- the Journal of Information, Knowledge and Research in

advertisement

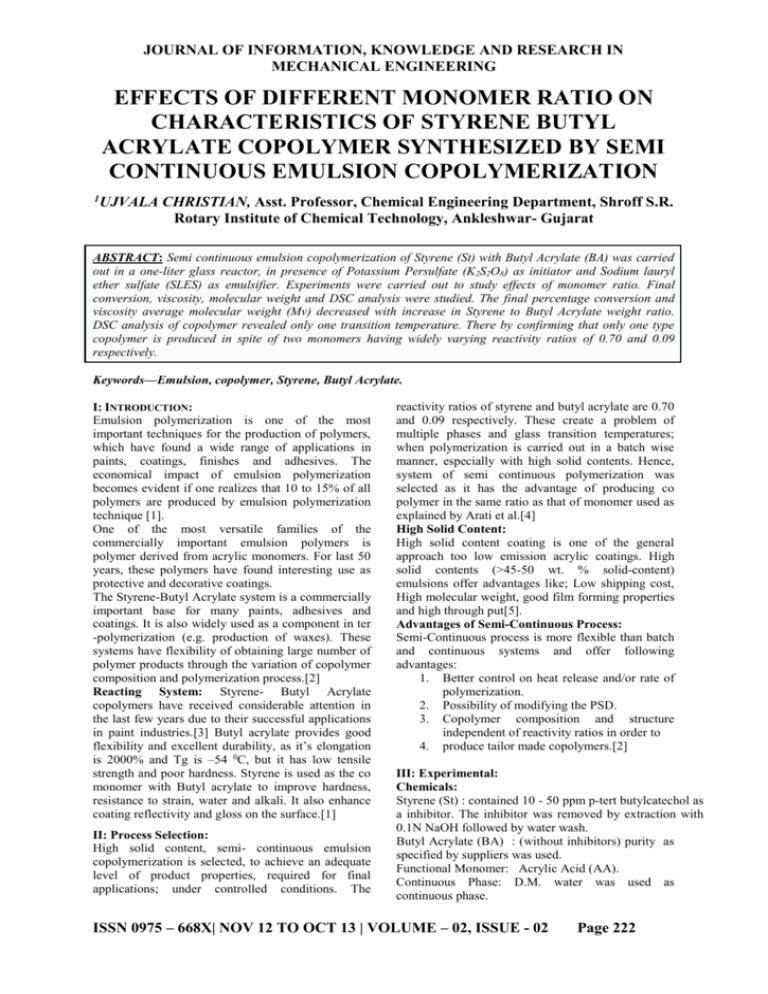

JOURNAL OF INFORMATION, KNOWLEDGE AND RESEARCH IN MECHANICAL ENGINEERING EFFECTS OF DIFFERENT MONOMER RATIO ON CHARACTERISTICS OF STYRENE BUTYL ACRYLATE COPOLYMER SYNTHESIZED BY SEMI CONTINUOUS EMULSION COPOLYMERIZATION 1UJVALA CHRISTIAN, Asst. Professor, Chemical Engineering Department, Shroff S.R. Rotary Institute of Chemical Technology, Ankleshwar- Gujarat ABSTRACT: Semi continuous emulsion copolymerization of Styrene (St) with Butyl Acrylate (BA) was carried out in a one-liter glass reactor, in presence of Potassium Persulfate (K2S2O8) as initiator and Sodium lauryl ether sulfate (SLES) as emulsifier. Experiments were carried out to study effects of monomer ratio. Final conversion, viscosity, molecular weight and DSC analysis were studied. The final percentage conversion and viscosity average molecular weight (Mv) decreased with increase in Styrene to Butyl Acrylate weight ratio. DSC analysis of copolymer revealed only one transition temperature. There by confirming that only one type copolymer is produced in spite of two monomers having widely varying reactivity ratios of 0.70 and 0.09 respectively. Keywords—Emulsion, copolymer, Styrene, Butyl Acrylate. I: INTRODUCTION: Emulsion polymerization is one of the most important techniques for the production of polymers, which have found a wide range of applications in paints, coatings, finishes and adhesives. The economical impact of emulsion polymerization becomes evident if one realizes that 10 to 15% of all polymers are produced by emulsion polymerization technique [1]. One of the most versatile families of the commercially important emulsion polymers is polymer derived from acrylic monomers. For last 50 years, these polymers have found interesting use as protective and decorative coatings. The Styrene-Butyl Acrylate system is a commercially important base for many paints, adhesives and coatings. It is also widely used as a component in ter -polymerization (e.g. production of waxes). These systems have flexibility of obtaining large number of polymer products through the variation of copolymer composition and polymerization process.[2] Reacting System: Styrene- Butyl Acrylate copolymers have received considerable attention in the last few years due to their successful applications in paint industries.[3] Butyl acrylate provides good flexibility and excellent durability, as it’s elongation is 2000% and Tg is –54 0C, but it has low tensile strength and poor hardness. Styrene is used as the co monomer with Butyl acrylate to improve hardness, resistance to strain, water and alkali. It also enhance coating reflectivity and gloss on the surface.[1] II: Process Selection: High solid content, semi- continuous emulsion copolymerization is selected, to achieve an adequate level of product properties, required for final applications; under controlled conditions. The reactivity ratios of styrene and butyl acrylate are 0.70 and 0.09 respectively. These create a problem of multiple phases and glass transition temperatures; when polymerization is carried out in a batch wise manner, especially with high solid contents. Hence, system of semi continuous polymerization was selected as it has the advantage of producing co polymer in the same ratio as that of monomer used as explained by Arati et al.