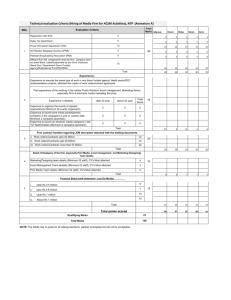

name of equipment

advertisement

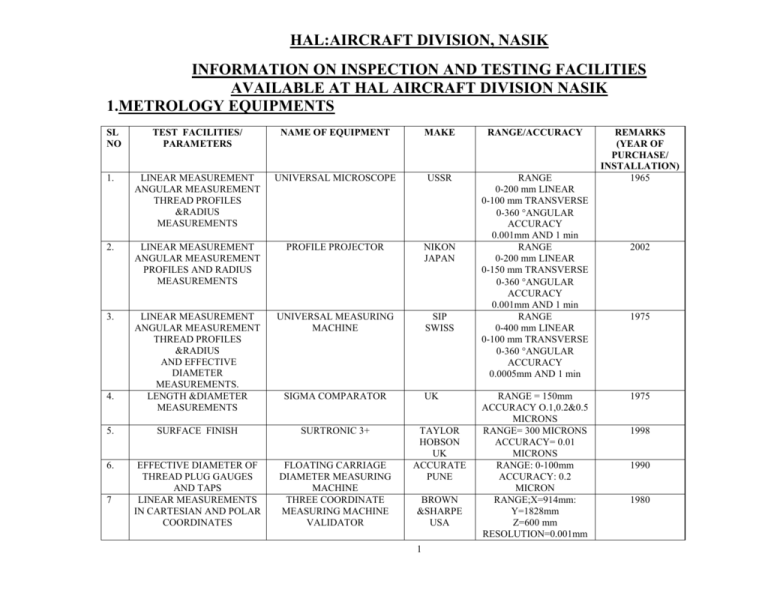

HAL:AIRCRAFT DIVISION, NASIK INFORMATION ON INSPECTION AND TESTING FACILITIES AVAILABLE AT HAL AIRCRAFT DIVISION NASIK 1.METROLOGY EQUIPMENTS SL NO TEST FACILITIES/ PARAMETERS NAME OF EQUIPMENT MAKE RANGE/ACCURACY 1. LINEAR MEASUREMENT ANGULAR MEASUREMENT THREAD PROFILES &RADIUS MEASUREMENTS UNIVERSAL MICROSCOPE USSR 2. LINEAR MEASUREMENT ANGULAR MEASUREMENT PROFILES AND RADIUS MEASUREMENTS PROFILE PROJECTOR NIKON JAPAN 3. LINEAR MEASUREMENT ANGULAR MEASUREMENT THREAD PROFILES &RADIUS AND EFFECTIVE DIAMETER MEASUREMENTS. LENGTH &DIAMETER MEASUREMENTS UNIVERSAL MEASURING MACHINE SIP SWISS RANGE 0-200 mm LINEAR 0-100 mm TRANSVERSE 0-360 ANGULAR ACCURACY 0.001mm AND 1 min RANGE 0-200 mm LINEAR 0-150 mm TRANSVERSE 0-360 ANGULAR ACCURACY 0.001mm AND 1 min RANGE 0-400 mm LINEAR 0-100 mm TRANSVERSE 0-360 ANGULAR ACCURACY 0.0005mm AND 1 min 5. SURFACE FINISH SURTRONIC 3+ 6. EFFECTIVE DIAMETER OF THREAD PLUG GAUGES AND TAPS LINEAR MEASUREMENTS IN CARTESIAN AND POLAR COORDINATES FLOATING CARRIAGE DIAMETER MEASURING MACHINE THREE COORDINATE MEASURING MACHINE VALIDATOR 4. 7 SIGMA COMPARATOR UK TAYLOR HOBSON UK ACCURATE PUNE BROWN &SHARPE USA 1 RANGE = 150mm ACCURACY O.1,0.2&0.5 MICRONS RANGE= 300 MICRONS ACCURACY= 0.01 MICRONS RANGE: 0-100mm ACCURACY: 0.2 MICRON RANGE;X=914mm: Y=1828mm Z=600 mm RESOLUTION=0.001mm REMARKS (YEAR OF PURCHASE/ INSTALLATION) 1965 2002 1975 1975 1998 1990 1980 SL NO TEST FACILITIES/ PARAMETERS NAME OF EQUIPMENT MAKE RANGE/ACCURACY YEAR OF PURCHASE/ INSTALLATION HEIGHT AND 2D MEASUREMENTS LINEAR HEIGHT MITUTOYO JAPAN RANGE=0-600mm LC= 0.001mm 1998 SQUARENESS OF ENGINEER’S SQUARE SQUARE TESTER FMS GERMANY RANGE: BLADE LENGTHS 40-400 mm ACCURACY=1 MICRON 10. EFFECTIVE DIAMETERS OF THREAD RING GAUGES MATRIX INTERNAL DIAMETER MEASURING MACHINE MATRIX UK RANGE 6-150mm ACCURACY= 0.2MICRON 1970 11. MEASUREMENT OF SMALL ANGLES AUTO COLLIMATOR LEITZ GERMANY RANGE: 30 Minutes ACCURACY: 0.5 Sec. 1971 12. 