Research Paper

advertisement

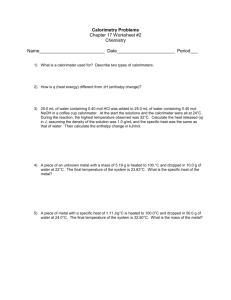

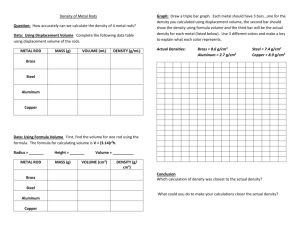

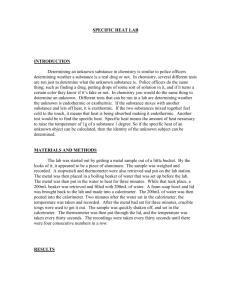

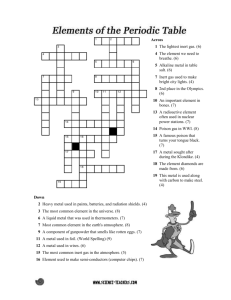

Jordan – Semones 1 Molybdenum Identification Sydni Jordan and Kyla Semones Macomb Mathematics Science Technology Center Chemistry / IDS 10 10C Mrs. Hilliard / Mr. Supal / Mrs. Dewey 20 May 2013 Jordan – Semones 2 Table of Contents Introduction ……………………………………………………………………………..3 Background ……………………………………………………………………………..5 Specific Heat Review of Literature ……………………………………………………7 Linear Thermal Expansion Review of Literature …………………………………..10 Problem Statement ……………………………………………………………………13 Specific Heat Experimental Design …………………………………………………15 Linear Thermal Expansion Experimental Design ………………………………….19 Data and Observations ……………………………………………………………….22 Data Analysis and Interpretation …………………………………………………….38 Conclusion ……………………………………………………………………………..53 Acknowledgements…………………………………………………………………... 56 Appendices …………………………………………………………………………….57 Works Cited ……………………………………………………………………………64 Jordan – Semones 3 Introduction Identification is the first step to understanding. Many occupations, such as those that involve chemistry and mining, require scientists to identify whether or not a discovered metal is the same as a known metal. The researchers adapted the ideas behind those jobs when conducting this experiment. In the following experiment, the researchers’ purpose was to identify whether or not two metal rods were composed of the same metal using only length, mass, and temperature values. One of the metal rods was composed of Molybdenum, a substance used in steel alloys to make them stronger. Molybdenum is used to strengthen steel because Molybdenum has properties that increase the melting temperature and enhance the corrosion and heat resistance ("Molybdenum Properties"). The experiment proved that there are many types of ways to identify a metal. In situations beyond this experiment, different methods of experimentation are often used, but for these experiments specific heat and linear thermal expansion tests were used to compare the two rods. Each metal has its own designated specific heat and linear thermal expansion coefficient. Specific heat is the amount of heat that it takes increase the temperature of a metal by one degree Celsius, and linear thermal expansion is the linear change in length that a metal undergoes when it is heated. The specific heat of Molybdenum is 0.25 J/g x ºC, and the linear thermal expansion is 4.8 x 10-6mm. The researchers used this information when comparing the two metals. First, the researchers performed a simple experiment to calculate the Jordan – Semones 4 specific heat of Molybdenum. Then, they performed the same experiment with the unknown metal and compared the two values. An experiment for linear thermal expansion was also conducted on the Molybdenum rods, and again, the same experiment was performed with the unknown metal rods and compared the results. The main objective of the experiment was to make a correct inference on whether or not the two given rods were composed of the same metal. Significance tests, which were conducted on the values from the trials, and percent error equations that calculated the extremity of their errors presented the researchers with statistics that helped them decide whether or not the two rods were actually the same metal. Jordan – Semones 5 Background and Reviews of Literature Molybdenum is a unique transition metal with a hard, silver outer appearance. A Swedish Chemist, Carl Welhelm Scheele, discovered Molybdenum in 1778. Although he was the first to recognize the element, he discovered it as Molybdenite. Peter Jacob Hjelm was the first to actually isolate the element and discover its pure form (Gagnon). Molybdenum has an atomic number of 42, meaning that there are 42 protons in a Molybdenum atom, and an atomic mass of 95.94 amu. Of Molybdenum’s 42 electrons, six of them are valence electrons. Figure 1 below shows the electron configuration of Molybdenum. Figure 1. The shortened electron configuration for Molybdenum The density of Molybdenum is 10.22 g/cm3 (Hogan). This is relatively high when compared to the density of water, 1 g/cm3, and the density of iron, 7.87 g/cm3. This means that the particles in Molybdenum are packed closer than those in water and iron. Molybdenum also has a melting point of 2623ºC. This is an extremely high temperature, and this puts Molybdenum in the top 10 elements with the highest known melting point. Jordan – Semones 6 Molybdenum is used in many ways, and new uses are constantly being discovered. When most think of Molybdenum, they think of it being used in industrial industries. This is true; it is frequently used for steel alloys. When added, Molybdenum transforms ordinary steel into "ultra-high strength steel". It makes for a stronger metal with a higher heat tolerance, strength, and resistance to corrosion. Molybdenum is unique because it has the capability to withstand extremely high temperatures without undergoing a change to its shape or form. Due to this, it is often used not only for the creation of alloys but also in space exploration ("Molybdenum Properties"). Molybdenum is a useful element but it is not always easy to find. One of the extraction processes involves roasting Molybdenum Disulfide (MoS2) to convert it to Molybdenum Trioxide (MoO3) ("Processing."). Figure 2 below shows the chemical equation used to extract Molybdenum. 2MoS2 + 7O2 (g) → 2MoO3 + 4SO2 MoS2 + 6MoO3 → 7MoO2 + 2SO2 2MoO2 + O2 → 2MoO3 Figure 2. The chemical equation that shows the extraction process of Molybdenum Figure 2 models the chemistry aspect behind Molybdenum extraction. Roasters are used to extract Molybdenum from the ground. The roasters use furnaces and heated air with temperatures between 500ºC and 600ºC. Jordan – Semones 7 Specific Heat Review of Literature Specific heat is the amount of heat needed to raise the temperature of one gram of a substance by one degree Celsius (Missouri State University). Specific heat is a type of physical property, known as an intensive property, meaning that the amount of the substance is not relevant to the results (Department of Chemistry, Texas A&M University). All substances are associated with temperature, and this means that the greater the temperatures of the substance, the faster its molecules are moving. The First Law of Thermodynamics, that energy is neither created nor destroyed, is proven when the concept of specific heat is applied. In specific heat experiments, the metal must be heated and cooled to calculate the specific heat of the metal. The energy from the heat enters and leaves the system, or the metal, but the total amount of energy does not change and energy is not created or destroyed. Most metals have a low specific heat; substances with a low specific hear need less energy to increase the temperature of the substance. Specific heat is calculated using the formula displayed below. Q = s • m • ∆T This equation shows that the heat released or absorbed by the reaction, Q, is equal to the specific heat, s, multiplied by the mass, m, multiplied by the change in temperature, ∆T. The heat released or absorbed by the reaction is measured in joules, the mass is measured in grams, and the change in temperature is