Comparison of Reliability-Availability Mission Simulators

advertisement

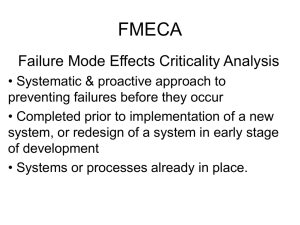

SURVEY OF SUPPORT SOFTWARE FOR RELIABILITY ENGINEERING By Reid Willis Washington Chapter, Society of Reliability Engineers April 1, 2006 This report is a survey of reliability support software tools that are distributed in the U.S. by vendors who offer a variety of reliability programs that can share common target system data. Any errors or omissions are the sole responsibility of the author, who requests comments by readers. Contact him by e-mail at reidwillis@juno.com. SURVEY OF SUPPORT SOFTWARE FOR RELIABILITY ENGINEERING April 1, 2006 Normally we think of computer support as a great labor and time saver. R&M software tools can guide data acquisition, respond quickly to system changes, provide mathematical support, and help prepare presentation of the results. But nothing is ever that easy. When selecting computer tools for the support of reliability analyses, the user should carefully consider several important factors including the R&M standards employed, data sharing, special capabilities and features, user friendliness, vendor support, and cost. Adherence to a given standard is one of the most popular features of support software–––and one of the most annoying. The user is on safe ground if the software strictly enforces conformance to the chosen procedure. However, if the user wants to incorporate a variation that is not in the rules, the tool’s program may not allow it. Commonality of user project data is a strong argument in favor of choosing a suite of tools from the same vendor. This means that the user can establish a project data base for the target system that supports and coordinates all ongoing reliability analyses for that project. Computer tools from different vendors that support a particular task may offer a wide variety of special features. The features deserve a close look, because they strongly affect the most significant cost of a reliability analysis task: the professional hours involved. The vendor directory and program summaries below are intended to suggest which tools might meet a user’s needs, and how to locate the vendor for further information. It can be said that a buyer will never get his money’s worth out of a tool if he and his engineers don’t like it because it is difficult for them to learn or awkward to operate. The vendors normally provide free demonstration versions of their software. When it comes down to final selection among competing programs that seem to have the desired capabilities, it is a worthwhile investment to obtain demos and try them out. This is also an opportunity to test the vendor’s support. The initial use of any scientific software is bound to be a frustrating experience because functions and displays that seemed obvious to the software producer may not be obvious at all to the new user. The best vendors have experts who can solve problems by phone or e-mail the same day. 1. Vendors Over a dozen vendors are currently in the R&M support software business. In general, their products are associated with the normal R&M tasks: prediction and allocation, fault trees, FMECA, mission simulation, etc. No single vendor touches all the analytical bases, but four of them, Relex, ReliaSoft, Item and Isograph, each offer a suite of programs that can share a common project system description. Figure 1 SELECTED VENDOR LIST Isograph Incorporated 8001 Irvine Center Drive Suite 1430 Irvine, CA 92618 (949) 502-5919 www.isograph-software.com/ Fax: (949) 502-5933 Item Software, Inc. (USA) 2190 Towne Centre Place, Suite 314, Anaheim, CA 93806 (714) 935-2900 www.itemsoft.com item@itemsoft.com Relex Software Corporation 540 Pellis Road, Greensburg, PA 15601 (724) 836-8800 www.relexsoftware.com info@relexsoftware.com ReliaSoft Corporation ReliaSoft Plaza 115 S. Sherwood Village Drive, Tucson AZ 85710 (888) 886 0410 www.reliasoft.com sales@reliasoft.com 2. Coverage Reliability engineers usually think of a system’s life cycle in terms of phases: concept development, system design, parts selection, prototyping, production, and field operation. The phases may have other names and their boundaries may be blurred while different parts are in different stages of development but whatever they are called, each phase can be associated with certain R&M tasks. Figure 2 lists common R&M tasks that are considered appropriate to each phase of a system’s life cycle. These tasks may change their form over time, for example data analysis may begin during design with analyses of component experience, and then, once prototypes have been built, refocus on test results; and finally on system performance in the field. The tasks that are fully supported by at least one of the four vendors listed above are shown in color. Figure 2 MISSION PHASES AND R&M TASKS Tasks supported by vendor tools shown in color Concept & Design Parts Selection Prototype Production Field <======================== Reliability Program ====================== > <===== Prediction ======> <== Allocation ==> <====== FMECA ======> <==== Risk Analysis ====> <==Fault Tree Analysis===> <===================== Mission Simulation ===================> <=================== Data Statistical Analysis ========================> <============ Life Cycle Cost =============> <===== Failure Reporting and Corrective Action =====> <========== Reliability Growth Analysis =========> <======= Maintenance Planning =======> <= Reliability Test => <===== ALT =====> <== Maint Demo ==> <= Quality Control => <= Parts Screening = > <== Age-==> Reliability 3. Standards R&M tools are concerned with two kinds of standards: standard definitions and procedures for performing R&M tasks, and standard libraries of device failure rates: Over the past few years the Department of Defense has phased out U.S. military standard procedures and data bases, to be replaced by new American and international