SuggestedAnswerCh4

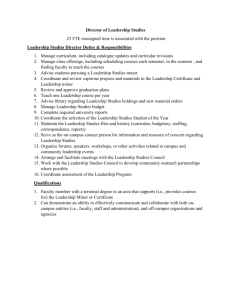

advertisement

4.5 REVIEW QUESTIONS 1. What are the characteristics of the joints in a truss structure and what are the effects of this on the deformation and stress properties in a truss element? Suggested answer: The joints of a truss structure are hinges (not welded together) that transmits only forces but not the moments. Therefore, a truss member is stressed only in the axial direction of the truss member, and only the axial deformation is the primary interest of analysis. This allows us to set the local coordinate along the axial axis, and only one DOF at a node is needed for the formulation based on the local coordinate. 2. How many DOFs does a 2-nodal, planar truss element have in its local coordinate system, and in the global coordinate system? Why is there a difference in DOFs in these two coordinate systems? Suggested answer: Local: DOF=2; global: DOF=4. As the local coordinate is taken along the axial direction of the truss member that is stressed only in one (axial) direction and only the axial deformation is concerned, there is hence only one DOF at a node. The global coordinate system is used for all members of the truss structure, and will not be possible at all the times for the coordinate axes to coincide with the axial directions of all the truss members. Therefore, freedom of a node in a planner space needs two displacement components to represent, because the node can move in two directions. The relation between the one local DOF and the two global DOF is given by the transformation matrix T defined in Eq.(4.33). 3. How many DOFs does a 2-nodal, space truss element have in its local coordinate system, and in the global coordinate system? Why is there such a difference? (Hint): Similar argument as those given for equation 2. 4. Write down the expression for the element stiffness matrix, ke, with Young’s modulus, E, length, le, and cross-sectional area, A 0.02x 0.01 . (Note: non-uniform crosssectional area). Suggested answer: Assume A A1 x A0 Using Equation (4.15), we have 1 l le e T E 1 B cBdV A 0 1 le l e ke Ve le 0 5. 1 dx le Al ( 1 e A0 ) E 1 1 E 1 1 ( A1 x A0 ) 2 dx 2 1 1 le 1 1 le Write down the expression for the element mass matrix, me, with the same properties as that in question 4 above. Suggested answer: Assume A A1 x A0 Using Equation (4.16), we have le N N m e NT NdV A 1 1 0 N 2 N1 Ve N1 N 2 dx N 2 N 2 le N N N1 N 2 ( A1 x A0 ) 1 1 dx 0 N 2 N1 N 2 N 2 x x x (1 ) 2 (1 ) le le le le dx A0 le 2 1 A1 x 0 6 1 2 x2 sym. le2 x2 ( x 2 l le e A1 0 sym. 1 2 1 ( 2 3 4 ) 2 A1le sym. 6. A1le2 1 1 12 1 3 x3 x 2 x3 ) ( ) le2 le le2 dx x3 le2 1 1 ( ) A l 2 3 4 0 e 1 6 1 4 A0 le 6 A0 le 6 2 1 1 2 1 2 2 1 1 2 Work out the displacements of the truss structure shown in Figure 4-9. All the truss members are of the same material (E = 69.0 GPa) and with the same cross-sectional area of 0.01 m2. 0.5 m 0.5 m 1m 0.5 m 1000N Figure 4-9 3 member planar truss structure 0.5 m D6 0.5 m D5 Y 3 1m 2 D4 2 1 D3 0.5 m D2 X 1 500N 1 D1 1000N Suggested answer: Analysis of the problem It is clear that the structure is symmetric. Hence, we can use only a half of the structure as shown in the above Figure. The cross-sectional area of bar 2 is reduced by half becoming 0.005 m2. The dimensions of all the members are given in Table 6.1. Table 6.1 Dimensions and properties of truss members Element number 1 2 Cross-sectional area, Ae m2 0.005 0.01 Young’s modulus E N/m2 69 x 109 69 x 109 Length le m 0.5 1.118 Step 1: Obtaining the direction cosines of the elements Knowing the coordinates of the nodes in the global coordinate system, the first step would be to take into account the orientation of the elements with respect to the global coordinate system. This can be done by computing the direction cosines using Eq. (4.21). Since this problem being a planar problem, there is no need to compute nij. The coordinates of all the nodes and the direction cosines of lij and mij are shown in Table 6.2. Table 6.2 Global coordinates of nodes and direction cosines of elements Global node corresponding to Element local local number node 1 node 2 (i) (j) 1 1 2 2 2 3 Coordinates in global coordinate system Direction cosines using Eq. (4.21) Xi, Yi Xj, Yj lij mij 0, -0.5 0, 0, 0 0.5, 1.0 0 0.4472 1 0.8945 Due to the symmetry, nodes 1 and 2 can only move vertically. As the external force is also vertical, the displacement of node 1 relative to node 2 can be obtain straight away as 0.5 500 7.246 107 m lP (6-1) d12 EA 69 109 0.005 and the stress in bar 1 is simply P 500 1.0 105 Nm -2 A 0.005 These data can be used to check FEM solution. 