2D CONTOUR MEASUREMENTS CONTUROGRAPH PERTHEN GERMANY 1982 13 MEASUREMENT OF ANGLES OPTICAL DIVIDING HEAD USSR RANGE: 5X,10X,20X,50X,100X, 200X RANGE 0-360 ACCURACY : 10 SEC. 8. 9. 2 1980 1965 2.MECHANICAL TESTING EQUIPMENTS SL TEST FACILITIES/ PARAMETERS NAME OF EQUIPMENT MAKE RANGE/ACCURACY 1. TESTING OF METAL SPECIMEN AND COMPONENTS BY APPLICATION OF STATIC LOAD IN TENSION,COMPRESSION,B EN-DING AND FOLDING TESTING OF METAL SPECIMENS AND COMPONENTS IN TENSION, COMPRESSION, BENDING AND REVERSE STRESS. FOR CHECKING OF HARDNESS BY BRINELL,VICKERS & ROCKWELL METHOD UNIVERSAL TENSILE TESTING MACHINE RUSSIAN 0-50 TON 10% UNIVERSAL TESTING MACHINE INSTRAN UK 0-10 Ton 0.5% 1979 HARDNESS TESTER WALPERT GERMANY HRC 20-60 BHN 200-240 VPN 300-800 MICROSCOPE ACCURACY 0.01mm 0.02N /200KN 0.5% 1995 2. 3. 4. 5. 6. 7 8. TENSION,COMPRESSION,F LE-XURAL &REVERSE STRESS TESTS ON ALL TYPES OF MATERIALS FOR TESTING OF SPECIMEN & COMPONENTS IN TENSION & COMPRESSION MODES. TO FIND OUT CHARPY IMPACT STRENGTH OF THE FERROUS MATERIALS COMPRESSION & TENSILE STATIC TEST OF COIL SPRING THE DEVICE USED FOR BEND TESTING ROUND WIRE 0.8-5 mm IN DIA OF FERROUS AND NONFERROUS METALS UNIVERSAL TESTING MACHINE ZWICK, GERMANY YEAR OF PURCHASE/ INSTALLATION 1969 1986 UNIVERSAL TESTING MACHINE FRANK GERMANY 0-10 TON 1% 1969 CHARPY IMPACT TESTING RUSSIAN MACHINE RUSSIAN 30 Kg.m 0.1Kgm 1968 SPRING TESTING EQUIPMENT RUSSIAN 0.1-10Kg 0.1% 1968 WIRE BENDING EQUIPMENT RUSSIAN WIRE DIA 0.8-5mm PRETENSION ON WIRES 2-6Kgs.15120Kgs 0.5% 1968 3 SL TEST FACILITIES/ PARAMETERS NAME OF EQUIPMENT MAKE RANGE/ACCURACY Remarks (Year of installation) TORSION TESTING ROUND WIRES OF DIA 1-5 mm WIRE TWISTING EQUIPMENTS RUSSIA 0.5 OF A REVOLUTION 1968 TO DETERMINE VICKERS & BRINNEL HARDNESS NUMBERS. VICKERS HARDNESS TESTER UK LOADS UPTO 120 Kg. MICROSCOPE ACCURACY 0.001 mm 1970 11. TO DETERMINE UTS & BREAKING LOADS OF SMALL DIA WIRES HOUSEN FIELD TENSOMETER UK 2 Ton 1% 1969 12. THE MACHINE USED FOR CARRYING OUT ERICHSEN DEEP DRAWING CUPPING TEST OF SHEETS UPTO 2 mm THICK TESTING FATIGUE OF FERROUS & NON-FERROUS METALS. CUPPING TESTING EQUIPMENT HUNGERY PISTON TRAVEL 1968 ROTARY BENDING FATIGUE TESTING EQUIPMENT GERMANY STRESS LEVEL UPTO 90 Kg/mm2 0.1Kg/mm2 1977 9. 