commercial standards. The Mil-Stds can no longer be made mandatory in government contracts and are no longer updated, but some old favorites are still in effect for optional use. Today there are a great many international and manufacturers’ association standards to choose from. This report lists only those supported by at least one of the selected R&M tool vendors. Some standards for reliability prediction are associated with failure data libraries. R&M prediction, allocation, fault tree, failure modes effects and criticality analysis (FMEA/FMECA) and mission simulation tasks may draw on these libraries of device failure rates. Each library lists thousands of devices and their known failure rates under various operating conditions and (in some cases) different quality levels. Mil-Hdbk-217F notice 2, the old warhorse for electronic devices Bellcore TR-332 Reliability Prediction Procedure for Electronic Equipment (also called Telcordia SR-332) The Reliability Analysis Center’s PRISM, which is primarily for electronics but incorporates infant mortality, reliability growth and software. The French CNET 93, which is similar to 217 but more up to date British HRD5, which is simpler International Electrotechnical Commission TR 62380 (formerly RDF 2000), for telecommunications electronics, developed in France by the Union Technique de l’Electricite Chinese GJBz 299B parts stress The Naval Surface Warfare Center’s NSWC Mechanical, for non-electronics NPRD 95, Non-electronics Parts Reliability Data, by RAC NOTE: The Mil-Hdbk-217 and NPRD libraries have not been updated for many years and are not recommended. Other libraries, notably the Italian Italtel RPH 2003, are not available with any of the products covered in this survey. Some vendors offer commercial data packages to extend the standard libraries, and provide for users to add their own data. Other tasks may employ procedural standards such as Mil-Hdbk-472 for maintainability prediction, the Air Transport Association’s MSG-3 for maintenance planning, and the Society of Automotive Engineers’ J1739 for failure modes and effects analysis. In all cases it is important to recognize tasks that will require options and exceptions from the standard in order to suit a particular project, and determine which tool has the necessary flexibility. 4. Data Sharing Each of the four vendors listed above provides for sharing project data among its tools that support R&M tasks. The user can create a common database of his project’s system description, component failure and repair rates, functional requirements and maintenance support strategy. Different tasks may assume different formats for the same input data, for example data entered for mission simulation in reliability block diagram form may appear for other tasks in level-of-indenture tree form or in spreadsheet tables. This kind of data sharing greatly simplifies the R&M Manager’s ability to synchronize experimental alternatives, design changes and data updates in all on-going tasks. It also provides for freezing project data in order to produce a set of analyses as of a given date, and then releasing an update for the next set. In any case, expect the common project database itself to be stored in a format that is unique to the vendor. Some vendors provide for automatic translation to a conventional industry format such as Computer Aided Design, Logistic System Analysis, Microsoft Excel and Access, or delimited text. However, the initial setup for such transfer may require work by an expert in computer data export-import. 5. Tool Capabilities Vendors’ brochures cite the special-purpose advantages of their products. These documents can help eliminate some candidates that plainly are unsuited to the user’s needs. If requested, for further selection, vendors may be willing to provide user manuals, which require much more study but clarify the tool’s options and features from a user’s viewpoint, give a feel for the degree of user-friendliness, and offer a starting point for technical discussion with the vendor. One significant feature concerns the production of displays. The presentation of results to others who are not R&M experts is an essential part of the R&M manager’s work, and good graphics can be crucial to his success. Vendors vary widely in the potential they offer for data display, and in the degree of user effort required to produce displays. User manuals are a good source for evaluating the graphics options and amount of learning involved in using them Important mathematical features include the statistical distributions of failure and repair that can be identified through data analysis and then input to models; reliability growth analysis methodology; and measures for quantitatively ranking components by their R&M importance. Mission simulators may represent single- or multi-phase missions and may employ Markov, analytical (closed-form), or Monte Carlo (open-form) algorithms; each has its advantages and disadvantages. 6. Vendor Support One vendor (Isograph) is a British firm with a U.S. distributor and the other three in this survey are American, but all are well established in the U.S. and responsive to user requests for assistance. Each vendor packages technical support with the tool in some combination of: Comprehensive R&M guidebooks Hard-copy or e-mail newsletters and magazines with articles and tips for users For a period of time, such as 3 months, access by telephone to a knowledgeable engineer who can usually answer questions on-line, or at most in a few hours For a further period, response to e-mail, normally with a one-day turnaround For some period, such as until the next release, free or reduced-price software upgrades A free web library of technical articles Extra-cost long-term support contracts for technical advice and free or reduced-price upgrades Regional or on-site classes, free or for a fee, on the use of specific products. NOTE: ReliaSoft is unique in providing technical support to users by phone, fax, and email for an unlimited period. 