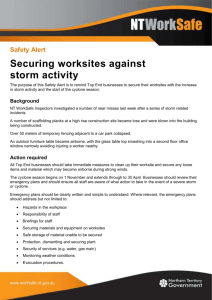

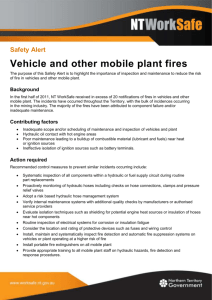

worksafe plan - Department of Commerce

advertisement