Standard Operating Procedure – Picking up BOP

advertisement

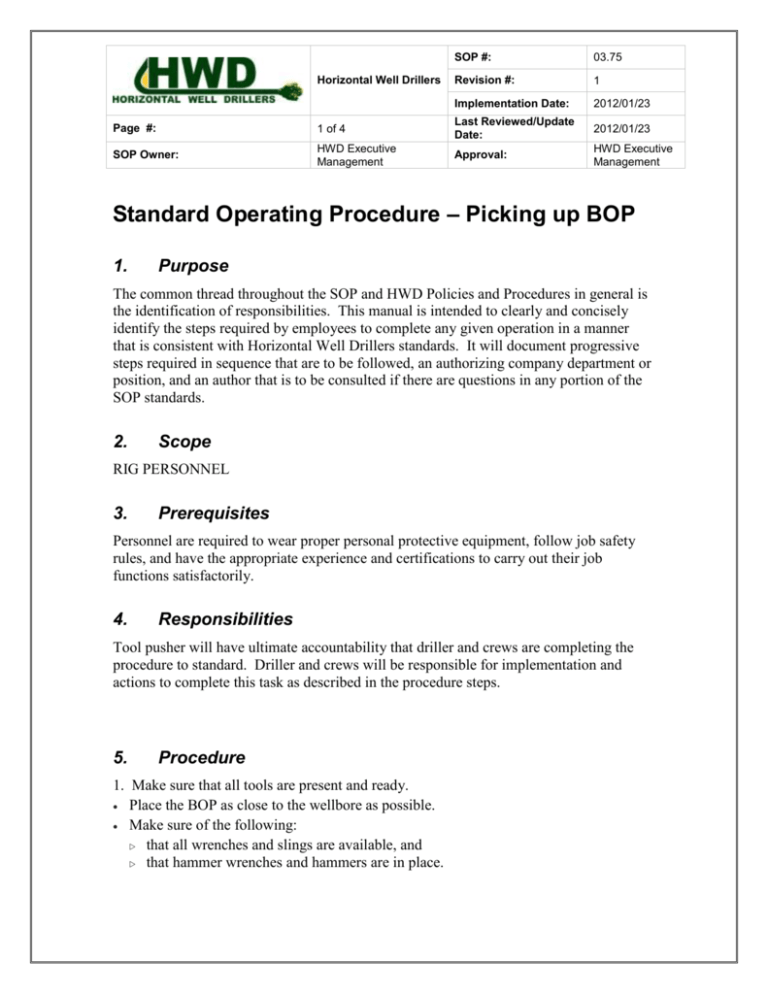

Horizontal Well Drillers SOP #: 03.75 Revision #: 1 Implementation Date: 2012/01/23 Page #: 1 of 4 Last Reviewed/Update Date: 2012/01/23 SOP Owner: HWD Executive Management Approval: HWD Executive Management Standard Operating Procedure – Picking up BOP 1. Purpose The common thread throughout the SOP and HWD Policies and Procedures in general is the identification of responsibilities. This manual is intended to clearly and concisely identify the steps required by employees to complete any given operation in a manner that is consistent with Horizontal Well Drillers standards. It will document progressive steps required in sequence that are to be followed, an authorizing company department or position, and an author that is to be consulted if there are questions in any portion of the SOP standards. 2. Scope RIG PERSONNEL 3. Prerequisites Personnel are required to wear proper personal protective equipment, follow job safety rules, and have the appropriate experience and certifications to carry out their job functions satisfactorily. 4. Responsibilities Tool pusher will have ultimate accountability that driller and crews are completing the procedure to standard. Driller and crews will be responsible for implementation and actions to complete this task as described in the procedure steps. 5. Procedure 1. Make sure that all tools are present and ready. Place the BOP as close to the wellbore as possible. Make sure of the following: that all wrenches and slings are available, and that hammer wrenches and hammers are in place. Horizontal Well Drillers SOP #: 03.75 Revision #: 1 Implementation Date: 2012/01/23 Page #: 2 of 4 Last Reviewed/Update Date: 2012/01/23 SOP Owner: HWD Executive Management Approval: HWD Executive Management If the BOP is being handled by the loader, push both forks together and lift the BOP with the slings wrapped around both forks. Use a minimum of ½ inch chain to lift the BOP. 2. Cut the casing and install the bowl. Work with the welder (if applicable) to complete a Safe Work Agreement for hot work. Use a monitor to test the atmosphere around the cellar and casing before striking an arc to cut the casing. When handling tools overhead at the rig floor, make sure that no personnel are working in the cellar. Use the tugger line to secure the casing before the casing is cut. Use the same tugger to lower the casing to the ground to safely remove it. Be sure the use “ALL CLEAR” signals when handling the casing. 3. Install the possum belly and flow line. Use the picker to hoist the flow line into position. Be sure to use “ALL CLEAR” signals when handling the possum belly, flow nipple, or flow line. NOTE: Refer to the procedure entitled “Installing Possum Belly and Flow Tee” for further clarification. 4. Pick up the BOP. The Driller must operate the controls to handle the BOP. The Driller must make sure that designated signal personnel and specific signals are established. Designated spotters must be in place to help during moving of the BOP stack. Before picking up the BOP, the flow nipple must be picked up, pulled into the possum belly, secured with the picker, and the air bag in the union must be pressured up. Once the flow nipple has been raised, make sure that absolutely no personnel are permitted to stand under the suspended flow nipple. Be sure