Final Report

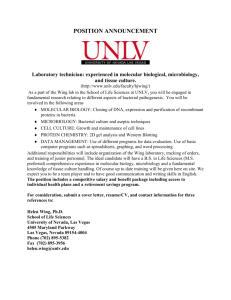

advertisement