International Journal of Science, Engineering and Technology Research (IJSETR)

Volume 1, Issue 1, July 2012

The Impact of Back-to-Back Converter used in

Doubly Fed Induction Generator Driven by Wind

Power

Shwe Hlaing

Abstract — This paper describes the improvement of

performance for wind power generation by Doubly Fed

Induction Generator (DFIG) with back-to-back converter by

Matlab simulations. As the wind power penetration into the grid

increases quickly, the influence of wind turbines on the dynamic

stability is becoming more and more important. The paper

studies the effect of back-to-back converter with DFIG on the

electric power system operation. The simulation results clearly

show the effect of back-to-back converter on the voltage,

frequency, and power factor stability of electric power system.

Index Terms—Active Power, Back-to-Back Converter, Doubly

Fed Induction Generator, Reactive Power, Wind Turbine

I. INTRODUCTION

Wind industry is becoming one of the world’s fastest

growing energy sectors nowadays, helping to satisfy global

energy demand, offering the best opportunity to unlock a new

era of environmental protection, and starting the transition to

a global economy based on sustainable energy. Wind turbines

based on doubly fed induction generators have attracted

particular attention because of their advantages such as

variable speed constant frequency operation, reduced flicker

and independent control capabilities for active and reactive

powers. The wind farm capacity is being continuously

increased through the installation of more and larger wind

turbines. Voltage stability and an efficient power supply to the

grid are the basic requirements for higher penetration. Wind

turbines have to be able to continue uninterrupted operation

under transient voltage conditions to be in accordance with

the grid regulations. Wind power systems should meet these

requirements for interconnection to the grid. One of the major

issues concerning a wind farm interconnection to a power grid

concerns its dynamic stability on the power system. For the

efficient operation of wind power generation, the DFIG with

back to back converter is presented in this paper.

II. WIND ENERGY CONVERSION SYSTEM

All wind perform the function of converting mechanical to

electrical energy for transportation via the electric

transmission network. The energy conversion process begins

Manuscript received Oct 15, 2011.

Shwe Hlaing, Department of Electrical Power Engineering, Mandalay

Technological University, (e-mail: shwehlaingbagan@gmail.com).

Mandalay, Myanmar..

with the energy input source: the wind, which obeys certain

aerodynamic characteristics. As wind flows past the blades of

a machine, whether rotating or stationary, mechanical lift is

produced and an aerodynamic torque (Tae) is applied to the

blades. Depending on the rotation of the blades, this torque

produces a mechanical power (Pm). The mechanical power

that the turbine extracts from the wind and applied to the

electrical subsystem for conversion is given by the following

relationship.

