Oxygen Demand Concepts and Dissolved Oxygen Sag in Streams

advertisement

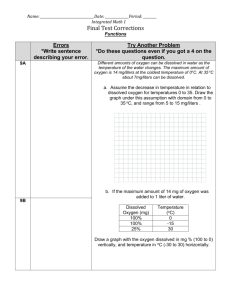

Oxygen Demand Concepts and Dissolved Oxygen Sag in Streams Introduction In recent years “biodegradable” has become a popular word. Often it is assumed that if something is biodegradable, then disposal is not a problem. We know that throwing non-biodegradable substances into our environment leads to degradation of our planet. But disposal of biodegradable compounds also can be detrimental to the environment. The effects of improper disposal of biodegradable substances became a source of public outrage in the early 1800's. The flush toilet was becoming popular and sewage was discharged directly into the nearest waterway. The receiving waters were quickly polluted. Fish in the receiving waters died and the water had a very offensive odor. Although there are many reasons why we no longer discharge untreated sewage into the environment, (including disease transmission, sediment buildup...) one of the reasons is directly related to the fact that sewage contains much that is biodegradable. Theory Biodegradable means that a substance can be converted into simpler compounds by biologically mediated reactions. The second law of thermodynamics predicts that oxidation of high energy level organics (relative to low energy level CO 2) is favored. Oxygen is one of the strongest oxidizing agents found in natural aquatic systems. Oxidation reactions are thermodynamically favored, but kinetically slow unless microbially mediated. The end products of complete aerobic biodegradation are CO2 and H2O. Production of CO2 has recently come under fire as a potential cause of global warming, but that is not the subject of this lab. The problem is not with the products of biodegradation, the problem is that aerobic biodegradation of a compound requires another reactant. Let's look at the biodegradation of a simple organic compound, glucose. C6 H12 O6 +? 6CO2 +6H 2 O 1.1 To balance the equation oxygen is needed. C6 H12 O6 +6O2 6CO2 +6H 2 O 1.2 The consumption of oxygen needed for biodegradation can be a problem. Oxygen is not very soluble in water. The equilibrium concentration of oxygen in water is approximately 10 mg/L (see Figure 1). That means that the degradation of a few mg/L of a biodegradable compound in a river could result in the depletion of dissolved oxygen. Fish have a bad day when oxygen is depleted from their environment. Some species of fish such as trout begin to suffer when the dissolved oxygen concentration drops below 5 mg/L. Oxygen in water is consumed during aerobic biodegradation of organic compounds and is replenished from the atmosphere. The two processes have different kinetics, but are coupled. As the oxygen is depleted by biodegradation the rate at which oxygen is transferred into the water increases because the transfer driving force increases. The rate at which oxygen is dissolved into water from the atmosphere is proportional to the deficit of oxygen in the water. The oxygen deficit is simply the difference between Figure 1. Equilibrium dissolved oxygen the equilibrium oxygen concentration concentration as a function of water and the actual oxygen concentration. temperature. These two reactions (reaeration, and biochemical utilization) are modeled by the Streeter-Phelps equation. In order to increase the rate at which the biodegradation occurs, the concentration of bacteria was increased for use in this laboratory experiment. Bacteria respire and thus consume oxygen even when no substrate is present. Thus an additional term for bacterial respiration will be needed to model the oxygen sag results obtained in the laboratory. Streeter Phelps Equation Development We’ll begin by developing the oxygen deficit as a function of time in a completely mixed batch reactor (no inflow and no outflow) with initial concentrations of Biochemical Oxygen Demand (BODL) and dissolved oxygen. We will include oxidation of BODL and reaeration from the atmosphere. These effects are coupled in equation 8.3 where C represents oxygen concentration. The first two terms on the right are negative since oxidation of BOD and respiration consume oxygen while the third term is usually positive since reaeration increases the concentration of oxygen (except in the rare instance where the dissolved oxygen concentration is greater than the