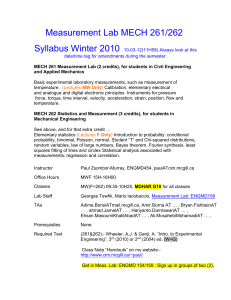

Northwestern_ME_Feb22_2008

advertisement

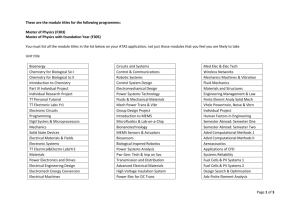

Northwestern Mechanical Engineering Source: http://www.mech.northwestern.edu/web/courses/index.php http://www.mech.northwestern.edu/web/undergrad/curriculum.php Note: 100, 200, and 300 level courses are nominally undergraduate; 400 and 500 level are nominally graduate. However it is common for undergraduates to take some 400 level classes, or for graduate students to take some 300 level classes. List of Courses: 100 / 200 Level GEN ENG 106-1,2 Engineering Design and Communication GEN ENG 205-3 Engineering Analysis 3 - System Dynamics ME 202 Mechanics II ME 220 Thermodynamics I ME 224 Experimental Engineering I ME 240 Introduction to Mechanical Design and Manufacturing ME 241 Fluid Mechanics I ME 262 Stress Analysis and Finite Elements I 300 level ME 314 Theory of Machines - Dynamics ME 315 Theory of Machines - Design of Elements ME 316 Mechanical Systems Design ME 317/318 Molecular Modeling and the Interface to Micromechanics ME 319 Applications of Surface Science to Nanomechanics and Nanotribology ME 325 Kinetic Theory and Statistical Thermodynamics ME 333 Introduction to Mechatronics ME 340-1, 340-2, 340-3 Computer-Integrated Manufacturing 1, 2, 3 ME 346 Introduction to Tribology ME 359 Reliability Engineering ME 362 Stress Analysis ME 363 Mechanical Vibrations ME 365 Finite Elements for Stress Analysis ME 366 Finite Elements for Design and Optimization ME 370 Thermodynamics II ME 373 Engineering Fluid Mechanics ME 377 Heat Transfer ME 381 Introduction to Microelectromechanical Systems (MEMS) ME 382 Micro/Nano Science and Engineering ME 385 Nanotechnology ME 389 Molecular Machines in Biology ME 390 Introduction to Dynamic Systems ME 391 Fundamentals of Control Systems ME 395 Special Topics in Mechanical Engineering ME 398 Engineering Design ME 399 Projects 400 level CE 414-1, CE 414-2 Mechanics of composite Materials CE 415 Elasticity ME 416 Nondestructive Evaluation ME 420 Micro- and Nanoscale Fluid Dynamics ME 421 Design and Analysis of Microfluidic Systems ME 422 Molecular Scale Fluid Dynamics ME 423 Introduction to Computational Fluid Dynamics ME 424 Advanced Topics in Computational Fluid Dynamics ME 425 Fundamentals of Fluid Dynamics ME 426-1 Computational Mechanics I ME 426-2 Computational Mechanics II ME 427 Viscous Fluid Dynamics ME 428 Compressible and Inviscid Fluid Dynamics ME 429 Turbulent Flows ME 432 Optimization Methods in Science and Engineering ME 433 Advanced Mechatronics ME 434 Random Data and Spectral Analysis ME 438-1,2,3 Interdisciplinary Nonlinear Dynamics ME 439 Computer Control in Manufacturing ME 442 Metal Forming ME 443 Metal Cutting ME 446 Advanced Tribology ME 448 Flexible Automation and Robotics ME 449 Robotic Manipulation ME 450 Geometry in Robotics ME 451 Micromachining ME 453 Micro Systems Design ME 456 Mechanics of Advanced Materials ME 465 Wave Propagation in Elastic Solids ME 466 Inelastic Constitutive Relations for Solids> ME 478 Combustion ME 489 Selected Topics in Cellular-Level Transport> ME 495 Selected Topics in Mechanical Engineering MMM 497 Design For Manufacture ME 499 Projects 500 Level ME 512 Seminar ME 513 Teaching Practicum (no credit) ME 590 Research Current Graduation requirements: Total requirement - 48 courses MATHEMATICS - 4 courses Math 214-1,2,3 Calculus Math 215 Multiple Integration and Vector Calculus ENGINEERING ANALYSIS AND COMPUTER PROFICIENCY - 4 courses Gen Eng 205-1,2,3,4 Engineering Analysis BASIC SCIENCES - 4 courses Phys 135-2,3 General Physics Chemistry through Chem 102 General Inorganic Chemistry or Chem 171 Accelerated General Inorganic Chemistry DESIGN AND COMMUNICATIONS - 3 courses Gen Eng 106-1,2 Engineering Design and Communication One speaking course from approved list BASIC ENGINEERING - 5 courses MECH ENG 220 Thermodynamics MECH ENG 241 Fluid Mechanics I CIV ENG 216 Mechanics of Materials or MECH ENG 262 Stress Analysis and Finite Elements I Mat Sci 201 Pinciples of the Properties of Materials ECE 270 Applications of Electronic Devices (Students planning to take advanced ECE courses as electives may substitute ECE 221 Fundamentals of Circuits) SOCIAL SCIENCES/HUMANITIES THEME REQUIREMENT - 7 courses UNRESTRICTED ELECTIVES - 5 courses MECHANICAL ENGINEERING DEPARTMENTAL PROGRAM - 16 