CN228_12-13_X

advertisement

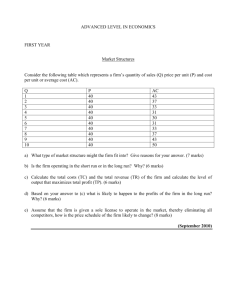

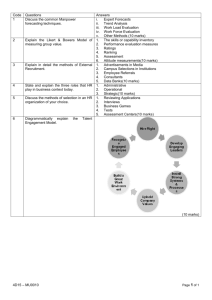

CN228 Design of Structural Steel Members 2012-13 School of Environment & Technology Semester 1 Examinations 2012-2013 CN228 DESIGN OF STRUCTURAL STEEL MEMBERS Instructions to Candidates Time allowed: TWO hours Answer FIVE questions from a total of SIX Total mark of this exam (each question 20 marks) (100 marks) An Aide Memorie is provided Monday 28th of January 2013, 9:30hours Page 1 of 12 CN228 Design of Structural Steel Members 2012-13 Question 1 (total mark = 20) (1-A) The required plastic modulus based on the design bending moment of a simply supported restrained beam (fully restrained against lateral torsional buckling) under uniformly distributed load is 530 cm3. Determine two closest UKB trial cross-sections that have enough ultimate bending resistance to withstand this bending moment. If there is a maximum height restriction for this beam in the roof, which one of those cross-sections would you choose? (7 marks) (1-B) The required area of the cross-section design based on the design force of a short/stub column is 47 cm2. Determine two closest UKB trial cross-sections that have enough ultimate tensile resistance to withstand this axial force. This member is embedded in a wall. If there is a maximum width restriction of the wall, which one of those cross-sections would you choose? (7 marks) (1-C) The required second moment of area of a cantilever restrained beam (that is covered by plaster of brittle finish) subjected to an un-factored imposed point-load at the end is 4400 cm4 to satisfy the serviceability limit state. Determine the closest UKB trial cross-section that satisfies the serviceability limit state. (6 marks) Question 2 (total mark = 20) The end plate shown in Figure Q2 is subjected to a tensile axial load and is 20 mm thick; and contains four lines of staggered holes drilled for 24 mm bolts; where its yield strength is fy = 275 N/mm2 and its ultimate strength is fu = 430 N/mm2 . (2-A) Calculate the ultimate tensile resistance of the plate (based on the probable failure modes). (10 marks) (2-B) Identify whether 14 non-preloaded Class 4.8 M24 diameter bolts can provide enough shear resistance to transfer this ultimate tensile force. (6 marks) (2-C) Determine the required length of a-(6 mm)-fillet-weld to transfer this ultimate tensile force if the end plate is welded (instead of being bolted). (4 marks) Figure Q2 Page 2 of 12 CN228 Design of Structural Steel Members 2012-13 Question 3 (total mark = 20) A 406 X 178 X 74 UKB (cross sectional properties on the next page) is designed as an unrestrained beam, which is subjected to equal end bending moments about its major axis. Length of the beam between points of lateral restraint (pinned at both ends) is Lcr = 4.5 m. Assuming the overall cross-section classification is “Class 1 in bending” and all partial safety factors for resistance are M =1.0 : (3-A) Select the appropriate section modulus for this cross section Wy . (2 marks) (3-B) Calculate elastic critical moment for lateral torsional buckling Mcr . (4 marks) (3-C) Work