[4] High Solid Content: High solid content coating is one of the general approach too low emission acrylic coatings. High solid contents (>45-50 wt. % solid-content) emulsions offer advantages like; Low shipping cost, High molecular weight, good film forming properties and high through put[5]. Advantages of Semi-Continuous Process: Semi-Continuous process is more flexible than batch and continuous systems and offer following advantages: 1. Better control on heat release and/or rate of polymerization. 2. Possibility of modifying the PSD. 3. Copolymer composition and structure independent of reactivity ratios in order to 4. produce tailor made copolymers.[2] III: Experimental: Chemicals: Styrene (St) : contained 10 - 50 ppm p-tert butylcatechol as a inhibitor. The inhibitor was removed by extraction with 0.1N NaOH followed by water wash. Butyl Acrylate (BA) : (without inhibitors) purity as specified by suppliers was used. Functional Monomer: Acrylic Acid (AA). Continuous Phase: D.M. water was used as continuous phase. ISSN 0975 – 668X| NOV 12 TO OCT 13 | VOLUME – 02, ISSUE - 02 Page 222 JOURNAL OF INFORMATION, KNOWLEDGE AND RESEARCH IN MECHANICAL ENGINEERING Emulsifier: anionic emulsifier sodium lauryl ether benzene as a solvent. Flow time was measured for sulfate (SLES), Initiator: water-soluble, thermal solution (t) and pure solvent (t0) using Ubbelohde initiator, Potassium Persulfate (KPS). suspended level viscometer (USLV). Protective Colloid: Cold water-soluble, partially From Intrinsic Viscosity, viscosity average molecular hydrolysed, medium viscosity poly vinyl alcohol weight (Mv) was determined by using Mark(PVA).pH Controller : Ammonia (NH 3) solution. Houwkin’s equation: Nitrogen (N2): Nitrogen was purged to remove oxygen[ n ] = k(Mv)a where, [n] is intrinsic viscosity, K and from reactor which inhibits the polymerization. a are constants for a given Experimental Procedure: The semi-continuous polymer/solvent/temperature system emulsion copolymerization was carried out using (iii) Copolymer Composition By NMRstandard recipes given as below: Spectroscopy: The copolymer composition was determined by Bruker advance NMR-Spectrophotometer at 300MHz. Table-1: Ingredients of Typical Recipe: From the NMR measurements, quantitative analysis Chemicals Total Weight (g) of final copolymer composition,can be obtained by comparing the proton resonance of two main groups i. H 2O 372 e. phenyl(-C6H5) and methoxy (-O-CH2).Using peak Styrene (St) 130 areas of the phenyl ring protons (S1) and that of Butyl Acrylate (BA) 155 methoxy group (S2) final copolymer composition is Acrylic Acid 12 obtained by following equation: PVA 5.0 Fraction Of Butyl Acrylate in FinalCopolymer SLES 4.0 = (S2/2) / (S2/2) + (S1/5) K2S2O8 8.25 (iv) Glass Transition Temperature: The glass transition temperature of final copolymer was obtained using Polymerization was carried out in a one liter, four PERKIN-ELMER 7 SERIES Thermal Analysis System, necked glass reactor placed in a constant temperature with