts on the spindle over a pair of tapered roller bearings, as shown in Figure 10. The purchasing and vendor information for this hub can be found in Appendix F. 20 Front Upright Spindle Front Hub Figure 10. Front hub and spindle. The rear hub was chosen by another part of the UA Formula SAE team as a part of a hub to hub drive train purchased a set. The decision to use this drive train meant that our rear upright design needed to incorporate rear hub and stub axle as shown in Figure 11. The purchasing and vendor information for this drive system can be found in Appendix F. Figure 11. Rear upright, hub, and stub axle. Rockers 21 The major characteristic of the rocker design is the motion (rocker) ratio. The pushrod attaches to one side and the shock to another as shown in Figure 12. The moment arms for these attachment points and different, giving motion ratios of 0.74 inches per inch for the front rockers and 1.25 inches per inch for the rear rockers. The rockers were manufactures from steel stock and weigh approximately 1.5 lbs each. The details of the motion ratio design are described in the next section of the report. Engineering drawings of the rockers can be found in Appendix A.4. Figure 12. Front rocker design. 22 DESIGN JUSTIFICATION This section of the report will describe the design process, calculation and analysis that lead to the final design of the suspension. While the method of analysis and calculation is described in this section, most of the detailed calculations are left for the appendices. General The Formula SAE rules (Appendix G) state that the vehicle must have 1 inch of jounce and 1 inch of rebound for a total of 2 inches total wheel travel. To make sure this is achieved the suspension is designed to have 1.25 inches of wheel travel in each direction for a total 2.5 inches of wheel travel. It is advantageous to keep suspension travel for a flat surface race vehicle to a minimum to reduce the change in inputs to the vehicle. Highly advanced Formula cars have only 0.5 inches of total travel (Milliken and Milliken 1995). The ground clearance design is focuses on minimizing ride height while providing the required amount of suspension travel. The rules state: “Ground clearance must be sufficient to prevent any portion of the car (other than tires) from touching the ground during track events.” (Appendix G). With the required one inch of jounce incorporated into the design, there is an additional inch provided for appropriate ground clearance during track events. As previously mentioned, the vehicle’s track width in the front and the rear vary. The front track width is 52 inches and the rear trackwidth is 50 inches. 50 inches is 96 percent of 52 inches, therefore satisfying the rule: “The smaller track of the vehicle (front or rear) should be no less than 75% of the larger track.” Control Arms Using an unequal length control arm configuration means that the upper control arm is a different length (shorter) than the lower control arm. The purpose of doing this is to achieve favorable camber change in the wheels during wheel travel. It is easy to imagine that if the control arms were parallel the angle the wheel makes with the road would not change as it moves 23 up and down. However, if the lengths are different as in this case, the wheels can be made to lean into a turn, resulting in more traction, and therefore more acceleration through the turns. Tire data from Goodyear® shows that the tires chosen for this car will be able to develop about 25 lbs more lateral thrust at -3 degrees of camber (Appendix H). For flat tread tires, the general limit to the maximum camber thrust that can be developed is found at about 3 to 5 degrees (Milliken and Milliken 1995). This camber change was used as a guideline for developing the suspension geometry for the Formula car. The geometry chosen for the final design generates a change in camber of 1.8 degrees in the front and 3.0 degrees in the rear at 1 g’ of lateral acceleration. The spreadsheet used to calculate these values also calculates the roll center height, scrub radius, and the length and angle of the frame mounting positions in the front-view geometry. Inputs for these calculations are length and angle of the control arms, length and angle of the kingpin axis, loaded tire radius, distance from the upright to the wheel centerline, and track width. The complete spreadsheet can be found in Appendix C.1. Initial estimates of lengths and angles were based on limiting factors such as inner wheel diameter, track width, and minimum frame width. The final camber profile was chosen to give 3 to 5 degrees of camber without creating a front and rear roll center height above 7 and 11 inches, requiring a large angle from vertical for the frame link, or placing the frame connections of the control arms too close to each other. The resulting camber change with respect to wheel travel for the front suspension is shown in Figure 13. Notice that at the maximum deflection of 1.25 inches, the camber change for the front is approximately 1.8 degrees. The major data extracted from the spreadsheet for the front and rear is represented in Table 2. 