10. 13. 4 3 NDT EQUIPMENTS SL TEST FACILITIES/ PARAMETERS NAME OF EQUIPMENT MAKE RANGE/ACCURACY Remarks (Year of Purchase / Installation) 1. TO DETECT INTERNAL DEFECTS SUCH AS CRACK,POROSITY,CAVITIES, NON-FUSION IN CASTING WELDING OF FERROUS, NON-FERROUS METALS,ALLOYS & SOME NONMETALLIC MATERIALS. INDUSTRIAL X-RAY EQUIPMENT MCN 321. PHILIPS GmbH GERMANY % SENSITIVITY 2% PENETRATION : 35 mm STEEL 1989 INDUSTRIAL X-RAY EQUIPMENT MCN 321. WITH DANA OVERHEAD SYSTEM INDUSTRIAL X-RAY EQUIPMENT ERESCO 200MF PHILIPS GmbH GERMANY RICK SEIFERT % SENSITIVITY 2% PENETRATION : 35 mm STEEL % SENSITIVITY 2% PENETRATION : 15 mm STEEL RANGE 1) TIME BASE 1.23 TO 7.5 Mtrs OF ACCURACY 1% 2) THICKNESS 0.01185.ACCURACY 0.001 Inch. RANGE 0.25 mm TO 99.99 mm.ACCURACY 0.003mmUPTO 9.999mm 0.01mm UPTO 99.99mm SOUND VELOCITY RANGE 1800TO 8000Mtr/Sec.ACCURAC Y 3Mtr/Sec 1987 2 -DO3. -DO- 4. TO DETECT INTERNAL DEFECTS MAINLY LAMINAR DEFECTS,SUCH AS CRACK,CAVITIES,POROSITY IN METALLIC MATERIALS. ULTRASONIC FLAW DETECTOR SONIC 10005 STAVLEY NDT TECHNOLOGIES UK 5. FOR ACCURACY MEASUREMENT OF WALL THICKNESS OF PRECISION COMPONENTS. ULTRASONIC THICKNESS METER CL 204 KRAUTKRAMM ER BRANSAN CO GERMANY 5 1998 2001 1986 4 PAINT AND SEALANT EQUIPMENTS SL TEST FACILITIES/ PARAMETERS NAME OF EQUIPMENT MAKE RANGE/ACCURACY Remarks (Year of Purchase / Installation) 1. TO CHECK FLOW/VISCOSITY OF PAINTS AND RELATED MATERIALS. VISCOMETER CUPS TYPE B3-1,B3-4 FORD CUP NO.4 RUSSIAN 100% 1968 100% 1988 100% 1968 UPTO 1% 2000 100%,0-100 RANGE 1997 99% 1999 100% 1994 IMPACT TESTER ASSOCIATED INSTRUMENTS MUMBAI RUSSIAN HARDNESS TESTER SHEEN UK --DO-2. 3. 4. 5. 6. 7 8. 9. 10 TO CHECK SUDDEN IMPACT EFFECT OF DRY PAINT FILM HARDNESS OF PAINT AND RELATED MATERIALS. TO CHECK GLOSS PARAMETER i.e. GLOSSY,SEMIGLOSSY,MATTFINISH TO CHECK CORROSION IN SALTY ATMOSPHERE GLOSS METER SALT SPRAY CHAMBER SHEEN UK THERMO LAB MUMBAI SYNREC KOLKATTA TO CHECK EXTENT OF CORROSION IN HUMID ATMOSPHERE ARTIFICIAL WEATHERING EFFECT HUMIDITY CHAMBER WEATHEROMETER Q-PANEL