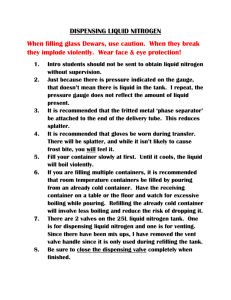

Hazwoper Study Guide - LSU Fire and Emergency Training Institute

advertisement