Rappeljing-Harness

advertisement

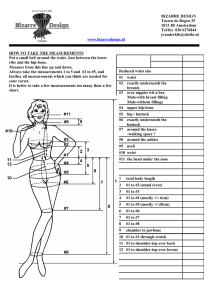

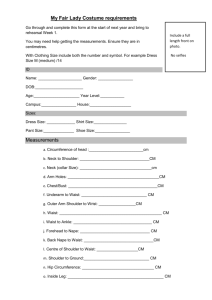

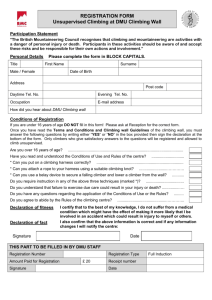

Larry, et al.; Since I assume everyone in the command is facing the same dilemma, I took this opportunity to expand on my earlier comments. Attached is a spreadsheet listing what I consider "appropriate" harnesses for cadet rappelling currently in production by the 16 largest commercial manufacturers of climbing harnesses. The spreadsheet also provides web addresses for the manufacturers where you can find photos and product details, as well as the web addresses of the cheapest online sources I could find for each model. Most models listed are one-size-fits-all, however some are also produced in extra-large or extra-small versions to cover a wider range of users. Prices range from less than $30 to more than $60, the higher costs usually indicating especially beefy models that will likely hold up better under hard use. Background: As anyone who has spent time around Fort Bragg can attest, just about any rigger worth his red ball cap, with access to a heavy duty sewing machine, can turn out a pretty good harness. I remember when STABO rigs were a booming cottage industry around Fayetteville. There is nothing wrong with home-made gear for personal use. But when we put a harness on a cadet, we need to consider the legal ramifications. We should stick with name-brand products that are safety certified and backed by big-league product testing and quality assurance programs. The 16 manufacturers I listed are the industry leaders in recreational climbing equipment. All adhere to UIAA/CE norms which dictate minimum breaking strength of 15 kN (3372 lbf) for climbing harnesses. That strength standard is based on the conclusion that an impact force greater than 12 kN (2698 lbf) would probably prove fatal to the harness wearer, so significantly greater strength is unwarranted and only adds weight and bulk. Some surplus strength however is necessary to account for equipment degradation due to UV exposure, abrasion, and age. In practice, climbing harnesses seldom break. When they do it is invariably because the owner continued to use a harness that was old, worn, or frayed and should have long since been retired and destroyed. By far the greatest number of harness failures (still a very rare occurrence) can be traced to improper use; wearing them too loose or too low on the hips, failing to double-pass buckles correctly, or failing to tie-in correctly. The models I listed all have single tiein points for simplicity, and most feature some safety marking or design feature to preclude improper buckling. I did not include full-body harnesses in the list. A full-body harness is intended to keep the wearer hanging in an upright position, prevent spinal injury, and reduce constriction of the diaphragm. These are certainly positive attributes which would be significant if heavy packs were worn, severe impacts were anticipated, or long hang times were expected. But cadet rappelling does not include any of these situations. A seat harness alone is entirely adequate for our purposes. The added safety of full-body harnesses must be weighed against their greater cost, difficulty of putting on and removing them, and difficulty in sizing or adjusting them correctly. Indeed the climbing community has all but abandoned full-body harnesses, even for high-altitude mountaineering where they would be most appropriate. Full-body harnesses remain the standard for industrial use where they provide the greatest protection in the event of unanticipated falls, and in aviation search and rescue where the wearer might be required to hang in the harness for an extended period. I intentionally did not list products from manufacturers who specialize in fire/rescue or industrial safety equipment. That equipment must comply with NFPA and OSHA standards that are significantly more demanding than what UIAA/CE specifies for recreational climbing. While fire/rescue or industrial safety harnesses are unquestionably robust and durable, they are serious overkill for cadet rappelling. They are intended for applications and environments much more damaging to equipment than anything we would likely encounter. We would not expose rappelling harnesses to the severe heat and caustic chemicals that those are designed to withstand, and if accidental exposure did occur we would retire the harness immediately. I reviewed all harness models currently offered by the 16 listed manufacturers and selected those I felt were appropriate for cadet rappelling. My selections were admittedly somewhat subjective, but based on considerable research, 30 years of personal climbing experience, and 11 years experience as a professional mountain guide. Most of the harnesses on the list are those recommended by their manufacturers for group/institutional use. I also included some lowerpriced introductory models and stripped-down alpine models that I thought would work well. I excluded models that I knew to be deficient in some regard. (e.g. The Black Diamond Alpine Bod harness meets the above criteria, but I know from personal experience that its two-piece buckle is very difficult to thread, especially when the end of the webbing becomes frayed. So I did not include it in the list.) I do not claim the list to be comprehensive. I may have overlooked some manufacturer or model that would be as good as or better than those included. If you are aware of a model that should be added, please share that information. Likewise, if you have personal experience with one of the models listed and know it to be inadequate, please share that information as well. -----------------------------------------CLIMBING HARNESSES - More information than you want: TYPE. Climbing seat harnesses come in a dizzying array of shapes and styles, but all fit into one of three basic design types. - The most common type features a waist belt connected to independent leg loops. Many feature a permanently attached belay/rappel loop. The waist belt and leg loops may be fully adjustable (as in one-size-fitsall models) or may have only a very limited range of adjustment so that the correct size must be worn for proper fit. Most require stepping through he leg loops and pulling up the waist belt to put them on, like you would pull on a pair of shorts. But some allow the waist belt andor leg loops to be fully unbuckled making them easier to put on and take off. - The second type is the "diaper" harness. In this type the two leg loops are formed by a single length of webbing, stitched to the