SRM 10x120 Bidding Spec

advertisement

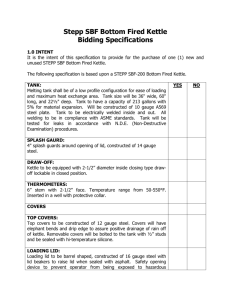

SRM 10x120Aspahlt Recycler Mixer Trailer with Asphalt Additive Tank Bidding Specifications 1.0 INTENT It is the intent of this specification to provide for the purchase of one (1) new and unused 10x120Aspahlt Recycler Mixer Trailer with Asphalt Additive Tank to be used for the purpose of recycling old asphalt to a new useable recycled hot mix patch material. The following specification is based upon a Stepp Mfg SRM10x120 Asphalt Recycler. The Public Works Department has evaluated different styles of asphalt hotbox equipment and has determined that this product is best suited for the DPW needs in terms of quality and features. This specification shall not be interpreted as restrictive but rather as a measure of quality and performance against which all other Asphalt Recyclers will be compared. In comparing proposals, comparison will not be confined to price only. The successful bidder will be one whose product is judged as best serving the interests of the DPW when price, product, quality and delivery are considered. The DPW also reserves the right to reject any or all bids or any part thereof, and to waive any minor technicalities. A contract will be awarded to the bidder submitting the lowest responsible bid meeting the requirements. STEPP SRMx120 SPECIFICATIONS Body and Trailer Portable unit shall be mounted on a NATM approved trailer Frame shall be compact, all steel, welded construction 2”x6”x3/16” Frame shall meet or exceed NATM safety load bearing standards Length shall be approximately 21’ (including trailer) Width shall be a minimum of 102" for increased stability Height shall not exceed 9’ 5” (including loading conveyor) Weight shall not exceed 8,500. lbs. (including trailer) Pre-Heating Bin Shall include a top loading Pre-Heat bin with minimum 11 Cubic foot capacity Exhaust heat shall allow preheating of RAP, reducing fuel consumption. Pre-Heat hopper shall have a minimum loading opening of 23" x 38" Loading Height shall not exceed 93” Pre-Heat hopper shall contain hydraulically operated loading doors. Loading doors shall be activated via electronic switch from control panel. Loading System Shall include conveyor belt loading system for materials Shall allow RAP to be loaded directly from towing vehicle Shall be self-loading and shall not require a loader or auxiliary equipment Minimum production capability shall be up to 3 tons per hour allowing for variation due to excessive moisture or varying material quality and varying ambient temperatures. Recycler Mixing System Shall be capable of maintaining a heated batch of hot mix inside the mixing chamber for up to 8 hours Mixing chamber liner shall be replaceable and constructed of AR400 wear resistant material Replacing mixing chamber shall not require torch cutting or welding, but will be of a bolt on off design Material Mixer shall be hydraulically driven and direct coupled to gear reduction which shall be direct coupled to hydraulic drive motor Hydraulic drive motor shall be a minimum of 11.9 ci Shall be equipped with replaceable mixing paddles Shall utilize solid, AR steel, abrasive resistant replaceable paddles Melter Kettle & Tack Systems Shall include a heated additive pumping system to allow liquid material to be added to the mixing chamber Shall include 120 gallon, heated melter kettle with internal flue for burner system Shall be capable of melting and pumping a metered amount of liquid asphalt or other additives to mixing kettle to enhance the quality of the RAP Shall include a heated, spray tack coating system, including an overhead boom with hose and wand to spray tack coat materials to repair site Shall utilize flues with submerged heating tubes, minimum 6” diameter Flues shall have a minimum heat transfer area of 3300 square inches Burner shall be forced air with spark ignition and flame out protection Burner shall be a forced air diesel burner. Burner shall be minimum of 105,000 btu. Burner flue liner shall be stainless steel for extended life Kettle shall be insulated with steel sheet metal outer cover Kettle shall have automatic temperature controls Thermostat and temperature gauge shall be located in control panel Tack pump shall have a minimum capability of 20gpm Kettle pumping system shall be submerged for fast heating & start up Hydraulic motor shall be a minimum of 2.8 ci. Kettle pump shall have forward-reverse Control panel shall display gallons pumped in 10ths of gallons pumped A material safety loading door shall be included Shall include minimum 15 gallon flush tank Controls & Control Panel Controls shall be an IFM Color display with a can buss controller to operate hydraulic and electric operations on the unit. All controls shall be located curbside rear for safety. All controls shall utilize electronic can buss switches for operator convenience All controls shall be electric over hydraulic All electronic controls shall include redundant manual hydraulic controls Operator Station Controls shall include: A) Burners On/Off B) Burner Timer C) Conveyor Off/Forward/Reverse D) Pre-Heat Bin Door Open/Close E) Mixer Mix/Dump/Off F) Mixer Low/High G) Additive-Tack Pump Forward/Off/Reverse H) Kettle Burner On/Off I) Kettle Auto Temperature Control Thermostat J) Liquid pumped Gallons Meter k) Burner liner min/max temperature controls l) Liner temperature m) Safety lights operation n) Operator warning indicator o) Batch counter Engine panel shall include: A) Keyed Ignition Start B) Engine Oil C) Battery Volt meter D) Temperature over limit E) Low oil/High Temp Shut down F) Hours Meter Safety Melter kettle shall be enclosed with 2" high temperature fiberglass insulation and steel outer sheeting for low heat transmission Recycler shall include Emergency Safety Shutdown Tack Kettle shall include safety loading door Conveyor shall include side rails to prevent spillage Engine Engine manufacturer shall be Kubota Engine shall meet all US emission standards tier 4. Engine shall be capable of running on BioDiesel #5 Engine shall be liquid cooled Engine shall