Jordan – Semones 8 measured in degrees Celsius. Thus, specific heat is measured in joules per grams degrees Celsius (J/g ºC) (Nave). Past experiments have been performed in which the specific heat of a certain substance was calculated. Most of these experiments involved the use of a calorimeter. A tool such as this can be as simple as a Styrofoam cup. In general, calorimetry was used to determine the heat released or absorbed in these experiments. The first experiment that was performed to calculate the specific heat of an unknown substance went as follows. A beaker of water was heated and the unknown metal was placed into the water. Afterwards, the change in temperature was calculated and recorded with the use of a thermometer that was placed through the top of the calorimeter. The heat gained during the initial heating of the metal was found to be the same amount of heat that was lost from the metal (Bauck). This experiment not only calculated the specific heat of a metal, but it also proved the First Law of Thermodynamics. The second experiment involved a completely different process than that of the first. The specific heat of the substance was calculated with the use of cylinders made entirely of the unknown metal. When different metal cylinders were heated to the same temperature and immersed individually in an equal quantity of water, the rise in the temperature of the water was directly proportional to the specific heat of the chosen metal cylinder (“HEAT”). These experiments seemed easy to execute and replicate, The different methods used in these experiments show just how intensive properties such as Jordan – Semones 9 specific heat can be used to identify a metal, regardless of experimental design. Each metal has its own unique specific heat, therefore knowing these important details have brought the researchers one step closer to discovering whether or not the unknown metal is the same as the known. Jordan – Semones 10 Linear Thermal Expansion Review of Literature One unique way of finding the identity of a substance is by using the concept of Linear Thermal Expansion. Linear Thermal Expansion is a metal's change in length when it experiences a change in temperature. In most cases, the length of a metal is increased when the heat is increased. It changes by an amount proportional to the change in temperature and the initial length of the object. ("Temperature and Thermal Expansion.") The expansion of metal is best described by the Kinetic Molecular Theory. The Kinetic Molecular Theory states that atoms are in constant motion and when heat is applied to the system, or the metal rod in this case, the speed of the atoms’ motion increases. When metal undergoes a heat increase, the energy from the heat causes the atoms in the metal to vibrate and move. These vibrations then increase the space between the atoms. This is what causes the metal to expand. ("223 Physics Lab: Linear Thermal Expansion."). Yes, Linear Thermal Expansion is the method with which the elemental composition of the metal will be discovered, but the observed value is actually the linear thermal expansion coefficient. A linear thermal expansion coefficient is a value unique to the metal it correlates with. ("Coefficients of Linear Thermal Expansion."). Every metal has a different linear thermal expansion coefficient, and this coefficient can be calculated by using the Linear Thermal Expansion equation. (R. Nave) ∆L = α • L0 • ∆T Jordan – Semones 11 The equation above calculates linear thermal expansion. The symbol α stands for the linear thermal expansion coefficient, L0 stands for the initial length of the object being measured, and ∆T stands for the change in temperature of the object. The equation calculates the change in length, or ∆L. By manipulating the equation, the linear thermal expansion coefficient can be calculated. It is often measured in 10-6 m/m °C. Past experiments have been performed to discover unknown metals. Both of the mentioned experiments contained an apparatus but there were set up differently to discover the linear thermal expansion coefficient. In the first experiment, the overall linear thermal expansion was calculated by the measuring of the change of length in the unknown metal. A steam generator was placed at one end of the apparatus and on the other end was a dial gauge that measured the variation in tolerance. First, the steam generator was filled with water. Next, the expansion apparatus was attached to the tube of the unknown metal. Then the data was recorded and inserted into the linear thermal expansion formula (Hurth). The second experiment was performed using the measurements for the initial lengths and diameters of the rods of the unknown metal. Then, the unknown metal was placed in the steam generator to be heated. Afterwards, the rods were removed and the data was inserted into the linear thermal expansion formula (Physics Department). Knowledge of these experiments has aided in the determination of the unknown metal rod’s linear thermal expansion coefficient. In the future, different Jordan – Semones 12 experiments may be conducted to further prove the identity of the unknown metal. With this knowledge, industries such as those that involve plumbing would benefit by knowing what type of pipes would be best for certain situations. It would not be a good idea for a plumber to install pipes made out of a metal that has a tendency to expand when it is heated. Jordan – Semones 13 Problem Statement: The researchers will use linear thermal expansion and specific heat equations along with percent error to correctly determine whether or not the unknown metal rod is made of Molybdenum. Hypothesis: When the linear thermal expansion coefficient in millimeters, the specific heat in joules per gram degrees Celsius, and the average percent error for the trials are calculated, the researchers will conclude that the unknown metal rod will not be composed of Molybdenum. Data Measured: In the specific heat calculation, the mass of the metal rod and water was measured in grams. The change in the temperature of the metal rod and water was measured in degrees Celsius. The overall specific heat of the Molybdenum and unknown metal rods was be measured in joules per gram degrees Celsius. The equation below was used to calculate the specific heats of the metal rods. Smetal • mmetal • ∆Tmetal = Swater • mwater • ∆Twater The equation above shows that the formula used to calculate the specific heat of the metal was set equal to the formula used to calculate the specific heat of the water. This was done because the heat used to change the temperature of one gram of both of the substances became the same when the metal was placed in Jordan – Semones 14 the water. The equation was then manipulated to find the specific heat of the metal alone. In the linear thermal expansion calculation, the initial length and the change in length were measured in millimeters. The change in temperature was measured in degrees Celsius. The equation below was used to calculate the linear thermal expansion coefficients of the metal rods. ∆L = α • L0 • ∆T The equation was manipulated so that the alpha coefficient was set to equal the change in length of the metal rod divided by the change in temperature and the initial length of the metal rod. Specific Heat Experimental Design Jordan – Semones 15 Materials: Scout Pro Electric Scale (0.01g precision) Calorimeter Corning Hot Plate Jiffy – Foil Loaf Pan (7 15/16 in. x 5 7/16 in. x 1 13/16 in.) Tongs Molybdenum Rod Water, H20 Logger Pro Logger Pro Temperature Probe TI-nSpire CX Graphing Calculator Thermometer Unknown Metal Rod Graduated Cylinder Jordan – Semones 16 Specific Heat Procedure: 1. Randomize the 15 trials for the Molybdenum rod and the unknown rod on the TI- nSpire calculator (see Appendix 1). 