Chapter 1

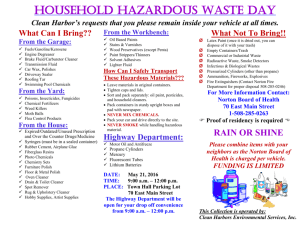

advertisement