courses The Mechanical Engineering Faculty has revised the Mechanical Engineering Curriculum (12/5/2001). Beginning fall 2001 a signed Mechanical Engineering Option will not be required. All students will be required to take 340-1 as a major course and 5 technical electives which will contain 2-300 level mechanical engineering courses, 1-200 or 300 level technical elective (any engineering, science or math course) and 2-300 level technical electives (any engineering, science or math course). A maximum of two 399's are allowed. Students will be encouraged to concentrate electives in an area of interest. All mechanical engineering students already in the program who have not filed a signed option form or are not following the form on file will be required to meet these new requirements with no signed option. Here is the curriculum that will be required. Required courses - 11 courses as follows: o Seven core courses Mech_Eng 202 Mechanics II Mech_Eng 224 Experimental I Mech_Eng 240 Int. Mechanical Design & Manufacturing Mech_Eng 315 Theory of Machines - Design of Elements Mech_Eng 340-1 Computer Integrated Manufacturing Mech_Eng 377 Heat Transfer Mech_Eng 390 Int. Dynamic Systems o One course from Mech_Eng 314 Theory of Machines - Dynamics Mech_Eng 363 Mechanical Vibrations Mech_Eng 391 Fundamentals of Control Systems I o One course from Mech_Eng 362 Stress Analysis Mech_Eng 365 Finite Elements for Stress Analysis Civ_Eng 327 Finite Element Methods in Mechanics o One course from Mech_Eng 370 Thermodynamics II Mech_Eng 373 Engineering Fluid Mechanics o One design course from Mech_Eng 340-2 Computer Integrated Manufacturing Mech_Eng 366 Finite Elements for Design & Optimization Mech_Eng 398 Engineering Design Electives - 5 courses as follows (a maximum of two 399's are allowed) o Two 300-level mechanical engineering courses o One 200- or 300-level technical elective o Two 300-level technical electives A technical elective would be a course in engineering, science or mathematics. Students are encouraged to concentrate electives in an area of interest. Suggested courses in the following areas may be obtained from the department office: biomedical engineering, fluid dynamics, intelligent mechanical systems, manufacturing, solid mechanics, nanotechnology/ micro-electromechanical systems, and design. Description of General Communication (EDC): Engineering 106-1,2 Engineering Design and Catalog description: Integrated introduction to the engineering design process and technical communication. Approaches to unstructured and poorly defined problems; conceptual and detailed design; team structure and teamwork; project planning; written, oral, graphical and interpersonal communications; use of software tools; discussion on societal and business issues. Who takes it: EDC introduces students to a vital part of an engineering career - working and communicating with real people. Students who would like to participate in development of real projects, working with real clients and finding creative solutions for real problems should take this course. What is EDC? Engineering Design and Communication (EDC) is a two-quarter sequence of courses for first-year engineering students in Northwestern University's McCormick School of Engineering and Applied Science. Students work in teams to solve real problems for real clients, designing solutions that range from websites to wheelchairs. EDC is designed to help you do the following: Understand the creative process used by professional engineers to solve complex problems. Acquire basic skills for managing design and communication effectively, including oral, written, interpersonal, and graphical communication. Gain experience in collaboration and teamwork. If you participate fully in the class, you will have a strong foundation for succeeding in engineering because design and communication lie at the heart of any engineering career. You can expect to become a more critical and creative thinker, a better reader, a more capable and effective team member, and a more flexible, confident, and effective communicator. EDC will be a new and challenging experience for you. More background information regarding EDC: Engineering Design and Communication, or EDC, was launched as a pilot program in 1996, and has grown to become a required course for all engineering students at