OP02 Purchasing Procedure

advertisement

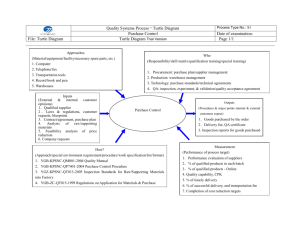

………… LIMITED OPERATING PROCEDURE No 2. Purchasing Procedure Authorisation and Amendment Record: Issue No. Date of Issue Prepared by: Authorised by: ________________________________________________________________________________________________ Operating Procedure No: … Issue: … Dated: ……………… Page 1 of 13 The procedure for Purchasing 1. Purpose and scope The purpose and scope of this procedure is to ensure that: (a) the staff of ………….. do not buy shoddy or inferior goods or services from the cheapest supplier. The goods or services bought must meet ……… and its customer’s requirements. The policy of ……… is to purchase from sources that consistently deliver on time, goods and services to the required specification at a fair and reasonable price; (b) all purchasing by ………. is carried out in a professional manner with adequate records kept. For the purpose of ISO 9001, this procedure need only apply to items affecting the quality of our product or service. However, to give a common approach all purchasing within …. will follow these procedures; 2. Responsibility 2.1 Any member of ………. may require and request raw material, tools, goods or services to be purchased (OR there may also be a purchase demand from Stock Control reaching a re-order quantity for the stores stock.) (OR this request is made on a Purchase Requisition Form, see Annex ….) ________________________________________________________________________________________________ Operating Procedure No: … Issue: … Dated: ……………… Page 2 of 13 Following such a request a formal purchase order may be written out by the store man or any manager. In practice the majority are raised by the Office Manager, (OR ……………) (OR may only be placed by the Purchasing Manager or a Director. 2.2 Before an order can be placed it must be reviewed and then signed for authorisation to place the order outside ………. It should be noted that this procedure outlines the only approved method of raising purchases on behalf of ………. Up to and including a value of £100 the purchase order can be reviewed and authorised by a manager (OR by……………). All orders above £100 must be authorised by a Director (OR ……). [OR for larger organisations, The levels of authority for review and signature are: MD = No limit ……… Director = £……….. ……….Manager = £……….. ……….Manager = £……….. ……….Supervisor = £……….. (replacement parts only) Whilst …………..have a Purchasing Manager his responsibility is to procure the goods. The Purchasing Manager cannot review and authorise Purchase Order.] ________________________________________________________________________________________________ Operating Procedure No: … Issue: … Dated: ……………… Page 3 of 13 2.3 Only the Quality Assurance manager (OR Managing Director, OR …….) can review and authorise additional suppliers onto the Approved Suppliers List. 2.4 Goods receiving inspection will be carried out by the Quality Manager (OR Site Foreman, OR ……) and in his/her absence by ……. (OR by the person who raised the Purchase Request). 3. Implementation 3.1 Approval of …………suppliers Items, material or services that affect the quality of the product or services that are provided by …………shall be purchased from suppliers or subcontractors that are on the formal ‘Approved Suppliers List’. This list is given an issue number and date of issue and is authorised by the Managing Director (OR QA Manager OR ………) to authorise its issue. To control its issue the list is attached as Annex A to this procedure (OR to control its issue and to ensure that the same copy is used throughout the organisation it is considered a controlled document and controlled as per Operating Procedure 8). 3.2 To gain entry onto the ……….’Approved Suppliers List’ the firm, organisation, consultant, certification body, or sole trader will be formally evaluated and recorded on form Annex B to demonstrate at least one of the following: (i) they are registered or certified by a recognised UKAS accredited independent third party body to ISO 9001 with a scope of registration equivalent to the products/services that …..require; ________________________________________________________________________________________________ Operating Procedure No: … Issue: … Dated: ……………… Page 4 of 13 (ii) they hold second party approval (i.e. approved by a recognised main contractor e.g. British Rail, British Nuclear Fuels, etc.) may be judged to be acceptable for appropriate products or services; (iii) there exists records that can demonstrate that the subcontractor or supplier has historic evidence of providing quality goods or services, to ……..consistently over at least 3 orders (OR …… orders) during the last 6 months (OR …….. months); (iv) the supplier is an official distributor or approved agent for the material, parts or service of a proprietary product; (v) that as a new supplier to ……. The organisation has been carefully evaluated for suitability and confirmation of ability to supply consistently to ……….specifications. This may be by trial order(s) or audit visit; the evaluation will be documented on the Supplier Evaluation Record at Annex B; (vi) special qualification. To be detailed by memo by Quality Assurance Manager (OR ………….), which will be signed and dated and stapled to the Supplier Evaluation Record. Record sheets are kept for each supplier/subcontractor to demonstrate the above evaluation, see Annex B to this procedure. The stages on Annex B are selfexplanatory and go through the alternative methods of approval (i)-(vi) above. Where a questionnaire is required this is shown at Annex C. ________________________________________________________________________________________________ Operating Procedure No: … Issue: … Dated: ……………… Page 5 of 13 3.3 If an audit or confidential visit is made to a potential supplier it is recorded on the form shown at Annex C of Operating Procedure 1. The items to check and report on during the visit should include the following, where appropriate: (i) quality of management and systems; (ii) systems documentation; (iii) quality, training and ability of staff and operatives; (iv) process control and capability of their equipment; (v) storage facilities; (vi) typical products/service and check against specification; (vii) reject rates; (viii) check against the clauses of ISO 9001 where they apply; (ix) size, location, condition of equipment and buildings; (x) stockholding of materials and spares etc; (xi) financial viability. (OR for critical components materials, the quality of the supply of …….. and …………... are absolutely critical to ………, therefore all potential and existing suppliers are/were visited and audited before an order is placed. They are audited at least very ….. months with formal reports raised, to confirm their continued suitability.) 