2. Construct the calorimeter (see Appendix 2). 3. Tar the scale so it’s initial value is zero, then place the Molybdenum rod on it. 4. Record the mass of the rod and remove the metal rod from the surface of the scale. 5. Fill half of the loaf pan with water. 6. Place the loaf pan on the hot plate and adjust the dial to the highest setting to boil the water. 7. Wait for the water to boil and use the thermometer to make sure the temperature of the water is approximately 98ºC. 8. Use the tongs to pick up the Molybdenum rod and gently place it in the loaf pan with the boiling water. 9. Keep the metal rod in the water for 3 minutes so its temperature is equivalent to that of the boiling water (98ºC). 10. Prepare the Logger Pro. 11. Measure 41 ml of room temperature water with the graduated cylinder and carefully pour it into the calorimeter. 12. Insert the thermometer into the calorimeter and record the temperature of the water. 13. Once the metal rod has been in the boiling water for 3 minutes, carefully use the tongs to insert it into the calorimeter. 14. Immediately place the cap on the calorimeter and secure it. Quickly insert the temperature probe through the drilled hole on the top of the calorimeter and begin data collection. 15. Keep the metal rod in the water for 90 seconds so the temperature of the water and metal may reach equilibrium. 16. After the 90 seconds, stop the data collection on the Logger Pro. 17. Remove the temperature probe and the metal rod with the tongs. Place it on the paper towel. Pour the water from the calorimeters into a sink. 18. Repeat steps 3 – 17 for each of the randomized trials for the Molybdenum rod and the unknown metal rod. 19. Pour the water from the loaf pan into a sink and proceed to tidy up the workspace. Diagram: Figure 3. One of the calorimeters from the procedure Figure 3 shows a picture of one of the calorimeters that was used in the specific heat procedure. Three calorimeters were created to test the specific heats of the rods. Linear Thermal Expansion Experimental Design Materials: Linear Expansion Jig (0.01 mm) TI- nSpire CX Calculator Caliper Hot Plate Timer Thermometer (0.1ºC) Tongs Aluminum Loaf Pan (dimensions) Unknown Metal Rod (2) Molybdenum Metal Rod (2) Graduated Cylinder Water, H2O (25 ml) Expo Marker Spray Bottle Jordan-Semones 21 Procedure: 1. Randomize the trials with the TI-nSpire calculator (See Appendix 1). 2. Carefully measure and record the length of the metal rod using the caliper. 3. Prepare the hot plate by plugging it in and adjust the dial to the highest setting to boil the water. 4. Fill half of the loaf pan with water and place it on the hot plate. Proceed to boil the water. 5. Prepare the timer on the TI-nSpire CX calculator by restarting it so that it does not display recorded time. 6. Carefully insert the thermometer into the water and record the temperature. Make sure the water is approximately 98ºC before proceeding to the next step. 7. Once the water is boiling, use the tongs to pick up the metal rod and carefully place it in the water. Start the timer once the rod is in the water. 8. Let the metal boil in the water for 3 minutes. 9. Use the tongs to remove the metal and instantly place in into the linear expansion jig. 10. Keep the linear expansion jig completely still and mark the beginning point with the marker. Jordan-Semones 22 11. For 3 minutes wait for the metal to cool to room temperature. Fill the spray bottle with water and lightly spray to metal rod to speed up the cooling process. Wait for the dial on the linear expansion jig to settle and mark the point where it stops. 12. Observe the difference of the position of the dial on the linear expansion jig and record the change in length. 13. Repeat steps 2 - 12 for each of the trials for the Molybdenum and unknown metal rods. Jordan-Semones 23 Data and Observations Table 1 Specific heat values for Molybdenum Change in Temp. (ºC) Initial Temp. (ºC) Trial Mass (g) Equilibrium Temp (ºC) Rod Water Metal Water Metal Metal Specific Heat Water (J/g x ºC) 1 B 20.1 98.0 25.7 5.6 -72.3 42.70 41 0.311 2 B 21.6 98.3 26.1 4.5 -72.2 42.70 41 0.250 3 A 22.3 98.3 27.4 5.1 -70.9 42.80 41 0.288 4 B 25.3 98.3 30.4 5.1 -67.9 42.80 41 0.301 5 A 30.0 98.3 32.7 2.7 -65.6 42.90 41 0.165 6 B 25.3 99.1 29.4 4.1 -69.7 42.70 41 0.236 7 A 25.3 99.1 29.0 3.7 -70.1 42.80 41 0.212 8 A 25.6 98.3 28.5 2.9 -69.8 42.83 41 0.166 9 B 25.6 98.3 29.1 3.5 -69.2 42.72 41 0.203 10 A 27.5 97.3 30.8 3.3 -66.5 42.84 41 0.199 11 B 27.4 97.3 30.6 3.2 -66.7 42.73 41 0.193 12 B 26.3 98.5 30.1 3.8 -68.4 42.74 41 0.223 13 A 27.3 98.3 31.4 4.1 -66.9 42.85 41 0.246 14 A 27.5 98.8 32.0 4.5 -66.8 42.86 41 0.270 15 B 27.5 98.8 32.2 4.7 -66.6 42.74 41 0.283 Jordan-Semones 24 In Table 1 above, the values for temperature and mass are recorded. These values were used to calculate the specific heat of the two Molybdenum rods. The differences in mass of the two rods may be a factor that contributed to the varying specific heat values. Another contributing factor to the varying values may be inconsistent testing methods by the researchers. Jordan-Semones 25 Table 2 The observations taken during the tests for the specific heat of the Molybdenum rods. Trial Rod Date Observations 1 B 04/17/13 Metal was placed into calorimeter 1. Time for metal in boiling water went about 5 seconds over. 2 B 04/17/13 Metal was placed into calorimeter 2. channel 2 in logger pro 3 A 04/17/13 Calorimeter 1. channel 1 in logger pro 4 B 04/17/13 Calorimeter 2 and channel 2 on logger pro. time for metal in boiling water went about 2 seconds over 5 A 04/17/13 Calorimeter 1 and channel 1 on logger pro. Time went a bit over 6 B 04/17/13 Calorimeter 2. Channel 2 in logger pro. went about 5 seconds over time while boiling in the water 7 A 04/17/13 Calorimeter 1. Channel 1 in logger pro. went about 5 seconds over time in boiling water 8 A 04/19/13 Calorimeter 3. Window open. Channel 4 in logger pro. went a bit over time while boiling (about 6 seconds) 9 B 04/19/13 Calorimeter 2. Window open. Channel 3 in logger pro. 10 A 04/19/13 Calorimeter 3. Window open. Logged on channel 4. 11 B 04/19/13 Calorimeter 2. Window open. Logged on channel 3. 