equilibrium dissolved oxygen concentration). Eventually we will make a comparison between time in a reactor and distance down a river. Crespiration Coxidation Creaeration C t t t t 1.3 Oxidation of BOD We must first develop a relationship for the change in oxygen concentration due to oxidation of organics. The rate that oxygen is used will be proportional to the rate that substrate (or biochemical oxygen demand) is oxidized. The rate of substrate utilization by bacteria is given by the Monod relationship dL kLX dt Ks L 1.4 where L is substrate concentration expressed as oxygen demand or BOD L [mg/L], k is the maximum specific substrate utilization rate, Ks is the half velocity constant, and X is the concentration of bacteria. However, the concentration of bacteria is a function of the substrate concentration and thus application of the Monod equation to a polluted river is not trivial. Often the bacterial concentration remains relatively constant. If the half velocity concentration is large relative to the concentration of substrate we obtain dL kXL kX L kox L dt Ks L Ks 1.5 where kox is a first order oxidation rate constant that includes both the approximation that the bacteria concentration is roughly constant and that the substrate concentration is smaller than the half velocity constant. Separate variables and integrate L t dL L L = 0 (kox )dt o 1.6 L Lo e koxt 1.7 to obtain The rate of oxygen utilization is equal to the rate of substrate utilization (when measured as oxygen demand) and thus we have Coxidation dL 1.8 = = -k ox L t dt where C is the dissolved oxygen concentration [mg/L]. Now we can substitute for L in equation 1.8 using equation 1.7 to obtain Coxidation = -k ox Lo e koxt t 1.9 Respiration Bacteria utilize oxygen for respiration and for cell synthesis. When no substrate is present the bacteria cease synthesis, but must continue respiration. This continual use of oxygen is termed "endogenous respiration." Bacteria use stored reserves for endogenous respiration. We can model this oxygen demand as a constant that is added to the demand for oxygen caused by substrate utilization. As a first approximation, we can assume that this oxygen demand is proportional to the concentration of bacteria. In addition, we will assume that the population of bacteria is relatively constant throughout the experiment. Crespiration 1.10 =-bX =-k e t where b is the specific endogenous oxygen consumption rate and ke is the endogenous oxygen consumption rate. Oxygen Transfer Coefficient The rate of oxygen transfer is directly proportional to the difference between the actual dissolved oxygen concentration and the equilibrium dissolved oxygen concentration. Creaeration ˆ 1.11 = kv,l C* - C t where C* is the equilibrium oxygen concentration, C is the actual dissolved oxygen concentration, and kˆv ,l is the is the overall volumetric oxygen transfer coefficient. If reaeration is the only process affecting the oxygen concentration then equation 1.11 can be integrated to obtain C* C ln * kˆv ,l (t t0 ) C C0 1.12 Oxygen Deficit We now have equations for the reaction of oxygen with BODL, endogenous respiration, and for reaeration. Substituting into equation 1.3 we get C = -k ox Lo e koxt k e + kˆv ,l C* - C t We can simplify the equation by defining oxygen deficit (D) as: 1.13 D=C* -C 1.14 and noting that the rate of change of the deficit must be equal and opposite to the rate of change of oxygen concentration dC dD = 1.15 dt dt We must remember that the deficit can never be greater than the equilibrium concentration (D must always be less than C *)! In addition, the BOD model breaks down if the dissolved oxygen concentration is less than about 2 mg/L because the dL lack of oxygen will limit microbial kinetics and will no longer equal -kox L . If we dt stick to conditions under which our assumptions are valid then we can substitute equations 1.14 and 1.15 into equation 1.3 to obtain D ke kox Lo e koxt - kˆv ,l D t 1.16 This is a first order linear differential equation. Integration with initial oxygen deficit = Do @ t = 0 gives: D ke k kˆ t k L - kˆ t Do e e v ,l ox o e koxt - e v ,l kˆv ,l kˆv ,l kˆv ,l kox 1.17 Application to a River We are interested in the oxygen deficit as a function of distance down a stream. As an approximation we can think of a cross section of a river as a completely stirred reactor that is slowly moving downstream. The