Northwestern. Part of Engineering First, the course is designed and taught by faculty from both the engineering school and the university's Writing Program. In EDC, students work in small teams to tackle real-world design problems brought to them by individuals, not-for-profit organizations, entrepreneurs and industry. Students learn about the design process, about written, spoken, and graphical communication, and about teamwork and collaboration. EDC is a two-quarter, two-credit sequence, and is designed to: Introduce freshmen to a user-centered design process and provide them with tools for the creative solving of complex, open-ended problems Provide students with design tools that will help them explore the design space, gather information, generate alternatives, develop design specifications, make decisions, and argue for their ideas Help students see that writing, speaking, graphical, and interpersonal communciation are an integral part of design and are crucial to the intellectual life and practice of successful engineers Improve students' skill in all these areas of communication Nurture undergraduate students' enthusiasm for engineering Initiate a culture of design at Northwestern, drawing on the design expertise of the current engineering faculty in ways that break the traditional model of undergraduate education. Full Outline: http://www.segal.northwestern.edu/undergraduate/edc/02/syllabus/sq_syllabus.html (bad link). http://www.segal.northwestern.edu/undergraduate/edc/students/ (requires user ID and password) Description of ME 240 Introduction to Mechanical Design and Manufacturing Catalog description: strategies and methods of designing, manufacturing, and testing of mechanical products. Engineering drawing and CAD, design methods, material properties, failure modes, selection methodology, fundamental GD&T, and selected manufacturing processes. Prerequisite: MAT SCI 201 and concurrent registration in ME 262 or CIV ENG 216. Who takes it: ME 240 is a required course for Mechanical Engineering students. This course is the first course of 3-course series “ME 340: Computer Integrated Manufacturing” and ME 315 “Theory of machines – design of elements”. What it's about: For many students, this course is one of their first professional engineering courses. As distinguished from background courses in science and mathematics, professional engineering is concerned with obtaining solutions to practical problems. Lectures: Design process Engineering drawing Tolerances Limits and fits GD&T Material types and properties Material selection Design for X (Strength, Rigidity) Competing failure modes Manufacturing processes Labs: Weekly three-hour lab exercises. Lab sections will be assigned by the end of first week. The final project will be a design competition. Prize will be given to the top group, which yields the highest performance index in testing their prototypes. 740 ME240 Class Schedule Spring Quarter 2002: Date T: 4/02 WEEK#1 Prof.* Lecture Subject E Course Overview Assigned Reading Homework/Lab p.2 – p.22 HW#1 W: 4/03 E Design Process F: 4/05 E Design Process M: 4/08 WEEK#2 E CAD – Solids W: 4/10 E Projections F: 4/12 E Eng. Drawing M: 4/15 WEEK#3 E Tolerances W: 4/17 E Limits & Fits F: 4/19 E GD&T M: 4/22 WEEK#4 E GD&T HW#4, Lab #3 W: 4/24 E Case Study UG - Primitives F: 4/26 p.23 – p. 53 HW#2, Lab #1 Intro to UG p.54 – p.87 HW#3, Lab #2 UG - Primitives Quiz #1 (W1-W3) M: 4/29 WEEK#5 C Material Properties W: 5/01 C Material Types F: 5/03 C Material Selection M: 5/06 WEEK#6 C Material Selection W: 5/08 C Design for Strength F: 5/10 C Design for Rigidity Prototype Design M: 5/13 WEEK#7 C Case Study HW#7, Lab #6 Quiz #2 (W4-W6) Material Selection & W: 5/15 p. 88 - 103 HW#5 Lab #4 UG - Assemblies p. 104 - 149 HW#6, Lab #5 p.150 – p.167 Shop training & F: 5/17 C Competing Failure Modes M: 5/20 WEEK#8 C Competing Failure Modes HW#8, Lab #7 Case Study Prototype Build & W: 5/22 Handouts Prototype Design Test #1 F: 5/24 No class M: 5/27 WEEK#9 Mem. Day Holiday W: 5/29 C Mfg. Processes F: 5/31 C Course Review M: 6/03 WEEK#10 Project Presentation: I W: 6/05 Project Presentation:II F: 6/07 Quiz #3 (W7-W9) HW#9, Lab #8 Handouts Class time may be rescheduled. Prototype Build & Test #2 Post Competition Analysis due 6/07 Source: http://www.mech.northwestern.edu/web/courses/info/ME240/syllabus.php