USA 100% 1998 HARDNESS OF PAINT FILM WITH LOAD ADHESION OF PAINT FILM FLEXIBILITY OF PAINT FILM SCRATCH HARDNESS TESTER ADHESION TESTER BEND TEST TESTER 1mm,3mmAND 5mm SHEEN-UK 100% 1998 SHEEN-UK INDIAN 100% 100% 1998 1986 6 5. OTHER EQUIPMENT (CHEMICAL,METALLURGICAL,DIMENSIONAL MEASUREMENT,SPECIAL TESTING EQUIPMENT) SL TEST FACILITIES/ PARAMETERS NAME OF EQUIPMENT MAKE RANGE/ACCURACY Remarks (Year of Purchase / Installation) 1. FOR CHECKING OF VISCOSITY OF OILS BY ‘U’ TUBE METHOD IN CENTI STOKES AT VARIOUS TEMP. FOR CHECKING FLASH POINT VISCOSITY BATH STANHOPE SETA,UK 0-150CENT 0.5CENT 1995 FLASH POINT APPARATUS TOSHNIWAL BROS,MUMB AI STANHOPE SETA,UK UPTO 200CENT 2 CENT 1985-86 UPTO 200CENT 2 CENT 1972 UPTO 100KV .5KV 1995 1-14 0.01 2000 AMBIENT TO 180 Deg.CENT. ( 0.5Deg. CENT) UPTO-70DEG.CENT 2DEGREE CENT 1997 UPTO 210C 1Deg.CENT RANGE 500-5000cm-1 (100%) WAVE LENGTH 1970 UPTO 300Gm LOAD(99%) 1998 2. 3. 4. 5. FOR CHECKING OIL PROPERTIES AFTER OXIDATION TO DETERMINE BREAK DOWN VOLTAGE IN INSULATING COILS Ph OF LIQUID MATERIAL OXIDATION STABILITY EQUIPMENT BREAK DOWN VOLTAGE TESTER ‘pH’ METER ZARAN MUMBAI TOSHNIWAL BROS, MUMBAI KOEHLER, USA 6. BOILING RANGE OF ORGANIC SOLVENTS DISTILLATION APPARATUS 7 FREZZING POINT OF OILS. LOW TEMP. CABINET RECO,UK 8. OIL SEPARATION IN STAGE OF GREASE FOR CHECKING BASE/ TYPE OF RUBBER COMPOUNDS DROP POINT APPARATUS OIL SEPARATION OF GREASE ON STORAGE COLLOIDAL STABILITY APPARATUS(AS PER IP121) STANHOPE SETA,UK PERKIN ELMAR USA INDIAN 9. 10 FTIR SPECTROPHOTOMETER 7 1988 1995 5. OTHER EQUIPMENT (CHEMICAL,METALLURGICAL,DIMENSIONAL MEASUREMENT,SPECIAL TESTING EQUIPMENT) SL TEST FACILITIES/ PARAMETERS NAME OF EQUIPMENT MAKE RANGE/ ACCURACY Remarks (Year of Purchase / Installation) 11 MELTING POINT OF ORGANIC POWDER MATERIALS MELTING POINT APPARATUS FOR ORGANIC UPTO 200C(1Deg CENT) 1968 12 MIXING OF GREASE GREASE WORKER AS PER IP-50 MATERIALS 100% 1999 13 FOR MASTICATION OF RUBBER TWO ROLL RUBBER MIXING MILL TOSHNIWAL BROS MUMBAI NEC MOTORS Pvt Ltd, WB INDIA RUSSIAN 1Kg CAPACITY 1968 14 FOR MOULDING OF RUBBER SPECIMEN HYDRAULIC PRESS RUSSIAN 