relation between time in a batch reactor and distance down the river is simply t= x u 1.18 where u is the stream velocity and x is distance. The Streeter-Phelps model assumes a constant input of biodegradable substrate, Lo, at x = 0 and the model is valid under steady-state conditions. Of particular concern is the maximum deficit, Dc. We want to know the value of Dc x and where (or when) it will occur ( t c = c ). This will be the "critical point." If there u are going to be adverse effects (like dead fish) this will be the place. The maximum oxygen deficit occurs when D =0 t We can substitute this into the first order differential equation 1.6 to get 1.19 0 ke kox Lo e koxtc - kˆv,l Dc 1.20 ke kox Lo e koxtc Dc kˆ 1.21 and solve for Dc to get v ,l an equation with unknowns tc and Dc. The Streeter-Phelps equation still holds at the critical point so we also have ke k kˆ t k L - kˆ t Do e e v ,l c ox o e koxtc - e v ,l c 1.22 kˆv ,l kˆv ,l kˆv ,l kox also with unknowns xc and Dc. So now we have two equations in two unknowns. We can solve for tc by eliminating Dc. Dc = ke -kˆv ,l Do kˆv ,l -kox kˆv ,l 1.23 tc = ln kox Lo kox2 kˆv ,l -kox To find Dc given the kinetic coefficients and the initial oxygen deficit, first find tc using equation 1.23. Then use equation 1.21 to solve for Dc. 1 Zero Order Kinetics An alternate model can be derived based on the assumptions that the concentration of bacteria is relatively constant and that the rate of substrate utilization is zero order, i.e., the concentration of the substrate is greater than the half velocity constant Ks. dL kLX = -kX =-k0 dt K s L 1.24 The change of the deficit of dissolved oxygen is equal to the change caused by microbial degradation (k0) plus change due to endogenous respiration minus the reaeration ( kˆ D ). v ,l dD = k0 + ke kˆv ,l D 1.25 dt This equation is only valid when the substrate concentration is greater than Ks. To simplify derivation, assume that Ks is very small relative to the initial BOD added to the system and apply the zero-order model until the substrate is completely oxidized. When the substrate concentration reaches zero a discontinuity will occur as substrate oxidation stops. Separating variables and integrating D k Do t dD 0 ke kˆv ,l D = dt 1.26 0 1 k0 ke kˆv ,l D ln = t kˆv ,l k0 ke kˆv ,l Do and solving for the dissolved oxygen deficit tkˆ k0 ke (k0 ke kˆv ,l Do )e v ,l D= kˆ 1.27 1.28 v ,l Lo . Substituting into equation 1.28 k0 to get the maximum dissolved oxygen deficit yields The substrate concentration is depleted when t = Dt = k0 ke (k0 ke kˆv ,l Do )e kˆ Lo kˆv , l k0 1.29 v ,l where Dt is the dissolved oxygen deficit at the transition when the substrate is all L utilized. For times greater than t = o there is no longer any substrate and thus k0 = 0 k and equation 1.25 becomes dD = ke kˆv ,l D dt Separating variables and integrating D Dt t dD = dt ke kˆv ,l D tt -1 ke kˆv ,l D ln = t - tt kˆv ,l ke kˆv ,l Dt D= 1.30 ke ke kˆv ,l Dt e 1.31 1.32 kˆv , l tt t kˆv ,l Equation 1.33 is valid for all times greater than 1.33 Lo . The general shapes of the two k types of sag curves are shown in Figure 2. Experimental Objectives 0.0 1.0 The objectives of this lab are to: firs t order DO 2.0 sag 1) Illustrate the effects of adding (mg/L) 3.0 4.0 biodegradable compounds to zero order 5.0 natural waters. 6.0 2) Evaluate the Streeter-Phelps 0.0 200 .0 400 .0 600 .0 800 .0 dissolved oxygen sag model Time (s) and a zero order substrate utilization model and compare Figure 2. Dissolved oxygen sag curves obtained from zero and first order models for substrate with laboratory data. utilization. 3) Explain the theory and use of dissolved oxygen probes. Experimental Methods In this lab we will examine the effects of adding a small amount of a biodegradable compound to a small batch reactor. We will measure the dissolved oxygen concentration over Hypodermic diffuser time using a dissolved oxygen probe. DO probe The apparatus is shown in Figure 3. The BOD measured using this 100 mL beaker technique will be lower than the BOD Water surface measured using the standard BOD test because a significant fraction of the Stirbar glucose will be converted into cell material (i.e. used for synthesis instead of for respiration). This technique can be used to obtain kinetic parameters for yield, half velocity constant and maximum Figure 3. Apparatus used to measure substrate utilization rate (Ellis et al., dissolved oxygen consumption rates. 