Forced convection - Department of Mechanical Engineering UPRM

advertisement

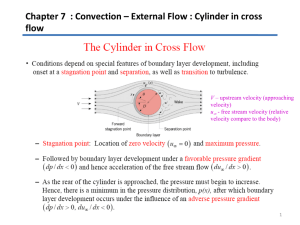

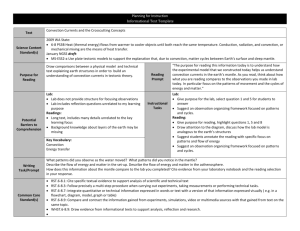

Experiment2 1 INME 4032 Table of Contents Principle 3 Objective 3 Background 3 Newton’s law of cooling 3 Experimental Setup 5 Description of the Combined Convection and Radiation Heat Transfer Equipment: 5 Useful Data 6 Procedure 7 1. Free convection experiments Observations 8 Analysis of results 8 Comparison to theoretical correlations 9 2. Forced convection experiments 10 Observations 10 Analysis of results 10 Comparison to theoretical correlations 11 Discussion Experiment2 8 12 2 INME 4032 University of Puerto Rico Mayagüez Campus Department of Mechanical Engineering INME 4032 - LABORATORY II Spring 2004 Instructor: Guillermo Araya Experiment 2: Natural And Forced Convection Experiment Principle This experiment is designed to illustrate the Newton’s law of cooling by convection and to understand how the heat transfer coefficient is obtained experimentally. Natural and forced convection over a heated cylinder is analyzed and experimental results are compared with standard correlations. Objective Determine the heat transfer coefficient for a flow around a cylinder under free and forced convection. Understand the correlation between Nu, Reynolds and Rayleigh numbers. Compare with standard correlation from textbooks on heat transfer. The effect of thermal radiation is also included. Background Newton’s law of cooling For convective heat transfer, the rate equation is known as Newton’s law of cooling and is expressed as: q h (Ts T ) Where Ts is the surface temperature, T the fluid temperature, h the convection heat transfer coefficient and q the convective heat flux. The heat transfer coefficient h is a function of the fluid flow, so, it is influenced by the surface geometry, the fluid motion in the boundary layer and the fluid properties as well. From the normalized momentum and energy equation in the boundary layer: Experiment2 3 INME 4032 * U * P * 1 2U * * U U V * Re L y * 2 x * y * x * * T * 1 2T * * T U V x * y * Re L Pr y * 2 * Momentum equation Energy equation Independently of the solution of these equations for a particular case, the functional form for U* and T* can be written as: U* = f(x*,y*,ReL, dp*/dx*) and T* = f(x*,y*,ReL, Pr, dp*/dx*) Heat transfer, due to the no-slip condition at the wall surface of the boundary layer, occurs by conduction; q s k f " T y y 0 By combining with the Newton’s law of cooling, we obtain: kf h Since T* was defined as T * T y y 0 Ts T T Ts T Ts h can be written in terms of the dimensionless temperature profile T* h k f (T Ts ) T * L(Ts T ) y * y * 0 k f T * L y * y* 0 This expression suggests defining a dimensionless parameter; Experiment2 4 INME 4032 hL T * Nu * kf y y* 0 From the dimensionless temperature profiles, we can imply a functional form for the Nusselt number, Nu = f(x*,ReL*,Pr,dp*/dx*) To calculate an average heat transfer coefficient, we have to integrate over x*, so the average Nusselt number becomes independent of x*. For a prescribed geometry, dp * is dx * specified and Nu L f (Re L , Pr) This means that the Nusselt number, for a prescribed geometry is a universal function of the Reynolds and Prandtl numbers. Doing a similar analysis for free convection, it can be shown that, Nu f (Gr , Pr) or Nu f (Ra , Pr) Where Gr is the Grashof number and Ra is the Rayleigh number. The Rayleigh number is simply the product of Grashof and Prandtl numbers (Ra = Gr Pr) Then, for free convection the Nusselt number is a universal function of the Grashof and Prandtl numbers or Rayleigh and Prandtl numbers. Experimental setup Description of the Combined Convection and Radiation Heat Transfer Equipment: The combined convection and radiation heat transfer equipment allows investigate the heat transfer of a radiant cylinder located in flow of air (cross flow) and the effect of increasing the surface temperature. The unit allows investigation of both natural convection with radiation and forced convection. The mounting arrangement is designed Experiment2 5 INME 4032 such that