MS 6-08 Use of Trailers

advertisement

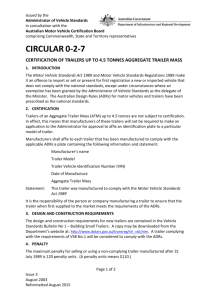

BP Ref 4.2 Review Due 01/12/2011 Owner OH&S Advisor Document Title MS 6-08 Use of Trailers Method Statement Risk Assessment/COSHH RA016 RA017 VP RA RA083 Resources For Activity Title On-site Parking of Vehicles Driving Vehicle and Plant Risk Assessments Trailers Two Competent Operatives, Suitable Tow Vehicle, Trailer, Trailer Board with Tow Vehicle Registration. Work Sequence 1 Hitching and Unhitching Trailers a) b) c) d) e) f) All handling should be carried out using the dip and drive method and wherever possible ensure you seek assistance from a suitably able colleague. Do not try and hitch or unhitch that is fully laden without the stabilisers and or jockey wheels set correctly. Become methodical about hitching up and unhitching so that you do not forget anything. If your towing vehicles mirrors do not give a good view past the trailer you should fit towing mirrors. Apply the trailer handbrake, remove any towball and electrical socket dust covers and security devices then wind the jockey wheel to the required height. Check the towball is lightly oiled. (Not greased) (If not being used with a head stabiliser.) g) Get a banksman to stand with their hands showing you where the hitch is (place a broom against it if you are alone) and reverse slowly back. Your helper indicates if you are off line. Coupling Head Safety Break Away Cable Brake Jockey Wheel h) Raise the front of the trailer by means of the jockey wheel assembly to the required height, roll trailer up to the rear of the towing vehicle. i) If the trailer has tandem axles, raise sufficiently to raise the front wheels clear of the ground to aid manoeuvrability. j) Do not attempt to lift the front of the trailer. Lower the trailer by means of the jockey wheel assembly onto the towball of the vehicle. k) Over the last foot or so, your helper should use their hands to show you the actual distance between towball and coupling head. l) If you have to stop a few inches short, judge how far back you are going by comparing the front wheels' movement to something on the ground. m) Wind the jockey wheel down to lower the coupling head onto the towball. n) Some coupling heads have a locking handle which stays up then automatically locks onto the ball, others Date last printed Version No 07/03/2016 Uncontrolled unless viewed on BMS Page 1 of 5 2.0 BP Ref 4.2 Review Due 01/12/2011 Owner OH&S Advisor Document Title MS 6-08 Use of Trailers Work Sequence o) p) q) r) s) t) u) v) w) x) have to be held up and may have an indicator to show when the ball is in place. Once the coupling head appears locked on, lower the jockey wheel a few turns to lift the back of the vehicle to prove the coupling head is on properly, then fully raise the wheel before unclamping it and, finally, securely locking it fully raised. Check that the wheel in the position you have locked it is not interfering with the operation of the coupling overrun mechanism. Attach safety breakaway cable(s) to the rear of vehicle. This cable will apply the hand brake if for any reason the trailer becomes detached whilst towing. (Clip the breakaway cable onto the special rings some towbars have or loop it around the bar, making sure it cannot foul the coupling head. Do not loop it round the towball neck unless you can find no alternative.) Check that the breakaway and lighting cables have enough slack for cornering but will not touch the ground. Plug in the lighting plug, and check all lights and indicators. The electrical plug only fits one way, so line up its cut-out with the lug on the bottom edge of the socket. Some cars have two sockets – use the one with the black cover flap because the one with the white flap is for caravan supplementary electrical systems. It is your responsibility as the driver to ensure all lights work. Turn on the car lights and check the trailer's lights. With the ignition on, make sure the correct indicators are working – car and trailer indicators not matching is a common fault – then get someone to see if the trailer brake lights work. (If you are alone, use a short stick between the pedal and the seat to hold down the brake pedal.) Adjust both external mirrors so that a view down both sides of the trailer can be obtained. (If this cannot be achieved extension mirrors should be fitted). When loading a trailer ensure the weight is distributed appropriately. Nose weight is a very important factor in making your vehicle and trailer combination stale during towing. Inadequate nose weight can cause snaking problems. Too much nose weight causes other problems. Noseweight should be at least 50kg when the outfit is stationary. Refer to the recommendations of you vehicle and trailer manufacturers. It is your responsibility, as the driver, to ensure that your vehicle or trailer is not overloaded. If the trailer has an eye coupling, after attaching the trailer, make sure that the safety locking catch on the towing pin is properly applied and that the safety pin or clip is fitted. (If this is not fitted, the trailer could become unhitched). Lift up and lock the jockey wheel assembly. (If this is not done, the jockey wheel will become damaged). 