to use “ALL CLEAR” signals when handling the BOP. Before picking up the BOP, make sure that the BOP ring is placed onto the casing bowl. Make sure that a properly rated hold-back sling is wrapped around the bottom spool of the BOP and hooked up to the tugger winch to act as a hold-back device in the cellar. Install all the BOP bolts into the bottom flange before picking up the BOP. Horizontal Well Drillers SOP #: 03.75 Revision #: 1 Implementation Date: 2012/01/23 Page #: 3 of 4 Last Reviewed/Update Date: 2012/01/23 SOP Owner: HWD Executive Management Approval: HWD Executive Management With the Driller operating the BOP handling controls and cellar winch controls, the Motor hand must stand in a safe position and provide additional signals as needed to raise and place the BOP onto the casing bowl. 5. Lower the BOP stack onto the casing bowl. The Driller must wait for the “ALL CLEAR” signal before lowering the BOP stack onto the bowl. Make sure that all personnel keep their fingers and hands clear of the BOP bolts as the BOP stack is lowered. If a BOP stud must be moved to line up with the holes, make sure that the Driller has been stopped and then move the stud with a hammer handle instead of using fingers. This will keep workers’ hands and fingers out of the line of fire. 6. Secure the BOP stack. Before securing the BOP studs, check the spacing between the bottom spool and the casing bowl. Once all the bolts have nuts in place and have been spun up snug, the Driller can then slowly release the tension of the BOP slings secured to the BOP stack. The crew can then finish tightening the BOP bolts on the stack. Make sure that the BOP slings are not removed until all studs have been torqued on the spool. 7. Hook up the lines. Remove the cellar winch and sling from the base of the BOP. Install the BOP hydraulic lines. Make sure that the lines are hooked up to the proper rams and annular on the BOP stack. Install the HCR valve and hook up the hydraulic lines to the HCR valve. Install the cross-chains to anchor the stack to the substructure to support the BOP. Once the cross-chains or straps have been installed and secured, then it is safe to remove the BOP handling lines on the stack. Make sure that personnel stand clear when slacking off the lines. Lower the flow nipple from within the possum belly onto the BOP stack and secure the flow nipple to the stack. Make sure that all personnel stay out from under the flow nipple as it lowered onto the stack. Air up all air unions. 8. Function test the BOP stack. Horizontal Well Drillers SOP #: 03.75 Revision #: 1 Implementation Date: 2012/01/23 Page #: 4 of 4 Last Reviewed/Update Date: 2012/01/23 SOP Owner: HWD Executive Management Approval: HWD Executive Management The Rig Manager or Driller must position themselves at the accumulator to function the controls and position a signal person at the BOP stack to relay the signals that the rams and HCR valve are functioning properly. Make sure that there has been a joint of pipe positioned in the BOP stack to ensure that the annular has a joint to close on. 9. Complete nipple up procedure. Make sure that the flare lines and degasser lines have been hammered up and secured. Make sure that the spacing between the wellbore and flare pit meets the minimum requirements. Fill up the BOP stack with water and prepare for pressure test. 6. References HWD Employee Handbook 7. NA Definitions