7. Products Figure 3 on the next page lists the R&M tools marketed in the U.S. by four vendors who offer support of several R&M tasks sharing common project data.. In some cases the method, standard, or other characteristic is shown, to indicate major differences among vendor programs. For a more complete listing and descriptions of R&M tasks, see MIL-STD-785B. Although cancelled long ago and now somewhat out of date, it is arguably the best R&M standard ever written, because it: (a) presents a menu of tasks from which the user may choose those appropriate to the target project, and (b) strongly recommends tailoring the standards to suit the user’s needs. 785B and other MIL-STDs may be downloaded at no cost from http://www.weibull.com/knowledge/milhdbk.htm Task Field and Test Data Analysis Reliability Prediction Maintainability Prediction Accelerated Life Test FIGURE 3 SUMMARY OF R&M TOOLS Isograph Item* Relex Weibull 4 distributions (also Allocation) 217, Telcordia, NSWC, 299B, 62380, PRISM MTTR Mil-Hdbk-472 Event Tree FaultTree+ Measures of importance p/o FaultTree Importance Mission Simulation AvSim+ Monte Carlo, Multi-phase Network Simulation NAP Importance Fault Tree Maintenance Planning FMECA Life Cycle Cost Quick Simulation Reliability Management RCMCost MSG-3, Spares optimization FMECA 7 standards, Risk Weibull 8 distributions (also Allocation and Derating) 217, Telcordia, NSWC, 299B, 62380, NPRD5 MainTain Mil-Hdbk-472 (also Allocation) 217, Telcordia, NSWC, CNET, HRD, 299B, 62380, PRISM Maintainability Mil-Hdbk-472 FaultTree 15 distributions Fault Tree Measures of importance p/o Fault Tree Importance Event Tree Importance, Consequences RBD Closed-form, Single phase, Importance SpareCost Spares Optimization FMECA 1629, BS 5760, SAE J1739, ISO 9000, IEC 61508 lccWare AvSim+/RBD Multi-phase Markov Multi-phase RBD Closed-form or Monte Carlo, Multi-phase BlockSim Monte Carlo, Single phase OpSim Spares Optimization FMEA/FMECA 10 standards MPC 3 MSG-3, Spares optimization Xfmea 4 standards, ISO 9000, Risk, Enterprise grade LCC p/o BlockSim Markov Single phase Markov Multi-phase FRACAS+ Reliability Growth Analysis *Item also distributes ReliaSoft products. Reliasoft Weibull++ 10 distributions, 2 upgrades Lambda Predict (also Allocation) 217, Telcordia, NSWC, 299B, 62380 p/o BlockSim & p/o RCM++ ALTA PRO upgrade BlockSim FTI Measures of imporance Markov Single phase BlockSim Single phase FRACAS p/o FRACAS Reliability curves XFRACAS Web-based, Enterprise grade RGA 8 Models, Statistics, PRO upgrade 8. Isograph Isograph offers the “Reliability Workbench” suite of closely related modules, together with independent R&M tools. The Workbench modules and the independent tools can all share common user data defining the project system configuration and failure and repair data, in the vendor’s unique format. They all can import data from CAD and other sources; send output to either Isograph pre-defined tables and graphs or to customized text reports, graphs and diagrams; and exchange data with Microsoft Access data bases, Excel spreadsheets; and text files. Web site www.isograph-software.com describes the program features and technical specifications, and you can download demos. (Isograph also offers RiskVu and HazOpPLUS, two programs that can share the common project data but are not discussed in this survey.) The Workbench modules are accessed as tabs in the Workbench home interface: Prediction, FMECA, RBD, MTTR, FaultTree+ and Markov. Prediction software has five optional failure data library modules: Mil-Hdbk-217, Telcordia, NSWC, IEC 62380, and 299B. 217 includes parts count and stress methods. Telcordia comes with three procedures: steady-state, one-year and mixed (library, field and test) data. The user may extend the standard libraries with additional data taken from manufacturers’ spec sheets and other sources. Workbench also offers a link to the RAC PRISM library. The predictions also support reliability allocation with a choice of models. MTTR prediction is incorporated into Prediction, and conforms to Mil-Hdbk-472. For maintainability prediction the user adds his own maintainability data, either by entering part MTTR values or by a guided analysis of the step-by-step repair process. The FMECA module conforms to Mil-Std-1629A, British BS 5760, aeronautical FMEA, SAE ARP5580 and SAE J1739, and accepts user modification to the standards. The user can adopt two approaches: a functional approach during system design or a hardware approach after component selection. Failure modes can be assigned at any level and can be defined as detectable or non-detectable. The module includes an apportionment library derived from Mil-Hdbk-338 that aids the user in grouping commonly used components and failure modes. The program creates a handy lexicon of user phrases. Users may also add the optional Design and Process FMEA upgrade, which accepts detection rankings and evaluates risk. Isograph’s RBD module solves reliability block diagrams for basic system figures of merit such as reliability, availability, mean time to failure and expected number of failures. Component failure and repair rates are limited to the Exponential statistical distribution and single-phase missions. The simulation engine uses minimal cut-set algorithms. Component importance (ranked responsibility for system failures or downtime) is measured in the user’s choice of four methods. The module also evaluates common cause failure factors and can conduct simple sensitivity analyses by automatically varying selected input values. FaultTree+ integrates fault tree, event tree and Markov analysis. The software employs minimal cut-set algorithms to solve for fault tree top events, common cause failures (CCF), and a choice of four measures of importance. For weighted event tree consequences, it evaluates CCF, uncertainty, sensitivity, and