24 Camber Angle vs. Wheel Travel 4 3 Camber Angle (deg) 2 1 0 -1 -2 -3 -4 -5 -3 -2 -1 0 1 2 Wheel Travel ( deg) Figure 13. Front camber change with respect to wheel travel. Table 2. Results from camber profile spreadsheet Resulting Suspension Geometry Parameters Front Suspension Frame connection Length (inches) Angle from vertical (degrees) 6.8 85 Roll center height (inches) Scrub radius (inches) 6 3.1 Rear Suspension Frame connection Length (inches) Angle from vertical (degrees) 5.3 63 3 25 Roll center height (inches) Scrub radius (inches) 10.8 3 The front suspension was designed in the side view geometry with anti-dive to allow the control arms to absorb a portion of the breaking forces and prevent the front of the car from hitting the road surface in extreme breaking. The front control arms will absorb 41% of the breaking forces with the remaining forces being absorbed by the shock abosorbers. The front and side view geometries were combined using a descriptive geometry method prescribed by Milliken and Milliken. The two dimensional points from the front and side view geometries are projected into the other’s view and three-dimensional coordinates are extracted. Figure X shows the front control arm layout with the front and side views. Figure X. Front control arm layout For the control arms, 5/8 inch chromoly tubing with a wall thickness of 0.058 inches was chosen. Research of existing cars indicated that 900 lbs. was a good estimate of the maximum axial force on the control arm tubes. A wall thickness of 0.058 inches was desirable to accommodate available rod end inserts, so calculations were done for ½ inch and 5/8 inch diameter tubing to find the appropriate size. Because the A-frame type geometry of the control arms creates unusual end constraints, a pinned-pinned Euler buckling model was used because it is the weakest model.( The results showed that the control arms would certainly not yield) and it would certainly not yield an overestimate of the strength. With this model we found that based on an applied load of 900 lbs. the ½ inch tubing had a safety factor of 2.9, and the 5/8 inch tubing had a safety factor of 6.1. It was also found that the weight difference based on the amount of tubing expected to be used in the car was 2.7 lbs (see calculations in Appendix B) and the price difference was approximately $25 in favor of the ½ inch tubing. The increased price and weight were sacrificed in choosing the 5/8 inch tubing to maintain a high degree of 26 confidence in the strength of the control arms. Complete engineering drawings of the control arms can be found in Appendix A.1. Rod Ends When considering the attachments of the suspension linkages to the frame a few choices came to mind. The choices that we considered were rod ends with tabs, cylindrical bushings, or rod ends without tabs. The placement of cylindrical bushings would be installed directly onto the frame. This means that the bushing would become part of a frame member. This set up is good for the forces that are acting on the suspension but the installation of this is a very difficult process and very time consuming. Next the consideration of using rod ends without tabs. In order to accomplish this, a hole would have to be machined into the frame. When the hole is cut into the frame, the rod end would be inserted into the hole and bolted to the frame. This again is a time consuming method. This method also causes a decline in the durability of the frame because holes are being machined out of the center of the cross members. The final consideration is to use rod ends with tabs. This is the method of welding tabs onto the side of the frame and bolting the rod end to the tabs. This is the better choice for several different reasons. Welded tabs provide an easy installation, easy replacement process for the rod end or tab, and simple adjustability of the rod ends. Also when competing we wanted the replacement of a rod end to be as easy as possible and to allow adjustment through loosening or tightening