4. Procedure for placing a purchase order 4.1 It is the policy of …….that all purchase orders be written, reviewed and authorised before the order is actually placed. (OR if the value of the purchase is ________________________________________________________________________________________________ Operating Procedure No: … Issue: … Dated: ……………… Page 6 of 13 above £…… a competitive quote will be obtained), (OR the Managing Director’s advice sought). 4.2 Occasionally and by exception a telephone order has to be placed to meet an urgent or emergency need. Such an order will be written down as soon as possible and endorsed ‘Confirmation of telephone order by our Mr/Mrs …… of the …../…../200…. 4.3 As …….does not place many orders and they are generally of brief description it has been found that a standard A5 stationery triplicate book with pre-printed serial numbered pages is entirely satisfactory for our needs. (OR the order will be written on a formal ……… Purchase Order Form, see Annex D.) The Purchase Orders will have a unique serial number. The order must be clearly legible and specify the supplier and the details of what are required. The entry must be sufficient to unmistakably identify the supplier and also the description must uniquely specify, without any doubt, precisely what is to be supplied. Use can be made of supplier’s brand names or catalogue numbers if appropriate. If a full engineering, technical or chemical specification is required, this will be written and detailed on the order, or referenced with a copy attached. Items to be identified on a Purchase Order may include: (a) Purchase Order Number; (b) Supplier name; (c) Date of Order; (d) Supplier address; ________________________________________________________________________________________________ Operating Procedure No: … Issue: … Dated: ……………… Page 7 of 13 (e) Goods, material or service required; (f) Any appropriate specification or part or drawing numbers; (g) Level, grade, type, etc; (h) Agreed fee or price (recommend clearly state whether with or without VAT); (i) Delivery date and address: mode of transport where appropriate; (j) Quantity; (k) Inspection, certification or special requirements; (l) ………project description or job number; (m) Markings, identification, or special pack, if required. (OR a copy of this page(s) with the above list will be placed adjacent to ……. In a plastic sleeve, to provide a checklist as purchase orders are made out. This will be personally controlled by the Quality Manager (OR ………….) to ensure it is the correct issue.) If a ……..customer has made a specification on raw material or components, this becomes the minimum required of any Purchase Order. If special QA arrangements, test or verified product documentation is required, they must be specified on the Purchase Order. If it is considered desirable that a representative of ………..inspect the suppliers processes, systems or the items/material before despatch this will be specified on the customer for these items/material will visit our supplier this also will be specified as a condition of the Purchase Order. 4.4 One of the persons designated in para. 2 will review the order to ensure: ________________________________________________________________________________________________ Operating Procedure No: … Issue: … Dated: ……………… Page 8 of 13 (i) the proposed supplier is on the Approved List; (ii) the detail given appears to be correct and adequate; (iii) the appropriate funds are available for this project/purchase order and it is agreed that this may be spent. If they are satisfied they will sign and date the Purchase Order in the Triplicate Book (OR Purchase Order Form). The top copy will go to the supplier (it may be photocopied and faxed, if required), the bottom copy will stay in the Purchase Order Book (OR outstanding Purchase Order File). The middle copy will be sent to the foods inward area so they can check the items delivered and the supplier’s advice and/or delivery note against the original Purchase Order (OR some of ……… suppliers, as a condition of their trading, will not accept written orders. In these cases the top copy will remain in the Triplicate Book endorsed ‘Verbal Purchase Order’.) 4.5 Purchases from unapproved suppliers. Occasionally and by exception it is sometimes essential to buy from an unapproved supplier. There may be several reasons, e.g. they are the sole supplier, emergency breakdown and they are on location, one-off purchase of uncommon item, etc. If this happened all copies of the Purchase Order (including the copy for the supplier) will be endorsed ‘unapproved supplier, items to be inspected carefully on receipt by …………….’, or other appropriate checks or verification. 4.6 Occasionally our customer will specify a supplier (or model/material) that is not approved by ……….. plc. This will be treated as a condition of the contract place on …………. plc , such orders will not be endorsed, refer to unapproved suppliers in previous paragraph. If it is considered or subsequently found that the ________________________________________________________________________________________________ Operating Procedure No: … Issue: … Dated: ……………… Page 9 of 13 material or items specified by the customer are not available, are illegal, will not perform, or give unacceptable health and safety risks, etc., the client will be requested in writing to approve an alternative (OR ………….will raise a formal concession). 