Tools & Holding Devices Guide: Clamps, Punches, Calipers

advertisement

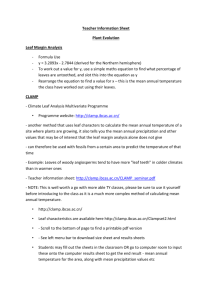

Tools and Holding Devices Text-based version Tools and Holding Devicesg Tools Word "A" - clamp Meaning Context "A" shaped clamping device. More Information These clamps are versatile and easy to use. They use a cam powered action. They prevent twisting of workpieces. "A" - clamp angle plate Angle plate is used in layout work and in setting up the work piece for drilling or milling at a 90 degree to the table. Angle plates are a common layout accessory. "C" - clamp Angle plate / layout Using "C" - clamps workpieces can be fastened to angle plates for layout operations. "C" shaped clamping device. "C" - clamps are available from 1 to 16 inches. Clamping devices are used by the operator for safe handling and ease of operation. center punch Center punch is used to enlarge prick punch holes. Center punch has an included point angle of 90 degrees. Center punches are used to mark the workpiece prior to machining operations such as drilling and should not be used in place of a layout punch. dividers Dividers transfer distances directly from the rule to the work and are used to scribe equally spaced divisions. They are also used to scribe arcs and circles. drill vise Dividers are usually set to rules. Similar to a pencil compass, it consists of two sharp points. Dividers are available in various sizes. Drill vise is a holding device used for clamping most workpieces while drilling. Points may be lightly honed for sharpness. The vises provide the quickest and most efficient set up method for parallel work. One of the most commonly used work-holding Available in many sizes. devices is also called a drill press vise. gooseneck clamp Gooseneck is a hold down device used to fasten a work piece to a table. The gooseneck clamp allows the top of the clamping bolt to be positioned below the surface to be machined. The measuring surfaces are lapped and polished to 200 milionths of an inch. Available in many sizes. Hermaphrodite caliper hermaphrodite locates and scribes caliper lines in a work piece parallel to its side. Reversible for inside lines. The hermaphrodite caliper can also be used to lay out the center of round stock. It consists of two legs, one sharp point and the other leg is a hook. Kant-Twist clamps weight approximately half as much as comparable C-clamps. Kant-Twist clamp Kant-Twist clamp is a heavy duty clamping devices. They are superior to standard Cclamps. Clamping devices are used for safe handling and ease of operation. laying out They eliminate distortion and twisting action. Laying out or lay-out is The information measured and transferred Accurate workmanship depends upon the operation of must be accurate. An error in layout will result the ability to use the proper transferring reference in an error in the finished part. marks from a blueprint to the work piece. parallel clamp A parallel clamp is a low reach heavy duty clamping device, also known as machinist or toolmakers' clamp. instruments and gages for measuring precisely. Clamping devices are used for safe handling and ease of operation. Stronger and smaller than a C-clamp. Toolmakers' parallel clamp prick punch scriber step blocks Prick punch is used lightly mark the location of holes. Scriber is a sharp, pointed tool used to draw straight sharp lines. The prick punch has an included point angle of 30 degree. A scriber is used with a square rule or straight-edge for drawing straight lines. This is particularly important when laying out. The pocket scriber can be reversed in the handle for safety. Available with carbide or hardened steel point. Step blocks are extremely useful clamping aids. Step blocks help to support the work piece. The height of the work piece determines the correct step block on which a clamp can be placed to secure the work piece. T-bolt The prick punch is the only punch that should be used in layout. It is used to preserve the location of a layout mark while doing minimum damage to the work piece. They are used in conjuction with gooseneck, "U" - clamps and strap clamps. T-bolts are used on milling machines tables and faceplates. Head has a T-shape and is used to fasten work to the table. The heads of the T-bolts often fit the slots on the drill press tables. T-slot bolt trammel Trammel measures between two points and scribes circles or arcs that are too large for dividers. Trammel points can be attached to a bar and set to circle dimensions or they may be clamped directly by rule graduations. Trammel Transfer punch can be used with any shape of hole-round rectangular, square, elongated, or tear-shaped materials up to 2 inches or 50 mm thick. Transfer punch used to transfer holes of any transfer punch diameter from 1/16th to 2 inches. Transfer punch set "U" - clamp "U" shaped device for holding down a work piece. One advantage of the "U" - clamp is that it can be removed without taking the nut off the T-bolt. It has a continuous slot. Clamping devices are used for safe handling and ease of operation. V-blocks V-blocks hold round stock for layout work. Round work pieces can be securely fastened in a set of V-blocks. To prevent the shaft from bending under cutting pressure a V-block and screw jack can be used to support the shaft.