out the non-dimensional lateral torsional slenderness (3-D) Determine reduction factor for lateral torsional buckling . LT (3 marks) LT – please note that buckling curve (a) is recommended for this cross-section. (7 marks) (3-E) Calculate lateral torsional buckling resistance of this member Mb,Rd. (4 marks) Question 4 (total mark = 20) A 406 X 178 X 74 UKB (cross sectional properties on the next page) is used as a beam that is bending about its strong axis (assume that the overall cross-section classification is Class 1 in bending and the beam is fully restrained against lateral torsional buckling): (4-A) Determine shear area of the cross section (Av). (3 marks) (4-B) Calculate shear resistance of the cross-section (Vpl, Rd). (4 marks) (4-C) Calculate the maximum bending resistance of this section if the design shear force in the section is 50 kN. (6 marks) (4-D) Calculate the maximum bending resistance of this section if the design shear force in the section is 50 kN and the design axial load is 25 kN. (7 marks) Question 5 (total mark = 20) A 406 X 178 X 74 UKB (cross sectional properties on the next page) is used as a 4.5 m column that is fully restrained against buckling about its weaker axis and free to buckle about the other axis (assuming the cross-section is fully effective in compression - Class 1 or 2): (5-A) Identify effective length of the column if its end conditions are free-fixed. (2 marks) (5-B) Calculate elastic critical buckling load. (4 marks) (5-C) Determine non-dimensional slenderness ( ). (3 marks) (5-D) Calculate flexural buckling reduction factor () – please note that buckling curve (b) is recommended for this cross-section when buckling about y-y axis. (7 marks) Page 3 of 12 CN228 Design of Structural Steel Members 2012-13 (5-E) Calculate flexural buckling resistance of the cross-section (Nb, Rd). (4 marks) Page 4 of 12 CN228 Design of Structural Steel Members 2012-13 Cross sectional properties for the questions 3, 4 and 5 b z tw h d y y r tf 406 × 178 × 74 UKB rolled beam z c Depth of cross section Web depth Width of the flange Web thickness Flange thickness Flange outstand Root radius Web depth between fillets Second moment of Area Radius of gyration Elastic section modulus Plastic modulus Warping Constant Torsional Constant Section area Modulus of elasticity Shear Modulus Nominal yield strength of steel h = 412.8 mm hw = h – 2 tf b = 179.5 mm tw = 9.5 mm tf = 16.0 mm c = 0.5 [ b – (tw + 2 r)] r = 10.2 mm d = 360.4 mm Iy = 27310 x 104 mm4 & Iz = 1545 x 104 mm4 iy = 17 mm & iz = 4.04 mm 3 3 Wel,y = 1323 x 10 mm & Wel, z = 172 x 103 mm3 Wpl, y = 1501 x 103 mm3 & Wpl, z = 267 x 103 mm3 12 6 Iw = 0.608 x 10 mm It = 62.8 x 104 mm4 A = 9450 mm2 E = 210 000 N/mm2 G = 81 000 N/mm2 fy = 355 N/mm2 Question 6 (total mark = 20) Describe the failure mode of the sections shown in the following five photographs; (6-A) An Angle (L-shaped connector) – connecting web of a beam to flange of a column (4 marks) Page 5 of 12 CN228 Design of Structural Steel Members 2012-13 ………………….. Questions 6 continues on the next page ……………. Questions 6 continued (6-B) I-shape beam (4 marks) (6-C) Top of an I-shape