1968 15 FOR VULCANISATION OF NON METALLIC MATERIALS SUCH AS RUBBER ,RUBBERISED FABRIC. FOR MASTICATION AND MANUFACTURING OF RUBBER COMPOUNDS. AUTOCLAVE STEAM VULCANISATION KETTLE INDIAN TWO ROLL RUBBER MIXING MILL OF M/s RICHARDSON MAKE INDIAN FOR TEMPERATURE UPTO 250C(2Deg C AND PRESSURE UPTO 200 Kg/cm2 TEMPERATURE UPTO 150+2Deg C AND PRESSURE UPTO 5Kg/cm2 10 Kg CAPACITY FOR TESTING OF PHYSICO MECHANICAL PROPERTIES OF NON METALLIC MATERIALS SUCH AS RUBBER ADHESIVES SEALANTS AND FABRIC ETC. FOR MEASURING MICROHARDNESS OF RUBBERS,SEALANTS etc. MICROPROCESSOR CONTROLLED UTM INSTRON MODEL 4467, 3 TON CAPACITY UK ACCURACY 0.1 gm CAPACITY 300Kgs 1995 MICRO HARDNESS TESTER M/s HEINRICH BAREISS MAKE GERMANY 0-100 SHORE.A 1998 16 17 18 8 1981 1987 19 20 FOR MEASURING SHORE-A HARDNESS TO CARRY OUT CYCLIC TEST AT DIFFERENT HUMIDITY & TEMP. CONDITION OF RUBBER AND ADHESIVES. IRHD/SHORE HARDNESS TESTER MODEL –903 ENVIRONMENTAL TEST CHAMBER OF BLUE STAR MAKE 9 GERMANY 0-100 SHORE-A 2001 INDIAN TEMO.-32C+200C 2C,HUMIDITY UPTO 98% 2001 5. OTHER EQUIPMENT (CHEMICAL,METALLURGICAL,DIMENSIONAL MEASUREMENT,SPECIAL TESTING EQUIPMENT) SL TEST FACILITIES/ PARAMETERS NAME OF EQUIPMENT MAKE RANGE/ACCURACY Remarks (Year of Purchase / Installation) 21 FOR DETERMINATION OF SOFTENING POINT OF ACRYLIC GLASS FOR TESTING OZONE RESISTANCE OF RUBBER AND NON-METALLIC SPECIMEN USED FOR ACCURATE AND DELICATE CUTTING OF METALLURGICAL SPECIMEN (FERROUS AND NONFERROUS) WITHOUT HEATING AND LOOSING PROPERTIES TO PRODUCE HIGH QUALITY METALLOGRAPHIC MOUNTS AND HEAT AND PRESSURE USED FOR FINAL POLISH OF METALLURGICAL SPECIMEN TO BE VIEWED UNDER OPTICAL MICROSCOPE TO OBSERVE AND STUDY METALLURGICAL STRUCTURE INCLUSION MODE OF FRACTURE, ACCURATE MEASUREMENT OF CARBURISED & NITRIDED LAYERS, DECARB etc., .. THERMAL STABILITY TESTER FRANK GERMANY TEMP UPTO 200C1C 1987 OZONE TEST CHAMBER MODEL MAST700-1 UK 100 PPO OZONE CONCENTRATION UPTO 80C 1983 METALLOGRAPHIC CUTTING MACHINE 10-1000-350 BUEHLER USA WHEEL DIA 235 & 300mm THICK 0.8TO 1.5mm SOFT TO RC 60 CUTTING 1980 METALLOGRAPHIC SPECIMEN MOUNTING PRESS-SIMPLIMET .2 