heat loss by conduction through the wall of the duct is minimized. A thermocouple (T10) is attached to the surface of the cylinder. The surface of the cylinder is coated with a matt black finished, which gives an emissivity close to 1.0. The cylinder mounting allows the cylinder and thermocouple (T10) position to be turned 360° and locked in any position using a screw. An index mark on the end of the mounting allows the actual position of the surface to be determined. The cylinder can reach in excess 600°C when operated at maximum voltage and in still air. However the recommended maximum for the normal operation is 500°C. Useful Data: Cylinder diameter D = 0.01 m Cylinder heated length L = 0.07 m Effective air velocity local to cylinder due to blockage effect Ue = (1.22) (Ua ) Physical Properties of Air at Atmospheric Pressure T K 300 V 1.568E-5 k W/mK 0.02624 Pr 0.708 350 2.076E-5 0.03003 0.697 400 2.590E-5 0.03365 0.689 450 2.886E-5 0.03707 0.683 500 3.790E-5 0.04038 0 .6 8 550 4.434E-5 0.04360 0 .6 8 600 5.134E-5 0.04659 0 .6 8 m2/s Where: T is the absolute temperature, V is the Dynamic viscosity of air, k is the thermal conductivity and Pr is the Prandtl number. Experiment2 6 INME 4032 Combined Convection and Radiation Heat Schematic Diagram showing the Combined Transfer Equipment Convection and Radiation Heat Transfer Equipment Procedure a) Connect instruments to the heat transfer unit b) Measure the reading for the surface temperature of the cylinder, the temperature and velocity of the air flow and the power supplied by the heater. c) Repeat steps 1 and 2 for different velocities the air flow and power input. Experiment2 7 INME 4032 1. Free convection experiments Observations Se t 1 2 3 4 V V o lts 4 8 12 16 I Amp T9 C T10 C hr W/m2K hC1th W/m2K hC2th W/m2K Analysis of results Se t 1 2 3 4 Qinput W 4 8 12 16 The total heat input is: Qinput = VI The heat transfer rate by radiation is: Qrad = A (Ts4 – Ta4) = hr A (Ts – Ta) So, hr (Ts4 Ta4 ) Ts Ta The heat transfer rate by convection is: Qconv = Qinput - Qrad From Newton’s law of cooling Experiment2 8 INME 4032 Qconv hc A(Ts Ta ) And hc Qconv A(Ts Ta ) Comparison to theoretical correlations For an isothermal long horizontal cylinder, Morgan suggests a correlation of the form, Nu D hD cRa nD k (1) c and n are coefficients that depend on the Rayleigh number Rayleigh number 10-10 – 10-2 10-2 – 102 102 – 104 104 – 107 107 – 1012 c 0.675 1 .0 2 0.850 0.480 0.125 n 0.058 0.148 0.188 0.250 0.333 The Rayleigh number is calculated from, Ra g(Ts Ta )D 3 Pr 2 where 1 Tfilm and Experiment2 9 INME 4032 Tfilm Ts Ta 2 Churchill and Chu recommend a single correlation for a wide range of Rayleigh number, 0.387Ra 1 / 6 Nu D 0.60 1 (0.559 / Pr) 9 / 16 8 / 27 2 Ra 1012 (2) From correlation (1) and (2) we can determine hC1th and hC2th and compare with hc obtained from the experiment. Forced convection Observations Se t 1 2 3 4 5 6 7 V V o lts 20 20 20 20 20 20 20 I Amp Va m/s 0 .5 1 2 3 4 5 6 T9 C T10 C Analysis of results Se t Qinput W hr W/m2K hC W/m2K Re - Nu1 - Nu2 - hC1th - hC2th - 1 2 3 4 5 6 7 Experiment2 10 INME 4032 The total heat input is: Qinput = VI The heat transfer rate by radiation is: Qrad = A (Ts4 – Ta4) = hr A (Ts – Ta) So, hr (Ts4 Ta4 ) Ts Ta The heat transfer rate by convection is: Qconv = Qinput - Qrad From Newton’s law of cooling Qconv hc A(Ts Ta ) and hc Q conv A(Ts Ta ) Comparison with theoretical correlations For an isothermal long horizontal cylinder, Hilper suggests, Nu D hD C Re mD Pr 1 / 3 k (3) where C and m are coefficient that depend on the Reynolds number: ReD 0.4-4 4-40 40-4000 4000-400000 40000-400000 C 0.989 0.911 0.683 0.193 0.027 m 0.330 0.385 0.466 0.618 0.805 All properties are evaluated at the film temperature Tfilm Ts Ta 2 Experiment2 11 INME 4032 Churchill and Bernstein proposed the following correlation for Re Pr>0.2 5/8 0.62 Re 1 / 2 Pr 1 / 3 Re D Nu D 0.3 1 1/ 4 0.4 2 / 3 282000 1 Pr 4/5 (4) where all properties are evaluated at the film temperature. From correlation (3) and (4) we can determine hC1th and hC2th and compare with hc obtained from the experiment. Discussion Experiment2 12 INME 4032