sides of the waist belt and drawn up between the legs to join the waist belt at the tie-in point. Small non-critical plastic buckles usually hold the leg loops in place around the thighs. Most models have a belay/rappel loop sewn permanently around the leg loop strap through which the waist belt must be buckled. If a rappel/belay loop is not provided you must clip or tie in to both the waist belt and leg loop strap. - The third type is the one-piece harness, consisting of a single continuous length of webbing that forms both leg loops and waist belt. This is the simplest and cheapest type of harness to make, and is usually marketed as an "introductory" or "beginner's" harness. These are one-size fits-all harnesses. Size adjustment is accomplished by tightening the leg loops through a pair of buckles then taking up the slack around the waist. While the design is simple, the adjustments can be awkward for inexperienced users. PURPOSE. Most harness manufacturers produce a number of different models, each optimized for a particular purpose. While there is a bit of overlap, no harness is ideal for every application or climbing situation. - Harnesses meant for Yosemite-style big wall aid climbing have wide heavily-padded and fleece-lined waist belts and leg loops, an abundance of gear loops for racking equipment, and a full-strength haul loop at the back of the waist belt. They must be comfortable enough to ride out long hours in a hanging belay and burly enough to withstand the constant abrasion of rough granite. - Harnesses intended for gymnastically difficult sport climbing are extremely lightweight and designed to maximize freedom of movement. They feature tiny buckles and ergonomically shaped waist belts and leg loops, often with foam stiffeners to maximize comfort while minimizing weight. They have gear loops and usually a small web loop at the back for attaching a chalk bag. They must be strong enough to withstand repeated falls, but are not designed to be comfortable to hang in for extended periods. - Harnesses designed for alpine climbing are meant to be worn over heavy clothing and under the waist belt of a pack so they usually have little or no padding and few if any gear loops. The fit must be adjustable to accommodate various clothing layers. Usually the waist belt and leg loops can be unfastened completely so the harness can be put on or removed while wearing mountaineering boots and crampons or skis. This also allows the wearer to unbuckle and drop the leg loops while remaining tied in to the waist belt -- a convenient feature for answering the call of nature in an inconvenient spot. - Harnesses intended for rental programs, climbing schools, or ropes courses are generally devoid of gear loops and padding, but have heavily reinforced wear points and redundant stitching. They must be easy for beginners to put on and adjust, and easy for instructors to check. They also must be durable enough to withstand heavy use as well as user negligence and indifference. USE. Properly used, climbing harnesses are unquestionably more comfortable, more secure, and safer than Swiss seats. But safety depends on proper use. Misuse or ignorance can negate the advantages. - Harnesses must be properly sized and/or adjusted for the wearer and worn correctly. The waist belt must be worn around the waist at the level of the navel – below the ribs and above the hips. It must be tight enough so that if the rappeller inverts it cannot possibly slip over the hips. Leg loops need not be excessively tight, but must hold around the thighs without sliding up to the crotch if the rappeller loses his footing and hangs vertically with his feet straight down. Buckles must be fastened properly so they cannot slip under load. Most climbing harness use double-pass buckles, requiring the tail of the webbing to be passed back over then through the opposite end of the buckle plate once fit adjustments have been made. - All harnesses have a prescribed tie-in point, usually identified by a webbing reinforcement of contrasting color or an embroidered “tie in here” label. If a belay/rappel loop is provided on the harness it should always be used to attach the rappel device/carabiner. Bypassing the belay/rappel loop and clipping a carabiner around the waist belt and leg loop strap can lead to a number of problems: It puts undue wear and tear on the other harness components. It also pulls the waist belt down too low on the hips and alters the balance point, causing the rappeller to tip too far backward and potentially letting him to slip completely out of the harness if he inverts. There is also the risk of clipping one but not both pieces of webbing. If the leg loop strap is missed and only the waist belt clipped, the rappeller's entire weight will bear on the waist belt, compromising respiration and causing painful constriction. If the waist belt is missed and only the leg loop strap clipped, the rappeller will invert. - Gear loops and chalk bag loops are not tie-in points or grab handles. They will not support body weight. Don’t use them as such. If you can’t resist the urge to grab them, cut them off to avoid the temptation. - Full-strength haul loops at the back of big-wall harnesses will support body weight and can be used as attachment points for instructor safety lines. But if they fall they will be suspended face down hanging from the waist belt only, unable to recover and extremely uncomfortable. Better to attach safety lines to the proper tie-in point at the front of the harness. If tower or cliff arrangement necessitates rear tie-ins, shorten safety lines so instructors can see over the edge but cannot fall over the edge. If this will not provide adequate freedom of movement consider using full-body industrial safety harnesses or aviation crew “monkey harnesses” for instructors. CARE. Harnesses, like ropes, must be protected from sharp objects, excessive sunlight, chemicals, and dirt; and must be retired and destroyed when they become unserviceable due to damage, age, or wear. Inspect them before and after use. If dirty, they can be machine washed, preferably in cold water using a non-detergent soap (e.g. Woolite). Store them clean and dry in a cool dark place. Nylon becomes brittle with age and loses the ability to absorb energy. Some harnesses come already labeled with the date of manufacture. If yours do not, mark them. Retire any harness more than 10 years old, even if it appears to be in good condition. If I can provide additional information or be of any other assistance, please call. Mr. Ashley Garman HQ USACC, JROTC Fort Lewis, WA 98433 (253) 967-3102