12 B 04/19/13 Channel 3. Calorimeter 2. Window open. 13 A 04/19/13 Channel 4. Calorimeter 3. Window open. 14 A 04/19/13 Calorimeter 3. Window open. Channel 4 on logger pro. 15 A 04/19/13 Calorimeter 2. Window open. Channel 3 on logger pro. Jordan-Semones 26 Table 2 shows the specific heat observations for the Molybdenum rods. All four of the channels on the logger pro and all three of the calorimeters were used when the testing for the specific heats of the Molybdenum rods. On the second day of specific heat testing, the window was opened and that may have altered the data when it made the room cooler. Jordan-Semones 27 Table 3 The values used to calculate the linear thermal expansion coefficient, alpha, of the Molybdenum rods. Trial Rod ΔL (mm) Initial Length Initial Temp. (ºC) Final Temp. (ºC) Change in Temp. (ºC) Alpha Coefficient (mm x 10-6) 1 B 0.0254 129.41 98.7 27.7 -71.0 2.764 2 A 0.0254 129.28 98.7 27.7 -71.0 4.683 3 A 0.0254 129.33 98 28.1 -69.9 2.810 4 B 0.0200 129.40 98 28.1 -69.9 2.211 5 A 0.0254 129.39 98.2 25.0 -73.2 2.682 6 B 0.0200 129.36 98.2 25.0 -73.2 2.112 7 A 0.0254 129.34 98.7 25.1 -73.6 2.668 8 B 0.0200 129.32 98.7 25.1 -73.6 2.101 9 B 0.0200 129.33 98.7 24.5 -74.2 2.084 10 A 0.0254 129.41 98.7 24.5 -74.2 2.645 11 B 0.0200 129.28 96.7 26.1 -70.6 2.191 12 A 0.0381 129.45 96.7 26.1 -70.6 4.169 13 B 0.0254 129.41 99.3 22.4 -76.9 2.552 14 A 0.0381 129.37 99.3 22.4 -76.9 3.830 15 A 0.0254 129.41 98.4 22.5 -75.9 2.586 Jordan-Semones 28 Table 3 shows the recorded length and temperature values for the Molybdenum rods. These values were used to calculate the linear thermal expansion coefficient alpha. In the table, the alpha coefficient is measured in millimeters multiplied by 10-6. Notice that the initial lengths of rod A are overall less than the lengths of rod B. This may be a contributing factor to the varying values for the alpha coefficient of the Molybdenum rods. Jordan-Semones 29 Table 4 The observations taken during the tests for the linear thermal expansion coefficient, alpha of the Molybdenum rods. Trial 1 2 3 Rod 6 7 8 9 10 Observations B 04/18/13 Went about 10 seconds over 5 minutes while boiling. Cooled in jig for about 3 minutes A 04/18/13 Went about 10 seconds 5 minutes while boiling. Cooled for about 3 minutes. A 04/18/13 Switched to boiling for 3 minutes. Cooled for 3 minutes. White film/ powder on the metal after cooling B 04/18/13 Boiled for 3 minutes. Fast decrease in length in the beginning. Cooled for 3 minutes. White film/powder on metal after cooling A 04/18/13 Boiled for 3 minutes. White film/powder formed. Window was opened and resulted in a drop in final temp. B 04/18/13 Boiled for 3 minutes. White film/powder formed on metal. Window was open. Drop in final temp. A 04/18/13 3 minutes boiling. Fast initial decrease in length. Switched to cooling for 2 minutes. Window open. B 04/18/13 3 minutes boiling. Fast decrease in length. Cooled for 2 minutes. Window open. B 04/18/13 About 8 seconds over 3 minutes while boiling. White powder on the cooled metal. Window open. A 04/18/13 3 minutes boiling but a 8 seconds over. White powdery film on metal. Window open. 4 5 Date Jordan-Semones 30 11 B 04/18/13 Boiled for 3 minutes. Boiled a bit under temperature. Window open. A 04/18/13 Boiled for 3 minutes. Boiled a bit under temperature. Window open. 13 A 04/19/13 Window closed. Boiled for 3 minutes. 14 B 04/19/13 Window closed. Boiled for 3 minutes. 15 A 04/19/13 Window closed. Boiled for 3 minutes. 12 Table 4 shows the observations for the linear thermal expansion tests of the Molybdenum rods. It shows that the linear thermal expansion trials were taken on two consecutive days. On the entire first and most of the second day, the window was opened. During and after trial 3, the researchers made a decision to boil the metal rods for three minutes instead of five. This decision was made for time purposes as well as accuracy and efficiency. Also, the metal rods were usually cooled from two to three minutes with the aid of water and air. Jordan-Semones 31 Table 5 The values used to calculate the specific heat of the unknown metal rods. Initial Temp. (ºC) Trial Change in Temp. (ºC) Mass (g) Equilibrium Temp (ºC) Rod Water Metal Water Metal Metal Water Specific Heat (J/g x ºC) 1 A 28.0 98.5 30.8 2.8 -67.7 26.58 41 0.267 2 B 27.8 98.5 30.9 3.1 -67.6 26.49 41 0.297 3 B 26.9 99.0 30.9 4.0 -68.1 26.55 41 0.380 4 A 27.4 99.0 30.8 3.4 -68.2 26.59 41 0.322 5 A 27.3 97.9 30.1 2.8 -67.8 26.58 41 0.267 6 B 27.1 97.9 30.8 3.7 -67.1 26.48 41 0.357 7 A 27.1 98.9 31.3 4.2 -67.6 26.59 45 0.440 8 B 26.7 98.9 31.2 4.5 -67.7 26.48 45 0.473 9 A 27.1 98.0 30.1 3.0 -67.9 26.56 45 0.313 10 B 30.2 98.0 31.4 1.2 -66.6 26.51 45 0.128 11 B 30.1 98.0 32.1 2.0 -65.9 26.47 45 0.216 12 A 30.1 98.0 32.3 2.2 -65.7 26.56 45 0.237 13 A 30.8 97.9 30.2 -0.6 -67.7 26.58 45 0.063 14 B 29.1 97.9 31.1 2.0 -66.8 26.49 45 0.213 Jordan-Semones 32 15 B 27.3 98.0 29.1 1.8 -68.9 26.50 45 Table 5 shows the masses and temperatures of the unknown metal rods. Notice that during and after trial 7 the amount of water that was added to the calorimeters was increased by four milliliters. This was the result of the late discovery that the water in the calorimeter did not completely cover the top of the unknown metal rod. This may have affected the rest of the data from trial 7 on. 0.186 Jordan-Semones 33 Table 6 The observations taken during the tests for the specific heat of the unknown metal rods. Trial Rod Date Observations 1 A 04/19/13 30 seconds over boiling. Window open. Calorimeter 3. 2 B 04/19/13 30 seconds over boiling. Window open. Calorimeter 2. 3 B 04/19/13 Calorimeter 2. window open 4 A 04/19/13 Calorimeter 3. window open 5 A 04/19/13 Calorimeter 3. Took out of boiling water 30 seconds early 6 B 04/19/13 Calorimeter 2. Took out of boiling water about 28 seconds early 7 A 04/23/13 Switched to 45 ml of water for the rest of the trials. window closed. Calorimeter 1. Channel 2 on logger pro. 8 B 04/23/13 Window closed. Calorimeter 2. Channel 1 on logger pro. 9 A 04/23/13 Calorimeter 1. Window closed. Channel 2. went about 6 seconds over 3 minutes boiling 10 B 04/23/13 Calorimeter 2. Window closed. Channel 1. About 8 Jordan-Semones 34 seconds over when boiling. 11 B 04/23/13 Calorimeter 2. Window closed. Channel 1 12 A 04/23/13 Calorimeter 1. Window closed. Channel 2 13 A 04/23/13 Calorimeter 1. Window closed. Channel 2 14 B 04/23/13 Calorimeter 2. Window closed. Channel 1. 15 B 04/23/13 Calorimeter 2. Window closed. Channel 1. Table 6 shows the observations that were taken during the specific heat tests on the unknown metal rods. The trials were taken on two separate days and all three calorimeters were used during the testing. The observations tell that the amount of water in the calorimeter was switcher from 41 to 45 milliliters. Jordan-Semones 35 Table 7 The table of values used to find the linear thermal expansion coefficient, alpha, for the unknown metal rods. Trial Rod ΔL (mm) Initial Length (mm) Initial Temp. (ºC) Final Change Alpha Temp. in Coefficient (ºC) Temp. (mm x 10-6) (ºC) 1 A 0.0508 139.44 98.1 20.3 -77.8 4.683 2 B 0.0508 139.94 98.1 20.3 -77.8 4.666 3 B 0.0508 139.03 96.7 23.9 -72.8 5.019 4 A 0.0508 139.30 96.7 23.9 -72.8 5.009 5 B 0.0635 139.27 98.5 22.2 -76.3 5.976 6 A 0.0508 139.01 98.5 22.2 -76.3 4.790 7 A 0.0508 139.10 98.2 27.5 -70.7 5.166 8 B 0.0535 139.31 98.2 27.5 -70.7 5.432 9 B 0.0635 139.33 99.7 22.1 -77.6 5.873 10 A 0.0635 139.01 98.6 22.1 -76.5 5.971 11 A 0.0508 139.05 98.0 23.1 -74.9 4.878 12 B 0.0508 139.25 99.7 23.9 -75.8 4.813 Jordan-Semones 36 13 B 0.0508 139.49 98.2 23.7 -74.5 4.888 14 A 0.0635 139.06 98.2 21.6 -76.6 5.961 15 A 0.0508 139.50 98.0 22.5 -75.5 4.823 Table 7 above shows the lengths and temperatures of the unknown metal rods. These values were used to calculate the linear thermal expansion coefficient, alpha, for the unknown metal rods. Notice that the initial lengths of rod A tend to be relatively less than the initial lengths of rod B. Also notice that the values for the alpha coefficient are in a relatively small range. Jordan-Semones 37 Table 8 The observations taken during the linear thermal expansion trials of the unknown metals. Trial Rod Date Observations 1 A 04/22/13 Calorimeter 2. Window closed. 