heating rate of 10 0C. bath at 76 0C. The reactor was equipped with a reflux condenser, stainless steel anchor type stirrer; V:Results and Discussion: monomer-emulsion feed inlet, initiator inlet and (i) Effect of Monomer Ratio on % conversion and nitrogen inlet tube[5]. Molecular Weight: Initial reactor charge was poured in the reactor and From the plot of conversion Vs monomer agitation speed was measured and adjusted to 500 (Styrene/Butyl Acrylate) ratio, (Fig.1), it is observed rpm, using stroboscope. Nitrogen purging was used that with increase in the monomer ratio the to remove the oxygen from the system. Liquid conversion decreases. This is because of different Ammonia was added as a pH controller. Pre-prepared water solubility of the two monomers Styrene and monomer emulsion feed was added at a constant rate Butyl Acrylate. Water solubility of Styrene is 0.07g/L. and initiator solution was also added at a continuous (at300 C),while that of Butyl Acrylate is 10g/L. (at rate; so as to complete the addition in three hours. 300C) [7]. Lower solubility of Styrene, cause large One hour cooking time was provided after all the desorption rate of radicals, thus with higher Styrene reactants were added, so as to ensure to complete concentration, conversion decrease sharply. Butyl conversion. Samples were collected at 30-minute Acrylate is more water-soluble which enhance the interval, each. homogeneous nucleation and hence higher Experiments were performed to study six different concentration of Butyl Acrylate leads to higher monomer (styrene/butyl acrylate) weight ratios (i.e. conversion. This is because the copolymer systems 30/70, 40/60, 45/55, 50/50, 60/40, 70/30) while other using water -soluble initiator; have direct bearing on parameters were constant. water solubility of monomers. Fig.1 Effect of Monomer Ratio on % Conversion IV: Analysis and Testing: (i) Instantaneous conversion: Measured quantity of sample was dried at 100 0C in a dryer for 1 hour. Dried sample was weighed and instantaneous conversion calculated based on polymer present in the reactor with respect to the amount of monomer already fed to the reactor. (ii) Viscosity: Emulsion viscosity was measured by Brookfield LVT model using RV5 spindle at 20 rpm. Intrinsic Viscosity: Emulsion was precipitated in acetone and air dried. Solution of polymer with various concentrations were prepared by using R10 (St/BA=30/70) R14(St/BA=40/60) R7 (St/BA=45/55) R18 (St/BA=50/50) R20 (St/BA=60/40) 100 R22 (St/BA=70/30) % Conversion 80 60 40 20 0 0 50 100 150 200 250 300 time (min.) ISSN 0975 – 668X| NOV 12 TO OCT 13 | VOLUME – 02, ISSUE - 02 Page 223 JOURNAL OF INFORMATION, KNOWLEDGE AND RESEARCH IN MECHANICAL ENGINEERING The viscosity average molecular weight decreases with increase in Styrene/Butyl Acrylate ratio (Fig.2); mainly due to poor solubility of styrene. Higher concentration of styrene drastically increases number of micelle (reaction centers) creation there by reducing average molecular weight of copolymer. Fig.2 Effect of Monomer Ratio on Mv formed is in the same ratio of monomer added and there are no multiple alloys unlike batch polymerization.