15510 - nycsca

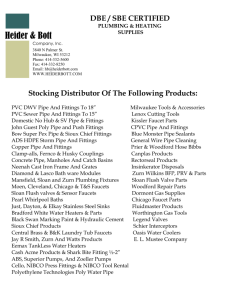

advertisement