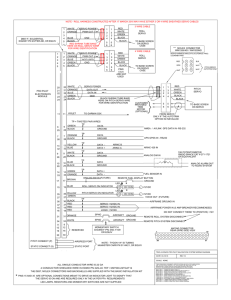

kopp bd-4 “n375jk” dynon auto pilot installation

advertisement

KOPP BD-4 “N375JK” DYNON AUTO PILOT INSTALLATION PHOTOS Roll Servo Installation in neutral position: Full Left Roll: Full Right Roll: The right cable blocks were canted forward for two reasons – 1 to provide 3/8” inch clearance between the servo mounting bolts and the bolts securing the cable blocks and 2) To Place the right bridle cable in plane with the CAPSTAN outer groove. The controls are smooth and free of any binding. Pitch Servo Installation in neutral position: Pitch Servo Installation in Full Fwd Position: Servo arm in full fwd position connected at the outer most arm hole (1.5” from center of rotation) is about 25-30 degrees forward of neutral position and cannot reach an overcenter condition. Pitch Servo in Full aft position: Again about 25-30 degrees displaced from neutral and in no danger of achieving an overcenter condition due to mechanical stops built into the flight control system. Both servos were wired to male DB-9 connectors. 5 wire cable was fitted with female DB-9’s and connected to each servo. Power runs through a dedicated AP 5 amp ckt breaker located just to the left of the pilot side yoke for easy access. To the right side of the yoke is mounted a momentary push-button switch wired normally open. When depressed the switch connects each servo disconnect wire to aircraft GND. Each servo DSAB wire was fitted with a crimp terminal ring and connected to a strip buss that connects EFIS, EMS and HS-34 DSAB lines. All wiring was checked for both continuity and shorts.