a rod end. The adjustments would change the features of the suspension allowing the team to run a better race in the competition. The rod ends for the upper control arms were chosen based on the expected load that they will bear. The 5/16 inch rod ends have a manufacturer’s rated radial capacity of 3,577 lbs. which is adequate for our design. The lower rod ends have a more complex loading due to the fact that the vertical loads are transferred through the lower rod end to the pushrod and up to the shocks. A three dimensional model was constructed in ANSYS to solve this problem. The model was 27 created from a cantilever beam model represented by a line meshed with the beam element type. The two inch beam was constrained on one end in all degrees of freedom and loaded on the other end with the maximum expected load as shown in Figure 14. The resulting maximum Von Mises stress was 32.5 ksi (224 MPa). This was acceptable compared with an expected yield stress of approximately 44 ksi. 1 inch 5/16 inch diameter Fz = 350 lbs Fx = 250 lbs Fy = 300 lbs Figure 14. Cantilevered beam model of rod end. Shocks and Rockers The track width, weight of the car, and the center of gravity determine the amount of weight shifted from onto the outside wheels during cornering. For this suspension, the lateral load transfer is calculated to be 58 lbs for the front and 157 lbs for the rear at 1 g’ of lateral acceleration. This is calculated using Excel Spreadsheet in Appendix C.2. To achieve 1.25 inches of wheel travel, the wheel rates must be 46 and 126 lbs/inch for the front and rear, respectively. The wheel rate describes how much force it takes to move the wheel one inch, similar to a spring rate. The wheel rate must be adjusted slightly for the stiffness of the tire. The tire will deflect at an assumed 500 lbs/inch based on data from Goodyear, which means that the rate of change of position of the center of the wheel will be different than the bottom of the tire. Adjusting for this 28 gives wheel center rates of 51 lbs/inch for the front and 168 lbs/inch for the rear. Achieving these design wheel rates involves setting two more parameters, the spring rate of the shocks, and the rocker ratio. The spring rate for the shocks is a fixed number that must be given when ordering the shocks. The rocker ratio describes how the pushrod and the rocker translate the motion of the wheel through to the shocks. Because of the angle and constraints of the pushrod, its motion at the rocker end is in a different direction than its motion at the wheel end. Also the rocker can be designed with different moment arms on the pushrod side and the shock side to give some amount of mechanical advantage. For this design the spring rates for the shocks were chosen to be 500 lbs/inch for the front and 600 lbs/inch for the rear. This results in motion ratios of 0.32 inches of shock travel per inch of wheel travel for the front and 0.53 inches/inch in the rear. The methods used for determining these values are prescribed by Milliken and Milliken (1998) and implemented using a spreadsheet developed for the Formula SAE competition by Mitchell (2001). Some changes were made to this spreadsheet and the formulas used. These changes are reflected in Appendix C.3. The spreadsheet determines the overall motion ratio for the vehicle based on the lateral load transfer, wheel travel and desired spring rate. Another spreadsheet was developed to determine the rocker ratio required to provide the motion ratio. The spreadsheet calculates the change in position of the pushrod with wheel displacement as the input. That value is then multiplied by the rocker ratio to give the displacement of the shock. The final rocker ratio had to be determined after the shocks were placed in a 3D model of the FSAE vehicle. The spreadsheet uses the 3D locations of the pushrod and a root finding method to determine the required rocker ratio. The rocker ratio is then drawn on the 3D model and the pushrod location is determined. The new pushrod location is placed in the spreadsheet and a new rocker ratio is determined. The 29 process was repeated until the rocker ratio was known to a reasonable level of accuracy, in our case four significant digits. The spreadsheet and motion ratio plots are found in Appendix XX. Other characteristics resulting from this design choice include the roll gradient and the ride frequency. The roll gradient describes how much the body rolls about its roll axis per g’ of lateral acceleration. For this design the roll gradient was calculated to be 1.2 degrees per g’. The ride