2 B 04/22/13 Calorimeter 3. Window closed. 3 B 04/22/13 window open. Went about 10 seconds over when boiling. 4 A 04/22/13 window open. Went about 11 seconds over when boiling. 5 B 04/22/13 Calorimeter 3. Window closed. 6 A 04/22/13 Calorimeter 2. Window closed. 7 A 04/22/13 Calorimeter 2. Window closed. 8 B 04/22/13 Calorimeter 3. Window closed. Quick initial decrease in length. 9 B 04/22/13 Calorimeter 3. Window closed. 10 A 04/22/13 Calorimeter 2. Window closed. Jordan-Semones 38 11 A 04/22/13 Calorimeter 2. Window closed. 12 B 04/22/13 Calorimeter 3. Window closed. Fast decrease in length in the beginning. 13 B 04/22/13 Calorimeter 3. Window closed. 14 A 04/22/13 Calorimeter 2. Window closed. 15 A 04/23/13 Calorimeter 3. Window closed. Table 8 shows the observations that were taken during the linear thermal expansion trials. All but one of the trials were taken on the same day, Each of the trials were tested when the window was recently closed. This means that this fact may have altered the data because the room was still cool after the window was closed. Jordan-Semones 39 Data Analysis and Interpretation Specific Heat While conducting each experiment, the researchers calculated the percent error. This was done as a check so that the researchers could alter their methods to perfect the experiments. The formula below was the formula used to calculate the percent error. The researchers took the actual specific heat or alpha coefficient of Molybdenum, or the true value, and subtracted it from the value they calculated after doing the experiment, or the experimental value. Then, that difference was divided by the true value and multiplied by 100 to calculate the percent error of the trial. See Appendix 3 for a sample that demonstrates how to correctly calculate the percent error from this set of data. Jordan-Semones 40 Table 9 Molybdenum specific heat percent error table. Trial 1 2 3 4 5 6 7 8 9 10 11 12 13 Rod B B A B A B A A B A B B A Specific Heat Percent (J/g x Error ºC) 0.311 24.468 0.250 0.157 0.288 15.323 0.301 20.418 0.165 34.168 0.236 5.472 0.212 15.380 0.166 33.437 0.203 18.761 0.199 20.516 0.193 22.958 0.223 10.807 0.246 1.787 Jordan-Semones 41 14 15 A B 0.270 0.283 7.850 13.299 The table 9 shows that there was variability between the trials. The percent errors range from 0.157 to 34.168. Trial two, using unknown metal rod B had the lowest percent error. Trial 5, using Molybdenum rod A had the highest percent error. In trial two the unknown rod was placed into calorimeter two and data was recorded in channel 2. In trial five the unknown rod was placed into calorimeter one and the data was recorded in channel 1, also the time went a bit over. This small mistake may have caused a slight change in data. The higher the percent error the more imperfections in the trial. The average percent error for the specific heat experiment with Molybdenum rods was calculated to equal 16.320. See Appendix 3 for how to calculate the percent error. Table 10 Unknown metal rod specific heat percent error table. Trial 1 2 3 4 5 6 7 8 9 10 Rod A B B A A B A B A B Specific Heat Percent (J/g x Error ºC) 0.267 6.770 0.297 18.787 0.380 51.804 0.322 28.651 0.267 6.613 0.357 42.888 0.440 75.974 0.473 89.047 0.313 25.282 0.128 48.813 Jordan-Semones 42 11 12 13 14 15 B A A B B 0.216 0.237 0.063 0.213 0.186 13.651 5.050 74.889 14.879 25.754 Table 10 shows that there is a wide range of percent error. The values have a large range of 5.050 to 89.047. The average percent error for the specific heat of the unknown metal rods was 35.257.This means that the trials were either not conducted with consistency or an outside force has influenced the results. To analyze the calculated values for specific heat, a two-sample t-test was chosen. This test was chosen over others to represent the data because a twosample t test compares the means of two independent samples without ever having or needing the standard deviation of the population. To use this test, a few assumptions have to be met first. The first assumption is that this experiment was a simple random sample, or an SRS. The experiments conducted were examples of SRSs because the two rods that were used for each test were picked with the aid of randomization. The second assumption is that the samples are independent. This assumption was met because the outcomes from one sample never affected those of the other, and the specific heat experiments for the Molybdenum rods and the unknown metal rods were conducted separately. The third assumption that would have to be accepted would be that each of the distributions of outcomes were normal distributions. When the number of outcomes tested is greater or equal to 30, this fact can automatically be Jordan-Semones 43 accepted, but because of neither of the tests for specific heat were conducted on groups of 30 or more, normal probability plots have to be shown to prove their normality. Figures 1 and 2 show the normal probability plots for the outcomes of the specific heat experiments on the Molybdenum and unknown rods. Figure 4. The normal probability plot for the specific heat of the Molybdenum rods. The normal probability plot shown above in Figure 4 demonstrates how the outcomes may be considered a normal distribution. In this figure, the points are fairly close to the line. This means that this model shows that the distribution is fairly normal. Jordan-Semones 44 Figure 5. The normal probability plot for the specific heat of the unknown metal rods. The normal probability plot shown in Figure 5 demonstrates another normal set of data. Notice that the points are still very close to the line and are nearly linear. This proves that the data from the outcomes of the specific heat experiment on the unknown metal rods was normal. Figure 6. Box Plots for Molybdenum and Unknown Rods The box plots in Figure 6 model the distributions of the data from the specific heat experiment conducted on the Molybdenum and unknown metal rods. The data collected from Molybdenum is displayed in the white box plot, and the data from the unknown metal rod is displayed in the grey. The unknown metal has a larger range of data, meaning there was more variability in the results. Molybdenum and the unknown metal have close medians, which means the metals in the rods have very close specific heat values. This could signify that the metals are actually made of the same metal. To test this conjecture and begin to conduct the two-sample t test, two hypotheses must be created: a null hypothesis and an alternative hypothesis. Jordan-Semones 45 The null hypothesis in this context is that the mean of the specific heat of the Molybdenum rods is equal to the mean of the specific heat of the unknown metal rods. This would mean that there is no significant difference between the two means and the rods are made of the same metal. The alternative hypothesis in this context would be that the mean of the specific heat of the Molybdenum rods is simply not equal to the mean of the unknown metal rods. This would show that there is a significant difference between the two means of the rods and the rods are not made of the same metal. These two hypotheses