Description of Mechanical Engineering 315, Theory of Machines -Design of Elements Catalog description: Factors influencing the proportioning of machine elements - Stresses, deformations, and failure criteria as applied to shafts, springs, belts, bearings, gears. Prerequisite: ME 240 and CIV ENG 216. Who takes it: Design of Elements is a required course for Mechanical Engineering students. This course is an introduction to the basic principles of modern engineering. It provides the students with fundamental skills of engineering, and the ability to apply the theories of science to practice. What it's about: The course focuses on the fundamentals and principles of basic mechanical elements, failure theories and design criteria, and structures of basic mechanical systems. The goal of the course is to learn how to design simple mechanical elements and systems. It includes: Understanding the principle of each element. Analyzing elements mechanically by applying the theories from statics, dynamics, mechanics of materials, and fluid mechanics with deterministic or statistic approaches. Learning how to design basic elements and simple systems. Designing elements and systems by means of CAD. Lectures: Labs: Getting Ready for Design of Elements Failure theories Variable loading and fatigue criteria Introduction to shafts Transmission elements Rolling element bearings Fluid-film bearings Connecting elements Other elements and review One lab each week on CAD of components and assembles Textbook: Design of Mechanical Elements (with electronic instruction), by Jane Wang, 2002 Lectures: Chapter 1: Getting Ready for Design of Elements Chapter 2: Failure theories Why do we need failure theories Summary of failure theories Applications of failure theories Chapter 3: Variable loading and fatigue criteria Variable loading · Fatigue criteria Chapter 4: Introduction to shafts Typical shaft systems Shaft design and analysis Chapter 5: Transmission elements Classification of transmission elements Gears and gear trains Theory of gearing Gear structures Gear failure and gear materials Gear forces and stresses Gear design principles Chapter 6: Rolling element bearings Bearing classification and bearing structures Ball bearing life and selection Tapered roller bearing life and selection Bearing support design Bearing comparison Chapter 7: Fluid-film bearings Introduction to sliding bearings Bearing comparison Chapter 8: Connecting elements Introduction to thread and fasteners Bolt and member stiffness Tensile connections Dynamic loading Design of bolted connections Chapter 9: Other elements and review Other elements Course summary Course map: Source: http://www.mech.northwestern.edu/web/courses/info/ME315/syllabus.php http://www.mech.northwestern.edu/web/courses/info/ME315/index.php Description of Mechanical Engineering 316, Mechanical Systems Design Catalog description: This course builds on ME 240 and ME 315. If you haven't taken ME315, visit with Prof. Stoll or Prof. Ehmann to see if this course is right for you. Who takes it: Mechanical engineers, Biomedical engineers, all students interested in manufacturing and design. What it's about: This course will focus on the design of mechanical systems with an emphasis on mechanism and precision machine design. Topics include mechanical system design process, mechanism synthesis to accomplish specified tasks involving force and motion, underlying principles of good design, engineering considerations of efficient design, principles of accuracy, repeatability, and resolution, and methods and techniques of precision machine design. The course involves lectures, case studies, in-class design exercises, and team-based design projects. Course Outline by weeks: 1. Mechanical Systems Design Process 2. Introduction to Mechanisms and the Mechanism Synthesis Process 3. Cam Mechanisms and Mechanism Trains (e.g., planetary gear trains, intermittent motion mechanisms, etc.) 4. Kinematic Synthesis of Linkages 5. Design Principles Engineering Concepts of Efficient Design 6. Case Studies In-depth discussion of 1 to 3 case studies illustrating application of design principles and efficient design concepts. Example case studies: design of an air-actuated disk brake for heavy truck applications design of automotive seat head restraint mechanism for rear impact design of a surgical abrading instrument. 