d111 - Quenched and Tempered Plate

advertisement

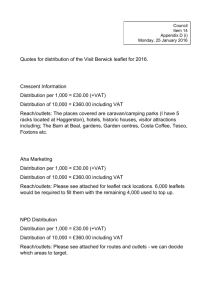

EXTRAS LIST 111 QUENCHED AND TEMPERED PLATE Effective: 01 OCTOBER 2015 1. QUALITY EXTRAS Quality Code Specification Product Condition (Applicable Extras will be Charged separately) Thickness Range (mm) Quality Extra R/t (VAT excl) Impact: Optional UT: Optional 8 - 25mm 2491 Primed: Optional Alloy: Not Applicable Impact: 1 set / 40t @ - 50ºC UT: B1 967 000 ROQ-tuf AM 700 # 8 - 25mm 2560 Primed: Optional Alloy: Add Moly Note: Not guaranteed for Yellow Goods applications with stringent surface and flatness requirements. # On enquiry only ROQ-last TH 400 2. 976 000 ITEM EXTRA ITEM Quantity Standard items 1) (ton) R/t (VAT exclusive) 5 < 10 539 10 < 25 276 ≥ 25 0 Complexity cost – Other items subject to extra of R219 per ton in addition to the above item extra. Notes: 1) Please refer to Paragraph 3, for all standard items 2) Any other dimensions or Quality not listed in Paragraph 3 3) Other items on enquiry only and subject to approval by ArcelorMittal South Africa Management. A minimum order quantity of 50 ton per item ordered for these enquiries to be considered is imposed. 3. WIDTH / THICKNESS EXTRAS - AVAILABLE STANDARD SIZES 1) 2) ROQ-tuf AM 700 Size ROQ-last TH 400 Length x Width x Thickness R/t (VAT exclusive) R/t (VAT exclusive) 12000 x 2000 x 8 800 800 12000 x 2400 x 10 368 368 12000 x 2400 x 12 368 368 12000 x 2400 x 16 149 149 12000 x 2400 x 20 149 149 12000 x 2400 x 25 149 149 Notes: 1) Non-standard sizes on enquiry only and subject to approval by ArcelorMittal South Africa Management. Minimum order quantity for these enquiries to be considered is 25 ton per item requested. Ad Hoc Width- Thickness Extras will be determined in such cases, after approval of the enquiry. 2) Other qualities, or modifications to qualities, on enquiry only. 2015-10-01 Cancels and supersedes issue dated 2015-07-01 Page 1 EXTRAS LIST 111 QUENCHED AND TEMPERED PLATE Effective: 01 OCTOBER 2015 4. LENGTH EXTRA Length (mm) 4 000 12 000 5. 5.1 5.2 5.3 5.4 5.5 5.6 5.7 5.8 5.9 R/t (VAT exclusive) 52 PROCESSING EXTRAS R/t (VAT excl) IMPACT TESTS (Longitudinal/Transverse) One set of Three tests per 40 ton (at – 50ºC for ROQ-tuf AM700) One set of Three tests per Plate / Serial PLATES UNCUT – not available ELEVATED TEMPERATURE TEST One test per temperature (0458; 0477) TEST PIECE CONDITION (if same as plate condition) Roller Quenched only (7691) Roller Quenched & Tempered (0535) RESTRICTED FLATNESS TOLERANCES 75% of ASTM A 6/A20 OVERAGE & UNDERAGE LIMITATIONS 50% of standard 2.5% of specified item mass Specified minimum quantities Specified maximum quantities Ordered number of plates – exact count Ordered number of plates minimum required WITNESSING AND INSPECTION Witnessing mechanical test Witnessing ultrasonic test Surface inspection Surface inspection and marking out of test pieces Inspection of packaging Inspection of packaging, weight & dimensions MARKING colour code according to SANS 0202 Enquiry only Thickness is Minimum 2015-10-01 Cancels and supersedes issue dated 52 140 153 0 0 464 (2408) (2409) (2440) (2293) (2170) (3497) 114 157 61 61 241 61 (0345) (0470) (0577) (6029) (0466) (7204) 57 57 39 122 30 39 (1361) 26 (3998) 131 2015-07-01 Page 2 EXTRAS LIST 111 QUENCHED AND TEMPERED PLATE Effective: 01 OCTOBER 2015 5. 5.10 PROCESSING EXTRAS (Continued) ULTRASONIC TESTING Ultrasonic Testing Specification or Customer Requirement if more stringent Codes Minimum Gauge to 20mm R/ton (VAT exclusive) Plate Thickness > 20mm to 40mm > 40mm R/ton R/ton (VAT exclusive) (VAT exclusive) None BS5996 B1 BS5996 B1/E1 BS5996 B1/E2 BS5996 B1/E3 BS5996 B2 BS5996 B2/E1 BS5996 B2/E2 BS5996 B2/E3 BS5996 B3 BS5996 B3/E1 7688 7709 7710 7711 7712 7713 7720 7714 7715 7684 7717 0 100 190 205 225 115 205 225 245 130 225 0 205 340 360 375 225 360 375 395 245 375 0 280 430 450 470 300 450 470 490 320 470 BS5996 B3/E2 BS5996 B3/E3 BS5996 B4 BS5996 B4/E1 BS5996 B4/E2 BS5996 B4/E3 EN10160 S0 EN10160 S0 E0 EN10160 S0 E1 EN10160 S0 E2 EN10160 S0 E3 EN10160 S0 E4 EN10160 S1 EN10160 S1 E0 EN10160 S1 E1 EN10160 S1 E2 EN10160 S1 E3 EN10160 S1 E4 EN10160 S2 EN10160 S2 E0 EN10160 S2 E1 EN10160 S2 E2 EN10160 S2 E3 EN10160 S2 E4 7718 7719 7784 7721 7722 7723 7761 7765 7766 7767 7768 7769 7762 7770 7771 7772 7773 7774 7763 7752 7753 7775 7754 7755 245 265 150 245 265 280 115 190 205 225 245 265 150 225 245 265 280 300 190 265 280 300 320 340 395 415 265 395 415 430 225 340 355 375 395 415 265 375 395 415 430 450 300 415 430 450 470 490 490 505 340 490 505 625 300 430 450 470 490 505 340 470 490 505 525 545 375 505 525 545 565 580 2015-10-01 Cancels and supersedes issue dated 2015-07-01 Page 3 EXTRAS LIST 111 QUENCHED AND TEMPERED PLATE Effective: 01 OCTOBER 2015 5. PROCESSING EXTRAS (Continued) 5.11 SHOTBLAST AND PRIMED (Optional product condition) Plate Thickness (mm) 8 to < 10 10 to < 12 12 to < 15 15 to < 25 Red Oxide (TH400) Light Grey (AM700) 6. Shot blast & Primed R/t (VAT exclusive) 807 631 535 421 Code 0226 Code 0227 PACKAGING EXTRAS Packaging code * Bundle mass Code 00* (t) R/t (VAT exclusive) < 2.0 ** 65 2.0 < 2.5 57 2.5 < 4.0 26 4.0 < 5.0 4 0 5.0 14 Note: * Refer Packaging Specification for Code Descriptions. ** On enquiry only. Standard Bundle mass is 5 ton plus, depending on plate mass. 2015-10-01 Cancels and supersedes issue dated 2015-07-01 Code 11* 65 57 26 4 0 Page 4