are represented by the equations below. Figure 7 below shows the values from the two-sample t test. The calculated t value correlates with the p value. The p-value stands for the probability of getting two means with this drastic of a difference by chance. See Appendix 4 for the full calculation of the two-sample t test. Jordan-Semones 46 Figure 7. Results and components of the specific heat two-sample t test. The researchers failed to reject their null hypothesis. There was not a significant difference between the means of the specific heat of the Molybdenum rods and the unknown metal rods. The alpha level, 0.1, allowed the researchers to accept that any p-value lower than that may have been deemed significant. This acceptance would have meant that there was, at most, a 10% chance of calculating that high of difference between means. The actual p-value, 0.2042, represents a 20.42% chance of calculating means with this drastic of a difference by chance alone if the null hypothesis was true. The p-value was greater than the accepted alpha level, 0.1, and that led to the fail of rejection of the null hypothesis. Jordan-Semones 47 Linear Thermal Expansion Table 11 Molybdenum linear thermal expansion percent error table. Trial 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Rod B A A B A B A B B A B A B A Alpha Percent Coefficient Error (mm x 10-6) 2.764 4.683 2.810 2.211 2.682 2.112 2.668 2.101 2.084 2.645 2.191 4.169 2.552 3.830 42.407 2.444 41.465 53.934 44.130 55.997 44.412 56.223 56.580 44.891 54.349 13.149 46.826 20.215 Jordan-Semones 48 15 A 2.586 46.126 The table 11 shows that there was a wide range in the percent errors. Trial 2, with Molybdenum rod A has the lowest percent error of 2.444, while in trial 9, with Molybdenum rod B, has the highest percent error of 56.580. The researchers’ observations have shown that in trial two the rod was heated for five minutes while in trial nine the rod was heated for three minutes, the longer heating time could have caused the two trials to vary. The higher percent errors signify imperfections in the trials and inconsistent testing. The average percent error of the linear thermal expansion tests on the Molybdenum rods was 41.543. See Appendix 5 for how to calculate percent error. Table 12 Unknown metal rod linear thermal expansion percent error table. Trial 1 2 3 4 5 6 7 8 9 10 11 12 13 Rod A B B A B A A B B A A B B Alpha Coefficient (mm x 10-6) Percent Error 4.683 4.666 5.019 5.009 5.976 4.790 5.166 5.432 5.873 5.971 4.878 4.813 4.888 2.444 2.792 4.564 4.361 24.495 0.218 7.616 13.165 22.356 24.401 1.618 0.267 1.841 Jordan-Semones 49 14 15 A A 5.961 4.823 24.194 0.485 Table 12 shows there are relatively small percent error values. This means that experiment ran well with consistent testing throughout the trials. The small variability within the values for the alpha coefficient and the average percent error, 8.988, proves this. A two-sample t test was chosen to analyze these two data sets. A twosample t test is a test used to find the difference between individual means of a population. This is the best test to analyze this data because, in a two-sample t test, the standard deviation of the population is not needed. To use this test, a few assumptions have to be met first. The first assumption is that this experiment was a simple random sample, or an SRS. The experiments conducted were examples of SRSs because the two rods that were used for each test were picked with the aid of randomization. The second assumption is that the samples are independent. This assumption was met because the outcomes from one sample never affected those of the other, and the linear thermal expansion experiments for the Molybdenum rods and the unknown metal rods were conducted separately. The third assumption that would have to be accepted would be that each of the distributions of all of outcomes were normal distributions. In samples with 30 or more trials, this fact can just be accepted, but with samples that have less than 30 trials, normal probability plots will have to prove the normality of the data sets. Figures 5 and 6 show the normal probability plots of the data sets from the linear thermal expansion experiments. Jordan-Semones 50 Figure 8. The normal probability plot for the alpha coefficients of the Molybdenum rods. The normal probability plot in Figure 8 shows that there is a lot of variation in the trials. The outliers from the data may have caused this. The researchers decided to proceed with the two-sample t test even though the normal probability plot shows that the distribution was not as normal as expected. This may cause the results of the two-sample t-test to be rendered inconclusive because one assumption was not fully met. Figure 9.The normal probability plot for the alpha coefficients of the unknown metal rods. Jordan-Semones 51 The normal probability plot in Figure 9 shows that the data had much variability. The results do not fully prove that the distribution was normal. The researchers decided to proceed with the two-sample t test even though the results may be rendered inconclusive. Figure 10. Box Plots for Molybdenum and Unknown Rods The box plot shown in Figure 10 illustrates the outliers in the Molybdenum trial. This could mean that there may have been an error in the trials. Also the medians for Molybdenum and the unknown metal rod are very far apart meaning the averages of the trials were not similar. This could signify that the two metals are not the same because the means for their alpha coefficients are not near each other. Jordan-Semones 52 To begin the two-sample t test, two hypotheses must be created: a null hypothesis and an alternative hypothesis. In this context, the null hypothesis would be that the mean of the alpha coefficients for the Molybdenum rods would be equal to the mean of the alpha coefficients for the unknown metal rods. The null hypothesis states that there is no significant difference between the two means and that would signify that the unknown metal rods and the Molybdenum rods are composed of the same metal. In this context, the alternate hypothesis would be that there is no significant difference between the mean of the alpha coefficients for the Molybdenum rods and the mean of the alpha coefficients for the unknown metal rods. The alternative hypothesis shows that there is a significant difference between the two means and that the two sets of rods are not composed of the same metal. The equations below represent the two hypotheses. Jordan-Semones 53 Figure 11. The results of the two-sample t test for linear thermal expansion. See Appendix 6 for the t test calculation. The researchers reject their null hypothesis. There was definitely a significant difference between the means of the alpha coefficients of Molybdenum rods and the unknown metal rods. The alpha level, 0.1, allowed the researchers to accept that any p-value below that may have been deemed significant. This would mean that there is, at most, a 10% chance of calculating such a drastic difference in means. The actual p-value is 7.633 x 10-10. This value is significantly lower than the alpha level, and it signifies that there is a 7.633 x 10-8 % chance of calculating means that have such a drastic difference by chance alone if the null hypothesis was true. The pvalue was lower than the alpha level, 