BUEHLER USA 25-30mm DIA MOULDS. TEMP. 138-150 Deg.C PRESSURE 29Mpa,MAXIMUM 1995 METALLOGRAPHIC POLISHING M/C 2 DISC POLISHER BUEHLER USA DISCS OF DIA 200mm WITH VARIABLE SPEEDS 1982 OPTICAL MICROSCOPE – MVS 235 UNION EXAMET JAPAN 30 X TO 1000X 1994 22 23 24 25 26 10 27 INCIDENT LIGHT MICROSCOPE FOR STUDY OF METALLURGICAL STRUCTURE,INCLUSION etc AND PHOTO MICROGRAPHY OPTICAL MICROSCOPE JANAVERT HD CARLZEISS JENA,GDR 11 50X-1500X 1991 5. OTHER EQUIPMENT (CHEMICAL,METALLURGICAL,DIMENSIONAL MEASUREMENT,SPECIAL TESTING EQUIPMENT) SL TEST FECILITIES/ PARAMETERS NAME OF EQUIPMENT MAKE 28 USEDTO STUDY SURFACE TOPOGRAPHY OF FRACTURE & FAILED COMOPONENT DURING DEFECT INVESTIGATION AND TO PHOTO GRAPH FRACTURE SURFACES. ZOOM STEREO MICROSCOPE SZH-10-111 OLYMPUS JAPAN HOT STAGE MICROSCOPE WITH MICROSCOPE WITH MICROPHOTOGRAPHY ARRANGEMENT USED TO MEASURE VICKERS/KNOOP HARDNESS OF THIN SAMPLE,LEAF SPRINGS,WIRES AND METALLURGICAL CONSTITUENTS. TO TEST JAMINY END QUENCH HARDENABILITY OF STEELS DURING INDIGENISATION. UNIVERSAL CAMERA MICROSCOPE-MeF2 REICHERT AUSTRIA 70X-1500X 1983 MINI LOAD HARDNESS TESTER LEITZ,GDR 100X & 500X mag 5Gm- 2000Gm LOAD 1981 JAMINY HARDENABILITY TESTER-J 0.01 ADAMEL LHAMARGY FRANCE 1980 TO MEASURE TEMPERATURE OF FURNACE/OVEN/CHAMBER ACCURATELY UTILISED FOR DAY TO DAY WORK OF CALIBRATION TEMPERATURE INDICATOR DIGIRAD 4000 FLEXIBLE/BEAD K TYPE THERMOCOUPLE RADIX PYTOTECH MUMBAI TEMPSENS UDAIPUR Pt/Pt RH 10% THERMO COUPLE,TEMP, RANGE Max 1500Deg Cent. ACCURACY 1Deg Cent -100Deg TO 1200DegCent 1Deg Cent FLEXIBLE-70 TO300C BEAD THERMOCOUP LE UPTO 1200C 29 30 31 32 33 12 RANGE / ACCURACY 3.5- Remarks (Year of Purchase / Installation) 1999 40X 1997 1998 34 FOR CALIBRATION OF THERMOCOUPLE WITH DIA INDICATOR AND THERMOCOUPLE OIL BATH RUSSIAN 13 UPTO 150C 1C 1967 5. OTHER EQUIPMENT (CHEMICAL,METALLURGICAL,DIMENSIONAL MEASUREMENT,SPECIAL TESTING EQUIPMENT) SL TEST FACILITIES/ PARAMETERS NAME OF EQUIPMENT MAKE RANGE/ ACCURACY 35 FOR DETERMINATION OF MELTING POINT OF DIFFERENT TYPE OF METALLIC MATERIALS MELTING POINT APPARATUS M/s SUN ELECTRICALS MUMBAI UPTO 900C 1C 36 TO