(In case of batch polymerization the composition of polymers changes with time because of difference in reactivity ratios)[6]. Fig.4DSC Curve: Table-2: Results of NMR and DSCAnalysis St/BA weight ratio 45/55 gave the best conversion profile with low overall viscosity. (ii) Final Copolymer Composition By H NMR – SPECTROSOPY: The 1H NMR spectrum for final copolymer product (St/BA=45/45) is given in Fig.3. Results of NMR analysis are given in Table-2, indicate that the final copolymer composition ratio is almost same as the feed composition ratio. Thus composition-controlled copolymers are obtained with use of semi continuous polymerization irrespective of reactivity ratio. Sr. Monomer No. (St/BA) ratio (St/BA) (wt/wt) (wt/wt) 30/70 45/55 45/55 60/40 31.8/68.2 50.9/49.1 50.9/49.1 58.93/41.06 1 Fig:3 NMR Spectrum: (ii) Glass Transition Temperature (Tg): DSC curve for final copolymer product (St/BA=45/45) is given in Fig.4. From the DSC analysis of the final copolymer samples; it was observed that the range for glass transition temperature (Tg) was 35.25 0C to 45.340C as for different monomer weight ratio, as given in Table-2. There was only one glass transition temperature in all the cases there by confirming that the copolymer 1 2 3 4 NMR Results Glass Transition Temp. (0C) 37.1 36.26 46.18 35.35 VI: CONCLUSION: From the present study on laboratory synthesis of Styrene/Butyl Acrylate emulsion copolymerization, with continuous separate mode of addition of initiator for a fixed time-interval of four hours; it is observed that, monomer weight ratio is one of the important process parameter for this polymerization process. Higher conversion and viscosity average molecular weight were obtained at high Butyl Acrylate to Styrene weight ratio in monomer emulsion feed. The viscosity of final product was about 1 poise and glass transition temperature (Tg) was 35.250C to 45.340C as for different monomer weight ratio. NMR analysis indicate that the final copolymer composition ratio is almost same as the feed composition ratio. Thus compositioncontrolled copolymers were obtained with use of semi continuous polymerization irrespective of reactivity ratio. REFRENCES [1] Kirk & Othmer D F, Encyclopedia of Chemical Technology, 4th edn (John Wileyand Sons, New York),[1998]. [2]Lovell Peter A & El Asser Mohamed S, Emulsion Polymerization and Emulsion Polymers (John Wiley and Sons, New York), [1997]. [3] Odian George, Principles of Polymerization, 2nd edn (John Wiley and Sons, New York), [1970]. ISSN 0975 – 668X| NOV 12 TO OCT 13 | VOLUME – 02, ISSUE - 02 Page 224 JOURNAL OF INFORMATION, KNOWLEDGE AND RESEARCH IN MECHANICAL ENGINEERING [4] Chandel Arti M, Kinetics of Styrenated Acrylics, M.E.Thesis, Faculty of Technology & Engineering, M S University, Baroda, 2001. [5] Madan R N & Dikshit R C, “Different Mode of Addition of Monomers for Styrene/Butyl acrylate Copolymer System”, Indian Journal of Chemical Technology, September, Vol.12, [2003]. [6] Christian Ujvala, Emulsion Copolymerization of Styrene/Butyl acrylate, M.E.Thesis, Faculty of Technology & Engineering, M S University, Baroda, 2003. [7] Djkhabha S and Guillot J, European Polymer Journal, [1989]. ISSN 0975 – 668X| NOV 12 TO OCT 13 | VOLUME – 02, ISSUE - 02 Page 225