7. Principles of Accuracy, Repeatability, and Resolution 8. Precision Mechanical Design Exact Constraint Design 9. Precision Machine Design Principles and Rules of Thumb 10. Precision Machine Design Case Studies Laboratory: Three hours per week. The purpose of the lab is to train students in ADAMS Mechanical System Simulation Software and to provide time for team project work. Team project results will be presented in the lab. The lab will be held in the ME CAD/CAE room. Source: http://www.mech.northwestern.edu/web/courses/info/ME316/index.php Description of Mechanical Engineering 340-1, Computer-Integrated Manufacturing Catalog description: Use of computers to improve productivity and reduce cost in manufacture of discrete parts and assemblies. Manufacturing processes: Analysis and evaluation of processes usage of the contemporary manufacturing environment. Prerequisite: 240 or consent of instructor. Who takes it: ME 340-1 is taken by Mechanical Engineers, Manufacturing Engineers, and Industrial Engineers. What it's about: This course is an introduction to the processes used in the contemporary manufacturing environment including casting, powder metal processing, polymer processing, machining, joining, metal forming, layered manufacturing and electronic materials processing. Process specific component design, materials selection and specification, capital equipment and tooling requirements will be covered. Minisyllabus: Introduction Properties of Materials Phase Diagram Casting Machining Layered Manufacturing Metal Forming Fastening Processes Laser Beam Processes Plastic Processing Integrated Circuits Electronic Assemblies Manufacturing Engineering. Course Summary Final Exam Textbook: Manufacturing, Engineering & Technology, 5/E Authors: Serope Kalpakjian, Steven Schmid Additional: Introduction to Manufacturing Processes, by J. A. Schey, McGraw Hill, 1987 Course website: http://www.mech.northwestern.edu/courses/c401/ Description of Mechanical Engineering 340-2, Computer-Integrated Manufacturing Catalog description: Geometric modeling, dimensioning systems, tolerances, design for manufacture, programming of machine tools. Team problem solving in a design and manufacturing technology environment. Prerequisite: ME 340-1 or consent of instructor. Who takes it: Any student who is interested in solid modeling and wants to have some practical experiences in the “from art to part” process should take this course. ME 340-2 is usually taken by juniors to graduate students majoring in Mechanical Engineering, Manufacturing, and Industrial Engineering. What it's about: It offers both the fundamental knowledge for being a successful engineer or manager in manufacturing, and practical skills. It includes GD&T, statistical tolerances, and metrology tools. The practical side of this course includes: Design of a plastic part within the specified domain, creating a solid model of the part, design of the injection molding tool, creating a solid model of the tooling, creating a cutting path, downloading the cutting path to a CNC machine, machining, injection molding the part, and finally measuring the part geometry and comparing to the original design. Sample past examples are: the relaxing palm beach with attractive fish, the vexing maze, the scary vampire teeth, the daily-used items (trash-can, scissors and key-chain) and the mini-models of transportation tools (unicycle, car and helicopter). Textbook: 1. Course Packet – available at Quartet Copies, 818 Clark Street, Evanston, IL 60201, Tel: 847-328-0720, Fax: 847-328-0742. 2. “Principles of CAD/CAM/CAE Systems”, by Kunwoo Lee, published by Addison-Wesley. Course website and detailed syllabus: http://www.mech.northwestern.edu/web/courses/info/ME340-1/syllabus.htm#web http://www.mech.northwestern.edu/web/courses/info/ME340-2/syllabus.php Description of Mechanical Engineering 340-3, Computer-Integrated Manufacturing Catalog description: Use of computers to improve productivity and reduce cost in manufacture of discrete parts and assemblies. Manufacturing automation: sensors,actuators, and computers for automation; principles of computer control; programmable logic controllers; robotic devices; assembly automation. Prerequisites: ME 340-2 or consent of instructor. Who takes it: The course is aimed at advanced undergraduate and first year