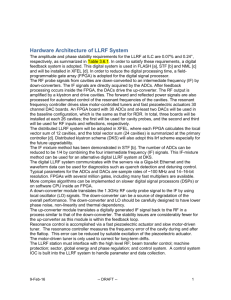

1 LLRF Controls System

advertisement