frequency of the car is the natural frequency of the sprung mass system that the suspension creates(Put in Glossary?). This was found to be 1.8 Hz for the front and 2.4 Hz for the rear. The ride frequency is important in determining the dampening required to critically dampen the system. The calculated ride frequencies result in optimum dampening of 81 lbf-s/inch for the front and 54 lbf-s/inch for the rear. This will be achieved using the adjustable dampening characteristics of the chosen shocks, the Fox Shox Twin Clicker motor cycle shock. These shocks were chosen based on their price, adjustability and reputation. The shocks and springs were obtained at a discount price of $300.00(Vendor information is found in Appendix XX) each because of XXXXXXXx. They meet our adjustability needs by having dampening adjustment for both compression and rebound, as well as adjustable spring position, which can be used to set the ride height of the vehicle. Front Uprights Central to the design of a working suspension are the uprights which must be designed to connect most of the major suspension components. For the front uprights this task is especially difficult because it is used to steer the wheels and a brake caliper must also be mounted to the upright. Another challenge when designing the front upright is that the front upright must incorporate a chosen kingpin and caster angle, and attempt to minimize the scrub radius by placing the kingpin axis as far inside the wheel as possible. The final design for the front upright is illustrated earlier in Figure 9. 30 The front upright design for this vehicle includes a kingpin angle of 5 degrees and a caster angle of 6 degrees, as shown in Figure 15. The kingpin angle was determined as part of the 4 bar linkage analysis done to find the control arm geometry. The advantage of this angle is seen in the camber change of the wheel through the wheel travel as discussed in the Control Arms section. The caster angle was chosen to be 6 degrees as a compromise between gaining auto-centering characteristics and increasing the scrub radius. The value for kingpin was recommended to be about 8 degrees by Milliken and Milliken (1995). The caster angle was chosen close the kingpin angle to counter the affects of caster causing the wheels to lean during turning. Figure 15. Caster angle, kingpin angle, and rotor clearance. Another important consideration for the front suspension is clearance from the brake rotor and position of the brake caliper. The back plate of the upright was positioned to provide 0.16 inches of clearance between the upright and the rotor and give an appropriate mounting position for the brake caliper. The front upright was fabricated from steel stock. This was done because the complex geometry of the part reflects a design best manufactured as components and then welded 31 together. The drawings for the individual components can be found in Appendix A. The front upright was modeled in ANSYS as a 3-dimensional solid, but difficulties using the educational version of the program and difficulties with the complex nature of the geometry prevented any useful stress data from being obtained through this method. In the interests of completing the project on time for the team, the decision was made to manufacture the upright and test it to determine if the design was adequate. As aids to the design process, the geometry of the front upright mimics the design of the rear upright. In order to stiffen the design to account for the additional forces from the brakes, support ribs were added from the center cylinder to the rod end connections. The geometry around the brake caliper attachment points was designed to transfer the vertical loads from the brakes over to the rod end connections, where the load will then be transferred to the chassis as shown in Figure 16. Complete engineering drawings of the front upright can be found in Appendix A.2. Figure 16. Front upright load transfer schematic. Rear Upright The design for the rear upright is considerably simpler than the front upright. Because the rear upright has no caster or kingpin angle, no brake caliper mounting point, and a closely 32 connecting toe linkage, both the size and complexity of the upright can be reduced. The rear upright is made from one piece to simplify the fabrication process and to increase the precision of the part. Aluminum was chosen as the work material upon strength verification in ANSYS. An ANSYS analysis screen shot from the rear upright design is shown in Figure 17. The upright was modeled as a solid and meshed using 10-node