importance. FaultTree+ also offers an optional Dynamic Link Library which allows users to construct applications, using C or Visual Basic language, and interface them directly with FaultTree+, for example other programs can run fault tree functions. FaultTree+ has been used on large trees to the order of 20,000 gates and events and can solve even larger trees. The Markov simulator is integrated into Isograph’s Fault Tree software. It can share project system models or accept interactive inputs in reliability block diagram, fault tree or transition diagram form. It can simulate multi-phase missions in which the system configuration and requirements vary at fixed times. Markov also accepts time-dependent failure rates that are phased-Weibull distributed. The simulation employs numeric solution of the Markov differential equations to calculate a wide variety of system figures of merit. AvSim+ is a mission simulator that can model system availability and reliability over a mission that may consist of a sequence of operational phases. The user may enter system configuration data in either fault tree or reliability block diagram form, accompanied by failure and repair rates and optional man-hours and spares data. Failures and repairs may be Exponential, Weibull, Normal or Lognormal distributed. The user may also enter spares constraints and costs at three supply echelons, labor constraints and costs, and safety and environmental effects. The simulation employs a Monte Carlo engine that calculates mission availability and reliability, and optionally man-hours, spares, safety and environmental consequences, at any level of system configuration. The relative significance of system components is indicated by their unreliability, with a choice of median, 90% or 95% confidence. A report generator can produce pre-formatted or customized graphs and tables, which can be displayed directly or inserted into Word reports Weibull is a module of AvSim+, RCMCost and FRACAS+ that supports statistical analyses of field data. The user can select one of several distributions including Exponential, Normal, Lognormal, Weibayse, and seven variations of Weibull for designated fields in the user’s project data base. The program calculates the MTBF or MTTR mean value and other statistics. RCMCost is a Reliability-Centered Maintenance planning tool that conforms to MSG-3 and Mil-Std-2173. It assists the user in entering or importing system FMECA data and structuring it in MSG-3 form, analyzing failure experience to develop a preventive maintenance plan or update it, compare maintenance strategies, predict maintenance man-hours and spares demands, and prepare either standard or tailored reports. lccWare is the Isograph life cycle costing tool. It aids the user in defining a cost breakdown structure, entering mathematical functions for cost elements, and estimating ownership costs at user-defined points in the system’s life cycle. The cost functions can be entered in Visual Basic-compatible language and the variables may be timedependent. A “Part Tree” capability simplifies data input for frequently used equipment, and lccWare aids the user in creating a cost element library and establishing data security. NAP is a tool for creating and analyzing a network diagram. The user defines network nodes and the communication links among them, including bi-directional paths. NAP can analyze networks that cannot be modeled in conventional reliability block diagrams. NAP assists in creating user parts and element libraries. The network analysis employs minimal cut set methodology to calculate system availability and reliability. NOTE: Markov tools have a similar capability, but as systems grow in complexity, their Markov models become more difficult to create and validate. FRACAS+ supports the Failure Reporting, Analysis and Corrective Action System method of monitoring and managing product reliability. It aids the user in structuring a data base of equipment descriptions and locations and entering failure reports and corrective actions. FRACAS+also assists in browsing failure reports by equipment or location, analyzing the data for Weibull or other statistical distribution, and tracking subsequent actions. NOTE: Although not part of standard FRACAS, a complete reliability management system might include a formal Failure Review Board or other management responsibility for reports discipline, configuration tracking, and assigning and following-up member actions. These functions are not directly supported by FRACAS+. 9 Item Item Software offers a “ToolKit” prediction and analysis suite and two related quality assurance programs, Design FMEA and Process FMEA. All of the programs share common project data. Input can be by a combination of RBD, level-of-indenture tree, and tabular grid graphics. Export-import data formats include Excel, Access and delimited text. Users can customize the toolbars and tailor the output report formats. Diagrams, charts, tables and diagrams, including reliability block diagrams, are compatible with Microsoft Word. Item’s Multi Document Interface manages target project data sharing. Item also distributes six ReliaSoft products: Weibull++, Xfmea, ALTA, BlockSim, MPC and QTMS; RAC PRISM; iQRAS risk assessment; and three TFD Group programs for life cycle costing, spares optimization, and total ownership cost. These tools are not participants in the Toolkit project data management system. The ToolKit suite includes five optional prediction modules: MIL 217 (Mil-Hdbk217F), Bellcore (Telcordia R332), Mechanical (NSWC), IEC 62380 (ex-RDF 2000), and China 299B. Add-on library packages are available including electronic devices and non-electronic NPRD 95. The prediction modules contain five allocation and seven derating methods. The system hierarchy may incorporate redundancy. RBD is the ToolKit’s mission simulation module. It is limited to single-phase missions but can