1996). Probe Calibration Calibrate the dissolved oxygen http://www.cee.cornell.edu/mws/Software/DOcal.htm). probe (see Oxygen Transfer Coefficient 1) Prepare to monitor dissolved oxygen. 2) Place the dissolved oxygen probe in the reactor. 3) Pour 50 mL of deoxygenated distilled water into the batch reactor. 4) Set the stirrer speed to 5. 5) Set the airflow rate to 50 mL/min. 6) Monitor the dissolved oxygen for 3 minutes (or longer). 7) Save the data as \\Enviro\enviro\Courses\453\oxygen\netid_O2trans. The data will be used later to estimate the oxygen transfer coefficient. Endogenous respiration oxygen requirements 1) Pour 50 mL of a bacterial suspension into the batch reactor. 2) Place the dissolved oxygen probe in the reactor. 3) Set the stirrer speed to 5. 4) Set the airflow rate to 250 mL/min to aerate the reactor contents. 5) Prepare to monitor dissolved oxygen. 6) After the dissolved oxygen concentration is close to saturation turn off the air and monitor the dissolved oxygen for 3 minutes (or longer). 7) Save the data as \\Enviro\enviro\Courses\453\oxygen\netid_endog. The data will be used later to estimate the endogenous respiration rate. BOD of glucose solution 1) Set the airflow rate to 250 mL/min and aerate the bacterial suspension used previously. 2) Prepare pipette to add 75 µL of glucose solution (this will provide a BOD of 15 mg/L when diluted by 50 mL bacterial suspension). 3) Prepare to monitor dissolved oxygen. 4) Turn off the airflow. 5) As quickly as possible, add glucose through the port in the bottle and begin monitoring the dissolved oxygen concentration. 6) Monitor the dissolved oxygen until the dissolved oxygen concentration reaches approximately 0 mg/L. 7) Save the data as \\Enviro\enviro\Courses\453\oxygen\netid_BOD. The data will be used later to estimate the BOD of the glucose solution. DO Sag Curves 1) Set the airflow rate to 250 mL/min and aerate the bacterial suspension used previously. 2) Prepare to monitor dissolved oxygen. 3) Reduce the airflow rate to 50 mL/min. 4) Begin monitoring the dissolved oxygen in the reactor. Use 5 second data intervals. 5) After ≈300 seconds of monitoring add 10 mg glucose BOD/L (50 L stock) to the reactor. 6) Observe the oxygen depletion in the reactor. 7) Continue monitoring until the dissolved oxygen concentration returns to within 90% of the original DO concentration. 8) Save the data as \\Enviro\enviro\Courses\453\oxygen\netid_sag. Prelab Questions 1) A dissolved oxygen probe was placed in a small vial in such a way that the vial was sealed. The water in the vial was sterile. Over a period of several hours the dissolved oxygen concentration gradually decreased to zero. Why? (You need to know how dissolved oxygen probes work to answer this!) 2) Which assumption is different between the Streeter-Phelps and the zero order model? Data Analysis The rate constants can be estimated using Excel. A sample spreadsheet is available at the course web site. Oxygen Transfer Coefficient 1) Estimate the gas transfer coefficient from equation 1.12 or by using the spreadsheet model. 2) Graph the dissolved oxygen concentration vs. time along with the theoretical curve. Endogenous Decay 1) Estimate the endogenous oxygen consumption rate from the slope of the graph or by using the spreadsheet model. 2) Graph the dissolved oxygen concentration for the bacteria culture in the BOD bottle without any added BOD vs. time along with the theoretical curve. BOD of Glucose 1) Use the "DO sag" Excel spreadsheet to estimate the first or zero order oxygen utilization coefficients, and the BOD exerted by the glucose. Which model fits the data best? 2) How long did it take for the biodegradation of the glucose to occur? 3) What was the change in dissolved oxygen concentration during that time? 4) How much BOD did the glucose solution exert expressed as a fraction of the BOD of the glucose added. 5) Graph the dissolved oxygen concentration vs. time for the glucose solutions along with the theoretical curves. Identify the regions where biodegradation of the glucose was occurring. Dissolved Oxygen Sag 1) Use the previous estimates of the oxygen transfer coefficient, endogenous respiration rate, and fraction of BOD exerted (note that a different amount of BOD was added for the sag curve than for the BOD measurement!) to plot zero and first order model predictions of the dissolved oxygen sag curve. Discuss any discrepancies. 