Pm = 0.5ρArCp( λ,β)ω3

λ=

Ω r rr

ω

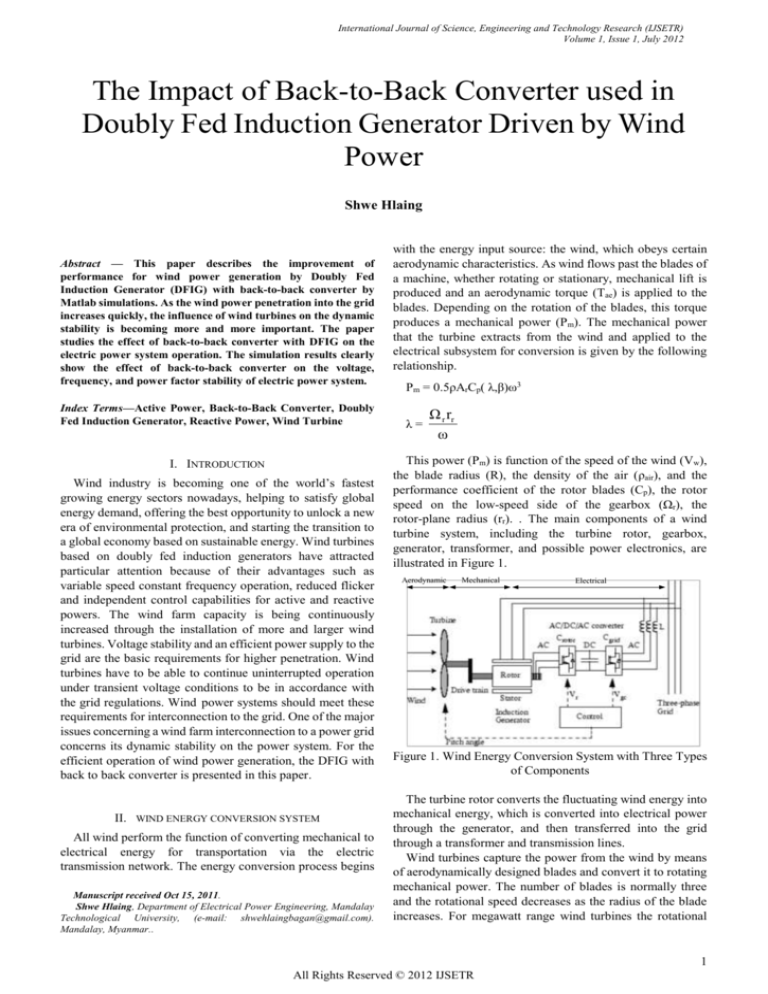

This power (Pm) is function of the speed of the wind (Vw),

the blade radius (R), the density of the air (ρair), and the

performance coefficient of the rotor blades (Cp), the rotor

speed on the low-speed side of the gearbox (Ωr), the

rotor-plane radius (rr). . The main components of a wind

turbine system, including the turbine rotor, gearbox,

generator, transformer, and possible power electronics, are

illustrated in Figure 1.

Aerodynamic

Mechanical

Electrical

Figure 1. Wind Energy Conversion System with Three Types

of Components

The turbine rotor converts the fluctuating wind energy into

mechanical energy, which is converted into electrical power

through the generator, and then transferred into the grid

through a transformer and transmission lines.

Wind turbines capture the power from the wind by means

of aerodynamically designed blades and convert it to rotating

mechanical power. The number of blades is normally three

and the rotational speed decreases as the radius of the blade

increases. For megawatt range wind turbines the rotational

1

All Rights Reserved © 2012 IJSETR

International Journal of Science, Engineering and Technology Research (IJSETR)

Volume 1, Issue 1, July 2012

speed will be 10-15 rpm. The weight-efficient way to convert

the low-speed, high-torque power to electrical power is to use

a gearbox and a generator with standard speed. The gearbox

adapts the low speed of the turbine rotor to the high speed of

the generator. The gearbox may be not necessary for

multipole generator systems.

The generator converts the mechanical power into

electrical energy, which is fed into a grid through possibly a

power electronic converter, and a transformer with circuit

breakers and electricity meters. The connection of wind

turbines to the grid is possible at low voltage, medium

voltage, high voltage, and even at the extra high voltage

system since the transmittable power of an electricity system

usually increases with increasing the voltage level. While

most of the turbines are nowadays connected to the medium

voltage system, large offshore wind farms are connected to

the high and extra high voltage level.

III. WIND TURBINE CONCEPTS AND GENERATOR TYPES

Referring to the rotation speed, wind turbine concepts can

be classified into fixed speed, limited variable speed and

variable speed. For variable speed wind turbines, based on the

rating of power converter related to the generator capacity,

they can be further classified into wind generator systems with

a partial-scale and a full-scale power electronic converter. In

addition, considering the drive train components, the wind

turbine concepts can be classified into geared-drive and

direct-drive wind turbines. In geared-drive wind turbines, one

conventional configuration is a multiple-stage gear with a

high-speed generator; the other one is the multibrid concept

which has a single-stage gear and a low-speed generator.

A. Fixed-speed Concept

The fixed speed wind generator systems have been used

with a multiple-stage gearbox and a SCIG directly connected

to the grid through a transformer as illustrated in Figure 2.

Because the SCIG operates only in a narrow range around the

synchronous speed, the wind turbine equipped with this type

of generator is often called the fixed-speed wind generator

system. Smoother grid connection was also achieved by

incorporating a soft-starter. Furthermore, a pole-changeable

SCIG has been used, which leads two rotation speeds.

The well-known advantages of SCIG are it is robust, easy

and relatively cheap for mass production. In addition, it

enables stall-regulated machines to operate at a constant

speed when it is connected to a large grid, which provides a

stable control frequency. Although the stall control method is

usually used in combination with the fixed speed SCIG for

power control, the active stall control or pitch control have

also been applied.

B. Limited Variable Speed Concept

The limited variable speed concept with a multiple-stage

gearbox is also known as the Optislip concept. This wind

turbine concept uses a wound rotor induction generator

(WRIG) with variable rotor resistance by means of a power

electronic converter and the pitch control method, as shown in

Figure 3.

Figure 3. Scheme of a limited variable speed concept with

WRIG system (Optislip)

The stator of WRIG is directly connected to the grid,

whereas the rotor winding is connected in series with a

controlled resistor. Variable-speed operation can be achieved

by controlling the energy extracted from the WRIG rotor;

however, this power must be dissipated in the external

resistor. With the increase in variable speed range, a higher

slip means a high power extracted by the rotor, and the lower

generator efficiency, so that the rating of the resistor must also

be higher. Therefore the dynamic speed control range

depends on the size of the variable rotor resistance, and the

energy extracted from the external resistor is also dumped as

heat loss in the controllable rotor resistance. A typical limited

variable speed range is less than 10% above the synchronous

speed.