generate 15 statistical distributions of component failure and repair times. The simulation engine converts the user’s system description to minimal cut-set logic and calculates system figures of merit by solving differential equations, using the Latin Hypercube sampling technique. Results are displayed as reliability, availability and related figures of merit at user-designated system and subsystem hierarchical levels. The simulator also rates each component’s impact on system R&M performance by a choice of three importance measures. The Markov module calculates system figures of merit at discrete or continuous intervals along a multi-phase timeline. Input is in the form of Markov transition diagrams, guided by a model editor that draws on the system data base. Component failure, repair and other transition rates are limited to the Exponential statistical distribution. The simulation engine operates by closed-form solution of differential equations to calculate reliability and availability figures of merit. Markov analysis is especially useful for mission simulations that consider degraded system states, and for optimizing operation and repair strategies. Item FMECA (Failure Modes Effects and Criticality Analysis) conforms to Mil-Std1629A and standards that have replaced it, including British BS 5760, SAE J1739 and IEC 61508. Input is by hierarchy tree (level of indenture), tabular text, or a customizable sreadsheet-like grid. A large phrase library may be customized by the user. There is also a Mil-Hdbk-338 failure mode apportionment library that can be accessed manually or automatically when transferring system data from a prediction module. The program automatically rolls up the end effect to the failure mode at the next higher level. For special analyses the user can relate failures to multiple effects and redefine the severity categories. Fault Tree analysis identifies and ranks the combinations of events that can lead to system failures. Users construct the tree via the drawing canvas or through the system tree view. The input screens have a comfortable intuitive feel with familiar cut-and-paste and drag-and-drop operation. The fault tree module provides 15 distributions and allows for time phase analysis. Item ARALIA works with Fault Tree to enhance its capabilities. Aralia is a recently developed mathematical technique for quick decision processing that produces precise results rather than approximations. It also provides for the statistical distribution of failure probabilities, computes exact measures of event importance, supports time dependent analyses, and can model incoherent fault trees. SpareCost is a ToolKit module that employs the British RepStock and OptCost models and algorithms. SpareCost optimizes spares stock costs at two repair echelons for a specified out-of-stock risk. Parts data is structured in configuration trees. The analysis assumes that the system is serial (all parts are equally important), skilled repairmen are available, and repair time is insignificant. Output reports include parts stock levels, costs, and performance over user-defined periods. Maintain can share system data with other ToolKit modules. It conforms to procedure V method A of Mil-Hdbk-472. The analysis is an extension of reliability prediction that is used to predict system downtime, maintenance manhours and costs, and identify problem areas. Maintenance activities are characterized by procedural steps. Item Software also offers a suite of quality assurance modules that can share project data with the ToolKit modules. Of these, Design FMEA, Process FMEA and iQRAS are of special interest to reliability engineers. The first two are special FMEA applications that simplify and discipline data collection and access in support of design, process and control management. They meet the requirements of ISO 9000, SAE J1739 and automotive QS-9000. iQRAS is a quantitative, multiphase mission risk assessment tool. 10. Relex Relex Software is the vendor of the “Relex” prediction and analysis suite, as well as a user-customizable FRACAS platform. The programs can share common data (system configuration and component failure and repair rates), under management of a central Project Navigator. The data format is unique to Relex products. Or data can be transferred externally by CAD or delimited text import-export. Standard reports and graphs are provided for presentation of results, all of which can be customized. The “Relex” suite consists of 17 optional modules for reliability prediction, data analysis and other support. Nine of them are prediction modules, based on a choice of standards: Mil-Hdbk-217, Telcordia, NSWC, 217 Parts Count, PRISM, CNET, HRD, 299B and IEC 62380. Each module comes with the related standard procedures and data library. All of the prediction modules also support reliability allocation. Library search aids, for example by part number, are included. Or users may enter their own test data and get an extrapolation of the failure rate. PRISM data analyses can be applied to the other libraries. In addition to the prediction modules, the Relex suite includes eight optional R&M analysis modules: Weibull, RBD, OpSim, Markov, FMEA/FMECA, Fault Tree/Event Tree, Maintainability, and LCC.. Weibull analyzes field histories and test results to find the best fit among eight statistical distributions of failure and repair data: Weibull, Normal, Exponential, Lognormal, Gumbell +, Gumbell –, Rayleigh or Weibayes. A test plan calculator and general statistics calculator are included. The user can display confidence bounds and overlay data sets for direct comparison. Failure and repair data can be directed as inputs to system prediction, FMEA and simulation modules, and Monte Carlo simulation results can be directed to Weibull for statistical analysis. RBD is a multi-phase mission simulator. It models system configuration, component failure and repair rates and system