2) Estimate the first and zero order oxygen utilization coefficients and the BOD exerted using the spreadsheet models by minimizing the RMSE using both models with your data. Use the endogenous respiration rate and the reaeration rate estimated previously. Which model (zero or first order) fits the data best? Are the fit parameters significantly different than those obtained in the BOD of glucose analysis? Include the estimated parameters in your report. 3) Graph the dissolved oxygen concentration vs. time for the dissolved oxygen sag curve along with the theoretical curves. 4) On the graph indicate maximum dissolved oxygen sag and compare with the BOD added. 5) Why is the dissolved oxygen sag less than the BOD added? References Ellis, T. G.; D. S. Barbeau; B. F. Smets and C. P. L. J. Grady. 1996. “Respirometric technique for determination of extant kinetic parameters describing biodegradation” Water Environment Research 68(5): 917-926. Lab Prep Notes Bacterial stock preparation using 20% PTYG Grow 4 liter culture of Ps. putida 1) Heat 1 L of distilled water and dissolve media for 4 L of 20% PTYG. 2) Dilute to 4 L in 6 L container containing aeration stone and stirrer. 3) Thaw one cryovial containing Ps. putida and transfer into PTYG media. 4) Stir and aerate for 24 hours. Wash/enumerate Ps. putida culture 1) Centrifuge 4 L culture in 250 mL bottles to obtain concentrated stock (5000 rpm for 10 minutes). 2) Resuspend total culture in 500 mL using 10x BOD dilution water (pH control is essential for bacterial growth and trace nutrients are required). 3) Refrigerate at 4C. Table 3. 20% PTYG culture media. (Prepare 4 L) compound peptone tryptone yeast extract glucose MgSO4 CaCl2·2H2O mg/L 1000 1000 2000 1000 470 70 g/4L 4 4 8 4 1.9 0.28 Table 1. Reagent list Description Supplier peptone tryptone glucose yeast extract MgSO4·7H2O CaCl2·2H2O KH2PO4 K2HPO4 Na2HPO4 · 7H2O NH4Cl FeCl3 · 6H2O Fisher Scientific Fisher Scientific Aldrich Fisher Scientific Fisher Scientific Fisher Scientific Fisher Scientific Fisher Scientific Fisher Scientific Catalog number BP1420-100 BP1421-100 15,896-8 BP1422-100 Fisher Scientific Fisher Scientific Table 2. Equipment list Description Supplier magnetic stirrer Accumet™ 50 pH meter ATI Orion DO probe 6 L container 250 mL PP bottle 15 mL PP bottles variable flow digital drive Easy-Load pump head PharMed tubing size 18 4 prong hypodermic tubing diffuser 1/4” plug 1/4” union stainless steel hypodermic tubing gas diffusing stone Fisher Scientific Fisher Scientific Catalog number 11-500-7S 13-635-50 Fisher Scientific 13-299-85 Fisher Scientific Fisher Scientific 03-484-22 02-925D Fisher Scientific 02-923-8G Cole Parmer H-07523-30 Cole Parmer H-07518-00 Cole Parmer H-06485-18 CEE shop Cole Parmer Cole Parmer McMaster Carr H-06372-50 H-06372-50 Fisher Scientific 11-139B Setup 1) Prepare the Ps. putida culture Table 4. BOD dilution water stock solutions. starting 48 hours before lab. Use 10 mL per liter of each of the 4 2) Prepare 100 mL glucose stock solutions to prepare 10x BOD dilution solution. water. 3) Attach one Easy-Load pump head to the pump drives and phosphate buffer M.W. g/L mg/100 µM plumb with size 18 tubing mL connected to the hypodermic 136.09 8.5 850 62.46 KH2PO4 diffuser. 174.18 21.7 2175 124.87 K2HPO4 5 4) Verify that DO probes are 3340 124.60 Na2HPO4 · 7H2O 268.07 33.4 operational, stable, and can be 53.49 1.7 170 31.78 NH4Cl calibrated. Magnesium 5) Mount DO probes on magnetic sulfate stirrers. (Use large stirbars.) 120.39 11 1100 91.37 MgSO4 6) Use 100 mL plastic beakers containing 50 mL of bacteria Calcium chloride 110.99 27.5 2750 247.77 CaCl2 suspension. The open tops will result in negligible oxygen Ferric chloride transfer during the course of 270.3 0.25 25 0.925 FeCl3 · 6H2O the experiments. 7) Prepare 1 L of deoxygenated distilled water right before class using the techniques outlined in the gas transfer lab (see page Error! Bookmark not defined.). Glucose Stock Solution C6H12O6 + 6O2 6CO2 + 6H2O 10gO2 L 10 gO2 moleO2 1moleC6 H12 O6 180 gC6 H12 O6 0.1 L = 0.9375 g C6 H12 O6 in 100 mL L 32 gO2 6moleO2 moleC6 H12 O6 Glucose Dilutions 10 mg BOD L 100 mL 100 L L 10000 mg O2 100 µL in 100 mL will provide 10 mg/L BOD 10 µL of stock solution diluted into 100 mL provides 1 mg BOD/L.