column (4 marks) (6-D) A simply supported I-shape beam (4 marks) (6-E) An I-shape beam (4 marks) Page 6 of 12 CN228 Design of Structural Steel Members 2012-13 SAL BEAMS (assume all Sections Class 1 in bending) nce UKB z y perties s z y z Plastic Modulus Axis Axis y-y z-z Buckling Torsional Warping Torsional Parameter Index Constant Constant U X 3 cm 3 cm 3 6 6 5 9 5 2 0 0 3 9 2 5 5 2 2 0 2 7 711 614 539 481 403 342 566 483 393 353 306 259 314 258 234 171 123 84.2 116 0.873 23.3 98.4 0.872 26.5 85.4 0.872 29.7 60.0 0.867 31.6 48.4 0.859 37.3 38.8 0.846 43.4 141 0.891 21.1 119 0.890 24.3 94.1 0.879 29.6 BS EN 1993-1-1:2005 54.8 0.873 27.5 BS 4-1:2005 46.0 0.866 31.4 37.3 0.856 36.3 88.2 0.882 21.5 70.9 0.876 25.6 49.7 0.888 22.4 41.6 0.886 22.6 31.2 0.890 19.5 22.6 0.894 16.3 Area of Section Iw dm6 IT cm 4 A cm 2 0.102 0.0846 0.0725 0.0442 0.0349 0.027 0.103 0.0857 0.0660 0.0280 0.0230 0.0182 0.0374 0.0294 0.0154 0.0099 0.00470 0.00200 31.8 21.1 14.8 12.2 7.40 4.77 23.9 15.3 8.55 9.57 6.42 4.15 10.3 5.96 7.02 4.41 3.56 2.85 61.2 53.4 47.2 41.8 35.9 31.6 54.8 47.2 39.7 36.1 UNIVERSAL BEAMS 32.0 28.0 Advance UKB 38.2 32.0 29.4 24.3 20.3 16.5 z y Properties elationship between Universal Beams (UB) and the Advance range of Section Second Moment Radius Designation of Area of Gyration Axis Axis Axis Axis y-y z-z y-y z-z 305x127x48 305x127x42 305x127x37 305x102x33 305x102x28 305x102x25 254x146x43 254x146x37 254x146x31 254x102x28 254x102x25 254x102x22 203x133x30 203x133x25 203x102x23 178x102x19 152x89x16 127x76x13 cm 4 cm 4 9570 8200 7170 6500 5370 4460 6540 5540 4410 4000 3410 2840 2900 2340 2100 1360 834 473 461 389 336 194 155 123 677 571 448 179 149 119 385 308 164 137 89.8 55.7 cm 12.5 12.4 12.3 12.5 12.2 11.9 10.9 10.8 10.5 10.5 10.3 10.1 8.71 8.56 8.46 7.48 6.41 5.35 cm 2.74 2.70 2.67 2.15 2.08 1.97 3.52 3.48 3.36 2.22 2.15 2.06 3.17 3.10 2.36 2.37 2.10 1.84 y z Elastic Modulus Axis Axis y-y z-z Plastic Modulus Axis Axis y-y z-z cm 3 cm 3 cm 3 cm 3 616 534 471 416 348 292 504 433 351 308 266 224 280 230 207 153 109 74.6 73.6 62.6 54.5 37.9 30.5 24.2 92.0 78.0 61.3 34.9 29.2 23.5 57.5 46.2 32.2 27.0 20.2 14.7 711 614 539 481 403 342 566 483 393 353 306 259 314 258 234 171 123 84.2 116 98.4 85.4 60.0 48.4 38.8 141 119 94.1 54.8 46.0 37.3 88.2 70.9 49.7 41.6 31.2 22.6 Buckling Torsional Warping Torsional Parameter Index Constant Constant Area of Section U X Iw dm 6 IT cm 4 A cm 2 0.873 0.872 0.872 0.867 0.859 0.846 0.891 0.890 0.879 0.873 0.866 0.856 0.882 0.876 0.888 0.886 0.890 0.894 23.3 26.5 29.7 31.6 37.3 43.4 21.1 24.3 29.6 27.5 31.4 36.3 21.5 25.6 22.4 22.6 19.5 16.3 0.102 0.0846 0.0725 0.0442 0.0349 0.027 0.103 0.0857 0.0660 0.0280 0.0230 0.0182 0.0374 0.0294 0.0154 0.0099 0.00470 0.00200 31.8 21.1 14.8 12.2 7.40 4.77 23.9 15.3 8.55 9.57 6.42 4.15 10.3 5.96 7.02 4.41 3.56 2.85 61.2 53.4 47.2 41.8 35.9 31.6 54.8 47.2 39.7 36.1 32.0 28.0 38.2 32.0 29.4 24.3 20.3 16.5 Advance and UKB are trademarks of Corus. A fuller description of the relationship between Universal Beams (UB) and the Advance Page 7 ofrange 12 of sections manufactured by Corus is given in section 12. FOR EXPLANATION OF TABLES SEE NOTE 3