tetrahedral. Forces were applied to the inside of the inner cylinder to simulate forces transmitted through the wheel bearing. The model was constrained at the upper and lower ball joints just as it is on the car, with the upper ball joint retaining freedom to move in the vertical direction. The element size was necessarily large due to limitations in the number of nodes that the educational version of ANSYS would permit. However, the mesh around the high stress areas of the part was refined to give better accuracy. For this model, the material is aluminum, with an expected yield stress of 40 ksi. The maximum stress as indicated on this part is approximately 5200 psi, thus giving a safety factor of just under 8. This seems large, but due to uncertainty with the program and lack of suitable hand calculation methods to back up the results, the decision was made to leave the high safety factor as is. 33 Figure 17. Rear upright design modeled in ANSYS. A CNC milling machine was used to cut the part to the exact tolerances specified by the drawing. An actual picture of the right rear upright is shown in Figure 18, with the wheel bearing already installed. CNC fabrication proved to be the best method to use for our project, and would also make sense in mass producing this part. The double roller bearings that are contained in the rear upright are press fit (Appendix I). Engineering drawings for the rear upright can be found in Appendix A.3. 34 Figure 18. Right rear upright with press fit wheel bearing. The rear tow linkage seen in Figure 19 enables each rear wheel to be adjusted through ten degrees about the kingpin axis. Ten degrees will be enough for alignment purposes or to adjust the rear of the car for any unusual conditions, such as an accidentally bent control arm from a collision. The toe linkage will attach to a tab welded onto the lower rear control arm and to the lower rear upright. This linkage was placed in this region to avoid bump steer and to reduce clutter in the “busy” rear of the vehicle. Figure 19. Rear tow linkage connected at rear upright. Hubs The hub selection was made in consideration with the bolt spacing of the wheels. The wheels were purchased before the hubs, so it was imperative that the bolt spacing for the hub match the bolt spacing for the wheel. This allowed the front hubs to be purchased. The rear hubs could not be purchased because the drive train team decided to use a hub to hub differential in the rear. A hub to hub differential is a complete set including wheel hubs, drive axles, and a differential that are made to work together. This decision caused a discrepancy between the front and rear bolt spacing. In order to use the rear differential a separate set of wheels with a bolt spacing to match the rear hubs was ordered. Purchasing a hub to hub unit allows for a 35 simplification of the rear drive train design. Different bolt spacing for the front and rear hubs does not constitute any problems. ADAMS Analysis The front suspension was simulated in ADAMS to provide verification for the suspension system. The suspension was constructed and tested using the ADAMS/Car simulator software (FigureX). The suspension was tested with parallel wheel travel, opposite wheel travel and Figure X. Front geometry construction in ADAMS/Car steering. The opposite wheel travel simulation showed that the static roll center height was about 5.7 inches from the ground which is close to the 6 inches determined by the spreadsheet. This case is similar to what the vehicle will experience during cornering. The test showed that the roll center height changes a total of XX inches for a simulation for full jounce to full rebound as seen in Figure X. Large changes in roll center height will change the handling Figure X. Plot of roll center height vs. wheel travel for opposite wheel travel. characteristics of the vehicle. Our total change in roll center height will keep the change handling small. The opposite wheel travel also shows that the roll center does not pass through the road surface; i.e., the roll center height is not negative which would cause significant changes in handling will cornering. The opposite wheel travel was used to determine the amount of bump steer in the suspension. Figure X plots the wheel (toe) angle vs. wheel travel. The figure shows that for full jounce or rebound the maximum toe angle is XX degrees. It is expected that this will result in minimal change in steering through suspension travel. The steering simulation was used to modify the steering characteristics for the vehicle. Milliken and