C. Variable Speed Concept with a Partial Scale Power

Converter

This configuration is known as the DFIG concept, which

corresponds to a variable speed wind turbine with a WRIG

and a partial-scale power converter on the rotor circuit, as

illustrated in Figure 4. The stator is directly connected to the

grid, whereas the rotor is connected through a power

electronic converter. The power converter controls the rotor

frequency and thus the rotor speed. This concept supports a

wide speed range operation, depending on the size of the

frequency converter. Typically, the variable speed range is

30% around the synchronous speed. The rating of the power

electronic converter is only 25 to 30% of the generator

capacity, which makes this concept attractive and popular

from an economic point of view.

Figure 4. Scheme of a variable speed concept with D FIG

system

IV. WIND TURBINE WITH DFIG

Figure 2. Scheme of a fixed speed concept with SCIG

system

Generally the wind turbines (WT) can either operate at

fixed speed or variable speed. For variable speed systems

2

All Rights Reserved © 2012 IJSETR

International Journal of Science, Engineering and Technology Research (IJSETR)

Volume 1, Issue 1, July 2012

with limited variable-speed range (±30% of synchronous

speed), the DFIG can be a cost effective solution. The DFIG

converter consists of two converters that are connected

“back-to-back” as in Figure; machine-side converter and grid

side converter. Between the converter, a dc-link capacitor is

placed as energy storage to keep the dc-link voltage variations

(or ripple) small.

With the machine side converter, it is possible to control

the torque or the speed of the DFIG, and also the power factor

at the stator terminals, while the main objective for the

grid-side converter is to keep the dc-link voltage constant.

VI. BACK TO BACK CONVERTER

The power electronic back to back converter also known as

AC-DC-AC converter system is the most common

configuration used to interface the variable speed DFIG wind

turbines to the grid. This converter system is also called as the

back-to-back Voltage Source Converter (VSC) configuration.

Few of the advantages of the Back-to-Back Converters (BBC)

are as follows:

It is a well-established technology and many

manufacturers produce components especially designed

for the BBC’s.

decoupling of the two VSC’s through a capacitor

allows for individual control of both the rotor-side

and grid-side converters.

Figure 5. Variable-Speed Wind Turbine with a Doubly-Fed

Induction Generator (DFIG)

V. OPERATING PRINCIPLE OF DFIG WITH BACK-TO-BACK

CONVERTER

The stator is directly connected to the AC mains, while the

wound rotor is fed from the Power Electronics Converter via

slip rings to allow DIFG to operate at a variety of speeds in

response to changing wind speed. Indeed, the basic concept is

to interpose a frequency converter between the variable

frequency induction generator and fixed frequency grid. The

DC capacitor linking stator and rotor side converters

allows the storage of power from induction generator for

further generation. To achieve full control of grid current, the

DC-link voltage must be boosted to a level higher than the

amplitude of grid line-to-line voltage. The slip power can

flow in both directions, i.e. to the rotor from the supply and

from supply to the rotor and hence the speed of the machine

can be controlled from either rotor- or stator-side converter in

both super and sub-synchronous speed ranges.

The AC/DC/AC converter is basically a PWM converter

which uses sinusoidal PWM technique to reduce the

harmonics present in the wind turbine driven DFIG system.

Here Crotor is rotor side converter and Cgrid is grid side

converter. Crotor and Cgrid have the capability for generating or

absorbing power and could be used to control the power or the

voltage at the grid terminals.

Figure 6. Basic Operating Principle of DFIG

Figure 7. Equivalent Circuit of the Back-to-Back

Converter

The back-to-back converter configuration shown in Figure

7 is a bidirectional power electronic IGBT converter

consisting of two voltage source converters connected back to

back. It consists of a three-phase controlled rectifier and

a three-phase controlled inverter, coupled through a

capacitor, called the dc link. Since, the back-to-back

converter configuration is implemented with the

variable-speed DFIG, the rectifier is also called as the

Grid-Side Converter (GSC), and the inverter is also called as

the Rotor-Side Converter (RSC).

VII. SIMULINK MODEL FOR THE BACK-TO-BACK PWM

CONVERTER

A simulation model for back to back converter controlled

DFIG system is developed using components from the Power

System’s Blockset (SimPower). This is a particularly useful

add-on to Simulink that provides models for a wide range of

power electronic devices and control structures. Most of the

blocks used in the design are available in the standard

Simulink library. The simulation model is executed with

Matlab/Simulink 2013a version. The simulation model for

Back to Back Converter Controlled DFIG is executed with

Matlab/Simulink 2013a version. This simulation model is

constructed to control Back to Back Converter Controlled

DFIG in various condition. Therefore various operation

conditions are created in this simulation as follow:

(i)Operation at below rated wind speed

(ii) Operation at above rated wind speed

At each operation, the various measurements are carried

out at DC sides as well as AC sides. The main measurements

3

All Rights Reserved © 2012 IJSETR

International Journal of Science, Engineering and Technology Research (IJSETR)

Volume 1, Issue 1, July 2012

are (i) the DC link voltage and current measurement, (ii) the

input AC voltage and current measurements from stator and

rotor side and (iii) the back to back converter measurement.