graduate students who are interested in the most frequently used technologies and methods for automating manufacturing and assembly operations. ME, MfE, IE and EE students have generally taken this course. What it's about: The course offers a blend of practical skills and a basic understanding necessary for an engineer to be able to address an array of automation tasks such as process/machine monitoring, execution of controlled motions, programming and integration of sequential controllers and robotic devices into complex systems, etc. The course is structured around weekly lectures that introduce the theoretical basis and extensive weekly laboratory exercises in which students, in a hands-on environment, learn the pragmatic implementation skills. Upon completion of ME 340-3 students should be able to: Select and implement digital/analog sensors and actuators for different assembly and manufacturing tasks in conjunction with real-time control computers. Develop program code for real-time control/monitoring applications. Design and implement simple stepping - or DC-motor based motion control systems. Analyze and program articulated robotic devices. Use computer vision systems. Design, program, and implement sequential logic control tasks using PLCs. Perform system integration to solve complex assembly tasks. Minisyllabus: Computers for automation - Interfacing to external devices Sensors and actuators - Analog and digital devices Motion Control - Introduction to computer control Sequential Control - Programmable Logic Controllers (PLCs) Robot programming Fundamentals of machine vision Automated assembly Lectures: The course meets two days per week for 90-minute lectures. Laboratory Exercises: Nine two- to three-hour laboratory exercises will be conducted, generally in small groups requiring everybody's participation to complete the assignments. The exercises are executed on state-of-the-art industrial grade equipment in the Manufacturing Processes Laboratory. Labs: 1. 2. 3. 4. 5. 6. 7. 8. Binary Devices and I/O Analog Devices and I/O Motion Control Manufacturing System Simulation Robot Programming Computer Vision PLC Programming Automated Assembly Textbook: Handouts. Reference Material: Systems Approach to Computer Integrated Design and Manufacturing, N. Singh, John Wiley and Sons, Inc., 1996. Course website: Not available Description of Mechanical Engineering 366, Finite Elements of Design and Optimization Catalog description: Numerical methods for interaction and optimal CAD. Fully stressed design; design sensitivity analysis and descent methods; optimality criteria to automated design. Prerequisites: senior standing and ME 365 or consent of instructor. Who takes it: Advanced students who did not take ME 365 can take this course with consent of instructor. What it's about: As structures and mechanisms grow more complex, so do the demands put on material from which they are built. Without thorough understanding of the stress imposed on the structure, and exact computation, these structures would never be possible. This course will provide a deeper understanding of finete-element method for stress analysis, and computer implementation for optimal Source: http://www.mech.northwestern.edu/web/courses/info/ME366/index.php Description of Mechanical Engineering 398, Engineering Design Catalog description: Product or system design projects carried out by small student groups. Project definition, conceptual and detailed design, evaluation, and documentation. Prerequisite: Senior standing. Who takes it: Nobel Prize winner Herbert Simon says "Science is the study of what is. Engineering is the creation of what is to be." The essence of engineering is design. Most engineers work on some sort of product development, whether it be creating new products or making better products, all based on a fairly well-defined design process. In ME 398, student teams create a new product for an outside client using this design process. Undergraduates take this course in their fourth year, after having mastered many of the engineering tools that they will use in their careers. Mechanical Engineering students are required to take either this course or ME 340-2 to fulfill their design requirement. Two former students in this course went on to win the iF Product Design Award in an international design competition