Milliken suggest that race vehicles under high lateral acceleration operate well with parallel wheel travel. Our steering system was modified based on Testing performed in ADAMS. Figure X plots the wheel 36 steer angle vs. steering rack displacement for the initial and final steering configuration. The final configuration provides better parallel wheel travel by changing the placement of the steering tie-rod connection on the front upright. CONCLUSIONS One key to winning the Formula SAE competition is experience. Because the members of this team are rookies in the Formula SAE competition, the University of Alabama’s previous and only effort in the Formula competition was used as a guide to designing the suspension for the 2004 racecar. However no documentation was retained from the previous vehicle so the team made estimates to improve on the previous design. In conclusion we believe that we have created a fully functioning suspension for the Formula car capable of competing at the Formula SAE Competition. The performance characteristics, though not tested at this point, are predicted to be comparable to those displayed by other schools leading the competition. The major barriers for this design were time, experience and man-power. The project timetable had to be lengthened almost a month and a half to accomplish our goals due to a design process hindered by lack of experience and a shortage of machining ability. Future efforts to complete a suspension for a Formula SAE race car should take these things into account as well as benefit fully from the progress this years team has made, as presented in this report. 37 EXPENSES The project’s budget, as seen in Table 3 below is 72% less than the $8080.00 initially proposed in the project proposal issued on January 26, 2004. This is due to increased cost awareness practiced by the team throughout the project. Table 3. 2004 FSAE Suspension Team Budget Description Steel Inserts Rod ends RH Rod ends LH Rod ends lower Rod inserts lower Shocks / Springs Front Shocks / Springs Rear Rockers Upright Materials Machine Shop Time Miscellaneous Price per each $ $ $ $ $ $ $ $ $ $ $ $ 120.00 5.84 5.00 5.18 12.53 10.92 300.00 300.00 25.00 20.00 20.00 100.00 Quantity 1 25 40 10 4 2 2 2 4 4 20 1 Shipping Total Spent $ 25.00 $ $ 15.00 10.00 $ $ 17.81 17.81 $ $ $ $ $ $ $ $ $ $ $ $ Total 145.00 146.00 200.00 66.80 60.12 21.84 617.81 617.81 100.00 80.00 400.00 100.00 $ 2,555.38 The expenditures are broken down into major categories, as seen in Table 4 and Figure 20, to allow this team as well as future teams to better understand where money is spent on a car’s suspension and where spending may be curtailed in the future. Table 4. Expenditures Breakdown Sub-System % of entire budget Steel 7% Rod Ends 22% Shocks / Springs 56% Rockers 5% Uprights 4% Machine Time 4% Miscellaneous 4% Total 100% 38 2004 FSAE Suspension Breakdown Steel Rod Ends Shocks / Springs Rockers Uprights Machine Time Miscellaneous Figure 20. Spending Breakdown 39 REFERENCES Milliken, W.F., & Milliken, D.L. (1995). Race Car Vehicle Dynamics (1st ed). Warrendale, PA: Society of Automotive Engineers Gillespie, T.D (1992). Fundamentals of Vehicle Dynamics (1st ed). Warrendae, PA: Society of Automotive Engineers APPENDICES Contents Page # A. AutoCAD Production Drawings 1. Control Arms 2. Front Upright 3. Rear Upright 4. Rockers B. Hand Calculations C. Excel Spreadsheets D. ADAMS Results E. ANSYS Results F. Purchasing/Vendor Information G. Formula SAE 2004 Rules H. Tire Data I. Bearing Press Fit Data 40 Appendix I. This data was taken from: http://www.buntingbearings.com/PM-1.htm. Press Fits (Interference Fits) Plane cylindrical journal bearings are commonly installed by press fitting the bearing into a housing with an insertion arbor. For housings rigid enough to withstand the press fit without appreciable distortion and for bearings with thickness approximately one eighth of the bearing outside diameter, the press fits shown in the Recommended Press Fits Table are suggested. Recommended Press Fits (Inches) Outside Diameter Minimum Up to 0.760 0.001 0.761 to 1.510 0.0015 1.511 to 2.510 0.002 2.411 to 3.010 0.002 Over 3.010 0.002 PressFit Maximum 0.003 0.004 0.005 0.006 0.007 41 Appendix H This tire data was provided by Goodyear and shows the amount of lateral force a tire will generate at different turning angles with four different vertical loadings. Tire with 250 lbs. vertical load Figure X. Lateral Force vs. Slip angle at 0 degrees of camber Tire with 250 lbs. vertical load Figure X. Lateral Force vs. Slip angle at -3 degrees of camber 42