0.1,and that lead to the rejection of the null hypothesis. The two experiments that were conducted on the Molybdenum and unknown metal rods resulted in varied results. For specific heat, the mean that was calculated from the Molybdenum rods is relatively close to the actual specific heat of Molybdenum, 0.25. This means that the results of that two-sample t test Jordan-Semones 54 was more than likely conclusive. For the linear thermal expansion coefficient experiment, the mean that was calculated from the Molybdenum rods was not close to the actual alpha coefficient for Molybdenum, 4.8 x 10-6. This means that the results of the two-sample t test would be considered inconclusive because the researchers compared the mean alpha coefficient of the unknown metal rods to a result that may not have been correct. The results of the linear thermal expansion experiment may have been lowered than it should have been because the window was opened in the middle of the testing. The change from cooling the rods for five minutes to cooling them for three minutes in trial 3 may have also been a contributing factor. Conclusion The objective of the experiment was to use linear thermal expansion and specific heat to determine whether or not the unknown rod was composed of Molybdenum. The hypothesis, stating that the two rods would not be composed of the same metal, was accepted. The p-value that was calculated through the two-sample t test for linear thermal expansion was low, meaning that the means of the rods from the linear thermal expansion tests had a significant difference and there was a small chance that the two metals were similar. Jordan-Semones 55 The results from the linear thermal expansion experiment supported the hypothesis and the researchers were able to correctly conclude that the unknown metal rod was not composed of Molybdenum. On the other hand, the results from the specific heat test did not support the researchers’ hypothesis. The twosample t test for the specific heat test produced results that showed the two rods could be composed of the same metal, but because both the linear thermal expansion and specific heat were not relatively close, the researchers correctly concluded that the unknown rods were not composed of Molybdenum. The data that the researcher’s received was varied and it was concluded that those results were a result of the varying experimental procedures. In the linear thermal expansion coefficient tests, the cooling time was switched from five minutes to three minutes. This may have caused an alteration in the data. Also, the window in the lab was opened during both of the experiments and that may have altered the data. One mistake that could’ve been was that the researchers assumed that the metal rod was the same temperature as the water after the boiling process. The researchers had no proof that the metal would be the same temperature as the water after three minutes of boiling. Overall, there were many factors that may have contributed to the varied results that were received by the researchers. If they had access to a more controlled environment, the results may have been more consistent. Some problems that the researchers encountered were that they were using two different linear thermal expansion jigs that read in two different units. Also, the jigs were not always the same size. At times, the metal rod had plenty Jordan-Semones 56 of room in the jig, and at others, the rod had barely any room to move at all. Another problem that the researchers encountered was that they did not have a fan for cooling the rods, but they did have access to water. The different temperatures of water could have cooled some rods down more than others. These inconsistent temperatures may have also contributed to the varying values in the data. Many trials were conducted with more than what some would call human error. At times, the rods were left in the boiling water for up to 30 seconds over three minutes. Thirty seconds is more than enough time to raise or drop the temperature of water a few degrees. If the researchers took the rods out after exactly three minutes, the results might have been more accurate. Also, the researchers would recommend using a real stopwatch instead of the TI-nSpire calculator software because there were times when the calculator screen froze and they had to make up for lost time. To further expand this research, the researchers would recommend that others do more than two tests to determine whether or not the metal rods are the same. It is recommended that future researchers perform tests that involve more intensive properties, such as a density or pressure test, and actually identify the metal. If more tests are performed and the actual identity of the metal is found, then it may serve as aid for scientists working in fields that involve mining and element identification. Also, knowledge of the linear thermal expansion of a certain metal may be useful in industries that involve plumbing. Jordan-Semones 57 Acknowledgements The researchers would like to thank Mrs. Hilliard for providing them with the information that they needed to complete this experiment. With her help, the researchers were able to correctly identify that the metal was not made of Molybdenum. The researchers would also like to thank Mr. Supal. With his help, the researchers were able to create the calorimeters needed in this experiment. Jordan-Semones 58 Finally, the researchers would like to thank Mrs. Dewey. She helped with the creation of the Data Analysis section. She also gave the researchers pointers on what was best to include in the two-sample t test discussion. Appendices Appendix 1: Randomization of trials with the TI-nSpire CX Calculator 1. Assign a number for each choice or option. For example, if there are two rods, then assign the number 1 to the first rod and the number 2 to the second rod. 2. From the main menu go to a calculator document screen or a new scratchpad page. 3. Press the menu button and select 5: Probability. 4. Select 4: Random and from the drop down menu, select 2: Integer. Jordan-Semones 59 5. A command will appear on the screen as randInt(). In the parentheses enter the lowest assigned number and the highest assigned number, separated by a comma. For example, if there are two options, the command would be: randInt(1,2). Figure 12. The menu for how to get to the random integer command. Figure 13. An example of the random integer command. Appendix 2: How to Construct the Calorimeter Materials: (3) PVC Pipe (0.75 in diameter by (3) PVC Caps (0.75 in) 5.5 in length) (6) PVC Caps (1.75 in) (3) PVC Pipe (1.75 in diameter by 6 Power Drill in length) Drill Bit (0.25 in) Jordan-Semones 60 Tape Measure Scissors Procedure: 1. Carefully apply the cement glue to one end of the 0.75 inch PVC pipe. 2. Place one of the 0.75 inch caps on the glued end of the PVC pipe and hold the it in place for about thirty seconds. 3. Use the tape measure to measure 4.5 inches of the PVC insulation. Cut the insulation and slide the it over the uncapped end of the 0.75 inch PVC pipe. 4. Slide the 0.75 inch PVC pipe and insulation inside of the 1.75 inch PVC pipe. 5. Carefully apply the cement glue to one end of the 1.75 inch pipe. Make sure this end is on the same side as the glued end of the 0.75 inch pipe. 6. Place one of the 1.75 inch caps on the glued end of the PVC pipe and hold it in place for about thirty seconds. 