based in Germany for their design of the Swingline Worx Mini Stapler in 2000. What it's about: ME 398 provides an experience in the creative aspects of design from project definition to ideation to functional prototypes. Lectures: The course meets two days per week for 2-hour lectures. Topics include: The total design model Customer-focused innovation The design process o Product goal o Product design specification o Project planning o Conceptual design o Optimizing a design o Prototyping o Detail design Tools for design o Design complexity o Design for manufacture and assembly o Design review o o o o Re-design Reverse engineering Safety Standards and codes Quality o Eight dimensions of quality o Quality function deployment Managing quality o Tolerance stack-up o Statistical process control o Taguchi methods o Reliability o Failure mode and effect analysis o Other quality management techniques Design and business skills o Estimating part costs o Financial statements o Economic decision making o Patents Labs: Machine shop training: all students are required to complete a 6-hour machine shop training course, if they have not previously done so Mock-up prototype: each team prepares a mockup of their design early in the design process CAD: each team prepares CAD drawings of their design using SolidWorks, Pro/Engineer, or UniGraphics Functional prototype: each team builds a fully functioning prototype of their design Textbooks: The Mechanical Design Process by David Ullman, McGraw-Hill 2003 ME 398 Lecture Notes by Richard M. Lueptow 2003 Advanced Study: Students interested in pursuing further study in product design development should consider the Master of Product Development program at Northwestern University. This program for working professionals requires at least 3 years of work experience. Source: http://www.mech.northwestern.edu/web/courses/info/ME398/index.php Description of ME 421 Design and Analysis of Microfluidic Systems: NOT AVAILABLE ONLINE Description of Mechanical Engineering 453, Micro Systems Design Catalog description: Theory and tools for analyzing and designing microsystems used in MEMS/Nanotechnology. Includes device physics and analysis, design techniques, and computer-aided design tools for micro systems technology. Prerequisite: None. Who takes it: Advanced graduate students interested in learning micro systems design usually take this course. What it's about: MEMS is an exiting new field of engineering. Its rapid development over the last few years, has brought many new techniques in design, and building of MEMS and Nano devises. This course covers basic principles and tools of MEMS and Nano design, physical and mathematical approaches, and a computer aided design approach. Source: http://www.mech.northwestern.edu/web/courses/info/ME453/ Description of Masters of Manufacturing Management 497, Design For Manufacture Who takes it: This course is essential for anyone who plans to work in a manufacturing industry where parts are made and assembled. This course is usually taken by graduate MMM students and mechanical Engineering students. What it's about: Design for manufacture (DFM) is recognized as the key to industrial efficiency…to minimizing manufacturing costs…to assuring product quality…and generating the increases in productivity promised by advanced manufacturing technology. This fiveweek course presents underlying principles, best practices, design guidelines, and management techniques for improving assembly and manufactureability of mechanical products. Topics include product simplification approaches, modularization (chunking) strategies, design for assembly, design for manufacturing processes such as plastic injection molding, analysis of tolerances, and standardization of components and features. Depending on class interest, other structured design methods such as FMEA, value engineering, and robust design are also covered. "Hands-on" exercises are employed throughout the course to help ensure mastery of proven methods such as the Boothroyd/Dewhurst Design for Assembly method. This course is an excellent way to bring yourself up to speed in DFM. A solid working knowledge of DFM is essential for anyone who plans to work in a manufacturing industry where parts are made and assembled. Source: http://www.mech.northwestern.edu/web/courses/info/MMM497/index.php