requirements. Where possible it uses quick closedform algorithms to solve for reliability, availability and other figures of merit against system requirements. Otherwise it employs Monte Carlo mathematics to calculate the system figures of merit. Component rates may be in any of the statistical distributions determined by Relex Weibull analysis. RBD can operate either stand-alone or linked to the prediction modules, and can also convert data from CAFTA format. The OpSim simulator model is an extension of RBD that optimizes system maintenance procedures and guides maintenance planning. The model encompasses onand off-site repair teams, spares, preventive maintenance and inspection schedules, parts and labor costs, and aging. The optimizing objective may be cost, reliability, or capacity. Markov is a closed-form simulator that accepts system state sequences in the form of Markov transition diagrams and employs cut-set algorithms to calculate mission reliability, availability, MTBF, MTTR and other figures of merit. The mission consists of a single phase of system operation and requirements, and component failure and repair rates are limited to the Exponential distribution. Markov models are especially useful for analyzing common cause failures, degraded states and other cases where the sequence of events is important. The FMEA/FMECA module supports failure modes, effects and criticality analyses, using the same data libraries as the prediction modules. The project system configuration may be entered graphically in either tree (level-of-indenture) or tabular (spread sheet) form. Procedures conform to the user’s choice of application and standards: Process, Design, Piece Part, Mil-Std-1629, SAE ARP5580, Ford, GM or Daimler-Chrysler. Results are compatible with logistic system analysis (LSAR) format. The Fault Tree/Event Tree module supports both fault tree and event tree analysis. (Fault and event trees model system failures or events, structured as logical sequences.) The program applies cut-set algorithms for quantitative solution. It offers Lambda-Tau representation of well-maintained systems, supports disjoint-event simplification of the tree, and has a neat tree-pruning feature. The user has a choice of four standard procedures and three measures of component importance: Birnbaum, Criticality or Fussell-Vessely. An advantage of fault tree analysis is that it can represent human errors and subsystem-interface failures that are not usually considered in other models. It is the user’s responsibility to include them. Maintainability is an extension of reliability prediction that forecasts system maintainability as a function of component failure modes and maintenance times. Maintenance actions can be modeled in up to seven procedural steps conforming to MilHdbk-472. Results are consistent with LSAR format. LCC is a life cycle cost model. It accommodates inflation factors, net present value, and cost- or work-breakdown structure. LCC allows users a choice of parametric, analogy, bottom-up or direct procedures, estimates design, production, warranty, repair and disposal cost, and makes net present value calculations. It provides an industry standard cost breakdown structure, modified by user-defined cost functions, and generates standard or user-tailored reports. The FRACAS (failure reporting, analysis and corrective action system) package provides a systematic way to organize and discipline failure data collection, examine data statistics using optional analytical programs, and assign and track corrective action. It is ISO 9000- and TickIT-certified. Relex offers FRACAS at three optional editions: Team, Corporate or Enterprise. The Team edition gives users the choice of a secure web browser or access to Windows data bases of system failures and other incidents, and aids in scoring departmental responsibility for failures, analyzing trends, and generating reports. The Corporate edition provides an SQL data base and assists the user to create custom data forms and tables, calculate MTBF and MTTR values, link to prediction results and Weibull statistical analyses, perform user-defined calculations, and create unique reports. The Enterprise edition can interface with several concurrent data bases, including those managed by SQL and Oracle, and track multiple products and participants. Depending on the edition, standard and optional modules may help the users monitor the data base and trigger alert messages; keep audit histories of incidents, design changes and other data; maintain security; assist in organizing projects, and assign and track actions. 11. ReliaSoft ReliaSoft Corporation’s products include Weibull++, ALTA, BlockSim, RGA, Lambda Predict, Xfmea, RCM++, MPC3 and XFRACAS. All of them can share a common set of project data, and all output reports are compatible with Word and Excel. The vendor has also introduced RENO, a useful simulator. Weibull++ examines field and test failure data and finds the best fit among several statistical distributions: Exponential, Normal, Lognormal, Weibull, generalized Gamma, Logistic, Loglogistic, Gumbell, Weibull-Bayesian, mixed-Weibull (with up to four subpopulations), or competing failure modes. Software is included to support nonparametric, warranty, degradation, and recurrent life data analyses, and test planning. Weibull++ DE (Developer Edition) is an extra-cost upgrade that allows users to write their own applications using ReliaSoft’s math and plotting engine. The ALTA program supports quantitative accelerated life testing (testing under high operating and environmental stress to forecast the effect of aging on reliability) where the applied stresses are not a function of time. Although accelerated tests are normally used to precipitate failures, ALTA supports forecasting long-term reliability in normal use. The program guides a choice of Arrhenius, Eyring, Inverse Power Law and other life- stress models. From test data