7. Use the power drill to drill a 0.25 inch hole in one of 0.75 inch caps and place it on the exposed end of the 0.75 inch PVC. Do not glue this cap on. Jordan-Semones 61 Figure 14. The constructed calorimeters with the holes in the caps. Appendix 3: Jordan-Semones 62 Percent Error – Specific Heat Experiment The equation above demonstrates how to calculate percent error. In the equation, the true value, or the actual value of the sample, is subtracted from the experimental value, or the value that was calculated by the researchers. Then, that number is divided by the true value and multiplied by 100. Figure 5 above shows a sample calculation from the first trial of the specific heat experiment with Molybdenum rods. Figure 5. A sample percent error equation from specific heat. Appendix 4: Jordan-Semones 63 Two-Sample T test – Specific Heat Experiment In the equation, the symbol stands for the mean of that specific sample. In this case, the mean of the two samples are 0.236 and 0.277. These are the two statistics that will be compared. The symbols including S stand for the standard deviations of the samples. Because this was a two-sample t test, these two standard deviations were the only two that were needed to analyze the data. Finally, the symbols including n stand for the individual sample sizes. The specific heat experiments with Molybdenum and unknown rods were both conducted with sample sizes of 15. See Figure 6 for a sample calculation. Figure 6. A sample t-test for specific heat. Appendix 5: Jordan-Semones 64 Percent Error – Linear Thermal Expansion Experiment The equation above demonstrates how to calculate percent error. In the equation, the true value, or the actual value of the sample, is subtracted from the experimental value, or the value that was calculated by the researchers. Then, that number is divided by the true value and multiplied by 100. Figure 7 below shows a sample calculation from the first trial of the linear thermal expansion experiment with Molybdenum rods. Figure 7. The sample percent error equation for linear thermal expansion. Appendix 6: Jordan-Semones 65 Two-Sample T test – Linear Thermal Expansion Experiment In the equation, the symbol stands for the mean of that specific sample. In this case, the mean of the two samples are 2.806 and 5.197. These are the two statistics that will be compared. The symbols including S stand for the standard deviations of the samples. Because this was a two-sample t test, these two standard deviations were the only two that were needed to analyze the data. Finally, the symbols including n stand for the individual sample sizes. The linear thermal expansion experiments with Molybdenum and unknown rods were both conducted with sample sizes of 15. See Figure 8 for a sample calculation. Figure 8. A sample t-test for linear thermal expansion. Jordan-Semones 66 Works Cited “223 Physics Lab: Linear Thermal Expansion.” 223 Physics Lab: Linear Thermal Expansion. Clemson University, 27 Jan. 2006. Web. 06 Apr. 2013. <http://www.clemson.edu/ces/phoenix/labs/223/expansion/index.html>. Battrum, Denis. "Stainless Steel and Molybdenum." Thompson Creek Metals Company, Inc. Thompson Creek Metals Company Inc., 03 Jan. 2008. Web. 17 May 2013. <http://www.thompsoncreekmetals.com/i/pdf/Molybdenum_Stainless_Stee l.pdf>. Bauck, Lori .”CHEMISTRY LAB: SPECIFIC HEAT OF A METAL.” Kwanga. Lori Bauck. Web. 25 Mar 2013. <http://www.kwanga.net/chemnotes/specificheat-lab.pdf>. “Coefficients of Linear Thermal Expansion.” Coefficients of Linear Thermal Expansion. The Engineering Toolbox, n.d. Web. 06 Apr. 2013. <http://www.engineeringtoolbox.com/linear-expansion-coefficientsd_95.html>. "Coefficient of Thermal Expansion Data." Coefficient of Thermal Expansion. The Industrial Repair Resource Center, n.d. Web. 01 May 2013. <http://www.repairengineering.com/coefficient-of-thermalexpansion.html>. Jordan-Semones 67 Commerce Resources Corp. "The Uses of Molybdenum." The Uses of Molybdenum. Commerce Resources Corp., n.d. Web. 25 Mar. 2013. <http://www.useofmolybdenum.net/>. Dartmouth College, . “Chem Lab.” Dartmouth. Trustees of Dartmouth College. Web. 25 Mar 2013. <http://www.dartmouth.edu/~chemlab/techniques/calorimeter.html>. Department of Chemistry, Texas A&M University, . “Chemistry Basics : Intenstive Versus Extensive Propertes.” Chemistry Texas A&M University. N.p.. Web. 25 Mar 2013. <http://www.chem.tamu.edu/class/majors/tutorialnotefiles/intext.htm>. Gagnon, Steve. "The Element Molybdenum." It's Elemental -The Periodic Table of Elements. Thomas Jefferson National Accelerator Facility - Office of Science Education, n.d. Web. 23 Mar. 2013. <http://education.jlab.org/itselemental/ele042.html>. Grobner, P. J., D. L. Sponseller, and D. E. Diesburg. "Effect of Molybdenum Content on the Sulfide Stress Cracking Resistance of AlSl 4130 Steel with 0. 035% Cb." Corrosion 35.4 (1979): 175-85. Print. “HEAT.” SchoolOrders. MiniScience, Inc.. Web. 26 Mar 2013. <http://www.schoolorders.com/heat2.html>. Hogan, C. Michael. "Molybdenum." (2008): n. pag. The Encyclopedia of Earth. Web. 23 Mar. 2013. <http://www.eoearth.org/article/Molybdenum>. Jordan-Semones 68 Hurth, . “LD Physics Leaflets.” Leybold. LD DIDACTIC GmbH. Web. 8 Apr 2013. <http://www.Id-didactic.de/literatur/hb/e/p2/p2112_e.pdf>. Kroeger, F. R. “Absolute Linear thermal-Expansion Measurements on Copper and Aluminum from 5 to 320 K.” Journal or Applied Physics 48.3 (1997): 853-64. IEEE Xplore Digital Library. Web. 6 Apr. 2013. <http://ieeexplore.ieee.org/xpl/login.jsp?tp=&arnumber=5103487&url=http %3A%2F%2ieeexplore.org%2Fxpls%2Fabs_all.jsp%3Farnumber%3d510 3487>. Missouri State University, Department of Chemistry. “Specific Heat.” Southeast Missouri State University. Linux Penguin. Web. 25 Mar 2013. <http://ch185.semo.edu/specheat/enter.html>. "Molybdenum Chemistry & Uses." Molybdenum Chemistry & Uses. International Molybdenum Association, n.d. Web. 25 Mar. 2013. <http://www.imoa.info/moly_uses/moly_chemistry_uses/molybdenum_che mistry_uses.php>. "Molybdenum Properties." Molybdenum Properties. International Molybdenum Association, n.d. Web. 23 Mar. 2013. <http://www.imoa.info/molybdenum/molybdenum_properties.php>. Nave , Carl R.. “Specific Heat.” Georgia State University. National Science Teachers Association. , n.d. Web. 25 Mar 2013. <http://hyperphysics.phyastr.gsu.edu/hbase/thermo/spht.html>. Jordan-Semones 69 Physics Department, Florida State. “Experiment VIII: Specific Heat and Calorimetry.” Florida State University. Web. 25 Mar 2013. <http://www.physics.fsu.edu/courses/fall04/phy2053c/labs/heat.pdf>. Physics Department, . “Thermal Expansion and Thermal Conductivity.” University of Guelf. University or Guelf. Web. 8 Apr 2013. <http://physics.uoguelph.ca/~cschultz/phys3510/outlines/thermal.pdf>. "Processing." Molybdenum. International Molybdenum Association, n.d. Web. 22 Mar. 2013. <http://www.imoa.info/molybdenum/mining_processing/molybdenum_proc essing.php> R. Nave. “Thermal Expansion.” Thermal Expansion. Georgia State University, 15 Oct. 2001. Web. 06 Apr. 2013. <http://hyperphysics.phyastr.gsu.edu/hbase/thermo/thesp.html>. “Temperature and Thermal Expansion.” Temperature and Thermal Expansion. Boston University, 29 Nov. 1999. Web. 06 Apr. 2013. <http://physics.bu.edu/~duffy/py105/Temperature.html>.