CALIBRATE DIFFERENT TYPE OF THERMOCOUPLE WITH STANDARD THERMOCOUPLES TO MEASURE EMF IN TEMPERATURE COTROLLER AND THERMOCOUPLE TO CALIBRATE ROUTINE THERMOCOUPLE AND USED AS PRIMARY STANDARD TO MEASURE VISCOCITY OF FLUIDS SUCH AS ADHESIVES, PAINTS etc… FOR ESTIMATION OF TRACE ELEMENTS AND ALLOYING ELEMENTS IN VARIOUS BASE ALOOYS BY SOLUTION TECHNIQUE TUBULAR FURNACE M/S CABOLITE UPTO1200C 1C 1986 EMF METER 200 MV 0.03% OF READING 1989 Pt-Rh THERMOCOUPLE M/s GP ELECTRICAS VADODARA INDIAN UPTO1200C 1C 1988 VISCOMETER MODEL LVF BROOKFIELD ENGG. LAB INC. 1994 ATOMIC ABSORPTION SPECTROMETER UNICAM ANALYTICAL SYSTEMS UK 41 SIMULTANEOUS ANALYSIS OF PROGRAMMED ELEMENTS IN IRON,Cu,Al BASE ALLOYS DIRECT READING EMMISION SPECTROMETER MODEL DV-4 BAIRD CORPORATION USA 42 ESTIMATION OF CARBON AND SULPHUR IN STEEL SAMPLES,CAST IRON LECO CARBON AND SULPHUR DETERMINATOR MODEL C6225 LECO CORPN. USA 15 TO 100000 CENTIPOISE 1% OF SCALE ACCURACY AND RANGE VARIES FROM ELEMENT.OVERA LL ACCURACY WITHIN 5% RANGE FROM TRACE ELEMENTS TO ALLOYING ELEMENTS ACCURACY 5% RANGE CARBON 0-99.9% SULPHUR 0-99.9% ACCURACY CARBON0.5% SULPHUR 5% 37 38 39 40 14 YEAR OF PURCHASE/ INSTALLATION 2000 1994 1984 1996 5. OTHER EQUIPMENT (CHEMICAL,METALLURGICAL,DIMENSIONAL MEASUREMENT,SPECIAL TESTING EQUIPMENT) SL TEST FACILITIES/ PARAMETERS NAME OF EQUIPMENT MAKE RANGE/ACCURACY Remarks (Year of Purchase / Installation) 43 FOR OBTAINING % TRANSMISSION GRAPHS OF PLAIN OPTICAL GLASSES,CALORIMETRIC ANALYSIS UV-VIS SPECTROPHOTOMETER MODEL CHEMITO 2500 THOSNIWAL INSTRUMENT Pvt.Ltd .MUMBAI 1994 44 MEASUREMENT OF pH OF LIQUID SAMPLE pH METER MODEL CL-54 45 ESTIMATION OF PHOSPHOROUS IN STEEL TESTING MICRO HARDNESS OF THIN PLATES,HARDENED SURFACE,PLATED LAYERS etc. RAPID PHOSPHOROUS DETERMINATOR MICRO HARDNESS TESTER TYPE M THOSNIWAL INSTRUMENT Pvt.Ltd .MUMBAI M/SELECTRON ICS Engg Inds M/s SHIMADZU CORPN. JAPAN RANGE ABSORBANCE 2.0-2.0ABS TRANSMITTANCE 1125%T ACCURACY0.005ABS AT 1 ABS WITH NBS 930 STANDARD FILTER RANGE: 00-14 pH Accuracy 0.01pH RANGE 0.005-0.05% ACCURACY 0.005% LOADING RANGE 151000g..f VICKERS 2001 46 15 2000 1996