the user can determine such parameters as chemical shelf life, system mean time to failure, B(x) life, failure modes, and warranty factors. The program employs maximum likelihood estimation and is integrated with Weibull++ to fit a Weibull, Exponential or Lognormal statistical distribution and calculate confidence bounds. A report generator produces tables and automated 2D and 3D plots. An ALTA PRO upgrade provides additional models for analyzing time-dependent stress profiles or up to eight simultaneous stress columns. BlockSim is the ReliaSoft mission simulator. BlockSim is limited to single-phase missions. It accepts user system data by reliability block diagrams, fault trees, level-ofindenture trees, or spreadsheet tables. Failure and repair can be assigned any of the distributions that Weibull can identify, or data can be imported directly from Weibull++ or ALTA. The diagrams can be solved analytically (closed form) and cost-based optimizations and reliability allocations can be performed based on this closed-form solution. Alternatively, the main simulation engine is Monte Carlo, including quick calculation of subsystem performance. The simulation includes inspection and preventive maintenance, crew and spares policies and costs. Users can create and beautify an unusually wide variety of graphics in support of preparing input data, drawing conclusions and presenting the simulation results. BlockSim FTI is an upgrade to BlockSim that supports fault tree analysis. User input can be a mix of reliability block diagram and fault tree graphics. RENO is an unusual stochastic event simulator that can perform simulations and spreadsheet calculations employing a novel graphic user interface. The user defines entities and flowcharts a model for Monte Carlo probabilistic solution. Inputs may be assigned 20 distributions including Normal, Weibull, and Exponential. NOTE: RENO is a useful stand-alone tool for the reliability analyst but not limited to R&M applications. To share project data with the ReliaSoft R&M suite, it must be printed out. MPC 3 conforms to the Air Transport Association’s MSG-3 standard for creating and optimizing maintenance plans. It guides the user in: Establishing a system data base using standard aeronautical work structure numbering and attaching documents in Word format. Identifying maintenance-significant items and describing related functions, failures, causes and effects Assisting Maintenance Review Boards in assigning tasks, developing and updating a maintenance program and preparing reports in ATA format. Xfmea is a FMEA and FMECA (failure modes effects and criticality analysis) tool. It supports SAE J1739 and ARP5580, AIAG FMEA-3, and Mil-Std-1629A and allows customization to other standards. It conforms to ISO 9000 and Six Sigma guidelines, and can be configured to the client’s analysis and reporting procedures. Xfmea offers a choice of FMECA or of design, process, machinery, system or service FMEA, and includes risk analysis. Input and editing may be in tabular (spreadsheet) or tree (level-ofindenture) format. Output displays provide for recommended actions and follow-up status. Xfmea is available in an Enterprise edition that is compatible with SQL data bases. XFRACAS is FRACAS software that the user accesses on the web to acquire, manage, analyze and resolve product failure data. The data may reside in an SQL or ORACLE database. Features include system tracking, customized queries and reports, and a configurable user interface. XFRACAS also supports the user’s Failure Review Board in establishing test and field incident reporting procedures, tracking systems, conducting data analyses, assigning and tracking corrective actions, querying the data base, and preparing reports. RGA supports reliability growth analysis, a method of forecasting the degree of system reliability and maintainability that can be achieved, tracking progress, and generating reports. ReliaSoft’s standard version is intended for use during system testing. A test planning utility is included. The test data may be continuous time-to-failure or discrete failure. The user has a choice of eight statistical models: Crow-AMSAA, Crow Extended, Power Law, Duane, Gompertz, Modified Gompertz, LLoyd-Lipow and Logistic. Depending on the data type, the program employs either maximum-likelihood or least-squares algorithms to calculate system figures of merit including MTBF, reliability and failure rate (intensity), as well as goodness-of-fit and trend analysis. The user can generate a variety of graphics and prepare reports for export into Word or Excel. An RGA PRO upgrade adds support of reliability improvement programs for fielded repairable systems. It includes Power Law and Crow Extended models for reliability projection and advanced techniques for data analysis. 12. Technical Support Isograph supports users by telephone, web meetings, e-mail and fax for 4 months at no cost following their purchase. Isograph also offers extended technical support and maintenance contracts that include upgrades to their products. Isograph can also provide utilities and services to convert models from obsolete software products. Isograph offers two annual User Group meetings in the United States; schedules regular one-day courses in their products at Newport Beach CA, Washington DC and Warrington UK; and will arrange other courses there or on site. Isograph logs user queries and solutions, and requests for program enhancements. The Customer area on Isograph’s web site provides up-to-date information on program releases, user group presentations, user requests, utilities, etc. Item provides with each module a free three-month maintenance contract that covers technical support, product updates and web-based training classes. Most technical questions are answered immediately; a few may require 24 hours to resolve. Failure data libraries are updated monthly, at no cost. Item publishes a monthly