4.7 Amendments to Purchase Orders will always be reviewed and if possible be in writing either by memo or fax. A copy of the amendment will be sent to the supplier, with copy attached to the office copy of the Purchase Order and an additional one for the goods inward copy of the Purchase Order. 4.8 (OR, site staff are authorised to make exceptional purchases of standard proprietary items or materials up to the value of £50, if required to keep the job going, or to time, to satisfy the customer. This will be reviewed by the Contract Manager and the monies refunded. If the items or materials are considered unsatisfactory by the Contract Manager, they will be replaced at no additional cost to the client), 5. Procedure for goods inward inspection 5.1 When the delivery has been inspected, to check both the delivery note and the goods provided satisfy the Purchase Order requirements, the goods inward copy of the Procedure Order (OR the delivery note) is signed (OR stamped), and dated and passed to ………..to clear the invoice. These copies are retained in a lever arch file to maintain a simple record of Goods Inward Inspection. (OR the record of Goods Inward Inspection of the quality critical items is maintained on the cards shown at Annex E) (OR due to the quantities and variety of items being delivered it has been found useful to maintain a Goods Inward Record Book. This takes two pages of A4 with the headings shown at Annex F). ________________________________________________________________________________________________ Operating Procedure No: … Issue: … Dated: ……………… Page 10 of 13 The member of staff requiring the goods is informed by phone that the ordered items have been delivered and may be collected (OR will be delivered) (OR will be booked into the stores). 5.2 If defective items are found they will be dealt with as Operating Procedure 4 ‘Control of Material’ and Operating Procedure 7 ‘Corrective & Preventive Actions’ 5.3 As the quantities delivered are small they will be inspected 100% (OR as some deliveries are large a statistically based sampling plan has been developed using “ BS 6001 Statistical Sampling of Batches for attributes ” as a guide). 5.4 As …….. is a small firm with relatively few suppliers, a defective delivery or a poor supplier has a serious affect on ………… production. Hence a poor supplier is automatically identified, therefore no formal vendor rating or scoring system is required. 5.5 All items arriving at ……… will be unboxed and checked for damage and visual appearance. Due note will be taken of any special requirement of the Purchase Order or printed on the product or manufacturer’s label. If a dimensional check or laboratory test is required on receipt this will be specified by the person raising the Purchase Order and will be on the Goods Inward copy of the Purchase Order (OR by memo that is signed and dated), (OR items designated ‘Quality Critical’ items will be identified on a list authorised by the Quality Manager. For these items a Goods Inward Record Card see Annex E, is completed. This card specifies and records the tests carried out on each delivery and the sample tested, ________________________________________________________________________________________________ Operating Procedure No: … Issue: … Dated: ……………… Page 11 of 13 etc). (OR items at Goods Inward will be verified and recorded as per the ‘Standing Work Instruction’ raised, see Annex …., [see Annexes of Operating Procedure 3 for typical examples of work instructions]). (OR ………, and ………..are delivered to ………………..in a designed protective pack. On balance it has been found better to simply check the box for damage and quantity and the specification on the label/advice notes and leave the items within their protective pack.) 5.6 ( OR ………………plc will specify on the Purchase Order four levels of Inspection: A = 100% inspection of receipt B = appropriate or intuitive sample inspection C = Inspection of delivery note against purchase order only. Do not unpack or break seal. Leave goods in protective pack. D = no inspection required. 5.7 Urgent release of material No incoming items or material should be used until cleared goods inward inspection. See Operating Procedure 4 para. 3.4 for emergency or urgent use. 5.8 Delivery of ‘free-issue’ material or customer property This will have limited visual inspection. Free Issue material and items WILL be recorded in the Goods Inward Records to demonstrate acceptance and control. They will be labelled as per Operating Procedure 4, or any special authorised instructions. The checks will be limited to: ________________________________________________________________________________________________ Operating Procedure No: … Issue: … Dated: ……………… Page 12 of 13 (i) ensure adequately labelled or identified to prevent misuse or disposal without customer’s permission; (ii) check quantities and advise any shortages; (iii) check if items are correct to type or description; (iv) if to be stored where they are not seen regularly, a periodic inspection for deterioration, (which will be recorded). It is also understood that customer property can include intellectual property such as designs, drawings, commercial-in-confidence information, etc. Such customer property will remain ‘commercial-in-confidence’, it will not be photocopied for supply to others, or used by …………..on our own products. If we have visitors to ……….., due care will be taken to ensure that the visitors do not have sight of their competitors work or designs. ________________________________________________________________________________________________ Operating Procedure No: … Issue: … Dated: ……………… Page 13 of 13