2 Towing trailers with medium sized vehicles between 3.5 and 7.5 tonnes a) In this article reference is made to the maximum authorised mass (MAM) of vehicles and trailers. This should be taken to mean the permissible maximum weight, also known as the gross vehicle weight. b) The gross vehicle weight (also known as the MAM) is shown on a manufacturers or DFT plate normally fixed in the cab of a vehicle, and is the maximum legal weight of the entire vehicle including the goods carried and the fuel. c) Subcategory C1: Medium sized goods vehicles 3.5 - 7.5 tonnes MAM d) Subcategory C1 vehicles may be coupled with a trailer up to 750kgs MAM allowing a combination of up to 8.25 tonnes MAM. But unlike category B, the 750kgs MAM trailer weight limit is an absolute limit. e) In order to gain this entitlement category B licence holders have to meet higher medical standards and pass both theory and practical tests for subcategory C1. f) Subcategory C1+E: Medium sized goods vehicles 3.5 - 7.5 tonnes MAM plus trailer over 750kgs MAM g) Subcategory C1+E allows vehicles to be combined with a trailer over 750kgs MAM provided the combination does not exceed 12 tonnes MAM and the laden weight of the trailer does not exceed the unladen weight of the towing vehicle. h) In order to gain this entitlement category B licence holders have to pass further tests - subcategory C1 (theory and practical) followed by C1+E practical. There is no subcategory C1+E theory test. It will not be possible to go directly from category B to subcategory C1+E. i) Because EC regulations limit drivers aged under 21 years to driving vehicles or combinations which weigh no more than 7.5 tonnes MAM, drivers under the age of 21 are not allowed to drive subcategory C1+E vehicles up to 12 tonnes MAM. But 18 year old drivers are allowed to take a test for subcategory C1+E which will Date last printed Version No 07/03/2016 Uncontrolled unless viewed on BMS Page 2 of 5 2.0 BP Ref 4.2 Review Due 01/12/2011 Owner OH&S Advisor Document Title MS 6-08 Use of Trailers Work Sequence allow trailers in excess of 750kgs MAM to be towed. Entitlement is limited to a combination weight of 7.5 tonnes MAM until the driver reaches 21 years, at which time the balance of 12 tonnes MAM entitlement automatically becomes effective. 3 Licence Category A – B License Code Vehicle type Minimum Age A1 Motorcycle 17 A Motorcycle 17 B1 3 or 4 wheeled light vehicles 17 B Cars 17 B Minibuses 21 B+E Cars with trailers 17 Notes Light motorcycles with a cubic capacity not exceeding 125cc and of a power output not exceeding 11kW (14.6 bhp) Motorcycles up to 25kW (33 bhp) and a power to mass ratio not exceeding 0.16W/kg. Motorcycle combination with a power mass ratio not exceeding 0.16W/kg. Motor tricycles/quadricycles up to 550kg unladen. Motor vehicles with a MAM not exceeding 3500 kg having not more than 8 passenger seats with a trailer up to 750 kg. Combinations of vehicles in Category B and a trailer, where MAM of the combination does not exceed 3500 kg and the MAM of the trailer does not exceed the unladen mass of the towing vehicle. Example: A vehicle with an unladen weight of 1.25 tonnes and a MAM of 2 tonnes coupled with a trailer with a MAM of 1.25 tonnes could be driven by the holder of a category B entitlement, as the MAM of the combination does not exceed the unladen weight of the towing vehicle. Vehicles with between 9 and 16 passenger seats not for hire or reward. MAM not exceeding 3.5T or 4.25T including specialist equipment for the carriage of disabled passengers. No trailer of any size may be pulled. B licence must have been held for 2 years. Combinations of vehicles consisting of a vehicle in category B and a trailer, where the combination does not come within category B. The MAM of the trailer must not exceed the mass of the unladen towing vehicle 4 License Category C License Code Vehicle Type Minimum Age C1 Medium sized vehicle 18 C1+E Medium sized vehicle with trailers C C+E Date last printed Large vehicles Large vehicles with trailers Notes Vehicles between 3500kg and 7500kg with a trailer up to 750 kg. 21 Combinations of vehicles where the towing vehicle is in subcategory C1 and its trailer has a MAM of over 750kg provided that the MAM of the combination thus formed does not exceed 12000 kg and MAM of the trailer does not exceed the unladen mass of the towing vehicle. Vehicles over 3500kg with a trailer up to 750kg. 21 Vehicles over 3500kg with a trailer over 750kg. 21 Version No 07/03/2016 Uncontrolled unless viewed on BMS Page 3 of 5 2.0 BP Ref 4.2 Review Due 01/12/2011 Owner OH&S Advisor Document Title MS 6-08 Use of Trailers Work Sequence 5 Carrying Plant on Trailers a) Ensure the trailer has its security marking and registration plate intact and legible. b) Only trained competent operatives must move the plant on and off the trailer. c) Ensure you know the weight of the plant and that it does not exceed the permissible carrying weight of the trailer. If in doubt contact your supervisor or Fleet Manager. d) Also take into account any additional plant or equipment including spare buckets, etc for diggers to the overall weight being carried on the trailer. e) Ensure adequate straps, tension bars and or chains are used to anchor plant firmly on the trailer. f) Use the dedicated lashing or anchor points on the trailer and do not put straps around any part of the plant or trailer that could become damaged when the tension is applied on the straps. g) Check all straps before each andd every use for signs of fraying, tears and ensure they do not get heavily soiled with oil, or fuel. Store the straps in a dry area when not in use. h) Ensure ramps are properly set out and put back securely after loading and unoading. i) Ensure Jockey wheel and any stabilising devices are properly set out and secure before attempting to load or unload trailer. Date last printed Version No 07/03/2016 Uncontrolled unless viewed on BMS Page 4 of 5 2.0 BP Ref 4.2 Review Due 01/12/2011 Owner OH&S Advisor Document Title MS 6-08 Use of Trailers Work Sequence j) Ensue Jockey wheel is lifted is lifted and secured when you are ready to move off. k) Also ensure any stabilising device is also removed or lifted and secured as applicable before moving off. l) Ensure all electrics are checked and lights work. Ensure Trailer Board is fitted with towing vehicles registration plate number clearly displayed. m) Double check all wheels on trailers before moving off for signs of corrosion or movement and ensure all wheel nuts are secure. Do this at various intervals throughout the shift. Date last printed Version No 07/03/2016 Uncontrolled unless viewed on BMS Page 5 of 5 2.0