newsletter of product bulletins and training course announcements. Their web site’s Tech Corner offers tool tip videos and articles on R&M practice. Item schedules 2-, 3-, and 4-day courses and workshops covering basic theory through advanced methodology in Anaheim, CA and College Park, MD. Attendees receive 45 days’ use of the ToolKit suite of products. Relex supports buyers free for 3 months, including technical support by phone, software and library upgrades, free instructor-led on-line training, and a discount on classes. After 3 months, technical support by e-mail or fax is still free and the vendor will furnish program and data upgrades at a reduced price. Long-term support contracts are available. Relex publishes QuarterFlash, a hard-copy quarterly newsletter that describes new products or upgrades and contains a helpful column of tips to users. The vendor will conduct a three-day course at the site of a major customer, schedules about ten free training courses for users around the country every year, and has developed an interactive training CD called Reliability 101 that is included with every software purchase. Helpful articles concerning the selection and use of Relex tools also appear on their web site. Reliasoft provides unlimited free technical support and minor software updates to registered users via phone, fax, e-mail and web meetings. User manuals are accompanied in most cases by a reference handbook. Reliasoft publishes the Reliability Edge newsletter, posted on the internet or in hard copy by free subscription, and posts or emails Reliability HotWire, an e-magazine that includes useful how-to information. The vendor publishes four on-line textbooks. A free web site, http://www.weibull, has thousands of pages of technical papers. Reliasoft offers a free seminar as part of an annual users group meeting, and also conducts five collections of courses for a fee: About two dozen five-day seminars a year, on different subjects and in different cities world wide, Three- and five-day training courses on R&M tasks, One-day courses in R&M management, Two- and three-day courses on related quality/reliability topics, and Three-, four- and five-day courses in preparation for advanced subjects. 13. Prices The cost of R&M tools is not as important as it may seem, considering the far higher cost of the professional hours required to learn and apply them, not just by R&M analysts but by the demands on design engineers and production, operations and maintenance supervisors. The vendors included in this survey are highly competitive and the costs of their products would probably be similar to the rough estimates shown in Figure 4, if their pricing were similarly based. The vendors structure their products differently, for example some tools incorporate other tools, or require other tools in order to operate. ReliaSoft prices are posted on their web site. The other vendors will quote current prices by phone or e-mail. Figure 4 illustrates typical prices of unbundled single items, licensed to a single user and bought outright, rather than rented or accessed on the internet. Figure 4 Typical Cost of Single User License for Purchased Product Task Data Statistical Analysis R&M Prediction (1 Library) R&M Prediction (4 Libraries) Mission Simulation FMECA Maintenance Planning (MSG-3) $ Cost * 1,000 2,000 6,500 2,500 2,000 5,000 Training Instruction at vendor’s site, per person, 1 day At vendor’s site, per person, 3 days At customer’s site, per classroom, 1 day At customer’s site, per classroom, 3 days 500 – 750 1,000 – 1,500 3,500** 8,000** * Prices will be higher for multi-user site license or with add-ons, lower for rental or for internet operation ** Plus instructor’s expenses For new releases, bargains are usually offered to early shoppers and to upgrade current customers to the new release level. Unadvertised discounts are available for academic or government buyers. And total cost can often be significantly reduced for tools purchased in volume or bundled with other tools, training packages, or extended maintenance (warranty). Extended maintenance typically consists of some combination of long-term technical support by telephone and free upgrades to new releases. Isograph offers various price options for single-user licenses, network license and special packages that include software products commonly used together. Extended maintenance follows a descending discount structure that is dependent on the length of the maintenance agreement. Item offers site and network licenses, sold by module and number of concurrent users. Discounted combination packages are available for the most commonly used configurations. Call or e-mail them at the telephone number and address shown in paragraph 1. Relex: For prices contact Relex directly at the telephone number or e-mail address listed in paragraph 1 above. Relex products can be bought outright, or accessed on the internet for a user fee. ReliaSoft maintains an updated price list on the web at http://www.reliasoft.com /order_form.htm. Network license and multi-user site license prices are available on request. A “Gold License” is available that includes all of ReliaSoft’s shrink-wrapped tools and one training course per year. Software can also be rented at an annual cost of half the retail price. Extended maintenance costs 20%, 30% or 45% of the retail price for 1-, 2- or 3-year terms. . 14. A Whiff of Snake Oil A final note: Some enthusiastic software marketers publish brochures and newsletters making it seem that their products can substitute computer tools for engineering expertise. Be not deceived. Even in the computer age it is still true that the single most important factor in any system analysis is how well the analyst understands the system. And engineers, operators and maintainers must still provide valid input information, and must still assist in translating the outputs into practical recommendations for action.