The Simulink block diagram is constructed as the system

described in Figure 8. It consists of AC input section, DC link

section, the converter, PWM controller and measurement

systems.

Figure 10. Power delivered from Stator Side at 9 m/s Wind

Speed

Figure 8. Simulink Model for Back to Back Converter

Controlled DFIG

VII. SIMULATIONS RESULTS

The proposed function models have been implemented

using the DFIG wind power system using back-to-back PWM

converters. The power rating of the DFIG is 1.5 MW, the grid

voltage is 33 kV, the grid frequency is 50 Hz, and the dc-link

voltage is 1150 V, the switching frequency for both converter

is 2 kHz and the simulation period is set as 6 sec. The DFIG

system is connected to the grid through a transformer with

turn ratio of 33/0.69. The simulation results are shown in

Figure 9 to 16. The results show active and reactive power

provided from rotor side, stator side, DFIG at variable wind

speed. The power provided from rotor side, stator side are

depend on dc-link voltage of back-to-back converter. Since

the dc-link voltage is nearly equal to 1150 V, thus

back-to-back converter is acceptable at variable wind speed

for power system.

Figure 11. Power delivered from DFIG at 9 m/s Wind Speed

Figure 12. DC Bus Voltage at 9 m/s Wind Speed

Figure 9. Power delivered from Rotor Side at 9 m/s Wind

Speed

Figure 13. Power delivered from Rotor Side at 13 m/s Wind

Speed

4

All Rights Reserved © 2012 IJSETR

International Journal of Science, Engineering and Technology Research (IJSETR)

Volume 1, Issue 1, July 2012

speed, the power factor is poor compared to rated wind speed

condition. DC bus voltage is 1143 V, it is nearly equal to 1150

V. So, it is acceptable for the back to back converter. At 13

m/s above rated wind speed is 1160 V. So, it is also acceptable

for the back to back converter.

ACKNOWLEDGMENT

The author wishes to express her deepest gratitude to her

teachers, Department of Electrical Power Engineering,

Mandalay Technological University. The author also wishes

to extend special thanks to her parent, her friends for their

supports and help. Similar thanks to all for their instructions

and willingness to share their ideas throughout all those years

of study.

Figure 14. Power delivered from Stator Side at 13 m/s Wind

Speed

REFERENCES

Goldind. E.W, “The Generation of Electricity by Wind Power”, E &

F.N Spon Limited, 22 Henrietta Street, London. 1995.

[2] E. Muljadi, C.P. “Wind Farm Power System Model Development,”

World Renewable Energy Congress VIII, Colorado, Butterfield. 2004.

[3] K. Johnsen, B. Eliasson, “SIMULINK Implementation of Wind Farm

Model for use in Power System Studies,” Nordic Wind Power

Conference, Chalmers University of Technology,2004.

[4] LEONHARD, W. “Control of electrical drives”Springer-Verlag, 1985.

[5] JONES, S.R., and JONES, R.“Control strategy for

Sinusoidal

supply side converters”, IEEColloquium on Developments in real

timeControl for induction motor drives. Digest 1993/024, February

1993.

[6] CARDICI, I., and ERMIS, M.,“Double-outputInduction generator

operating at sub synchronous andsuper synchronous speed:steady

statePerformance optimization and wind energy

recovery”,IEE

proc. B, 1992, 139, (5), pp.429- 442

[7] MITSUTOSHI, Y., and MOTOYOSHI, O., “Active and reactive power

control for doubly fed wound rotor induction generator”, IEE Trans.

Power Electron, 6, (4), pp. 624-629,1991.

[8] R .Erickson. Fundamentals of PowerElectronics. Kluwer, 1997.

Shwe Hlaing received her B.E (Electrical power) degree from

Technological University, in 2009 and now pursuing M.E (Electrical Power)

at Mandalay Technological University.

[1]

Figure 15. Power delivered from DFIG at 13 m/s Wind Speed

Figure 16. DC Bus Voltage at 13 m/s Wind Speed

VIII. CONCLUSION

Simulation studies have shown that the application of

DFIG with back to back converter can significantly improve

the wind turbines performance. The interconnection of wind

farms to grids also influences the safety of wind turbine

generators. The dynamic performance of wind farms in a

power grid is improved by the application of a back to back

converter. The back to back converter helps to provide better

power generation characteristics and stability under various

wind speeds. This paper examines the application of DFIG

with back to back converter in wind farms to stabilize the grid

voltage and to improve power flow in the system under

various wind speed condition. At 9 m/s below rated wind

5

All Rights Reserved © 2012 IJSETR