1 (6-2) Step 2: Calculation of element matrices in global coordinate system After obtaining the direction cosines, the element matrices in the global coordinate system can be obtained. Note that the problem here is static. Hence, the element mass matrices need not be computed. What is required is thus the stiffness matrix. Recall that the element stiffness matrix in the local coordinate system is a 2×2 matrix since the total degrees of freedom is two for each element. However, in the transformation to the global coordinate system, the degrees of freedom for each element becomes four, therefore, the stiffness matrix in the global coordinate system is a 4×4 matrix. The stiffness matrices can be computed using Eq. (4.35) and is shown below. 0 0 0 0 9 0.005 69 10 1 0 1 e1 K 0 0 0.5 1 sy. (6-3) 0 0 0 0 6.9 0 6.9 108 Nm-2 0 0 6.9 sy. 0.2 0.4 0.2 0.4 9 0.01 69 10 0.8 0.4 0.8 K e2 0.2 0.4 1.118 0.8 sy. (6-4) 1.234 2.469 1.234 2.469 4.938 2.469 4.938 108 Nm-2 1.234 2.469 4.938 sy. Step 3: Assembly of global FE matrices The next step after getting the element matrices will be to assemble the element matrices into a global finite element matrix. Since the total global degrees of freedom in the structure are six, the global stiffness matrix will be a 6×6 matrix. The assembly is done by adding up the contributions for each node by the elements that share the node. Element 1 contribute to DOFs of D3 to D6. In summary, we have the final global stiffness matrix. D1 D2 D3 D4 D5 D6 0 0 0 0 0 D1 0 6.9 0 6.9 0 0 D2 0 1.234 0 2.469 1.234 2.469 D3 K 108 6.9 4.938 2.469 4.938 D4 1.234 2.469 D5 sy. 4.938 D 6 (6-5) Step 4: Applying boundary conditions The global matrix assembled initially is usually not PD. It becomes PD after applying boundary conditions, which can leads to a deduction in dimension (condensation). In this case, D1, D2, D3 and D5 are constrained and thus D1 = D3 = D5 = D6 = 0 (6-6) This implies that the first to third and fifth rows and columns will actually give no effect to the solving of the matrix equation. Hence, we can simply remove the corresponding rows and columns. D1 D2 D3 D4 D5 D6 0 0 0 0 0 0 6.9 0 6.9 0 0 1.234 2.469 1.234 2.469 8 K 10 11.838 2.469 4.938 1.234 2.469 sy. 4.938 D1 D2 D3 D4 D5 D6 (6-7) The condensed global matrix becomes a 2×2 matrix given as follows. 6.9 6.9 K 108 Nm-2 6.9 11.838 (6-8) It can easily confirm that this condensed stiffness matrix is SPD. The constrained global FE equation is KD = F where (6-9) DT D2 D4 (6-10) and the force vector F is given as 500 F (6-11) 0 Note that the only force applied is at node 1 in the downward direction of D2. Equation (6-9) is actually equivalent to two simultaneous equations (of SPD) involving the two unknowns D2 and D4 as shown below. 6.9 D2 6.9 D4 108 500 (6-12) 6.9 D2 11.838D4 108 0 Step 5: Solving the FE matrix equation The final step would be to solve the FE equation, Eqs. in (6-12), to obtain the solution for D2 and D4. This can be done manually, since this only involves two unknowns. To this end, we obtain first (6-13) D2 = D4 and then D2 =1.7367×10-6 m (6-14) D4 =1.0121×10-6 m We can also calculate d1 2 D2 D4 7.246 107 m (6-15) which is the same as in Eq. (6.1), which confirms our solution. To obtain the stresses in the elements, Eq. (4.37) is used as follows: 0 6 1 1 0 1 0 0 1.7372×10 1 EBTDe 69 109 0 0.5 0.5 0 0 0 1 (6-16) 1.0126 106 1.7372 6 5 34.5 109 1 1 10 1.0 10 Pa 1.0126 1 1 2 EBTDe 69 109 1.118 1.118 0 0 0 0 0.4472 0.8945 (6-17) 0 0.4472 0.8945 0 0 1.0126 106 0 6 4 61.717 109 1 1 10 5.59 10 P 0.9057 which is the same as in Eq. (6.1), which confirms our solution once again. Note that the FEM produces exact solution for this case.