BioHitech America Frequently Asked Questions (FAQ) Have a

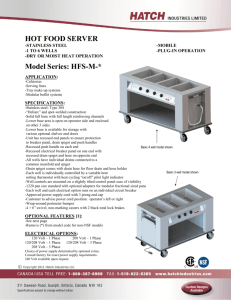

advertisement

BioHitech America Frequently Asked Questions (FAQ) Have a question? Check here first, as we are constantly updating our BioHiTech Frequently Asked questions section. . Q.Is financing available? Q.What are the operating costs? Q.MAINTENANCE, INSTALLATION & SERVICE Q.How is the machine installed? Q.How long does it take to install? Q.Do you have a training program? Q.Can you service the entire country? Q.Is the machine a continuous feed? Q.What is the optimal feeding schedule? Q.What are acceptable food waste items? Q.What are unacceptable food waste items? Q.How much effluent is generated per pound? Q.Will the machine perform at full capacity every day? Q.How long does it take to receive the machine? Q.What is the warranty? Q.Are the microorganisms dangerous? Q.What are the requirements? Q.What are the micro-organism characteristics? Question: Is financing available? Yes, BioHitech can customize financing to meet our customer's needs. Rental and Lease programs are available. Question: What are the operating costs? Operating costs (including an Annual Maintenance contract) are approximately $4000 per year. The utility costs (included in the $4000) are offset by lower utility and janitorial costs realized by using the compactor less, and having little to no wet waste available for processing. Costs will fluctuate depending on energy costs as well as the specific environment such as temperature, hot water supply, etc. at customer location. Question: MAINTENANCE, INSTALLATION & SERVICE Quarterly: A quarterly maintenance plan with BioHitech is recommended to ensure maximum productivity, and also to keep the warranty valid. Preventative maintenance can easily be performed by customer staff. Quarterly: • Replenishment of microorganisms • Grease and lubrication • Adjust PLC parameters • Inspect and clean all nozzles • Deodorizer if necessary 6 Months: • Replenishment of microorganisms • The habitat will need to be replenished • Nozzles cleaned and/or replaced • Lubrication • Computerized operating parameters adjusted Question: How is the machine installed? The machine needs hot water supply (if not available, we have a machine with an internal hot water heater option), drain line, 208V, 30 AMP, static IP address. The machine also needs sufficient room around it for optimum performance and maintenance. It should be placed in a room that is at least 40 degrees Fahrenheit. Question: How long does it take to install? Once the roughing is confirmed to be correct and the site is prepped, installation and training is normally done in one day. Question: Do you have a training program? Yes. We have a BioHitech representative solely dedicated to each customer (from point of install) to ensure successful acclimation of product into each unique infrastructure. Our training program doesn't end until all staff is comfortable and proficient on all levels of system operation. Question: Can you service the entire country? Yes Question: Is the machine a continuous feed? Yes. The machine can be fed 24 hours a day, 7 days per week. In fact, that is the preferred situation; however, most customers do not meet this criteria. The machine will function best if loaded every 3 or 4 hours with large feedings, but if space and storage are issues, it can be fed more frequently and will perform well. We have customers who do both. Question: What is the optimal feeding schedule? The machine should be fed every 4 hours with large feedings. If there is a space constraint, smaller more frequent feedings are acceptable. For optimal microorganism performance, a mixed diet containing protein, carbohydrates, fruits, vegetables and some fats should be introduced into the mixing chamber throughout the day. Question: What are acceptable food waste items? Meat, poultry, fish, fruit, vegetables, rice, pasta, bread & baked goods, coffee grinds, eggshells and dairy products. Question: What are unacceptable food waste items? Large beef bones, pineapple tops, bottoms, skins and core, fruit seeds over ½ inch in diameter (e.g., mango, avocado, peach), corn husks and cobs, raw dough, pure flour, oil, grease, and fats. These items do not breakdown efficiently and will need to be removed periodically. They may also cause damage. NOTE: Do not add any cleaning agents, chemicals, or boiling water to the machine, they will kill the microorganisms and the machine will need to be sanitized and restarted to resume operation. Avoid adding straight fat or oil to the machine, they will cause clogs within your drainage and grease trap systems and will greatly reduce digestion rate. Question: How much effluent is generated per pound? Effluent amounts vary by machine size, by quantity and type of food waste being disposed of and by operating efficiency. A 1200 machine will typically discharge approximately 400-500 gallons per day. Question: Will the machine perform at full capacity every day? The machine is expected to be between 80 and 90% efficient over approximately 12-16 hours. If 24 hour feeding is available, the machine may process more than its rated capacity. Question: How long does it take to receive the machine? Most orders can be filled within two weeks. Inventory is available, so installation can begin once roughing is completed by customer. Question: What is the warranty? One year limited warranty. Question: Are the microorganisms dangerous? No, the particular strands of microorganisms are not dangerous to humans or animals. Question: What are the requirements? Power: 208V, 3Phase + 1ground No less than 30 amp breaker required. Integrity of power source is vital; line must be carrying at least 220 volts. Water: Mixing valve required to combine, regulate and dispense hot and cold water received from two inlets. The temperature which needs to be maintained is 86° to 102° Fahrenheit (30° to 39° Celsius). Drain: 3" Drain Pipe 4" Floor Drain Space: The optimal space for the machine has at least 5 ft of clearance on both sides in addition to the machine's width. The additional room is necessary to help facilitate maintenance of the machine. Due to the weight and size of the machine, we strongly recommend that these criteria be met. In the event this space is not available, a custom application may be necessary. Variation in space will occur depending on which GOHBio model is installed. Connectivity: Ethernet port required to allow technological maintenance Static IP address is required to allow for remote access and system monitoring. Mandatory Accessories: Thermometer incorporated into water line to visually monitor water temperature. Garden hose attachment incorporated into water line with separate shut off valve, for use in cleaning and servicing the food decomposing unit. Question: What are the micro-organism characteristics? The Micro-Organism Characteristics are made of up four strands, consisting of Saccharomyces cerevisiae Lactobacillus paracasei Bacillus subtilis Aspergillus oryzae