be a minimum 4 cylinder engine Engine horsepower shall be a minimum 36 HP Engine displacement shall be a minimum 81 cubic inch Engine shall be equipped with 12 volt integral starting system, key start Engine shall be mounted to frame on a low-vibration-mount bracket system Electric current shall be provided by an electric 12-volt DC battery Engine shall have a manually operated crankcase oil drain valve to direct drain oil away from recycler Fuel tank shall be a minimum 30 gallon diesel fuel tank Engine shall have a full flow spin on oil filter Engine shall have a replaceable fuel filter Engine Enclosure A lockable, weather protector, vandal proof, vented enclosure for the engine. Enhances overall security and appearance. Color to match. Hydraulics Hydraulic system shall be driven by the engine via a hydraulic pump directly mounted to the engine Hydraulic pump shall utilize a load sensing system with a variable pump displacement of 0 to 1.9 cubic inches Hydraulic reservoir capacity shall be a minimum of 30 gallons Preheat hopper doors shall open and close via a hydraulic cylinder Hydraulic Valve shall be a Force America ADD-A-Fold valve with can buss controller Mixing Chamber Heating System Shall utilize bottom fired heating system radiating heat through The mixer walls Shall circulate the exhaust heat through the mixing chamber Shall utilize twin (2) burners Burners shall be capable of burning bio-diesel as well as diesel fuel Burner output capacity shall be minimum 840,000BTU Burners shall be diesel fueled forced air Burners shall be manufactured by Beckett Corp Burner operations shall be controlled from control panel. Burner system shall have automatic flame-out, fault sensing and strobe light warning. Shall include adjustable burner timer, shutting off burners upon countdown Unloading shall be capable of unloading full batch in 2 minutes or less Shall have Low and High discharge speed Discharge functions shall be operator controlled from control panel Shall include a folding shovel platform Shovel platform shall allow hot mix to be discharged to shovel platform, ground or loader bucket. Shall include a grain door style discharge with handle Trailer Shall be DOT approved, tandem axle trailer shall utilize electric brakes on all four wheels Shall be minimum 12,000 lbs GVWR rating Shall be fitted with a 26"-32" height adjustable hitch. Perimeter and tongue frame members shall be constructed using heavy wall steel tube with a minimum thickness of 2”x6”x 3/16” Suspension shall use a tandem leaf spring type minimum of 6000# each with a one piece bolt on shackle Hitch shall be Pintle style ring Shall utilize US standard axles. No other standard will be accepted Shall utilize US standard steel wheels. No other style will be accepted Trailer electrical system shall be 12 volt DC Turn signals and stop lights shall be sealed beam, DOT compliant Reflectors shall be appropriately mounted on the unit Lights Combination stop, turn, and clearance lights with license plate bracket wired in a protective loom with 4 prong connector. Lighting options are as follows: Standard 2 light system or 2 light LED system; Optional 4 light system: 2 separate lights for stop and turn signal, located on the rear on each side of the unit; or 4 light LED system: 2 separate LED lights for stop and turn signal, located on the rear side of each unit. Paint Surfaces of the unit will be properly prepared and primed per standard industry practices. The machine shall be painted in your choice of High Visibility Safety Orange, Yellow or Black. Custom colors shall be available, upon request. Shall have a two (2) part polyurethane paint. Warranty Engine Manufacturer’s warranty shall be minimum of 3 years Recycler manufacturer’s warranty shall be minimum of 1 year Delivery Equipment shall be furnished fully assembled, serviced and quality checked Two operator and parts manuals shall be furnished with the unit Unit shall be delivered to DPW US facility as indicated Delivery shall be 120 days or sooner from arrival of purchase order Optional Equipment Spare Tire with Mount Spare Tire mounted to the trailer frame Electric over Night Heat for Tack Tank 1500Watt 110Volt to keep oil heated in the kettle for quick start up times. Wash-down System 12 volt spray system with 5 gallon tank and spray wand with nozzle. For spraying tools and shovel platform with nonstick solvent. Wash-down Hose Reel Hose reel with auto rewind for wash-down system. Strobe Light Beacon mounted strobe light. Fire Extinguisher 10# fire extinguisher mounted. Tool Box Mounted in the front of the trailer to store tools. SMV sign Slow Moving Sign mount on the rear of the unit. Manual Holder Shovel Cleaning Compartment For storing and keeping shovels clean in a solvent bath. Arrow Board Mounted in the rear for directing oncoming traffic, LED amber. Front Step with Railing Shall add easy access to the towing vehicle. To be constructed of grip strut grading. Shall be bolted to frame. Stainless Steel Tool Holders Spring loaded tool clamps will hold anything with a handle firmly. Unloading Conveyor Replaces shovel pan to aid in the loading of hot boxes or dump trucks. Heated Overhead boom with 8’ Hose and Steel Wand Electric Heated overhead boom, hose and wand prevents oil from setting up in the hose and wand. Only recommended with high temperature asphalts. Heated Overhead Boom with 12’ Hose and Steel Wand Electric Heated overhead boom, hose and wand prevents oil from setting up in the hose and wand. Only recommended with high temperature asphalts. Aluminum Wand Lighter weight tack wand. Hose Reel for Tack Tank Spring Rewinding hose reel. Not available heated overhead boom option, Hydraulic Tool Power attachment Power beyond for running hydraulic power tools. Hydraulic Jack Hammer Stanley BR67 Hydraulic jack hammer for cleaning up potholes. Hydraulic Tamper Dual Hydraulic Hose Reel for Tool Attachment Spring Rewind hose reel for hyd tools. Deduct Liquid Additives tack Kettle Platform to replace Additive Kettle Hydraulic Surge Brakes Hydraulic Surge Brakes in lieu of electric brakes.